Академический Документы

Профессиональный Документы

Культура Документы

Chlor Alkali Final

Загружено:

Kurniadi SetyantoИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chlor Alkali Final

Загружено:

Kurniadi SetyantoАвторское право:

Доступные форматы

IndustrialIT for the Chlor-alkali Industry

Creating value through integrated solutions

Combining technology with operations know-how

Combining technology with operations know-how

A major addition to ABBs knowledge in the chloralkali industry came in January 2001, with the acquisition of Eutech Engineering Solutions Ltd., the international engineering consultancy subsidiary of the ICI Group1. This acquisition has allowed us to strengthen our position in the chlor-alkali industry by combining the practical engineering knowledge of an operating company with the technology of the ABB group. Are you planning an investment in chlor-alkali assets? ABB can help you to move from the initial business idea through the early stages of project development to the appointment and management of an EPC contractor and the successful integration of the new investment into your business. Do you have existing assets? ABB can help you improve operations by, for example, reducing energy consumption, increasing water recycling, reducing emissions and raising plant performance and availabilitysome of the key business drivers in the industry. ABB emphasizes a one team approach to provide integrated solutions and exploit best practices. Whether were procuring a single valve or developing designs for an entire plant, we believe in teamwork across the enterprise. Benefits are provided through the teams access to ABBs extensive range of products, services, technologies and know-how in the chlor-alkali industry. ABB offers support in two business activity cycles:

Overview

ABBs IndustrialIT solutions for the chlor-alkali industry are more valuable than the sum of our Products and Services. ABB is the worlds largest supplier of automation systems, power products, advanced solutions and services to the chemical industry. With IndustrialIT, ABB has combined state-of-the-art technologies to develop an integrated suite that meets the needs of modern chemical facilities today and in the future. In the past you have probably thought of us as an electrical company, a controls company or an automation company. We are all of these and more! ABB has an extensive knowledge base for the chloralkali industry - chlorine/caustic soda

production plants, chlorine derivatives and intermediate plants, vinyl chloride monomer and PVC plants. We have highly qualified and

experienced consultants and engineers, many of whom are specialists in the chlor-alkali industry with backgrounds in operations. They are wellequipped to deliver practical and realistic IndustrialIT solutions based on global best practices.

Product and capital asset cycle Supply chain and operating cycle ABB has the unique advantage of being able to operate in both of these cycles, integrating them and optimizing their interaction.

The ICI Group was a leading multi-national Chlor-alkali producer with headquarters in the UK

chlorine/caustic soda production plants chlorine derivatives

Creating value through integrated solutions

Modern power and automation systems are important to success in the chlor-alkali industry. The lifetime costs of power and automation systems far exceed their initial capital costs. Therefore, it is essential that power and automation systems be regarded as strategic elements in any new investment. All major capital projects are subject to cost and schedule risks. However, decisions taken during the design stages of a new investment have a major impact on lifecycle costs. The ability to influence investment costs is greatest in the early phase of a project. ABBs experience indicates that as an integral power and automation partner we can help to mitigate the risks and reduce both capital and lifecycle costs. The key to risk mitigation and cost reduction is the early involvement of ABB, allowing us to leverage our expertise for your benefit.

Influence of design on project life cycle costs

Through more intimate customer relationships and in-depth understanding of business objectives, ABB helps to refine operational processes and create sustained performance improvement by: Exploiting state-of-the-art technology Improving business and supply chain performance

Feed Design Detailed FAB STE Operations Definition Design

Improving variable cost performance Optimizing the asset base Improving the contribution of operations to business Ensuring compliance with licensing and regulatory agencies ABBs powerful blend of knowledge, skills and resources is a spur to innovation. To help us create leading edge solutions, we have links with major universities and research programs and maintain our own ABB corporate research center. For the chlor-alkali industry, ABB has embarked upon a program to develop new applications of our technologies and enhance our comprehensive range of standard products. These new developments are aimed specifically at delivering operational benefits to producers in the industry.

