Академический Документы

Профессиональный Документы

Культура Документы

Modulo Controlador Válvula MIQ - CHV

Загружено:

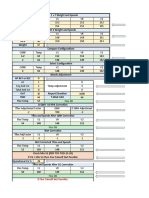

igize2Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Modulo Controlador Válvula MIQ - CHV

Загружено:

igize2Авторское право:

Доступные форматы

Operating Manual

MIQ/CHV

OK

er Pow

Valve module for compressed air-operated sensor cleaning heads

ba75319e01

04/2003

Accuracy when going to press

The use of advanced technology and the high quality standard of our instruments are the result of continuous development. Consequently, this may result in some differences between this operating manual and your instrument. Also, we cannot guarantee that there are absolutely no errors in this manual. Therefore, we are sure you will understand that we cannot accept any legal claims resulting from the data, figures or descriptions.

Copyright

Weilheim 2002, WTW GmbH & Co. KG

Reprinting - even as excerpts - is only allowed with the explicit written authorization of WTW GmbH & Co. KG, Weilheim. Printed in Germany.

IQ SENSOR NET MIQ/CHV

List of contents

1 2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 2.2 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 3.2 3.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Mounting for use in the IQ SENSOR NET . . . . . . . . . . . . . 3-1 Mounting for other applications . . . . . . . . . . . . . . . . . . . 3-1 3.3.1 Stack mounting . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 3.3.2 Distributed mounting . . . . . . . . . . . . . . . . . . . . . 3-5 Installation of the modules at the installation location . . 3-9 3.4.3 General information . . . . . . . . . . . . . . . . . . . . . . 3-9 3.4.4 Mounting on a mounting stand with the SSH/IQ sun shield . . . . . . . . . . . . . . . . . . . . . . 3-10 3.4.5 Mounting under the SD/K 170 sun shield . . . . 3-12 3.4.6 Wall mounting: . . . . . . . . . . . . . . . . . . . . . . . . 3-13 Connecting the valve control line . . . . . . . . . . . . . . . . . 3-14 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16 Connecting the compressed air hoses . . . . . . . . . . . . . 3-17

3.4

3.5 3.6 3.7

Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 4.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

What to do if ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 5.2 Tips on clearing faults . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 Checking the voltage supply . . . . . . . . . . . . . . . . . . . . . 5-2

6 7

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 Accessories and options . . . . . . . . . . . . . . . . . . . . . . 7-1

0-1

List of contents

IQ SENSOR NET MIQ/CHV

0-2

IQ SENSOR NET MIQ/CHV

Overview

1

General characteristics

Overview

The MIQ/CHV valve module provides a switchable compressed air valve for the operation of sensor cleaning heads. The valve is controlled via an external switch. The switch can consist of one of the following:

l the relay of an IQ SENSOR NET MIQ/CR3 combined output module l the relay of a measurement converter with the R option l any other switch (relay or sensor)

Warning The valve circuit must not supply any unauthorized voltages or currents. The circuit must comply with all the standards of a circuit with limitations ( Limited Circuit or Limited Power) as well as for safety extra low voltage ( SELV) at all times. For more details, see chapter 6 TECHNICAL DATA. The valve module is connected with the external switch via a control line. The following application example shows a cleaning system made up of a CH cleaning head and an MIQ/CHV valve module with a longrange MIQ/PS power supply:

1-1

Overview

IQ SENSOR NET MIQ/CHV

Application example

Fig. 1-1

Application example of the MIQ/CHV valve module

Power supply

The valve module requires a 24 Volt power supply (for details, see chapter 6 TECHNICAL DATA) to operate. When used in the IQ SENSOR NET, the valve module is supplied with voltage by the IQ SENSOR NET. The MIQ/CHV can be fully integrated in the IQ SENSOR NET using the MIQ standard module housing. The housing has the same characteristics as all MIQ modules regarding stability, leakproofness and weather resistance. It also provides the same wide variety of installation options (stacked mounting, canopy mounting, tophat rail mounting, etc.).

IQ SENSOR NET compatibility

1-2

IQ SENSOR NET MIQ/CHV

Overview

Terminal strip

The MIQ/CHV has the following electrical connections on the terminal strip inside the housing:

l 1 x valve circuit connection l 2 x SENSORNET connection

Note Due to the limited number of cable glands, only one SENSORNET connection can be used. SENSORNET connection 1 or 2 can be selected.

1-3

Overview

IQ SENSOR NET MIQ/CHV

1-4

IQ SENSOR NET MIQ/CHV

Safety instructions

Safety instructions

This operating manual contains special instructions that must be followed during the installation of the MIQ/CHV valve module. Thus, it is essential for the operator to read this component operating manual before carrying out any work with the system. Always keep the operating manual in the vicinity of the valve module. General safety instructions The following safety labels in the individual chapters of this operating manual indicate different levels of danger: Warning indicates instructions that must be followed precisely in order to prevent serious danger to personnel. Attention indicates instructions that must be followed precisely in order to avoid slight injuries to personnel or damage to the instrument or the environment. Other labels Note indicates notes that draw your attention to special features. Note indicates cross-references to other documents, e.g. operating manuals.

2-1

Safety instructions

IQ SENSOR NET MIQ/CHV

2.1

Authorized use

The authorized use of the MIQ/CHV consists of providing a control valve for compressed air-operated sensor cleaning heads. Please adhere to the technical specifications given in chapter 6 TECHNICAL DATA. Only operation according to the instructions in this operating manual is authorized. Any other use is considered to be unauthorized. Unauthorized use invalidates any claims with regard to the guarantee.

