Академический Документы

Профессиональный Документы

Культура Документы

Method 22 - Visual Determination of Fugitive Emissions From Material Sources and Smoke Emissions From Flares

Загружено:

Venkat RanganИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Method 22 - Visual Determination of Fugitive Emissions From Material Sources and Smoke Emissions From Flares

Загружено:

Venkat RanganАвторское право:

Доступные форматы

1168 METHOD 22 - VISUAL DETERMINATION OF FUGITIVE EMISSIONS FROM MATERIAL SOURCES AND SMOKE EMISSIONS FROM FLARES NOTE:

This method is not inclusive with respect to Some material is incorporated by

observer certification. reference from Method 9. 1.0

Scope and Application. This method is applicable for the determination of the

frequency of fugitive emissions from stationary sources, only as specified in an applicable subpart of the regulations. This method also is applicable for the

determination of the frequency of visible smoke emissions from flares. 2.0 Summary of Method. 2.1 Fugitive emissions produced during material

processing, handling, and transfer operations or smoke emissions from flares are visually determined by an observer without the aid of instruments. 2.2 This method is used also to determine visible

smoke emissions from flares used for combustion of waste process materials. 2.3 This method determines the amount of time that

visible emissions occur during the observation period (i.e., the accumulated emission time.) This method does not Since

require that the opacity of emissions be determined.

this procedure requires only the determination of whether

1169 visible emissions occur and does not require the determination of opacity levels, observer certification according to the procedures of Method 9 is not required. However, it is necessary that the observer is knowledgeable with respect to the general procedures for determining the presence of visible emissions. At a minimum, the observer

must be trained and knowledgeable regarding the effects of background contrast, ambient lighting, observer position relative to lighting, wind, and the presence of uncombined water (condensing water vapor) on the visibility of emissions. This training is to be obtained from written

materials found in References 1 and 2 or from the lecture portion of the Method 9 certification course. 3.0 Definitions. 3.1 Emission frequency means the percentage of time

that emissions are visible during the observation period. 3.2 Emission time means the accumulated amount of

time that emissions are visible during the observation period. 3.3 Fugitive emissions means emissions generated by

an affected facility which is not collected by a capture system and is released to the atmosphere. This includes

emissions that (1) escape capture by process equipment exhaust hoods; (2) are emitted during material transfer; (3)

1170 are emitted from buildings housing material processing or handling equipment; or (4) are emitted directly from process equipment. 3.4 Observation period means the accumulated time

period during which observations are conducted, not to be less than the period specified in the applicable regulation. 3.5 Smoke emissions means a pollutant generated by

combustion in a flare and occurring immediately downstream of the flame. Smoke occurring within the flame, but not

downstream of the flame, is not considered a smoke emission. 4.0 Interferences. 4.1 Occasionally, fugitive emissions from sources

other than the affected facility (e.g., road dust) may prevent a clear view of the affected facility. This may If

particularly be a problem during periods of high wind. the view of the potential emission points is obscured to

such a degree that the observer questions the validity of continuing observations, then the observations shall be terminated, and the observer shall clearly note this fact on the data form. 5.0 Safety. 5.1 Disclaimer. This method may involve hazardous This test method may

materials, operations, and equipment.

not address all of the safety problems associated with its

1171 use. It is the responsibility of the user of this test

method to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to performing this test method. 6.0 Equipment. 6.1 Stopwatches (two). Accumulative type with unit

divisions of at least 0.5 seconds. 6.2 Light Meter. Light meter capable of measuring

illuminance in the 50 to 200 lux range, required for indoor observations only. 7.0 8.0 Reagents and Supplies. [Reserved]

Sample Collection, Preservation, Storage, and Transfer.

[Reserved] 9.0 10.0 11.0 Quality Control. [Reserved] [Reserved]

Calibration and Standardization. Analytical Procedure. 11.1

Selection of Observation Location.