Savings are established by: Leveraging ABBs knowledge base in the chlor-alkali industry Maintaining continuity through successive stages of a project Sharing information electronically and integrating it with CAE systems Transfering risk for delivery Standardizing products, services and work processes Reducing organizational interfaces Simplifying the supply chain Integrating products and services more closely

and intermediate plants vinyl chloride monomer and PVC plants

IndustrialIT for the Chlor-alkali industry

Advanced Technologies, Systems and Services

ABB supplies the total needs of the chlor-alkali industry for both batch and continuous processes. We offer global solutions customized to fit every situation while providing full lifecycle support. The IndustrialIT suite of scalable solutions is perfectly matched to todays dynamic enterprises and focuses on keeping reliability and performance at the highest level. ABB collaborates with chlor-alkali customers to understand their needs, provide information to sustain their industry leadership and develop solutions that exploit new automation frontiers for controlling their plants. A key feature of ABBs automation technologies and services is ABBs IndustrialIT Aspect ObjectsTM . This feature integrates information from a variety of applications (including computer-aided engineering systems used by engineering contractors) and makes it available in real-time to any authorized user regardless of their location. Plant data and plant components are presented as configurable software objects. Each object carries a range of related information that makes the object instantly recognizable to plant-wide information networks. With ABB Aspect Objects, plant information is deployed rapidly and uniformly, so that personnel throughout your enterprise view your business through the same real-time window. Better information means faster decision-making and more control over assets. For the chlor-alkali industry, ABB offers a suite of products encompassing power, measurement, analysis, control, automation and management solutions and integrates them into a single architecture, IndustrialIT. Our products are designed for aggressive environments and meet the full range of industry standards and protection requirements. Because world-class performance and reliability are key requisites of the chloralkali industry, ABB products are specifically designed for a long mean time between failure. ABB is committed to full lifecycle service, aimed at creating and sustaining value. Through our chlor-alkali unit, we reach out to a global network of experts, who continually deliver the best available technology and support throughout the life of your assets.

chlorine/caustic soda production plants chlorine derivatives an

Optimizing asset productivity and total lifecycle support

Optimization Solutions and Advanced Applications

The solutions and services developed by ABBs chlor-alkali unit form an integral part of the IndustrialIT suite. They are designed to address the needs of the industry by offering: Improved performance More eco-efficient production Reduced waste Sustainable operations ABB solutions for the chlor-alkali industry include: Chlorine Electro-Chemical Process Optimization A process optimizer that balances the current efficiency across cells to optimize performance and to identify and diagnose faults. The software can be operated with any DCS platform. It exploits all the capabilities of your current information processing systems to interpret data and determine performance variability in oxygen, hydrogen and chlorine. The main objectives are to improve overall cell performance, maximize production and improve product quality and membrane life. PVC Reaction Process Optimization This optimizer model has been developed as an off-line tool for process investigation and as an on-line tool for operating and controlling PVC batch reactors. As an off-line tool, the model is calibrated with historical data and enables what if scenarios to be carried out, to identify opportunities for improvements in product quality, productivity and cost reduction. The model can be tuned to optimize for different criteria (for example, maximum output, minimum cost and product quality). As an on-line tool the model can be used to support batch optimization and characterization. The model supports on-line real-time parameterization to predict, control and optimize such items as initiator charge and reactor temperature profile. As a result, reaction times are optimized, plant throughput increases and coarse out-of-specification batches are detected earlier. PVC Quality Optimization A derivative of the reaction process optimizer, this quality optimizer focuses on PVC product consistency. Target values and ranges are defined for all of the key polymer properties; the objective of the optimization is to constrain the properties within these limits. Process Plant Simulation Process plant simulators that can be used for training and validating operators, and for developing and testing new operating strategies. Weve provided more operator training simulators to the chemical industry than any other company. ABB simulators can interface to the plant control system and use real data to populate the models. The simulators are configurable for different processes, both batch and continuous: for example, chlorine diaphragm and membrane cell processes, VCM and PVC processes. Predictive Asset Management Using existing sensor data and known fault conditions, our predictive asset management tools determine the operating conditions of manufacturing assets without the use of dedicated asset monitoring equipment. This approach is particularly beneficial in areas of the plant where operating conditions make it difficult to take specific measurements. With this technique, were able to predict and avoid accelerated asset failure regimes and thereby reduce planned and unplanned maintenance. Advanced Applications World-class technology from both our own R&D and our software partners. We combine expertise in advanced applications and expertise in the chlor-alkali industry to deliver tangible results to your plant. ABB professionals are available world-wide to design and commission real-time integrated applications for your site, using best-in-class tools. Technology-based Solutions Tapping into the power, automation and process technologies of IndustrialIT, ABB brings about major improvements in the performance of your businesses. Our technology builds upon years of industry experience, state-of-the-art software applications and expertise in plant operational design, process engineering and licensing. Whether you require specialized reporting, connectivity to business systems, composition control or a customized planning and scheduling system, our Advanced Applications Engineering group will find the solution.