2.2

General safety instructions

The MIQ/CHV is constructed and inspected according to the relevant guidelines and norms for electronic instruments (see chapter 6 TECHNICAL DATA). It left the factory in a safe and secure technical condition. Function and operational safety The failure-free function and operational safety of the MIQ/CHV is only guaranteed if the generally applicable safety measures and the special safety instructions in this operating manual are followed during its use. The failure-free function and operational safety of the MIQ/CHV is only guaranteed under the environmental conditions that are specified in chapter 6 TECHNICAL DATA. Safe operation If safe operation is no longer possible, the MIQ/CHV must be taken out of operation and secured against inadvertent operation. Safe operation is no longer possible if the MIQ/CHV:

l has been damaged in transport l has been stored under adverse conditions for a lengthy period of time l is visibly damaged l no longer operates as described in this manual.

If you are in any doubt, contact the supplier of your MIQ/CHV.

2-2

IQ SENSOR NET MIQ/CHV

Installation

3

3.1

Installation

Scope of delivery

The following parts are contained within the scope of delivery of the MIQ/CHV:

l MIQ/CHV. All openings and open electrical contacts must be closed with suitable covers or blank covers. l 2 x cable glands with seal l 2 x ISO blind nuts M4 l 2 x cheese-head screws M4x16 with plastic washer l 1 x contact base l 2 x plastic tapping screws for fixing the contact base l 1 x hose clip l Operating manual.

3.2

Mounting for use in the IQ SENSOR NET

The IQ SENSOR NET provides a number of options for integrating the MIQ/CHV mechanically and electrically in the system (stacked mounting, distributed mounting, etc.). The individual types of installation are described in detail in the INSTALLATION chapter of the system operating manual.

3.3

Mounting for other applications

Note This section is important if you want to operate the MIQ/CHV in connection with conventional measurement converters or some other control unit. For details of mounting in the IQ SENSOR NET, see section 3.2.

3.3.1 Mounting the power supply module

Stack mounting

If the power supply module and the MIQ/CHV are not yet premounted, both modules can be assembled as a stack. This type of mounting is described in this section. Mounting the modules also establishes the electrical connection at the same time.

3-1

Installation

IQ SENSOR NET MIQ/CHV

A stack may consist of up to three modules ( e.g. one power supply module and two MIQ/CHV modules). Further MIQ/CHV modules can be connected via the SENSORNET module connections with the aid of IQ SENSOR NET cable (see section 3.3.2 DISTRIBUTED MOUNTING). Attention Always place the power supply module at the back of the stack.

Materials required (contained in the scope of delivery) Tools Preparing the stack mounting

l 2 x ISO blind nuts M4 l 2 x cheese-head screws M4x16 with plastic washer l 1 x contact base with two plastic tapping screws. l Phillips screw driver.

1

MIQ/CHV module

3

MIQ/CHV

Be i en Stap tfe elm rne o n u nta n ge Fo mo d Ko Aufk rs nti nta le ta ere ktt be n rg r an ck m d in ou er sta ntin ll c g re on m tac ov t c e la arr be ier l

2

Fig. 3-1 Preparing modules for stack mounting

1 2 3

Remove the covers from the drilled mounting holes (pos. 1 and 3 in Fig. 3-1). Remove the contact cover (pos. 2). Pull off the adhesive label (pos. 4).

3-2

IQ SENSOR NET MIQ/CHV

Installation

Mounting the contact base

MIQ/CHV

6

Fig. 3-2 Mounting the contact base

Attention Only use the plastic tapping screws supplied for attaching the contact base. They ensure the correct fit.

4 5

Attach the contact base (pos. 5 in Fig. 3-2) to the front module with the two plastic tapping screws (pos. 6). Remove the two countersunk screws (pos. 7 in Fig. 3-2) on the front module and swing open the module lid.

Premounting the ISO blind nuts

MIQ/CHV

8

Fig. 3-3 Premounting the ISO blind nuts

3-3

Installation

IQ SENSOR NET MIQ/CHV

Insert the cheese-head screws (pos. 8 in Fig. 3-3) with the plastic washers in the drilled mounting holes in the housing and loosely screw in the ISO blind nuts (pos. 9).

Stacking the modules MIQ/CHV module MIQ/CHV

Fig. 3-4

Stacking the modules

Fig. 3-5

Closing the housing

3-4

IQ SENSOR NET MIQ/CHV

Installation

Attach the prepared module to the lid of the back module. At the same time, ensure that the two clips on the front module click into place in the lid of the back module. Then tighten the two screws (pos. 8 in Fig. 3-3). Close the lid of the front module and fix in place with the two countersunk screws (pos. 7 in Fig. 3-5).

3.3.2

Distributed mounting

Warning Electrical voltages that present a danger of electrical shock may be present inside the the power supply module. Before opening the power supply module, read the operating manual. Follow the safety instructions specified there. General information Distributed mounting can be made with the aid of the following IQ SENSOR NET cables:

l SNCIQ cable l SNCIQ/UG earth cable - suitable for underground laying according to VDE 01816, Part 2 and DIN/VDE 0891, Part 6.

The cables are delivered as piece goods (please specify length when ordering!). All 3-fold terminal strips with the designation "SENSORNET x" can be used for distributed mounting. Note Due to the limited number of cable glands, only one SENSORNET connection can be used. SENSORNET connection 1 or 2 can be selected. Attention The IQ SENSOR NET cable may only be connected to the SENSORNET connections. Do not connect any wires of the cable with an external electrical potential. Otherwise, malfunctions could occur.

