Академический Документы

Профессиональный Документы

Культура Документы

Optimization of Rapid Prototyping Parameters For Production of Flexible ABS Object

Загружено:

Sachin BanerjiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Optimization of Rapid Prototyping Parameters For Production of Flexible ABS Object

Загружено:

Sachin BanerjiАвторское право:

Доступные форматы

Journal of Materials Processing Technology 169 (2005) 5461

Optimization of rapid prototyping parameters for production of exible ABS object

B.H. Lee, J. Abdullah, Z.A. Khan

School of Mechanical Engineering, Universiti Sains Malaysia Engineering Campus, 14300 Seri Ampangan, Nibong Tebal, Penang, Malaysia Received 12 March 2004; received in revised form 14 December 2004; accepted 9 February 2005

Abstract In this study, the Taguchi method, a powerful tool to design optimization for quality, is used to nd the optimal process parameters for fused deposition modeling (FDM) rapid prototyping machine that was used to produce acrylonitrile butadiene styrene (ABS) compliant prototype. An orthogonal array, main effect, the signal-to-noise (S/N) ratio, and analysis of variance (ANOVA) are employed to investigate the process parameters in order to achieve optimum elastic performance of a compliant ABS prototype so as to get maximum throwing distance from the prototype. Through this study, not only can the optimal process parameters for FDM process be obtained, but also the main process parameters that affect the performance of the prototype can be found. Experiments were carried out to conrm the effectiveness of this approach. From the results, it is found that FDM parameters, i.e. layer thickness, raster angle and air gap signicantly affect the elastic performance of the compliant ABS prototype. The optimum levels of parameters at different angle of displacement are also presented. 2005 Elsevier B.V. All rights reserved.

Keywords: Rapid prototyping; Flexibe ABS; Fused deposition modeling; Taguchi method

1. Introduction Since the introduction of the rst commercial rapid prototyping (RP) machine widely known as Stereolithography in 1986, a wide range of RP machines have been commercialized, and many more newer systems continue to be developed in various parts of the world [1]. The future is clear as rapid prototyping is now becoming a key technology that shortens product development time for faster building of physical prototypes, tooling and models. Rapid prototyping in general, is more exible and can readily accommodate changes in product design as compared to conventional method of casting, molding or machining. Studies have been conducted to improve and optimize the process, so as to obtain high quality parts produced on a wide range of commercial RP machines [26]. Fused deposition modeling (FDM) is one RP system that produces prototypes from plastic materials such as ABS by

Corresponding author. Tel.: +60 4 5937788x6365; fax: +60 4 5941025. E-mail address: zakhanusm@yahoo.com (Z.A. Khan).

laying tracks of semi-molten plastic lament onto a platform in a layer wise manner from bottom to top. It is known that process parameters such as the air gap between adjacent tracks, raster angle, raster width and thickness of deposited layers inuence the performance of parts produced on an FDM machine. Nevertheless, the suitable levels of parameters associated with different performance criteria still need further investigation. Some studies have been conducted to determine the optimum parameters of FDM, and performance criteria often used include build time, strength, toughness and surface integrity of the prototypes, normally for injection molding and tooling applications [4,5,7]. Some work to determine the feasibility/capability of fabricating fused deposition modeling (FDM) parts concurrently from elastomeric and structural members using FDM 1600 machine has been done [8]. Optimization method for producing exible prototype using FDM 1650 to achieve optimum performance of the prototype has also been reported [9]. It is to be noted that FDM machine has potential for direct use in certain applications such as actuator in electro-mechanical systems and construction of plastic toys. In these areas, compliant mem-

0924-0136/$ see front matter 2005 Elsevier B.V. All rights reserved. doi:10.1016/j.jmatprotec.2005.02.259

B.H. Lee et al. / Journal of Materials Processing Technology 169 (2005) 5461

55

bers that exhibit elastic and exible behavior are increasingly being used due to reduce parts counts and therefore, lead to ease of assembly and lower product costs [10]. It has been reported that compliant member in general, gains its mobility and performs its functions through elastic deformation of its structure which is a function of material properties or geometrical design [10]. Childrens toys such as sling shot, bow and arrow are examples where compliant or exible plastic members are widely used. Toys have long been produced using the conventional methods of casting and molding. As design becomes more complicated and product life cycle gets shorter due to market needs, alternative approaches such as RP, that offers more exibility and responsiveness to design changes, are needed. This paper attempts to describe the optimization of FDM process parameters for optimum performance of compliant ABS prototypes in terms of elasticity and exibility. A model of a catapult that can be used in sling shot toy is taken as case example. Elasticity and exibility are assumed to be related to its ability to throw a plastic ball a distance. Four FDM parameters i.e. air gap, raster angle, raster width and layer thickness, each with three levels, are investigated in this study. Other parameters such as humidity and temperature are kept constant. In the following, an overview of the Taguchi method is given rst. This is followed by the description of experiments using the Taguchi method to determine and analyze the optimal FDM parameters. The optimal FDM process parameters with regard to the performance criteria, i.e. throwing distance and elasticity, are considered. Results are discussed and nally the paper concludes with the ndings of the study.

ferent combinations of parameters and their levels for each experiment. According to this technique, the entire parameter space is studied with minimal number of necessary experiments only [14,15]. Based on the average output value at each parameter level, main effect analysis is performed. Analysis of variance (ANOVA) is then used to determine which process parameter is statistically signicant and the contribution of each process parameter towards the output characteristic. With the main effect and ANOVA analyses, possible combination of optimum parameters can be predicted. Finally, a conrmation experiment is conducted to verify the optimal process parameters obtained from the process parameter design.