Survey the

affected facility, or the building or structure housing the process to be observed, and determine the locations of potential emissions. If the affected facility is located

inside a building, determine an observation location that is consistent with the requirements of the applicable regulation (i.e., outside observation of emissions escaping the building/structure or inside observation of emissions

1172 directly emitted from the affected facility process unit). Then select a position that enables a clear view of the potential emission point(s) of the affected facility or of the building or structure housing the affected facility, as appropriate for the applicable subpart. A position at least

4.6 m (15 feet), but not more than 400 m (0.25 miles), from the emission source is recommended. For outdoor locations,

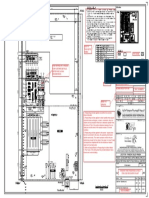

select a position where the sunlight is not shining directly in the observer's eyes. 11.2 11.2.1 Field Records. Outdoor Location. Record the following Company

information on the field data sheet (Figure 22-1):

name, industry, process unit, observer's name, observer's affiliation, and date. Record also the estimated wind Sketch the

speed, wind direction, and sky condition.

process unit being observed, and note the observer location relative to the source and the sun. Indicate the potential

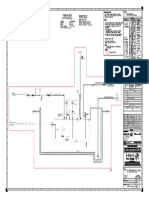

and actual emission points on the sketch. 11.2.2 Indoor Location. Record the following Company

information on the field data sheet (Figure 22-2):

name, industry, process unit, observer's name, observer's affiliation, and date. Record as appropriate the type,

location, and intensity of lighting on the data sheet. Sketch the process unit being observed, and note the

1173 observer location relative to the source. Indicate the

potential and actual fugitive emission points on the sketch. 11.3 Indoor Lighting Requirements. For indoor

locations, use a light meter to measure the level of illumination at a location as close to the emission source(s) as is feasible. An illumination of greater than

100 lux (10 foot candles) is considered necessary for proper application of this method. 11.4 11.4.1 Observations. Procedure. Record the clock time when

observations begin.

Use one stopwatch to monitor the Start this stopwatch If the observation

duration of the observation period. when the observation period begins.

period is divided into two or more segments by process shutdowns or observer rest breaks (see Section 11.4.3), stop the stopwatch when a break begins and restart the stopwatch without resetting it when the break ends. Stop the The

stopwatch at the end of the observation period.

accumulated time indicated by this stopwatch is the duration of observation period. When the observation period is During the observation Upon

completed, record the clock time.

period, continuously watch the emission source.

observing an emission (condensed water vapor is not considered an emission), start the second accumulative stopwatch; stop the watch when the emission stops. Continue

1174 this procedure for the entire observation period. The

accumulated elapsed time on this stopwatch is the total time emissions were visible during the observation period (i.e., the emission time.) 11.4.2 Observation Period. Choose an observation

period of sufficient length to meet the requirements for determining compliance with the emission standard in the applicable subpart of the regulations. When the length of

the observation period is specifically stated in the applicable subpart, it may not be necessary to observe the source for this entire period if the emission time required to indicate noncompliance (based on the specified observation period) is observed in a shorter time period. In other words, if the regulation prohibits emissions for more than 6 minutes in any hour, then observations may (optional) be stopped after an emission time of 6 minutes is exceeded. Similarly, when the regulation is expressed as an

emission frequency and the regulation prohibits emissions for greater than 10 percent of the time in any hour, then observations may (optional) be terminated after 6 minutes of emission are observed since 6 minutes is 10 percent of an hour. In any case, the observation period shall not be less In some cases, the process In such cases, it

than 6 minutes in duration.

operation may be intermittent or cyclic.

1175 may be convenient for the observation period to coincide with the length of the process cycle. 11.4.3 Observer Rest Breaks. Do not observe

emissions continuously for a period of more than 15 to 20 minutes without taking a rest break. For sources requiring

observation periods of greater than 20 minutes, the observer shall take a break of not less than 5 minutes and not more than 10 minutes after every 15 to 20 minutes of observation. If continuous observations are desired for extended time periods, two observers can alternate between making observations and taking breaks. 11.5 Recording Observations. Record the accumulated

time of the observation period on the data sheet as the observation period duration. Record the accumulated time

emissions were observed on the data sheet as the emission time. Record the clock time the observation period began and ended, as well as the clock time any observer breaks began and ended. 12.0 Data Analysis and Calculations. If the applicable subpart requires that the emission rate be expressed as an emission frequency (in percent), determine this value as follows: Divide the accumulated

emission time (in seconds) by the duration of the observation period (in seconds) or by any minimum