3-5

Installation

IQ SENSOR NET MIQ/CHV

Materials required

l 1 x SNCIQ or SNCIQ/UG connecting cable (see chapter 7 ACCESSORIES AND OPTIONS) l Wire end sleeves for 0.75 mm2 wire cross-section with matching crimping tool l 1 x cable gland with seal (scope of delivery of MIQ module).

Tools

l Cable stripping knife l Wire stripper l Phillips screw driver l Small screw driver.

Preparing the cable ends

1 2

Cut the cable to the required length. Remove approx. 45 mm of cable insulation (in the case of the SNCIQ/UG earth cable, remove both the inner and outer insulation). Only for the SNCIQ/UG earth cable: Remove a further 35 mm of the outer insulation. Shorten the exposed shielding braid up to the cable sheath. Shorten the two fillers (plastic inlays) up to the cable sheath. Bare the red and green wires and fit them with wire end sleeves. Fit the filler stranded wire with a wire end sleeve.

3 4 5 6 7

3-6

IQ SENSOR NET MIQ/CHV

Installation

ca. 45 mm

SNCIQ

ca. 35 mm

ca. 45 mm

SNCIQ/UG

Fig. 3-6 Prepared cable end

Connecting the cables

1 2 3

Open the module. Select any SENSORNET connection. Before doing so, look out for the SENSORNET designation. Open the dummy screw fitting under the SENSORNET connection. Keep the dummy screw fitting for possible later modifications.

3-7

Installation

IQ SENSOR NET MIQ/CHV

SENSORNET 1 SENSORNET 2

2 1 3

SNCIQ SNCIQ/UG

Fig. 3-7 Connecting the cables to the module

4 5 6 7

Screw the cable gland (pos. 1 in Fig. 3-7) with the sealing ring (pos. 2) into the module housing. Loosen the coupling ring (pos. 3 in Fig. 3-7). Feed the cable through the cable gland into the module housing. Connect the cable ends to the terminal strip. While doing so, look out for the designations of the terminals (red / shield / green). Loosen the coupling ring (pos. 3 in Fig. 3-7). Close the module.

8 9

3-8

IQ SENSOR NET MIQ/CHV

Installation

3.4

Installation of the modules at the installation location

Note The installation possibilities in the IQ SENSOR NET are described in the IQ SENSOR NET system manual.

3.4.3

General information

Attention Modules installed outside must always be protected against the effects of the weather (snow, ice and direct solar radiation) by a sun shield. Otherwise, malfunctions can result. Always mount modules vertically. Never install modules without rain protection with the lid facing upwards (danger of retained humidity and penetration of moisture). Installation options The most important types of installation for modules and module stacks are described in the following chapters:

l Mounting on a mounting stand with the SSH/IQ sun shield: The SSH/IQ sun shield provides enough space for one unit made up of up to three stacked MIQ modules (section 3.4.4). l Mounting on the SD/K 170 sun shield: The SD/K 170 sun shield provides enough space for two MIQ modules. The sun shield can be mounted on round or square section pipes ( e.g. rails) with the aid of the MR/SD 170 mounting kit (section 3.4.5). l Wall mounting: The back module of a module stack or a single module is screwed permanently to a wall (section 3.4.6).

Attention No contact base may be mounted on the back of the module (danger of short-circuit!) if the module is mounted on a wall, a sun shield, or a top hat rail.

3-9

Installation

IQ SENSOR NET MIQ/CHV

3.4.4 Materials required Tools

Mounting on a mounting stand with the SSH/IQ sun shield

l SSH/IQ sun shield (see chapter 7 ACCESSORIES AND OPTIONS). l 4 mm set screw wrench l Phillips screw driver.

Mounting the sun shield on a mounting stand

2 3 4

Fig. 3-8

Mounting the SSH/IQ sun shield on a mounting stand

Screw the sun shield (pos. 1 in Fig. 3-8) with the four hexsocket head screws (pos. 2), the washers (pos. 3) and the clamps (pos. 4) at the required height on the mounting stand from the back.

Premounting the ISO blind nuts

5

6

Fig. 3-9 Mounting the sun shield: Premounting the ISO blind nuts

3 - 10

IQ SENSOR NET MIQ/CHV

Installation

2 3

Remove the two screws (pos. 5 in Fig. 3-9) and swing open the module lid. Insert the cheese-head screws (pos. 6 in Fig. 3-9) with the plastic washers in the drilled mounting holes and loosely screw in the ISO blind nuts (pos. 7).

Mounting the module under the sun shield

Fig. 3-10 Mounting the module on the SSH/IQ sun shield

4 5

Position the module on the sun shield and fix it into place with the two screws (pos. 6 in Fig. 3-9). Close the module lid and fix it in place with the two countersunk screws (pos. 5 in Fig. 3-9).

3 - 11

Installation

IQ SENSOR NET MIQ/CHV

3.4.5

Mounting under the SD/K 170 sun shield

If a single module is to be installed outside, it must be provided with a sun shield that protects it against the effects of weather. The SD/K 170 sun shield can be mounted directly on a wall, on a mounting stand or on a railing. The MR/SD 170 mounting kit is also required for mounting on a mounting stand or railing. Note How to mount the sun shield at the installation location is described in the instructions for the sun shield or mounting kit. Materials required

l SD/K 170 sun shield (see chapter 7 ACCESSORIES AND OPTIONS) l The MR/SD 170 mounting kit is also required for mounting the sun shield on a mounting stand or railing (see chapter 7 ACCESSORIES AND OPTIONS).