nd intermediate plants vinyl chloride monomer and PVC plants

Integrated solutions in the

ABB provides

Technology, Products, Applications, and S

Close the Gap between Plan and Reality with ABBs IndustrialIT bas With IndustrialIT you are fully Web-enabled, Collaborative an

ABB Power Products balance your operational, reliability and safety performance while reducing operating costs.

ABB Motors and variable speed to operate in aggressive, corrosi with very high reliability and low

ABB Rectifier systems are ideally suited to Chlorine manufacturing operations. They exploit latest technology and are designed for high efficiency, reliability, long life and low maintenance.

Electricity Hydrogen Brine Treatment Chlorine

Salt Water

Depleted brine

Caustic soda

Chlor Proces

Chlorine Production

Purification Caustic Concentration

ABB consultants can provide support in the development and maintenance of water systems to optimize usage and treatment.

ABB OptimizeIT systems can help to monitor cell efficiency and optimize energy consumption.

chlorine/caustic soda production plants chlorine derivatives and

Chlor-alkali chain from ABB

Services for the Chlor-alkali industry.

sed Solutions to increase your Profit. nd Operative in Real-Time across all Levels and Systems.

drives are designed ive environments overall costs.

ABB open control systems with a single window interface to all operations and applications can provide increased efficiencies and reduced costs.

EDC/VCM Production PVC Production

Ethylene Water Initiator Additives

VCM

rine ssing PVC

HCI EDC

ABB Instrumentation, Analytics and Measurement devices can produce increased efficiency and improved quality throughout the Chlorine Chain.

ABB OptimizeIT systems can increase PVC yield, reduce energy costs and improve quality consistency.

intermediate plants vinyl chloride monomer and PVC plants

ABB: your preferred provider

Rectifier Systems

ABB is the market leader in rectifier systems for chlor-alkali industry. ABBs IndustrialIT rectifier systems feature high reliability, long life and low maintenance, ensuring a high return on investment. Each systems scalable modular design allows for a high level of standardization along with the flexibility to adapt to your specific needs. Application specific control features include: Constant current control Power factor regulation Ampere-hours regulation Active compensation of DC current over swing due to tap changing Trending

Motors and Drives

ABB is the market leader in high and low voltage motors, with a complete range of standard designs up to 11 kV. The motors feature high efficiency, high reliability and long bearing life. Low voltage motors work with variable speed drives and with low levels of noise. ABB has a complete range of high, medium and low voltage drives from 0.15 kW to 18 mW, incorporating variable speed and flux optimization for energy efficiency. Built with reduced harmonics and the minimum number of components, these drives perform with higher reliability and lower overall costs.

Analytical Solutions

Innovation and experience are combined in ABBs analytical products to offer our customers exceptional functionality, reliability and accuracy in the harshest environments while maintaining a clear display of the process. We recognize that first-class analytical results are essential for understanding your process and for identifying ways to reduce costs while improving product quality. ABB offers an unprecedented range of process analyzers including over 75 analyzers specifically designed for the rigorous demands of the chlor-alkali industry, such as infrared and near infrared photometers, ultraviolet photometers, paramagnetic and thermo-magnetic analyzers, thermal conductivity analyzers and mass spectrometers. We have a premier record in combining our products with third-party products to supply turnkey solutions for the chlor-alkali industry. Our Systems Integration Units enable us to engineer and supply sample handling systems and enclosures specifically designed for demanding chlor-alkali duties.