3. Optimization of fused deposition modeling parameters 3.1. Selection of process parameters The FDM3000 rapid prototyping machine with Insight 3.1 software was used in the study. Four parameters, each at three levels as presented in Table 1 were taken into consideration in the study. It can be noted that raster angle was specied as 0 /90 , 45 /45 and 30 /60 in Table 1. The 0 /90 angle means that FDM machine fabricates the alternate layers of the catapult on the horizontal plane by changing direction at 0 and 90 angles from the coordinate of the machine. Similarly, 45 /45 and 30 /60 indicate the same deposition pattern followed by the machine. The interactions between the parameters were not considered and other factors such as temperature and humidity were kept constant. To select an appropriate orthogonal array for the experiments, the total degrees of freedom need to be determined. The degrees of freedom are dened as the number of comparisons between process parameters that need to be made to determine which level is better and specically how much better it is. For example, a three-level process parameter counts for two degrees of freedom. The total degrees of freedom are obtained by multiplying the degrees of freedom of each process parameter to the number of parameters. Therefore, in this study, four parameters, each with three levels count for eight degrees of freedom. Basically, the degrees of freedom for the orthogonal array should be greater than or at least equal to those for the process parameters. Obviously the appropriate orthogonal array in this case was the standard L9 , with four columns and

2. The Taguchi approach The Taguchi method is a well-known technique that provides a systematic and efcient methodology for design optimization. It has been widely used for product design and process optimization worldwide [1113]. This is due to the advantages of the design of experiment using Taguchis technique, which includes simplication of experimental plan and feasibility of study of interaction between different parameters. Lesser number of experiments means time and costs are reduced. This is especially vital for rapid prototyping where cost to produce prototypes is still high. Taguchi proposes experimental plan in terms of orthogonal array that gives dif-

Table 1 FDM parameters and their levels Symbol A B C D FDM parameter Air gap Raster angle Raster width Layer thickness Unit mm Degree angles mm mm Level 1 Solid ne 0 /90 0.305 0.178 Level 2 Sparse 45 /45 0.655 0.254 Level 3 Double wide 30 /60 0.980 0.305

56

B.H. Lee et al. / Journal of Materials Processing Technology 169 (2005) 5461

Table 2 Experimental plan using L9 orthogonal array Experiment number Parameter/level A 1 2 3 4 5 6 7 8 9 1 1 1 2 2 2 3 3 3 B 1 2 3 1 2 3 1 2 3 C 1 2 3 2 3 1 3 1 2 D 1 2 3 3 1 2 2 3 1

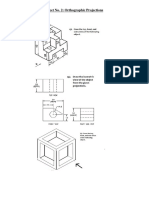

nine rows. The L9 orthogonal array for this study is shown in Table 2. 3.2. Testing of compliant ABS product The isometric and top views of the selected catapult design are shown in Fig. 1a and b, respectively. Nine samples were produced on an FDM3000 machine using ABS (acrylonitrile butadiene styrene) material according to the parameters and their levels as indicated in Table 2. For testing, the catapult was xed on a specially designed xture. The isometric and side views of the experimental setup are illustrated in Fig. 2a and b, respectively. The xture was placed on a laboratory bench. The catapult was bent and held in place using a stopper placed at locator holes for 10 , 15 and 20 angle of displacement from the initial position of the catapult. A 5 g ball was loaded onto the catapult. When the stopper was released, then the catapult got deected and threw the ball at a distance as shown in Fig. 2b. Thin powder layer was spread evenly on the bench so that when the ball was thrown, it left a

mark upon landing. Three throws were performed using the catapult produced from parameters settings of experiment number 1 (Table 2), after bending it to an angle of displacement of 10 . The average throwing distance was recorded. Next, this catapult was replaced by another catapult obtained from parameters settings of experiment number 2 and average throwing distance for the same angle of displacement was recorded. Similarly, the average throwing distances at the same angle of displacement of 10 was recorded for the catapults produced from parameters setting of experiment number 39, respectively. This procedure was repeated for the other two angles of displacements i.e. 15 and 20 , respectively. During testing of the catapults it was observed that the catapults did not loose their elastic strength and were also not plastically deformed. This observation was based on fact that there was consistency in the throwing distances and the catapults did not loose their original shape. This is to mimic the way catapult is normally used as component in toys.

4. Results and discussion The results were obtained by testing all the nine prototypes for different angles of displacement i.e.10 , 15 and 20 . Each prototype represented each experiment of the orthogonal array (Table 2). The average throwing distance at different angles of displacement is summarized in Table 3. In the latter, the results were analyzed by employing main effects, ANOVA, and the signal-to-noise ratio (S/N) analyses. Finally, a conrmation test was carried out to compare the experimental results with the estimated results. 4.1. Main effects For performing the main effect, average throwing distance from the prototypes, which were produced according to the experimental plan of the orthogonal array (Table 2), at each angle of displacement was calculated and the results are shown in Table 3. Figs. 35 depict graphs for the output characteristic (average throwing distance) of the prototypes when they were bent at angle of displacement of 10 , 15 , and 20 respectively. It can be seen from Fig. 3 that on the

Table 3 Average throwing distances at various angles of displacement Experiment number Throwing distance (cm) 10 1 2 3 4 5 6 7 8 9 96.70 95.53 100.07 98.23 107.80 104.63 99.83 104.37 125.33 15 160.13 165.50 164.10 157.20 185.87 179.97 171.20 169.90 213.83 20 250.17 256.00 253.77 234.13 304.80 275.53 275.27 263.37 325.43

Fig. 1. Catapult design: (a) isometric view; (b) top view.