Tools Mounting the module under the sun shield

l Phillips screw driver.

2

Fig. 3-11 Mounting the module on the SD/K 170 sun shield

Remove the two screws (pos. 1 in Fig. 3-11) and swing open the module lid.

3 - 12

IQ SENSOR NET MIQ/CHV

Installation

7 8

Position the module on the sun shield and fix it into place with the two screws (pos. 2 in Fig. 3-11). Close the module lid and fix it in place with the two countersunk screws (pos. 1 in Fig. 3-11).

3.4.6 Materials required

Wall mounting:

l WMS/IQ kit for wall mounting (see chapter 7 ACCESSORIES AND OPTIONS).

Note Depending on the condition of the wall, dowels other than those contained in the kit may be required.

Tools

l Drilling machine and drill bit, depending on the condition of the wall l Phillips screw driver.

Preparing the wall mounting

Be i en Stap tfe elm rne o n u nta n ge Fo mo d Ko Aufk rs nti nta le ta ere ktt be n rg r an ck m d in ou er sta ntin ll c g re on m tac ov t c e la arr be ier l

2

Fig. 3-12 Preparing the module for wall mounting

1 2 3

Remove the covers from the drilled mounting holes (pos. 1 in Fig. 3-12). Insert the distance washers (pos. 2) in the drilled mounting holes. Remove the two screws (pos. 3) and swing open the module lid.

3 - 13

Installation

IQ SENSOR NET MIQ/CHV

Fixing the module in place

m 15 =1

m

4

5 6

Fig. 3-13 Wall mounting

Screw the module to the previously drilled wall with the aid of the dowels (pos. 4 in Fig. 3-13), the washers (pos. 5) and the screws (pos. 6). Close the module lid and fix it in place with the two countersunk screws (pos. 2 in Fig. 3-12).

3.5

Connecting the valve control line

Warning The valve circuit must not supply any unauthorized voltages or currents. The circuit must comply with all the standards of a circuit with limitations ( Limited Circuit or Limited Power) as well as for safety extra low voltage ( SELV) at all times. For more details, see chapter 6 TECHNICAL DATA. General installation instructions Observe the following instructions when attaching the connecting wires to the terminal strip:

l Shorten all the wires used to the length required for the installation. l Basically, fit all stranded wire ends with wire end sleeves before connecting them to the terminal strip. l Any wires that are not used and project into the housing must be cut off as closely as possible to the cable gland.

Materials required

l Wire end sleeves, suitable for the connecting wires, with suitable crimping tool l 1 x cable gland with sealing ring (scope of delivery MIQ/CHV)

3 - 14

IQ SENSOR NET MIQ/CHV

Installation

Tools

l Cable stripping knife l Wire stripper l Phillips screw driver l Small screw driver

Warning Danger of injury from lines that are under pressure. The compressed air glands in the housing may only be opened by a service technician authorized by WTW. Attention Danger of burning on a hot resistor. The resistor can heat up to 80 C during operation. Do not touch the resistor.

Connecting control lines to the terminal strip

1 2

Open the module. Open the left dummy gland.

Fig. 3-14 Clamping termination for the valve control line

3 4

Screw the cable gland (pos. 1 in Fig. 3-14) with the sealing ring (pos. 2) into the module housing. Loosen the coupling ring (pos. 3 in Fig. 3-14).

3 - 15

Installation

IQ SENSOR NET MIQ/CHV

5 6 7 8 9

Feed the line through the cable gland in the module housing. Connect the wires to the terminal strip. Loosen the coupling ring (pos. 3 in Fig. 3-14). Perform the function check according to section 3.6. Close the module.

3.6

General instructions

Function check

After connecting the valve control line, check that the valve triggers correctly. This check is also suitable for the troubleshooting of malfunctions. A yellow LED (Fig. 3-15) is located on the board for indicating the status of the valve. It lights up when the valve is open.

LED

Fig. 3-15 Pilot LED on the board

3 - 16

IQ SENSOR NET MIQ/CHV

Installation

To check that the valve triggers correctly, proceed as follows: Warning Danger of injury from lines that are under pressure. The compressed air glands in the housing may only be opened by a service technician authorized by WTW. Attention Danger of burning on a hot resistor. The resistor can heat up to 80 C during operation. Do not touch the resistor. 1 MIQ/CHV + IQ SENSOR NET: Put the IQ SENSOR NET system into operation. MIQ/CHV + Measurement converter: Supply the power supply module with voltage and put the measurement converter into operation. 2 3 4 Open the MIQ/CHV module. Adjust the cleaning intervals on the measuring system so that the relay switches. Check whether the yellow LED on the board of the MIQ/CHV lights up when the relay is closed.

3.7

General instructions

Connecting the compressed air hoses

Pay attention to the following instructions when connecting the compressed air hoses (they can be connected either way round):

l Follow the specification of the compressed air according to chapter 6 TECHNICAL DATA. l Only use hoses that match the compressed air connections. l Secure all hose connections with hose clips.

Open the compressed air line Pay attention to the following instructions if you want to open the compressed air line ( e.g. during a modification): Warning Danger of injury from lines that are under pressure. Before opening the compressed air line, ensure that the section of line concerned is free of pressure. The compressed air glands in the housing may only be opened by a service technician authorized by WTW.