chlorine/caustic soda production plants chlorine derivatives

Integrating process and power management to IndustrialIT

Power Products

Composite Plant Solutions ABB supplies IndustrialIT products and services on a turnkey basis. Large projects require supply coordination and total integration of products and services. Our equipment and electrification solutions have proven very successful in new plant projects worldwide. These solutions include: Transformers Capacitors Switchgear and motor control centers Remote services Power optimization Plant design IndustrialIT solutions, systems and equipment efficiently transmit, distribute and control electricity. With our extensive hardware, our expertise in network management, control, protection and monitoring, and our consulting and diagnostic capabilities, we can optimize your asset utilization and contribute to the profitable operation of your business. Power Systems ABB is able to help you develop your power systems through computerized modeling. We use your real maintenance history to carry out a structured analysis. This analysis pinpoints the asset development strategy that enables you to balance performance, cost and risk. High power rectifiers and drives are necessary for chlorine production but can introduce harmonics into power distribution systems. ABB can help you optimize your power distributions systems and co-ordinate solutions, including ABB capacitors and harmonic filters for controlling harmonics. ABB is the market leader for distribution transformers with over thirty production facilities around the world. Based on proven technology, we offer a complete product range up to 72.5 kV (oil type, dry type and special applications). ABBs IndustrialIT switchgear covers the full range of requirements for chloralkali producers. The fixed pattern design has fewer components, to improve reliability, minimize maintenance and lower overall costs. The equipment is fully arc protected for enhanced safety. The equipment incorporates multi-function, software-configurable, protection relays. The relays feature real-time self-monitoring for disturbance recording and power quality measurements. Our specialists work with you to identify and provide solutions for your electrical system over its entire life-cycle.

and intermediate plants vinyl chloride monomer and PVC plants

Showing the way to peek performance

Consultancy Services

The engineers and consultants in our ABB Process Solutions group have unprecedented know-how in the chlor-alkali industry gained through their operational heritage with ICI. Drawing upon this unique heritage and wealth of experience in the chlor-alkali industry, we develop, improve and maintain the performance of manufacturing operations and associated infrastructure. Some of the services that we offer include: Asset management Business process optimization Energy and utilities Environmental services and IPPC Manufacturing process optimization Operational plant support Safety management ABB consultants are helping chlor-alkali producers throughout the world to deliver tangible benefits in the following areas: Capacity increases. Carry out discovery studies, make recommendations and implement changes to process design. Quality improvements. Study existing quality standards with recommendations on measures to improve absolute values, quality and consistency. Cost reduction. Study costs and make recommendations for their reduction. Typically, this would include energy and raw material costs. Environmental or safety improvements. Make recommendations and design modifications to improve performance. Problem solving. Identify the causes of process problems, and recommend solutions, for example, to extend asset life, reduce downtown and improve efficiency.

10

chlorine/caustic soda production plants chlorine derivatives an

Improving operational performance

Here are three examples of services provided by ABB consultants for the chlor-alkali industries; Water Technology Water quality, brine purification and the control of impurities are critical features in the efficient operation of a membrane cell chlorine plant.Therefore, these areas of the process have much tighter specifications for demineralised water. ABBs water technologists are very experienced in developing systems for the chlor-alkali industry and providing life-cycle services to maintain the systems. Risk Based Inspection ABB can help you develop a robust, cost-effective inspection program that maximizes production time, minimizes downtime, maintains a safe operational regime and offers added value. Risk-based inspection is a powerful technique. ABBs methodology is based on partnership with the customer to understand what can go wrong and what the consequences are. We make sure that inspections identify damage before it escalates. In todays environment, regulatory compliance is essential, and inspection work must be integrated into the maintenance routine. It can no longer be treated as a separate issue. Inspections must concentrate on areas where the risks associated with failure are greatest, using techniques that are appropriate to the risk. This risk-based methodology can be applied to all types of equipment to determine the most appropriate inspection strategy. Typical approaches include: Non invasive techniques minimizing vessel entries Techniques to lengthen the intervals between inspections Focused inspection, to concentrate on key areas Equipment looked at on a system basis combining to: Reduce the total cost of inspection Increase availability Improve reliability Fewer, shorter, more manageable plant overhauls Benchmarking ABB uses a rapid, quantitative approach to assess the performance of assets and related processes and to identify opportunities for improvement. Our approach to benchmarking is to evaluate current performance and improvement opportunities. We provide a quantitative appraisal that compares your asset performance against external measures, evaluates the performance gap and highlights areas for improvement. We show you the impact of performance gaps on your most important financial and business indicators. This analysis provides the information thats essential for go/no-go decisions, without incurring large costs. The benchmark study defines the size of the strategic opportunity and clearly shows you where the money is. Overall Manufacturing Performance Distribution