B.H. Lee et al. / Journal of Materials Processing Technology 169 (2005) 5461

57

Fig. 2. Experimental setup for catapult testing: (a) isometric view; (b) side view.

basis of average throwing distance, the best combination of parameters and their levels for the optimum performance of compliant ABS prototype for 10 angle of displacement is A3 B3 C2 D1 . The parameters and their levels, i.e. A3 B3 C2 D1 once again appear to be the best combination for 15 angle of displacement as it is evident from Fig. 4. Finally, it can be observed from Fig. 5 that the best combination of parameters and their levels for 20 angle of displacement is A3 B3 C3 D1 .

Fig. 4. Main effect chart at 15 angle of displacement.

4.2. Analysis of variance (ANOVA) The purpose of the analysis of variance (ANOVA) was to investigate which parameters signicantly affected the quality characteristic. In order to perform ANOVA rst, the total sum of squared deviations, SST was calculated from the following formula [14]:

n

SST =

Fig. 3. Main effect chart at 10 angle of displacement.

i=1

2 yi C.F.

(1)

58

B.H. Lee et al. / Journal of Materials Processing Technology 169 (2005) 5461

Fig. 5. Main effect chart at 20 angle of displacement.

where, n is the number of experiments in the orthogonal array, yi the throwing distance of i-th experiment and C.F. the correction factor. C.F. was calculated as [14]: C.F. = T2 n (2)

and then raster width. Therefore, based on main effect and ANOVA analyses, the optimal parameters for achieving maximum throwing distance from the prototype were the air gap at level 3, the raster angle at level 3, the raster width at level 2, and the layer thickness at level 1. Similarly, it can be observed from Table 5 that for 15 angle of displacement, all the four parameters had a signicant effect on the throwing distance. However, the contribution order of the parameters for the desired output was raster angle, layer thickness, air gap, and then raster width. Based on the main effect and ANOVA analyses, the optimal parameters were air gap at level 3, raster angle at level 3, raster width at level 2, and layer thickness at level 1. Finally, Table 6 reveals that for 20 angle of displacement all the four parameters once again had a signicant affect on the desired output. The contribution order for the parameters was layer thickness, air gap, raster angle, and then raster width. Based on the main effect and the ANOVA analyses, the optimal parameters were air gap at level 3, raster angle at level 3, raster width at level 3, and then layer thickness at level 1. 4.3. Signal-to-noise ratio (S/N) The signal-to-noise ratio measures the sensitivity of the quality investigated to those uncontrollable factors (error) in the experiment. The higher value of S/N ratio is desirable because greater S/N ratio will result in smaller product variance around the target value. The quality characteristic used in this study was the-bigger-the-better, i.e. the farther the throwing distance, the better the catapult performance. In order to perform S/N ratio analysis, mean square deviation (MSD) for the-bigger-the-better quality characteristic and S/N ratio were calculated from the following equations [14]: MSD = 1 n

n i=1

where, T is the total of the throwing distances. It should be noted that the prototypes resulting from each experiment was used three times to throw the ball at each angle of displacement and thus the value of n (27) was used in the calculation. The total sum of squared deviations, SST was decomposed into two sources: the sum of squared deviations, SSd due to each process parameter and the sum of squared error, SSe . The percentage contribution, p by each of the process parameter in the total sum of squared deviations, SST was a ratio of the sum of squared deviations, SSd due to each process parameter to the total sum of squared deviations, SST . Statistically, there is a tool called F test to see which process parameters have signicant effect on the quality characteristic. For performing the F test, the mean of squared deviations, SSm due to each process parameter needs to be calculated. The mean of squared deviations, SSm is equal to the sum of squared deviations, SSd divided by the number of degrees of freedom associated with the process parameters. Then, the F value for each process parameter is simply the ratio of the mean of squared deviations, SSm to the mean of squared error, SSe . Usually, when F > 4, it means that the change of the process parameter has signicant effect on the quality characteristic. Tables 46 show the results of ANOVA for 10 , 15 and 20 angles of displacement respectively. The F-ratios were obtained for 99% level of condence [14]. In addition to this, percent contribution of each parameter was also calculated. It can be seen from Table 4 that for 10 angle of displacement, within the range investigated as shown in Table 1, all the four parameters i.e. air gap, raster angle, raster width and layer thickness were signicant in terms of affecting the exible performance resulting in maximum throwing distance. However, the contribution order of the parameters for maximum throwing distance was air gap, raster angle, layer thickness,

1 2 yi

(3) (4)

S/N = 10 log10 (MSD)

where yi is the throwing distance for ith experiment. The S/N ratio obtained for each angle of displacement is presented in Tables 79, respectively. It can be seen from these tables that for each angle of displacement, the combination of the parameters and their levels, A3 B3 C2 D1 has consistently resulted in the maximum value of S/N ratio. This shows that in the present case study the parameters and their levels, A3 B3 C2 D1 yield optimum quality characteristic with minimum variance around the target value for each angle of displacement. 4.4. Conrmation test Once the optimal combination and levels of the process parameter at each angle of displacement had been obtained,