1176 observation period required in the applicable subpart, if the actual observation period is less than the required period, and multiply this quotient by 100. 13.0 14.0 15.0 16.0 Method Performance. Pollution Prevention. Waste Management. References. 1. Missan, R., and A. Stein. Guidelines for [Reserved] [Reserved]

[Reserved]

Evaluation of Visible Emissions Certification, Field Procedures, Legal Aspects, and Background Material. Publication No. EPA-340/1-75-007. 2. April 1975. Guideline for EPA

Wohlschlegel, P., and D.E. Wagoner.

Development of a Quality Assurance Program: Volume IX-Visual Determination of Opacity Emissions from Stationary Sources. 1975. 17.0 Tables, Diagrams, Flowcharts, and Validation Data. EPA Publication No. EPA-650/4-74-005i. November

1177 FUGITIVE OR SMOKE EMISSION INSPECTION OUTDOOR LOCATION Company Location Company Rep. Sky Conditions Precipitation Industry Observer Affiliation Date Wind Direction Wind Speed Process Unit

Sketch process unit: indicate observer position relative to source; indicate potential emission points and/or actual emission points.

OBSERVATIONS Clock Time Begin Observation __________ __________ __________ __________ __________ __________ __________ __________ __________ __________ End Observation __________

Observation period duration, min:sec

Accumulated emission time, min:sec

Figure 22-1

1178 FUGITIVE OR SMOKE EMISSION INSPECTION INDOOR LOCATION Company Location Company Rep. Industry Observer Affiliation Date Process Unit

Light type (fluorescent, incandescent, natural) Light location (overhead, behind observer, etc.) Illuminance (lux or footcandles) Sketch process unit: indicate observer position relative to source; indicate potential emission points and/or actual emission points.

OBSERVATIONS Clock Time Begin __________ __________ __________ __________ __________ __________ __________ __________ __________ __________ End Observation __________ Figure 22-2

Observation period duration, min:sec

Accumulated emission time, min:sec

Вам также может понравиться

- Water Pipeline Design GuidelinesДокумент13 страницWater Pipeline Design Guidelinesbalachanderda100% (5)

- Set StandardsДокумент83 страницыSet Standardsnikola5702Оценок пока нет

- Pipe Hangers and SupportsДокумент179 страницPipe Hangers and SupportsVenkat RanganОценок пока нет

- Emission Regulations Part-ThreeДокумент84 страницыEmission Regulations Part-ThreeGanesh DivekarОценок пока нет

- FlangeДокумент7 страницFlangenandhamech25Оценок пока нет

- SP 2390 StressДокумент60 страницSP 2390 StressVenkat RanganОценок пока нет

- Time Lapse Approach to Monitoring Oil, Gas, and CO2 Storage by Seismic MethodsОт EverandTime Lapse Approach to Monitoring Oil, Gas, and CO2 Storage by Seismic MethodsОценок пока нет

- Heater Tube InspectionДокумент129 страницHeater Tube Inspectionuniquepp100% (2)

- Loads On FlangesДокумент16 страницLoads On Flangesccoollest100% (3)

- Smoke Sensor in AHUДокумент23 страницыSmoke Sensor in AHUmingming1Оценок пока нет

- Failure Analysis of Weld Neck Flange in A RefineryДокумент10 страницFailure Analysis of Weld Neck Flange in A RefineryVenkat RanganОценок пока нет

- AHU 02 performance qualificationДокумент5 страницAHU 02 performance qualificationpravingaikwad100% (2)

- 【文章】Stationary Source EmissionsДокумент26 страниц【文章】Stationary Source Emissionslaoying qdОценок пока нет

- DuctSmokeDetector Application Guide HVAG53Документ16 страницDuctSmokeDetector Application Guide HVAG53Hamid QaziiОценок пока нет