3 - 17

Installation

IQ SENSOR NET MIQ/CHV

3 - 18

IQ SENSOR NET MIQ/CHV

Maintenance and cleaning

4

4.1

Maintenance and cleaning

Maintenance

The MIQ/CHV requires no special maintenance.

4.2

MIQ modules

Cleaning

Clean the worst of any dirt off modules that are mounted outside as required. To avoid any coarse dirt getting into the open housing, it is advisable to always roughly clean the module and the surrounding area before the module is opened. To clean the module, wipe the housing surfaces with a damp, lint-free cloth. If compressed air is available on site, blow off the worst of the dirt beforehand. Keep the housing closed while doing so.

4-1

Maintenance and cleaning

IQ SENSOR NET MIQ/CHV

4-2

IQ SENSOR NET MIQ/CHV

What to do if ...

5

5.1

No compressed air at the output Cause

What to do if ...

Tips on clearing faults

Remedy Check the compressed air supply IQ SENSOR NET: See the chapter, WHAT TO DO IF... in the system manual Other applications: See section 5.2 CHECKING THE

VOLTAGE SUPPLY

Compressed air supply interrupted or too weak Supply voltage not present or too low

Error in triggering

Perform the function check according to section 3.6. If the LED does not light up, check the triggering (detached terminal connection, broken control line, defective relay output) Check whether the valve switches (switching noise) when the light of the LED changes. If the valve does not switch, contact WTW.

5-1

What to do if ...

IQ SENSOR NET MIQ/CHV

5.2

Checking the voltage supply

The MIQ/CHV has two LEDs on the side for monitoring the supply voltage (Fig. 5-1).

MIQ W WT

OK

US

. 101 NO OR 1 .2 NF 310TO CO STD D C22 UL RTIFIE STD CEN/CSA CA

9 75 01 20 MS TO

r we Po

99 99 K 99 O r. 99 ! .-N ower P Ser

Fig. 5-1

Voltage LEDs on the MIQ/CHV

The LEDs show the following states: Yellow lights up Red lights up No LED lights up Operational voltage OK Operational voltage in warning range. It is possible that the valve may no longer open. Operational voltage in the range of error. The valve no longer functions. Remedy Install another power supply module and, if necessary, split the installation Install another power supply module and, if necessary, split the installation Check the cable connection step-by-step starting with the power supply module, and replace any defective cable sections. Check the contacts on the MIQ modules (stack mounting). Clean any dirty contacts. Carefully bend back contact springs that have been pressed flat or bent (pay attention to sufficient spring tension).

Diagnosing faults in the voltage supply

Cause Too many MIQ/CHV on one power supply module Cable too long for distributed mounting (voltage drop too large) Electrical connection between the power supply module and MIQ/CHV is defective (distributed mounting)

5-2

IQ SENSOR NET MIQ/CHV

Technical data

6

Dimensions

Technical data

Fig. 6-1

Dimension drawing of the MIQ/CHV (dimensions in mm)

6-1

Technical data

IQ SENSOR NET MIQ/CHV

Mechanical construction

Maximum number of modules in a module stack Materials

3 (plus a terminal component in the IQ SENSOR NET) Housing: Polycarbonate with 20 % glass fiber Pressure hose sleeves: POM

Weight Type of protection

Approx. 0.5 kg IP 66 In accordance with NEMA 4X MIQ modules are not suitable for conduit connection NEMA 3S

Environmental conditions

Temperature Operation - 20 C ... + 55 C (- 20 C ... + 40 C for stack mounting on an MIQ/PS) - 25 C ... + 65 C

Storage Relative humidity Yearly average Dew formation

90 %

Possible

6-2

IQ SENSOR NET MIQ/CHV

Technical data

Electrical data

Nominal voltage

Max. 24 VDC via a separate power supply module. IQ SENSOR NET: For details, see chapter TECHNICAL DATA of the IQ SENSOR NET system operating manual Suitable power supply modules: MIQ/PS MIQ/24V

Power consumption Protective class

Approx. 2 W III

Number of MIQ/CHV per IQ SENSOR NET: Depending on the power conditions in the power supply module whole system (see system manual). Other applications: Maximum of 8 (restrictions possible in long cables due to the voltage drop).

Instrument safety

Applicable norms

EN 61010-1

EMC product and system characteristics

EN 61326

EMC requirements for electrical resources for control technology and laboratory use Interference immunity according to EN 61326/A1 table A.1 Resources for industrial areas, intended for indispensable operation Interference emission limits for resources of class B

System lightning protection

Noticeably extended qualitative and quantitative protective characteristics as opposed to EN 61326/A1 table A.1 and NAMUR NE 21

EN 61000-3-2/A 14 EN 61000-3-3 FCC, class A NAMUR NE 21

6-3

Technical data

IQ SENSOR NET MIQ/CHV

Terminal connections

IQ SENSOR NET connections

2 Additional connectable SENSORNET terminator (terminating resistor) Note Due to the limited number of cable glands, only one SENSORNET connection can be used. SENSORNET connection 1 or 2 can be selected.