B.H. Lee et al. / Journal of Materials Processing Technology 169 (2005) 5461 Table 4 ANOVA for 10 angle of displacement Symbol A B C D All other/error Total Table 5 ANOVA for 15 angle of displacement Symbol A B C D All other/error Total Table 6 ANOVA for 20 angle of displacement Symbol A B C D All other/error Total FDM parameter Air gap Raster angle Raster width Layer thickness Degrees of freedom 2 2 2 2 18 26 Sum of squares 5425.93 4721.39 1013.32 8392.10 214.94 19,767.68 Mean square 2712.97 2360.70 506.66 4196.05 11.94 F 227.22 197.71 42.43 351.43 FDM parameter Air gap Raster angle Raster width Layer thickness Degrees of freedom 2 2 2 2 18 26 Sum of squares 2125.85 2408.41 354.95 2407.49 142.31 7439.01 Mean square 1062.93 1204.21 177.48 1203.75 7.91 F 134.38 152.24 22.44 152.18 FDM parameter Air gap Raster angle Raster width Layer thickness Degrees of freedom 2 2 2 2 18 26 Sum of squares 693.21 636.60 104.51 545.06 28.79 2008.17 Mean square 346.61 318.30 52.26 272.53 1.60 F 216.63 198.94 32.66 170.33

59

Contribution (%) 34.52 31.70 5.20 27.14 1.44 100

Contribution (%) 28.58 32.38 4.77 32.36 1.91 100

Contribution (%) 27.45 23.88 5.13 42.45 1.09 100

the nal step was to verify the estimated result against experimental value. Estimated throwing distance at optimum condition for each angle of displacement was calculated by adding the average performance to the contribution of each parameter at the optimum level using the following equations [15]: yopt = m + (mAopt m) + (mBopt m) + (mCopt m) + (mDopt m) T n (5)

m=

(6)

the throwing distance for A3 B3 C2 D1 is same as that of estimated value and thus there was no need for any conrmation test. However, conrmation test was required for 20 angle of displacement only because the optimum parameters and their levels (A3 B3 C3 D1 ) did not correspond to any experiment of the orthogonal array. The prototype at optimal levels of the factors i.e. A3 , B3 , C3 and D1 was produced on the FDM machine. The prototype was bent at 20 angle of displacement so as to throw the ball. This was repeated three times and for each time, throwing distance was measured. Subsequently, the average throwing distance was calculated. The experimental throwing distance was compared with the estimated throwing distance

Table 7 S/N values at 10 angle of displacement Experiment number 1 2 3 4 5 6 7 8 9 Average distance, yave (cm) 96.70 95.53 100.07 98.23 107.80 104.63 99.83 104.37 125.33 MSD (105 ) 10.69 10.96 9.99 10.37 8.60 9.13 10.03 9.18 6.30 S/N 39.71 39.60 40.00 39.84 40.65 40.39 39.98 40.37 41.96

where m is the average performance, T the grand total of average throwing distance for each experiment, n the total number of experiments and mAopt the average throwing distance for parameter A at its optimum level, mBopt the average throwing distance for parameter B at its optimum level, mCopt the average throwing distance for parameter C at its optimum level, and mDopt the average throwing distance for parameter D at its optimum level. It was found that for 10 and 15 angle of displacement, the optimum parameters and their levels (A3 B3 C2 D1 ) corresponded to experiment number 9 of the orthogonal array. And furthermore, it can be seen from Table 10 that for 10 and 15 angles of displacement the experimental value of

60

B.H. Lee et al. / Journal of Materials Processing Technology 169 (2005) 5461

Table 8 S/N values at 15 angle of displacement Experiment number 1 2 3 4 5 6 7 8 9 Average distance, yave (cm) 160.13 165.50 164.10 157.20 185.87 179.97 171.20 169.90 213.83 MSD (105 ) 3.90 3.65 3.71 4.04 2.89 3.09 3.41 3.48 2.19 S/N 44.09 44.37 44.30 43.93 45.38 45.10 44.67 44.60 46.60

Table 9 S/N values at 20 angle of displacement Experiment number 1 2 3 4 5 6 7 8 9 Average distance, yave (cm) 250.17 256.00 253.77 234.13 304.80 275.53 275.27 263.37 325.43 MSD (105 ) 1.60 1.52 1.55 1.82 1.08 1.31 1.32 1.44 9.45 S/N 47.96 48.16 48.09 47.39 49.68 48.80 48.79 48.41 50.25

The optimal parameters and their levels for 10 , 15 and 20 angle of displacement are A3 B3 C2 D1 , A3 B3 C2 D1 and A3 B3 C3 D1 , respectively. For 10 angle of displacement, air gap produces maximum contribution to the output performance of the product (throwing distance). For 15 angle of displacement, raster angle and layer thickness demonstrate almost equal maximum contribution to the output performance of the product (throwing distance). For 20 angle of displacement, layer thickness gives the highest contribution to the output performance. The parameters and their levels, i.e. A3 B3 C2 D1 yield the optimum quality characteristic with minimum variance for all angles of displacements considered in the study.

Acknowledgements Logistic support from the School of Mechanical Engineering, Universiti Sains Malaysia is acknowledged. The material for FDM experiment is also nancially supported partly by USM short-term grant #6035064. Technical support from the rapid prototyping laboratory personnel, Mr. Mohd. Najib Hussain is greatly acknowledged.