nd intermediate plants vinyl chloride monomer and PVC plants

11

IndustrialIT Solutions from ABB

IndustrialIT solutions from ABB blend the industrys broadest portfolio of compatible knowledge components with a proven architecture for real-time enterprise automation and information.

Visit us at: www.abb.com/chemical Email: chemical.info@us.abb.com

You can find ABB in more than 100 countries. Visit us at www.abb.com/chemical email: chemical.info@us.abb.com

For more information on ABB IndustrialIT solutions for the chlor-alkali industry, please contact your local sales representative

Form No. 3BUS015207R0001 Copyright 2004 by ABB Inc. All rights to trademarks reside with their respective owners. Specifications subject to change without notice. Pictures, schematics and other graphics contained herein are published for illustration purposes only and do not represent product configurations or functionality. User documentation accompanying the product is the exclusive source for functionality descriptions.

Вам также может понравиться

- Optimizing Oil (Caterpillar Engine) PDFДокумент8 страницOptimizing Oil (Caterpillar Engine) PDFKurniadi Setyanto100% (1)

- Abb Low Voltage Capacitor Banks April 2011Документ16 страницAbb Low Voltage Capacitor Banks April 2011IppiОценок пока нет

- Tesys F Lc1f330Документ4 страницыTesys F Lc1f330Kurniadi SetyantoОценок пока нет

- Review Jurnal Internasional-1Документ48 страницReview Jurnal Internasional-1Kurniadi SetyantoОценок пока нет

- Varplus M.PDF VallejosДокумент4 страницыVarplus M.PDF VallejosJazmín SampierОценок пока нет

- Centaur® 50 Gas Turbine-Driven Generator SetДокумент16 страницCentaur® 50 Gas Turbine-Driven Generator SetKurniadi Setyanto60% (5)

- Motorpact Training Material 2011Документ114 страницMotorpact Training Material 2011Kurniadi Setyanto100% (1)

- GE Capacitor Bank ControllerДокумент8 страницGE Capacitor Bank ControllerKurniadi SetyantoОценок пока нет

- Electrical #002-Cathodic Protection Rev 2Документ31 страницаElectrical #002-Cathodic Protection Rev 2Kurniadi Setyanto100% (5)

- COMECA EBT - Company Profile PDFДокумент1 страницаCOMECA EBT - Company Profile PDFKurniadi SetyantoОценок пока нет

- Powersuite Software Workshop: Presentation, FunctionsДокумент4 страницыPowersuite Software Workshop: Presentation, FunctionsKurniadi SetyantoОценок пока нет

- ETAP Zig-Zag TransformerДокумент2 страницыETAP Zig-Zag Transformervlady33Оценок пока нет

- 02.first AidДокумент60 страниц02.first AidKurniadi SetyantoОценок пока нет

- Application 2-W Transformer INST ProtectionДокумент3 страницыApplication 2-W Transformer INST ProtectionKurniadi SetyantoОценок пока нет

- HVAC Calculation (Room)Документ5 страницHVAC Calculation (Room)Kurniadi SetyantoОценок пока нет

- ABB Oy Distribution Automation Event List For RET 541 and RET 543 January 20 2005Документ36 страницABB Oy Distribution Automation Event List For RET 541 and RET 543 January 20 2005Kurniadi SetyantoОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Restaurant Report Card: February 9, 2023Документ4 страницыRestaurant Report Card: February 9, 2023KBTXОценок пока нет