Valve switching contact Terminal type Terminal ranges

1 Screw-type terminal strip, accessible by raising the lid Solid wires:0.2 ... 4.0 mm2 AWG 24 ... 12 Flexible wires:0.2 ... 2.5 mm2 Cable glands M16 x 1.5 on the underside of the module

Cable feeds

Valve circuit

Switching voltage Max. switching current

Approx. 12 V Approx. 70 mA

Warning The valve circuit must not supply any unauthorized voltages or currents. The circuit must comply with all the standards of a circuit with limitations ( Limited Circuit or Limited Power) as well as for safety extra low voltage ( SELV) at all times. These include the following limiting value specifications: l AC voltage: max. 30 V effective / 42.4 V peak

l DC voltage: max. 60 V l Current limit: max. 8 A l Power output limitation: max. 150 VA

Compressed air

Required air quality Operating pressure Connections

Dry, dust-free and oil-free Max. 7x105 Pa (7 bar) absolute 6 mm hose liners

6-4

IQ SENSOR NET MIQ/CHV

Accessories and options

Accessories and options

Model CH CH/Epack Order no. 900 107 900 111

Description Cleaning head for online sensors with 40 mm diameter Hose set, consisting of: 15 m compressed air hose 1 Quick-acting connection, complete 2 Hose clamps 1 Teflon tape Long-range power supply for 100240 VAC nominal input voltage Long-range power supply for 24 V AC/ DC nominal input voltage Combined output module with 3 current outputs and 3 relay outputs each IQ SENSOR NET cable - please specify required length in m when ordering Sun shield for a unit of up to three stacked MIQ modules Sun shield for a unit of up to two stacked MIQ modules Mounting kit for fixing the SD/K 170 sun shield on horizontal or vertical pipes Kit for wall mounting of a MIQ module Kit for panel mounting of MIQ modules; Panel aperture 138 x 138 mm in accordance with DIN 43700 or IEC 473 Kit for mounting of MIQ modules on a 35 mm top hat rail in accordance with EN 50022

MIQ/PS MIQ/24V MIQ/CR3 SNCIQ SNCIQ/UG SSH/IQ SD/K 170 MR/SD 170 WMS/IQ PMS/IQ

480 004 480 006 480 014 480 046 480 047 109 295 109 284 109 286 480 052 480 048

THS/IQ

480 050

7-1

Accessories and options

IQ SENSOR NET MIQ/CHV

7-2

Вам также может понравиться

- Operating Instructions: OPTISWITCH 5100 C, 5150 C With Relay OutputДокумент32 страницыOperating Instructions: OPTISWITCH 5100 C, 5150 C With Relay OutputJose Mario Ferreyra MoranОценок пока нет

- KC5 deДокумент66 страницKC5 degmclellanОценок пока нет

- Instruction Manuals For Installation and Maintainance PDFДокумент36 страницInstruction Manuals For Installation and Maintainance PDFlhphong021191Оценок пока нет

- Aparat US Petrea SCOUT 55Документ64 страницыAparat US Petrea SCOUT 55Valentina BrumaОценок пока нет

- Mitsubishi PLC - Linha - Q - User - Manual PDFДокумент170 страницMitsubishi PLC - Linha - Q - User - Manual PDFrafaeldesouzamartins100% (1)

- MVI69 MNET User Manual PDFДокумент159 страницMVI69 MNET User Manual PDFsasanchez3Оценок пока нет

- Melsec Q-Beginner's Manual 209093-A (08.07)Документ170 страницMelsec Q-Beginner's Manual 209093-A (08.07)pipikikikiОценок пока нет

- Mp55 A Diferencijalni PresostatДокумент68 страницMp55 A Diferencijalni Presostatamijoski6051Оценок пока нет

- CSC-122M Numerical Bus Coupler Protection EquipmentДокумент47 страницCSC-122M Numerical Bus Coupler Protection EquipmentMarkusKunОценок пока нет

- Recloser S280771Документ52 страницыRecloser S280771Gamal YonesОценок пока нет

- Nice MCA2Документ20 страницNice MCA2johnny7975% (4)

- Sirius enДокумент532 страницыSirius enJim_____Оценок пока нет

- System 57 Quick Start GuideДокумент24 страницыSystem 57 Quick Start GuideEduleofОценок пока нет

- System 57 Quick Start GuideДокумент24 страницыSystem 57 Quick Start GuidePuneet BachalОценок пока нет

- Iqan-Xt2 Uk Ed0145 InstructionbookДокумент32 страницыIqan-Xt2 Uk Ed0145 InstructionbookPavelОценок пока нет

- SIFANG - CSC-121A - V1.00 - Numerical Auto Reclosing and Circuit Breaker Auxiliary Protection Equipment Manual - 2012-03Документ52 страницыSIFANG - CSC-121A - V1.00 - Numerical Auto Reclosing and Circuit Breaker Auxiliary Protection Equipment Manual - 2012-03MarkusKunОценок пока нет

- Operating Instructions: BA208C/07/en/10.05 51517596Документ32 страницыOperating Instructions: BA208C/07/en/10.05 51517596Kristen CollierОценок пока нет

- ModCon 75 Instruction Manual - enДокумент79 страницModCon 75 Instruction Manual - enRahul DevaОценок пока нет

- S7 300 First Time User enДокумент68 страницS7 300 First Time User enLeonardo AlencastreОценок пока нет

- Cutler Hammer Hv9000 TD - 08h40teДокумент86 страницCutler Hammer Hv9000 TD - 08h40tecascade1Оценок пока нет

- 7XV5655-0BA00-Hub Manual A3 enДокумент53 страницы7XV5655-0BA00-Hub Manual A3 enmeraatОценок пока нет

- Abb MVFTДокумент32 страницыAbb MVFTParmar JenishОценок пока нет

- ZKW 40 50Документ52 страницыZKW 40 50ricardo100% (1)

- Vega 66Документ68 страницVega 66Enrique MoralesОценок пока нет

- Fx1s Fx1n Fx2n (C) Fx3u Beginner's ManualДокумент0 страницFx1s Fx1n Fx2n (C) Fx3u Beginner's ManualbryanaranzazuОценок пока нет