Table 10 Estimated result against experimental value Angle of displacement Estimated result (mm) Experimental value for experiment number 9 (mm) 125.33 213.83 Does not correspond to any experiment in the orthogonal array

References

[1] P.F. Jacobs, Stereolithography and other RP&M Technologies: from Rapid Prototyping to Rapid Tooling, SME, Dearbon, MI, 1995. ISBN 0-87263-467-1. [2] S.H. Choi, S. Samavedam, Modelling and optimization of rapid prototyping, Comp. Ind. 47 (2002) 3953. [3] S.O. Onuh, K.K.B. Hon, Optimising build parameters for improved surface nish in stereolithography, Int. J. Machine Tools Manuf. 38 (4) (1998) 329392. [4] K. Thrimurthulu, P.M. Pandey, N.V. Reddy, Optimum part deposition orientation in fused deposition modeling, Int. J. Machine Tools Manuf., in press. [5] P.M. Pandey, N.V. Reddy, S.G. Dhande, Real time adaptive slicing for fused deposition modeling, Int. J. Machine Tools Manuf. 43 (2003) 6171. [6] J.G. Zhou, D. Herscovici, C.C. Chen, Parametric process optimization to improve the accuracy of rapid prototype stereolithography part, Int. J. Machine Tool Manuf. 40 (2000) 363379. [7] R. Anitha, S. Arunachalam, P. Radhakrishnan, Critical parameter inuencing the quality of prototype in fused deposition modelling, J. Mater. Proc. Technol. 118 (2001) 385388. [8] K. Elkins, C. Janak, H. Nordby, R.W. Gray IV, J.H. Bohn, D.G. Baird, Soft Elastomers for Fused Deposition Modelling, in: Proceedings of the 8th Solid Freeform Fabrication Symposium, The University of Texas at Austin, August 1113, 1997, pp. 441448. [9] J. Weinmann, H. Ip, D. Prigozhin, E. Escobar, M. Mendelson, R. Noorani, Application of Design of Experiments (DOE) on the Processing of Rapid Prototyping Samples, in: Proceedings of the 14th Solid Freeform Fabrication Symposium, The University of Texas at Austin, August 46, 2003, pp. 340347. [10] L.L. Howell, Compliant Mechanism, Wiley, New York, 2001. [11] W.H. Wang, Y.S. Tarng, Design optimization of cutting parameters for turning operations based on the Taguchi method, J. Mater. Proc. Technol. 84 (1998) 122129.

10 15 20

125.32 213.83 331.53

Table 11 Results of conrmation experiment Optimal condition Estimation Level Distance achieved (cm) S/N value A3 , B3 , C3 , D1 331.53 Experiment A3 , B3 , C3 , D1 330.93 50.39 0.6 Difference

as presented in Table 11. It can be seen from Table 11 that the difference between experimental result and the estimated result is only 0.6 cm. This indicates that the experimental value is very close to the estimated value. This veries that the experimental result is strongly correlated with the estimated result, as the error is only 0.18%.

5. Conclusions On the basis of the results obtained the following can be concluded:

B.H. Lee et al. / Journal of Materials Processing Technology 169 (2005) 5461 [12] T. Chung-Chen, H. Hong, Comparison of the tool life of tungsten carbides coated by multi-layer TiCN and TiAlCN for end mills using the Taguchi method, J. Mater. Proc. Technol. 123 (2002) 14. [13] C.Y. Nian, W.H. Yang, Y.S. Tarng, Optimization of turning operations with multiple performance characteristics, J. Mater. Proc. Technol. 95 (1999) 9096.

61

[14] R.K. Roy, A Primer On The Taguchi Method, Competitive Manufacturing Series, Van Nostrand Reinhold, New York, 1990. [15] M.S. Phadke, Quality Engineering Using Robust Design, Prentice Hall International Inc., 1989.

Вам также может понравиться

- Productivity and Efficiency Measurement of Airlines: Data Envelopment Analysis using RОт EverandProductivity and Efficiency Measurement of Airlines: Data Envelopment Analysis using RОценок пока нет

- Chemical Engineering Process SimulationОт EverandChemical Engineering Process SimulationРейтинг: 4 из 5 звезд4/5 (13)

- Minimization of Warpage and Sink Index in InjectionДокумент6 страницMinimization of Warpage and Sink Index in InjectionS-HafizNomanОценок пока нет

- Optimization of Injection Molding Cycle Time Using Moldflow AnalysisДокумент3 страницыOptimization of Injection Molding Cycle Time Using Moldflow AnalysisAdrianSomoiagОценок пока нет

- Optimization of FFF Processing Parameters To Improve Geometrical Accuracy and Mechanical Behavior of Polyamide 6 Using Grey Relational Analysis (GRA)Документ29 страницOptimization of FFF Processing Parameters To Improve Geometrical Accuracy and Mechanical Behavior of Polyamide 6 Using Grey Relational Analysis (GRA)nader zirakОценок пока нет

- Sreenidhi Institute of Science and TechnologyДокумент15 страницSreenidhi Institute of Science and TechnologyPrashanth GurramОценок пока нет

- Productionofnylon - 2Документ15 страницProductionofnylon - 2IAEME PublicationОценок пока нет

- Application of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing OperationДокумент7 страницApplication of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing Operationwww.irjes.comОценок пока нет

- Optimization of FDM 3D printing using Taguchi techniqueДокумент12 страницOptimization of FDM 3D printing using Taguchi techniquekuldeep sharmaОценок пока нет

- Submission For PublicationДокумент6 страницSubmission For PublicationPrashanth GurramОценок пока нет

- 4968 17633 1 PB PDFДокумент20 страниц4968 17633 1 PB PDFShan PinОценок пока нет

- Durão2019 Article OptimizingAdditiveManufacturinДокумент23 страницыDurão2019 Article OptimizingAdditiveManufacturinAlamОценок пока нет

- Ijaiem 2014 03 15 042Документ12 страницIjaiem 2014 03 15 042International Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Roughness TaguchiДокумент7 страницRoughness TaguchiAnudatt A. GowdaОценок пока нет