- Science G9 Ext Educator-14.1.2020 WebДокумент355 страницScience G9 Ext Educator-14.1.2020 WebNadya AnggrainiОценок пока нет

- NEBOSH IOG1 Element4Документ36 страницNEBOSH IOG1 Element4Adewusi David Oluwashola100% (1)

- MSS SP 45 2008Документ12 страницMSS SP 45 2008Venkat RanganОценок пока нет

- Should EM Mudballs Be Used For Treating Rivers and SeafroДокумент21 страницаShould EM Mudballs Be Used For Treating Rivers and SeafroPeter Chen100% (7)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentОт EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Standard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemДокумент20 страницStandard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemMaryanthony Namyalo100% (3)

- Cleanroom Technology: Fundamentals of Design, Testing and OperationОт EverandCleanroom Technology: Fundamentals of Design, Testing and OperationОценок пока нет

- Cleanroom Requirements, Certification and Monitoring Per Common Accepted Standards by Sean Birch, Lighthouse Worldwide SolutionsДокумент3 страницыCleanroom Requirements, Certification and Monitoring Per Common Accepted Standards by Sean Birch, Lighthouse Worldwide SolutionsApoloTrevino100% (1)

- ASME VIII CalculationДокумент15 страницASME VIII CalculationJoao Osmar Correa100% (1)

- PMS (1CC1P01)Документ263 страницыPMS (1CC1P01)Venkat RanganОценок пока нет

- Sop MBRДокумент4 страницыSop MBRprabhu rajendranОценок пока нет

- ASTM E1002 Leaks Using UltrASTM E1002 Leaks Using Ultrasonics Airborneasonics AirborneДокумент4 страницыASTM E1002 Leaks Using UltrASTM E1002 Leaks Using Ultrasonics Airborneasonics AirborneSebastiánRodrigoPérezHenríquezОценок пока нет

- EPA Method 21-DETERMINATION OF VOLATILE ORGANIC COMPOUND LEAKSДокумент17 страницEPA Method 21-DETERMINATION OF VOLATILE ORGANIC COMPOUND LEAKSwholenumberОценок пока нет

- Water for Pharma ValidationДокумент14 страницWater for Pharma ValidationPépé TechopathamОценок пока нет

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteДокумент20 страницQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106Оценок пока нет

- PAPER 8 The Miskar Gas Field RevДокумент27 страницPAPER 8 The Miskar Gas Field RevVenkat RanganОценок пока нет

- IZOMBE FLOWSTATION FIRE AND GAS SYSTEM ASSESSMENTДокумент26 страницIZOMBE FLOWSTATION FIRE AND GAS SYSTEM ASSESSMENTLawrence Osuvwe OfuokuОценок пока нет

- Understand The Basics of Centrifugal Pump Operations (CEP)Документ5 страницUnderstand The Basics of Centrifugal Pump Operations (CEP)Ari Firmansyah100% (1)

- Field Operator Pulse Jet Dust Collector Certification GuideДокумент37 страницField Operator Pulse Jet Dust Collector Certification GuideRobson DE Freitas WerlingОценок пока нет

- Wastewater TreatmentДокумент25 страницWastewater TreatmentLTE002Оценок пока нет

- Process Design Basis: LPG Train-4 Project at MAA RefineryДокумент42 страницыProcess Design Basis: LPG Train-4 Project at MAA RefineryVenkat RanganОценок пока нет

- Gas DetectorДокумент16 страницGas Detectoramirhosseine00100% (1)

- Air Quality MonitoringДокумент43 страницыAir Quality MonitoringTulika GalaniОценок пока нет

- MSA Gas Detection HandbookДокумент146 страницMSA Gas Detection HandbookVid YullОценок пока нет

- Environment Protection (Noise Measurement Manual) Approval 2009 (No 1)Документ11 страницEnvironment Protection (Noise Measurement Manual) Approval 2009 (No 1)FGHUIJОценок пока нет

- Cleanroom Clean-Up TimesДокумент7 страницCleanroom Clean-Up TimesgmpaudittrainingОценок пока нет