- Neles Valvguard™ Vg9200H: Installation, Maintenance and Operating InstructionsДокумент75 страницNeles Valvguard™ Vg9200H: Installation, Maintenance and Operating InstructionsGiancarlo Puma C.Оценок пока нет

- EAGLE Controller: Installation & Commissioning InstructionsДокумент42 страницыEAGLE Controller: Installation & Commissioning InstructionsDaniel EneaОценок пока нет

- Sigma CP Main Man-1078Документ24 страницыSigma CP Main Man-1078Gelu BordeaОценок пока нет

- Operating Instructions - VEGASON 65-4-20 Ma - HART - Four-WireДокумент64 страницыOperating Instructions - VEGASON 65-4-20 Ma - HART - Four-WireSantiago Eliú Castillo BarreraОценок пока нет

- Hygropro Moisture Transmitter Operating Manual EnglishДокумент60 страницHygropro Moisture Transmitter Operating Manual EnglishBEN ADEGBULUОценок пока нет

- TIM 40 Instruction BookДокумент44 страницыTIM 40 Instruction BookMarkus SenojОценок пока нет

- Installation and Commisioning of Eagle ControllerДокумент42 страницыInstallation and Commisioning of Eagle ControllerAbdul Rehman ZafarОценок пока нет

- PrimeTest 350 Instruction Manual Aus NZ Rev4Документ92 страницыPrimeTest 350 Instruction Manual Aus NZ Rev4lechbrОценок пока нет

- CopieДокумент62 страницыCopieYacine BoumertitОценок пока нет

- 7XV5673 Manual IO-Unit A3 UsДокумент226 страниц7XV5673 Manual IO-Unit A3 UsPurathany PalanyОценок пока нет

- ESABVision LEManualДокумент352 страницыESABVision LEManualAndrada MarceloОценок пока нет

- Hitachi 50HDT50Документ128 страницHitachi 50HDT50ricardo_MassisОценок пока нет

- VF MicroVLT DanfossДокумент102 страницыVF MicroVLT DanfossJose Arley Gil Machado100% (1)

- Power Factor Regulator: Computer Smart Fast 6 / 12Документ33 страницыPower Factor Regulator: Computer Smart Fast 6 / 12Fastabiq HidayatulahОценок пока нет

- MP60 A0616Документ76 страницMP60 A0616PedrosasОценок пока нет

- Roche AVL9120,9130,9140,9180,9181 - Service Manual PDFДокумент114 страницRoche AVL9120,9130,9140,9180,9181 - Service Manual PDFJose Rolando Orellana Rodriguez0% (1)

- Roche AVL9120,9130,9140,9180,9181 - Service Manual PDFДокумент114 страницRoche AVL9120,9130,9140,9180,9181 - Service Manual PDFThien Nguyen100% (2)

- HAIER 32e2000a Service Manual PDFДокумент52 страницыHAIER 32e2000a Service Manual PDFcarlos amaya100% (1)

- User Guide: Part Number: 0460-0084-05 Issue Number: 5Документ26 страницUser Guide: Part Number: 0460-0084-05 Issue Number: 5Juan Antonio Tomas HerreroОценок пока нет

- Opisane Funkcije Mitsubishi ProgManual For Beginners ManualДокумент106 страницOpisane Funkcije Mitsubishi ProgManual For Beginners ManualbekavacsОценок пока нет

- Wa 23VS+ 29VS+ 23VS 29VS 70036 enДокумент13 страницWa 23VS+ 29VS+ 23VS 29VS 70036 enKarl-Gustav NõgolsОценок пока нет

- Oxitec 22 4.06 en PDFДокумент59 страницOxitec 22 4.06 en PDFDe DetОценок пока нет

- Mitsubishi Alpha Beginners Manual PDFДокумент53 страницыMitsubishi Alpha Beginners Manual PDFGuillermo Osvaldo Rivera MelladoОценок пока нет

- Sinumerik 810 820 GA3 Interface - Part - 2 - Connection - ConditionsДокумент128 страницSinumerik 810 820 GA3 Interface - Part - 2 - Connection - ConditionsSam eagle goodОценок пока нет

- ABB VFD EN - ACS320 - SFUM - A - A4 User ManualДокумент44 страницыABB VFD EN - ACS320 - SFUM - A - A4 User ManualRahul GuptaОценок пока нет

- Icontrol AC Rel 3 4 42-02-2223 B5Документ414 страницIcontrol AC Rel 3 4 42-02-2223 B5ElputoAmo XDОценок пока нет

- ASO O&M Indus Rail 71-242Документ11 страницASO O&M Indus Rail 71-242DmitriiȘtirbuОценок пока нет

- Dcmiine0sline R302 20120418 WebДокумент68 страницDcmiine0sline R302 20120418 WebTest TestОценок пока нет

- E3 and E3 Plus Solid-State Overload RelayДокумент230 страницE3 and E3 Plus Solid-State Overload RelayfabianОценок пока нет

- Simatic FM NCUДокумент108 страницSimatic FM NCUSam eagle goodОценок пока нет

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsОт EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsОценок пока нет

- Practical Modern SCADA Protocols: DNP3, 60870.5 and Related SystemsОт EverandPractical Modern SCADA Protocols: DNP3, 60870.5 and Related SystemsРейтинг: 5 из 5 звезд5/5 (6)

- ODO Measurement in Gas - Technical NoteДокумент2 страницыODO Measurement in Gas - Technical Noteigize2Оценок пока нет