- Billet Optimization For Steering Knuckle Using Taguchi MethodologyДокумент5 страницBillet Optimization For Steering Knuckle Using Taguchi MethodologyAnonymous ijGnA6CWEaОценок пока нет

- Optimization of Machining Parameters in CNC Turning Using Firefly AlgorithmДокумент6 страницOptimization of Machining Parameters in CNC Turning Using Firefly AlgorithmElakkiya KarthicОценок пока нет

- Recent Methods For Optimization of Plastic Injection Molding Process - A Retrospective and Literature ReviewДокумент15 страницRecent Methods For Optimization of Plastic Injection Molding Process - A Retrospective and Literature Reviewdanaluca2753Оценок пока нет

- Taguchi CNCДокумент7 страницTaguchi CNCAndrésОценок пока нет

- Experimental Investigation Using Taguchi Method To Optimize Process Parameters of Fused Deposition Modeling For ABS and Nylon MaterialsДокумент9 страницExperimental Investigation Using Taguchi Method To Optimize Process Parameters of Fused Deposition Modeling For ABS and Nylon MaterialsArukana KotoОценок пока нет

- Polymers 13 03697Документ17 страницPolymers 13 03697hykiОценок пока нет

- 3D PRINTING Literature ReviewДокумент9 страниц3D PRINTING Literature ReviewVenkateswar Reddy Mallepally100% (5)

- Investigation of Post Processing Techniques To Reduce The Surface Roughness of Fused Deposition Modeled PartsДокумент14 страницInvestigation of Post Processing Techniques To Reduce The Surface Roughness of Fused Deposition Modeled PartsIAEME PublicationОценок пока нет

- Benchmarking of Different Sls or SLM ProcessesДокумент7 страницBenchmarking of Different Sls or SLM ProcessesGabriel PetreaОценок пока нет

- Sahu 2013Документ16 страницSahu 2013avt01Оценок пока нет

- Optimization of Process Parameters in Drilling of GFRP Composite Using Taguchi MethodДокумент7 страницOptimization of Process Parameters in Drilling of GFRP Composite Using Taguchi MethodMostafa AdilОценок пока нет

- Investigation of The Effect of Built Orientation On Mechanical Properties and Total Cost of FDM PartsДокумент6 страницInvestigation of The Effect of Built Orientation On Mechanical Properties and Total Cost of FDM PartsAnilОценок пока нет

- Taguchi MethodДокумент8 страницTaguchi MethodLSARAVANAN91Оценок пока нет

- Application of Taguchis Experimental Design and Range Analysis in Optimization of FDM Printing Parameters For Pet G Pla and HipsДокумент12 страницApplication of Taguchis Experimental Design and Range Analysis in Optimization of FDM Printing Parameters For Pet G Pla and HipsMohammedrafficОценок пока нет

- 3D Printed Parts With Honeycomb FDMДокумент25 страниц3D Printed Parts With Honeycomb FDMSeçkin KoçОценок пока нет

- Mechanical Strength and Shape Accuracy Optimization of Polyamide FFF Parts Using Grey Relational AnalysisДокумент17 страницMechanical Strength and Shape Accuracy Optimization of Polyamide FFF Parts Using Grey Relational Analysisnader zirakОценок пока нет

- Ijmer 46064551 PDFДокумент7 страницIjmer 46064551 PDFIJMERОценок пока нет

- Optimizing Surface Roughness in Turning Using Taguchi TechniqueДокумент7 страницOptimizing Surface Roughness in Turning Using Taguchi Techniquekarpaga raj aОценок пока нет

- Sivasurya 2017Документ10 страницSivasurya 2017AynamawОценок пока нет

- Multi-Objective Optimization of The Fiber-Reinforced Composite Injection Molding Process Using Taguchi Method, RSM, and NSGA-IIДокумент21 страницаMulti-Objective Optimization of The Fiber-Reinforced Composite Injection Molding Process Using Taguchi Method, RSM, and NSGA-IIClynoesОценок пока нет

- Modelling extrusion process and optimizing parameters using Taguchi method and ANOVAДокумент5 страницModelling extrusion process and optimizing parameters using Taguchi method and ANOVAElaine JohnsonОценок пока нет

- Process-structure-properties relationship in 3D printed polymersДокумент61 страницаProcess-structure-properties relationship in 3D printed polymersDhananjayОценок пока нет

- Analysis of Injection Moulding Machine ProcessДокумент4 страницыAnalysis of Injection Moulding Machine ProcessJagdish KhaireОценок пока нет

- Rapid Prototyping Optimization for Additive Manufacturing Accuracy and CostДокумент9 страницRapid Prototyping Optimization for Additive Manufacturing Accuracy and CostJohovani SuarezОценок пока нет

- Waste Process Flows': General OverviewДокумент11 страницWaste Process Flows': General OverviewLiyanaОценок пока нет

- D D P I M A C: Esign and Evelopment of Lastic Njection Oldfor UTO OmponentДокумент7 страницD D P I M A C: Esign and Evelopment of Lastic Njection Oldfor UTO OmponentSreedhar PugalendhiОценок пока нет

- An Experimental Study of FDM Parameters Effects On Tensile Strength, Density, and Production Time of ABS/Cu CompositesДокумент19 страницAn Experimental Study of FDM Parameters Effects On Tensile Strength, Density, and Production Time of ABS/Cu Compositessubhashraj18Оценок пока нет

- Article 1Документ8 страницArticle 1Kay WhiteОценок пока нет

- Additive Manufacturing A Framework For ImplementationДокумент8 страницAdditive Manufacturing A Framework For Implementationnicero555Оценок пока нет