- Lab7part2 Air Lab ManualДокумент8 страницLab7part2 Air Lab ManualMehul RanaОценок пока нет

- HSG 54 Mintenance and Testing of LEV Rev 2 1998Документ38 страницHSG 54 Mintenance and Testing of LEV Rev 2 1998Cashew PandaramОценок пока нет

- SOP 6.2: Air MonitoringДокумент3 страницыSOP 6.2: Air MonitoringUntung SuropatОценок пока нет

- Ventilation or Continuous Air Monitoring DevicesДокумент3 страницыVentilation or Continuous Air Monitoring DevicesMetaОценок пока нет

- ENV543 Industrial Hygiene LAB 2Документ13 страницENV543 Industrial Hygiene LAB 2wwmxsmkrbtОценок пока нет

- VOC Leak Detection Method DeterminationДокумент7 страницVOC Leak Detection Method DeterminationCésar Oswaldo Aguilera Ojeda100% (1)

- Hse Maintenance Examination and Testing of Local Exhaust VentilationДокумент42 страницыHse Maintenance Examination and Testing of Local Exhaust VentilationRICARDOALEXBORGESОценок пока нет

- Introduction To ISO 14698Документ32 страницыIntroduction To ISO 14698Daniel EdbertОценок пока нет

- Air Monitoring: 1. PurposeДокумент15 страницAir Monitoring: 1. PurposeMarr Fernand FortadesОценок пока нет

- Entry and Work in Confined SpacesДокумент51 страницаEntry and Work in Confined Spacesyadhu100% (1)

- En - GMD-13 Information-Brochure 1.0Документ12 страницEn - GMD-13 Information-Brochure 1.0Alexis BerrúОценок пока нет

- Gas Detection SystemДокумент20 страницGas Detection SystemMikhail BagliukОценок пока нет

- HVAC System Validation - Pharmaceutical GuidelinesДокумент2 страницыHVAC System Validation - Pharmaceutical GuidelinesakbarmulangathОценок пока нет

- Technical Paper on Air Sampler Selection for cGMP EnvironmentsДокумент11 страницTechnical Paper on Air Sampler Selection for cGMP EnvironmentsBLUEPRINT Integrated Engineering ServicesОценок пока нет

- M 325aingДокумент32 страницыM 325aingSebastian PalaciosОценок пока нет

- COINDS Emissions PartIII PDFДокумент84 страницыCOINDS Emissions PartIII PDFsid3592Оценок пока нет

- Mtro (Fifth Unit)Документ17 страницMtro (Fifth Unit)Selva GanapathyОценок пока нет

- Improve Flaring OperationsДокумент4 страницыImprove Flaring Operationsaa dd qqОценок пока нет

- Selecting Flammable Gas DetectorsДокумент4 страницыSelecting Flammable Gas Detectorsadilmomin45Оценок пока нет

- Risk Assessment Guide for Petroleum SitesДокумент17 страницRisk Assessment Guide for Petroleum SitesRuffey JОценок пока нет

- MSC 1-Circ 1370Документ7 страницMSC 1-Circ 1370Renato RiveraОценок пока нет

- MET ISO 18562 Testing LaboratoryДокумент4 страницыMET ISO 18562 Testing LaboratoryAVINASHОценок пока нет

- Guidance On Uncertainty CalculationsДокумент9 страницGuidance On Uncertainty CalculationsraosudhОценок пока нет

- Ansi - Ahri 850 2004Документ12 страницAnsi - Ahri 850 2004mpwasaОценок пока нет

- Method 21 8/3/2017: Method 21 - Determination of Volatile Organic Compound LeaksДокумент7 страницMethod 21 8/3/2017: Method 21 - Determination of Volatile Organic Compound LeaksBounty HunterОценок пока нет

- Stack Monitoring KitДокумент53 страницыStack Monitoring KitknbiolabsОценок пока нет

- Pre-Commissioning Procedure - Air Blowing of Fuel Gas System 1Документ3 страницыPre-Commissioning Procedure - Air Blowing of Fuel Gas System 1AdelОценок пока нет