- Firesting O2 FlyerДокумент4 страницыFiresting O2 Flyerigize2Оценок пока нет

- Trends in Chemical Engineering Education Process, Product and Sustainable Chemical Engineering Challenges - 2008 - Education For Chemical Engineers PDFДокумент6 страницTrends in Chemical Engineering Education Process, Product and Sustainable Chemical Engineering Challenges - 2008 - Education For Chemical Engineers PDFRamaOktavianОценок пока нет

- E08 E01Документ38 страницE08 E01igize2Оценок пока нет

- Carta Psicrometrica CarrierДокумент1 страницаCarta Psicrometrica Carrierigize2Оценок пока нет

- Racor DieselFuelFilterДокумент9 страницRacor DieselFuelFilterigize2Оценок пока нет

- Ba76036 MIQ CHV PLUS E01Документ44 страницыBa76036 MIQ CHV PLUS E01igize2Оценок пока нет

- Fitting Acero CarbonoДокумент5 страницFitting Acero CarbonoAndrés Lagos MéndezОценок пока нет

- Atuador Ip67Документ6 страницAtuador Ip67Wellington SoaresОценок пока нет

- Grade 3 Unit 3 (English)Документ1 страницаGrade 3 Unit 3 (English)Basma KhedrОценок пока нет

- Management Science BUMA 20103 Module New PDFДокумент290 страницManagement Science BUMA 20103 Module New PDFLee TeukОценок пока нет

- Advantages and Disadvantages of EscalatorsДокумент2 страницыAdvantages and Disadvantages of EscalatorsMuhammad Nabill Jeffri100% (1)

- "Roughness": Filtering and Filtering and Filtering and Filtering and Surface Surface Texture TextureДокумент29 страниц"Roughness": Filtering and Filtering and Filtering and Filtering and Surface Surface Texture TextureZouhair BenmabroukОценок пока нет

- Mapping of Significant Natural Resources: Category: Bodies of WaterДокумент3 страницыMapping of Significant Natural Resources: Category: Bodies of WaterDei HernandezОценок пока нет

- Industrial Wire Cutting Machine: A Senior Capstone Design ProjectДокумент17 страницIndustrial Wire Cutting Machine: A Senior Capstone Design ProjectTruta IonutОценок пока нет

- Ch05 - Deformation - HamrockДокумент14 страницCh05 - Deformation - HamrockMuhammad Mansor BurhanОценок пока нет

- ACP160DДокумент14 страницACP160Dinbox934Оценок пока нет

- Final Koni FinalДокумент124 страницыFinal Koni FinalBinod BoharaОценок пока нет

- Rom, Eprom, & Eeprom Technology: Figure 9-1. Read Only Memory SchematicДокумент14 страницRom, Eprom, & Eeprom Technology: Figure 9-1. Read Only Memory SchematicVu LeОценок пока нет

- Gamma Ray Log ShamshadДокумент36 страницGamma Ray Log Shamshadgadi_143100% (6)

- ETEEAP Application SummaryДокумент9 страницETEEAP Application SummaryAlfred Ronuel AquinoОценок пока нет

- EPC Contractor Rep. Authority/Authority's EngineerДокумент6 страницEPC Contractor Rep. Authority/Authority's Engineersunil kuldeepОценок пока нет

- Thandeka, Learning To Be White: Money, Race, and God in America (New York: Continuum International Publishing Group, 1999), 169 PPДокумент2 страницыThandeka, Learning To Be White: Money, Race, and God in America (New York: Continuum International Publishing Group, 1999), 169 PPFefa LinsОценок пока нет

- Regulation of AlternatorДокумент6 страницRegulation of Alternatorkudupudinagesh100% (1)

- BATAM Selco Amprah Agustus (@) 2021Документ31 страницаBATAM Selco Amprah Agustus (@) 2021rentalkiosОценок пока нет

- Balino, Shedina D. Beed 2-CДокумент5 страницBalino, Shedina D. Beed 2-CSHEDINA BALINOОценок пока нет

- Lesson Plan in Science 10 2nd QuarterДокумент5 страницLesson Plan in Science 10 2nd QuarterJenevev81% (21)

- DX DiagesДокумент36 страницDX DiagesBpbd Kota BengkuluОценок пока нет

- In The Shadow of The CathedralДокумент342 страницыIn The Shadow of The CathedralJoy MenezesОценок пока нет

- Quicksort and Heapsort Algorithms ExplainedДокумент41 страницаQuicksort and Heapsort Algorithms ExplainedRahul SaxenaОценок пока нет

- Trip WireДокумент19 страницTrip Wirepinky065558100% (2)

- A320 Flex CalculationДокумент10 страницA320 Flex CalculationMansour TaoualiОценок пока нет

- L1Документ7 страницL1Francisco Roberto Trujillo LeonОценок пока нет

- Port Ps PDFДокумент2 страницыPort Ps PDFluisОценок пока нет

- Aadhaar is proof of identity, not citizenshipДокумент1 страницаAadhaar is proof of identity, not citizenshipPARTAPОценок пока нет

- Ausa 300-RH - en Parts ManualДокумент93 страницыAusa 300-RH - en Parts ManualandrewhОценок пока нет

- Mockups Showeet (Standard)Документ46 страницMockups Showeet (Standard)Palo Alto Turismo y EntretenimientoОценок пока нет

- Telescopic sight basics and reticle typesДокумент18 страницTelescopic sight basics and reticle typesKoala LumpurОценок пока нет