- Design of Experiment Based Analysis For Sheet Metal Blanking Processes OptimisationДокумент9 страницDesign of Experiment Based Analysis For Sheet Metal Blanking Processes OptimisationMD Al-AminОценок пока нет

- Experimental Investigation of The Plasma Arc Cutting ProcessДокумент6 страницExperimental Investigation of The Plasma Arc Cutting ProcessKevin MaciasОценок пока нет

- Optimization of Cutting Parameters in CNC Turning: Harish Kumar, Mohd. Abbas, Dr. Aas Mohammad, Hasan Zakir JafriДокумент4 страницыOptimization of Cutting Parameters in CNC Turning: Harish Kumar, Mohd. Abbas, Dr. Aas Mohammad, Hasan Zakir JafriShakeel RanaОценок пока нет

- Ijamev4n6spl 01Документ6 страницIjamev4n6spl 01ahmed titoОценок пока нет

- Original ResearchДокумент6 страницOriginal ResearchbalajimetturОценок пока нет

- Numerical Optimization On Hot Forging PRДокумент7 страницNumerical Optimization On Hot Forging PRAnkit SahuОценок пока нет

- Optimizing Impeller GeometryДокумент7 страницOptimizing Impeller GeometryDanang JoyoeОценок пока нет

- 10.1016@j.jmapro.2020.04.014 Important 1Документ6 страниц10.1016@j.jmapro.2020.04.014 Important 1Arul KirubakaranОценок пока нет

- Establishment of Process Model For Rapid Prototyping Technique (Stereolithography) To Enhance The Part Quality by Taguchi MethodДокумент10 страницEstablishment of Process Model For Rapid Prototyping Technique (Stereolithography) To Enhance The Part Quality by Taguchi MethodmanpreetОценок пока нет

- Optimization of Broaching Tool Design: Intelligent Computation in Manufacturing Engineering - 4Документ6 страницOptimization of Broaching Tool Design: Intelligent Computation in Manufacturing Engineering - 4Rishikesh GunjalОценок пока нет

- Optimizing Multi MachiningДокумент21 страницаOptimizing Multi Machininger_preet012Оценок пока нет

- Gassara2009 Article OptimizationOfSpringbackInL-beДокумент7 страницGassara2009 Article OptimizationOfSpringbackInL-beAhmed MabroukОценок пока нет

- Optimizing green sand casting process parameters using Taguchi's methodДокумент6 страницOptimizing green sand casting process parameters using Taguchi's methodpsprajkotОценок пока нет

- OPTICast Workbook 8-3-0 11-18-14Документ51 страницаOPTICast Workbook 8-3-0 11-18-14emilianoОценок пока нет

- Semi-Automated Gating System Design With Optimum Gate and Over Flow Positions For Aluminum HPDCДокумент15 страницSemi-Automated Gating System Design With Optimum Gate and Over Flow Positions For Aluminum HPDCsobheysaidОценок пока нет

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionОт EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionРейтинг: 5 из 5 звезд5/5 (3)

- Computational Methods and Production Engineering: Research and DevelopmentОт EverandComputational Methods and Production Engineering: Research and DevelopmentОценок пока нет

- Sheet No. 2: Orthographic ProjectionsДокумент1 страницаSheet No. 2: Orthographic ProjectionsSachin BanerjiОценок пока нет

- Syllabus For Phd/M.Tech/Ms Written Test: Mathematics (Compulsory For All)Документ2 страницыSyllabus For Phd/M.Tech/Ms Written Test: Mathematics (Compulsory For All)Sachin BanerjiОценок пока нет

- GATE 2018 Information Brochure - v1Документ39 страницGATE 2018 Information Brochure - v1Charan ReddyОценок пока нет

- Understanding Stress and StrainДокумент47 страницUnderstanding Stress and StrainSachin BanerjiОценок пока нет

- Syllabus For Written TestДокумент2 страницыSyllabus For Written TestSachin BanerjiОценок пока нет

- 3 Distortion Energy Theory DerivationДокумент6 страниц3 Distortion Energy Theory DerivationVaisakh FSzОценок пока нет

- Agriculture, Productions and Research Centres PDF by AffairsCloud PDFДокумент8 страницAgriculture, Productions and Research Centres PDF by AffairsCloud PDFSachin BanerjiОценок пока нет

- Distortion Energy Notes XДокумент5 страницDistortion Energy Notes XApril SnowОценок пока нет

- 3 Distortion Energy Theory DerivationДокумент6 страниц3 Distortion Energy Theory DerivationVaisakh FSzОценок пока нет

- Gia Report PEC 2009-10Документ21 страницаGia Report PEC 2009-10Sachin BanerjiОценок пока нет

- Qip Ice 06 Valve Timing DiagramsДокумент29 страницQip Ice 06 Valve Timing Diagramsام احمدОценок пока нет

- Heat PipesДокумент67 страницHeat PipesLibin LalОценок пока нет

- Application Form ArchitectureДокумент3 страницыApplication Form ArchitectureSachin BanerjiОценок пока нет

- Classification of Heat ExchangersДокумент77 страницClassification of Heat Exchangers4605566vivek100% (1)

- M.Tech Thesis on Additive Manufacturing History and ApplicationsДокумент16 страницM.Tech Thesis on Additive Manufacturing History and ApplicationsSachin BanerjiОценок пока нет

- Additive Manufacturing: Conversion of Various File FormatsДокумент14 страницAdditive Manufacturing: Conversion of Various File FormatsSachin BanerjiОценок пока нет