- Dokumen Pak RudiДокумент7 страницDokumen Pak RudiAlfarizki wuka nugrahaОценок пока нет

- Sampling Method EPA Approved and InhouseДокумент9 страницSampling Method EPA Approved and InhouseFarhan TaseenОценок пока нет

- Guidelines On Sampling Strategy and Submission of Air Monitoring Sample Analysis Report PDFДокумент0 страницGuidelines On Sampling Strategy and Submission of Air Monitoring Sample Analysis Report PDFmikecostantiniОценок пока нет

- Leak Testing Standards GuideДокумент12 страницLeak Testing Standards GuideDavid VargasОценок пока нет

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsОт EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsОценок пока нет

- Use of Periodic Safety Review for Long Term Operation of Nuclear Power PlantsОт EverandUse of Periodic Safety Review for Long Term Operation of Nuclear Power PlantsОценок пока нет

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsОт EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsОценок пока нет

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlОт EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlОценок пока нет

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesОт EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesОценок пока нет

- 1671 8560 71 C160 0165 Commented 25.10.22Документ1 страница1671 8560 71 C160 0165 Commented 25.10.22Venkat RanganОценок пока нет

- SP 1125Документ12 страницSP 1125Venkat RanganОценок пока нет

- Passive Fire Proofing Layout For Proposed EquipmentsДокумент1 страницаPassive Fire Proofing Layout For Proposed EquipmentsVenkat RanganОценок пока нет

- CS-19335-12-PIP-4010 - Rev 08Документ1 страницаCS-19335-12-PIP-4010 - Rev 08Venkat RanganОценок пока нет

- 2411-8820-25-O000-0225 - 01 - Pid-Bd, TW & UwДокумент1 страница2411-8820-25-O000-0225 - 01 - Pid-Bd, TW & UwVenkat RanganОценок пока нет

- CS-19335-12-PIP-4014 - Rev 06Документ1 страницаCS-19335-12-PIP-4014 - Rev 06Venkat RanganОценок пока нет

- General Design Specification Piping Design Basis: CFU Feed Handling ProjectДокумент7 страницGeneral Design Specification Piping Design Basis: CFU Feed Handling ProjectVenkat RanganОценок пока нет

- Apps On Google PlayДокумент5 страницApps On Google PlayVenkat RanganОценок пока нет

- Preface: Discourses Book 2, ChapterДокумент2 страницыPreface: Discourses Book 2, ChapterVenkat RanganОценок пока нет

- Material ScienceДокумент43 страницыMaterial ScienceVitor MagnoОценок пока нет

- ISO 13709/ API 610 (VS6) Vertical Multistage Double Case Process PumpДокумент8 страницISO 13709/ API 610 (VS6) Vertical Multistage Double Case Process PumpVenkat RanganОценок пока нет

- PortlandДокумент50 страницPortlandVenkat RanganОценок пока нет

- Basket Type Strainer 1Документ2 страницыBasket Type Strainer 1Venkat RanganОценок пока нет

- Method 22 - Visual Determination of Fugitive Emissions From Material Sources and Smoke Emissions From FlaresДокумент11 страницMethod 22 - Visual Determination of Fugitive Emissions From Material Sources and Smoke Emissions From FlaresVenkat RanganОценок пока нет

- Driving On Biomass: John Ohlrogge, Doug Allen, Bill Berguson, Dean Dellapenna, Yair Shachar-Hill, Sten StymneДокумент2 страницыDriving On Biomass: John Ohlrogge, Doug Allen, Bill Berguson, Dean Dellapenna, Yair Shachar-Hill, Sten StymneVenkat RanganОценок пока нет

- Astm A0020 - 1 (En) PDFДокумент31 страницаAstm A0020 - 1 (En) PDFDinesh SaiОценок пока нет

- Metric PVC Piping SystemДокумент20 страницMetric PVC Piping SystemVenkat RanganОценок пока нет

- Glasslined Pipes & FittingsДокумент3 страницыGlasslined Pipes & FittingsVenkat RanganОценок пока нет