- LG Sigma+EscalatorДокумент4 страницыLG Sigma+Escalator강민호Оценок пока нет

- What Says Doctors About Kangen WaterДокумент13 страницWhat Says Doctors About Kangen Waterapi-342751921100% (2)

- Information Technology Project Management: by Jack T. MarchewkaДокумент44 страницыInformation Technology Project Management: by Jack T. Marchewkadeeps0705Оценок пока нет

- Elastomeric Impression MaterialsДокумент6 страницElastomeric Impression MaterialsMarlene CasayuranОценок пока нет

- Mangas PDFДокумент14 страницMangas PDFluisfer811Оценок пока нет

- College of Computer Science Software DepartmentДокумент4 страницыCollege of Computer Science Software DepartmentRommel L. DorinОценок пока нет

- Vocations The New Midheaven Extension ProcessДокумент266 страницVocations The New Midheaven Extension ProcessMiss M.100% (24)

- MECANISMOS de Metais de TransicaoДокумент36 страницMECANISMOS de Metais de TransicaoJoão BarbosaОценок пока нет

- Tachycardia Algorithm 2021Документ1 страницаTachycardia Algorithm 2021Ravin DebieОценок пока нет

- Ac1025 Exc16 (1) .PDFTTTTTTTTTTTTTTTTTTTДокумент50 страницAc1025 Exc16 (1) .PDFTTTTTTTTTTTTTTTTTTTHung Faat ChengОценок пока нет

- Model TB-16Документ20 страницModel TB-16xuanphuong2710Оценок пока нет

- Ideal Gas Law Lesson Plan FinalДокумент5 страницIdeal Gas Law Lesson Plan FinalLonel SisonОценок пока нет

- BS en Iso 06509-1995 (2000)Документ10 страницBS en Iso 06509-1995 (2000)vewigop197Оценок пока нет

- Mitsubishi FanДокумент2 страницыMitsubishi FanKyaw ZawОценок пока нет

- Pricing of A Revolutionary ProductДокумент22 страницыPricing of A Revolutionary ProductiluvparixitОценок пока нет

- NGCP EstimatesДокумент19 страницNGCP EstimatesAggasid ArnelОценок пока нет

- Ac221 and Ac211 CourseoutlineДокумент10 страницAc221 and Ac211 CourseoutlineLouis Maps MapangaОценок пока нет

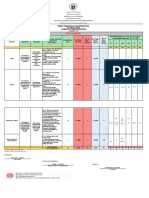

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Документ6 страницRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoОценок пока нет

- Explore The WorldДокумент164 страницыExplore The WorldEduardo C VanciОценок пока нет

- Homework 1Документ8 страницHomework 1Yooncheul JeungОценок пока нет

- Broiler ProductionДокумент13 страницBroiler ProductionAlexa Khrystal Eve Gorgod100% (1)

- Use of Travelling Waves Principle in Protection Systems and Related AutomationsДокумент52 страницыUse of Travelling Waves Principle in Protection Systems and Related AutomationsUtopia BogdanОценок пока нет

- Part Time Civil SyllabusДокумент67 страницPart Time Civil SyllabusEr Govind Singh ChauhanОценок пока нет

- Oracle SOA Suite 11g:buildДокумент372 страницыOracle SOA Suite 11g:buildMohsen Tavakkoli100% (1)

- Assignment Csi104Документ11 страницAssignment Csi104Minh Lê KhảiОценок пока нет

- Footing - f1 - f2 - Da RC StructureДокумент42 страницыFooting - f1 - f2 - Da RC StructureFrederickV.VelascoОценок пока нет

- Electric Vehicles PresentationДокумент10 страницElectric Vehicles PresentationVIBHU CHANDRANSH BHANOT100% (1)

- LKG Math Question Paper: 1. Count and Write The Number in The BoxДокумент6 страницLKG Math Question Paper: 1. Count and Write The Number in The BoxKunal Naidu60% (5)

- Object-Oriented Design Patterns in The Kernel, Part 2 (LWN - Net)Документ15 страницObject-Oriented Design Patterns in The Kernel, Part 2 (LWN - Net)Rishabh MalikОценок пока нет