- Dislocation TheoryДокумент37 страницDislocation TheoryAbbireddy Siva Ganesh100% (1)

- Mike Allen (Editor) - The SAGE Encyclopedia of Communication Research Methods (2017, SAGE Publications, Inc) - Libgen - LiДокумент2 013 страницMike Allen (Editor) - The SAGE Encyclopedia of Communication Research Methods (2017, SAGE Publications, Inc) - Libgen - LiCharlette Inao100% (2)

- A Review On The Formation Causes Measurement Implications and Reduction of Neps During Cotton ProcessingДокумент104 страницыA Review On The Formation Causes Measurement Implications and Reduction of Neps During Cotton ProcessingMohammad AliОценок пока нет

- BIRCH: Balanced Iterative Reducing and Clustering using HierarchiesДокумент33 страницыBIRCH: Balanced Iterative Reducing and Clustering using HierarchiesSpandan RoyОценок пока нет

- The Parenting Style and The Academic Performance of Grade 6 Pupils of Saint Mary'S College of CatbaloganДокумент24 страницыThe Parenting Style and The Academic Performance of Grade 6 Pupils of Saint Mary'S College of CatbaloganVincent Nalazon-Caranog Pamplina-ArcallanaОценок пока нет

- An Ultimate Guide To Writing A DissertationДокумент5 страницAn Ultimate Guide To Writing A DissertationBuySchoolPapersOnlineUK100% (1)

- Chapter 1 - Introduction To StatisticsДокумент38 страницChapter 1 - Introduction To Statisticshimu6749721Оценок пока нет

- Dr. Arlene G. Fink - The Survey Kit, 2nd Edition, How To Ask Survey Questions 2-Sage Publications, Inc (2002)Документ77 страницDr. Arlene G. Fink - The Survey Kit, 2nd Edition, How To Ask Survey Questions 2-Sage Publications, Inc (2002)joseph xavierОценок пока нет

- MD-CS-12 - Manually Entering Points in Carlson Software Page 1 of 3Документ3 страницыMD-CS-12 - Manually Entering Points in Carlson Software Page 1 of 3GeomanjeriОценок пока нет

- Restoring Belagavi Fort and MoatДокумент60 страницRestoring Belagavi Fort and MoatMohamed FaizanОценок пока нет

- Impact of Facebook Advertisement To Saleability oДокумент31 страницаImpact of Facebook Advertisement To Saleability olovely guerraОценок пока нет

- Quality ChartsДокумент21 страницаQuality ChartsSivakumar BalaОценок пока нет

- Synopsis Machine LearningДокумент18 страницSynopsis Machine LearningVismay Agarwal cse07419Оценок пока нет

- Certificate in Mera Lund 195709294Документ2 страницыCertificate in Mera Lund 195709294Rohit SinghОценок пока нет

- Remotesensing 12 04076 v2Документ23 страницыRemotesensing 12 04076 v2Matt HoulsonОценок пока нет

- Feasibility of Fly Ash Brick: A Case Study of Surat & Tapi District of South Gujarat RegionДокумент6 страницFeasibility of Fly Ash Brick: A Case Study of Surat & Tapi District of South Gujarat RegionPRAKОценок пока нет

- Efektivitas Relaksasi Nafas Dalam Dan Aromaterapi Lavender Terhadap Kecemasan Mahasiswa Menghadapi Ujian SkillДокумент8 страницEfektivitas Relaksasi Nafas Dalam Dan Aromaterapi Lavender Terhadap Kecemasan Mahasiswa Menghadapi Ujian SkillalfandiОценок пока нет

- Course Outline MEC441 - March2015Документ4 страницыCourse Outline MEC441 - March2015RusyidiAbdullahОценок пока нет

- Competitor Analysis ResearchДокумент15 страницCompetitor Analysis ResearchMhaiza GonzalesОценок пока нет

- ASTM D7778-15 Planificación InterlaboratorioДокумент11 страницASTM D7778-15 Planificación InterlaboratorioDoina Marquez100% (1)

- Van Everdingen, A. F. The Skin Effect and Its Influence On The Productive Capacity of A WellДокумент6 страницVan Everdingen, A. F. The Skin Effect and Its Influence On The Productive Capacity of A WellSolenti D'nouОценок пока нет

- Gd&t-Multi MetricsДокумент356 страницGd&t-Multi MetricsdramiltОценок пока нет

- CastrolДокумент50 страницCastrolKing Nitin Agnihotri33% (3)

- Feasibility Study for Sukud Slipper ShopДокумент27 страницFeasibility Study for Sukud Slipper Shopbless erika lendroОценок пока нет

- Lesson PlanДокумент4 страницыLesson PlanesterlitaОценок пока нет

- Avery Sporting GoodsДокумент15 страницAvery Sporting GoodsKodem JohnsonОценок пока нет

- Structural Equation ModelingДокумент22 страницыStructural Equation Modelingjohn949Оценок пока нет

- (Health Metrics Network) World Health Organization - Assessing The National Health Information System - Assessment Tool Version 4.0 - World Health Organization (2008)Документ78 страниц(Health Metrics Network) World Health Organization - Assessing The National Health Information System - Assessment Tool Version 4.0 - World Health Organization (2008)afianti sulastriОценок пока нет

- Performance AppraisalДокумент43 страницыPerformance Appraisalamn_thkrОценок пока нет

- Ezekiel Project Work-1Документ35 страницEzekiel Project Work-1saheedОценок пока нет

- Section - 8 Case-8.3Документ9 страницSection - 8 Case-8.3syafiraОценок пока нет