- Caesar II App GuideДокумент5 страницCaesar II App GuideVenkat RanganОценок пока нет

- Problem Areas in The Ecosystem, Philippine Environmental Problems, and Environmental GovernanceДокумент16 страницProblem Areas in The Ecosystem, Philippine Environmental Problems, and Environmental GovernanceMa. Solita VirtudazoОценок пока нет

- Sample Paper Annual: Fas / English (184) / Class Viii / EXAMINATION / 2021-22Документ5 страницSample Paper Annual: Fas / English (184) / Class Viii / EXAMINATION / 2021-22Flashlight GaMinGОценок пока нет

- Cat. OSD Supergreen Eco Update 2023Документ2 страницыCat. OSD Supergreen Eco Update 2023Engrel PTK Region IIОценок пока нет

- Coastal Depositional FeaturesДокумент6 страницCoastal Depositional Featuresapi-298948027Оценок пока нет

- UNIT 9 - Soil ConservationДокумент53 страницыUNIT 9 - Soil ConservationMaria Lourdes samontinaОценок пока нет

- 2016 Ipec Characterizing Air Emissions From Wastewater FacilitiesДокумент29 страниц2016 Ipec Characterizing Air Emissions From Wastewater FacilitiesSUNDARAMAHALINGAM AОценок пока нет

- Oxygen, DissolvedДокумент4 страницыOxygen, DissolvedcolorОценок пока нет

- CH 1 - Boat Basics and The Marine EnvironmentДокумент3 страницыCH 1 - Boat Basics and The Marine EnvironmentJay DiazОценок пока нет

- Catalog Water Purifier 2016 YOUTHFULДокумент5 страницCatalog Water Purifier 2016 YOUTHFULhamadalami2007Оценок пока нет

- Bio Reactor Kinetic and Reactor ConceptsДокумент33 страницыBio Reactor Kinetic and Reactor ConceptsYunyong SungkhagornmanitОценок пока нет

- sửa bài kiểm tra 15 phút và 1 số gợi 1 bài viếtДокумент3 страницыsửa bài kiểm tra 15 phút và 1 số gợi 1 bài viếtTường KhangОценок пока нет

- CePIETSOBP Slide PresentationДокумент61 страницаCePIETSOBP Slide Presentationheikal hajazieОценок пока нет

- Ecology and Ecosystem PPT - T. Lakshmi - Gsol-2023Документ17 страницEcology and Ecosystem PPT - T. Lakshmi - Gsol-2023Sairam GodithiОценок пока нет

- Regulations For Sanitary InstallationsДокумент207 страницRegulations For Sanitary Installationsyusuf100% (1)

- MSMA2ed Chapter1 3 PDFДокумент98 страницMSMA2ed Chapter1 3 PDFDoughnut Chilli PiОценок пока нет

- 2015 - Shim - Microplastics in The OceanДокумент4 страницы2015 - Shim - Microplastics in The OceanLim Kok PingОценок пока нет

- Desalting of Crude OilДокумент19 страницDesalting of Crude OilaciОценок пока нет

- Environmental Quality (Sewage) Regulations 2009Документ29 страницEnvironmental Quality (Sewage) Regulations 2009YudhisthiraОценок пока нет

- CHM 576 (Environmental Chemistry)Документ60 страницCHM 576 (Environmental Chemistry)Ummu UmairahОценок пока нет

- Jntuk M Tech r16 Ee SyllabusДокумент28 страницJntuk M Tech r16 Ee SyllabusRamya SriОценок пока нет

- MTPDF5 - Main Module PDF Sewerage SystemsДокумент19 страницMTPDF5 - Main Module PDF Sewerage SystemsEunnice PanaliganОценок пока нет

- Environmental Law Reflection JournalДокумент16 страницEnvironmental Law Reflection JournalDeep SinghviОценок пока нет

- GJESM Volume 8 Issue 2 Pages 237-250Документ14 страницGJESM Volume 8 Issue 2 Pages 237-250GJESMОценок пока нет

- Pentair Water 740Документ48 страницPentair Water 740Rebeca Zarazúa Díaz100% (1)