Академический Документы

Профессиональный Документы

Культура Документы

Metode Monitoring Trafo Distribution

Загружено:

Siswoyo SuwidjiИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Metode Monitoring Trafo Distribution

Загружено:

Siswoyo SuwidjiАвторское право:

Доступные форматы

METHOD FOR MONITORING OF DISTRIBUTION TRANSFORMER

ANURUDH KUMAR1, ASHISH RAJ2, ABHISHEK KUMAR3, SIKANDAR PRASAD4 & BALWANT KUMAR.5

1,2,3,4&5

Dr. M.G.R, Educational and Research Institute, University, Chennai-600095

Abstract Distribution transformers are one of the most important equipment in power network. Because of, the large number of transformers distributed over a wide area in power electric systems, the data acquisition and condition monitoring is a important issue. This project presents design and implementation of a mobile embedded system to monitor and diagnose condition of transformers, by record key operation indictors of a distribution transformer like load currents, transformer oil, ambient temperatures and voltages. The proposed on-line monitoring system integrates a Global Service Mobile (GSM) Modem, with a solid state device named PLC (programmable logic controllers)and sensor packages. Data of operation condition of transformer receives in form of SMS(Short Message Service) Using the suggested online monitoring system will help utility operators to keep transformers in service for longer of time. Keywords Monitoring , Distribution Transformers , Modular Software , GSM Networks .

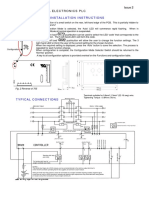

I. INTRODUCTION Communication network and GSM devices such as GSM modems have a large attraction in wide area network applications. To conquer the transferring and collecting problem of these large amount of data about transformers condition, These devices would be so useful to transfer and acquire the large amount of data about the transformers condition. So with development of infrastructure of wireless communication, offer new and cost effective possibilities to monitor distribution transformers. II. HARDWARE REQUIRED Controller: Programmable logical controller, Pc as a monitor device. Sensors: Current transformer , Potential transformer, Temperature sensor , Pressure sensor. Accessories Transducer circuit, alarming circuit, GSM Modem, Load.

III. DTMAS SOFTWARE The DTMAS software is consist of 3 major layers, condition monitoring, analysis layer and alarm layer. Detail of layer is reviewed consequently. A. Condition Monitoring Layer This layer or module is utilized to display received data including three-phase voltage or current and the oil or air temperature. As we can see in (a), these parameters are shown in display window. User can choose each one of these parameters by selecting buttons, which has been located under this display window B. Analysis Layer In this layer of DTMAS, data has been analyzed. This layer is directly connected to the data acquisition layer. Once the data enter the server system, has been analyzed and if they exceed values, the alarm layer will be informed. In (b) the analysis part of the software has been indicated. . 1 .Novel Software Architecture for Power Distribution Automation In this paper, a unified, modular structure for the key software elements of distribution automation system the master DA software and the engineering analysis software, is proposed. These software elements are responsible for achieving various DA functions. The proposed structure suggests the software development as a combination of different applications, which are functionally independent hut interfaced appropriately. An application, in turn, is conceptualized as an outcome of interaction between a set of processes andor databases. This hierarchical structure, which is composed of application process and database, facilitates modular development, maintenance, upgrade I modification while extending the flexibility in interfacing (including laying down the interface

Undergraduate Academic Research Journal (UARJ), ISSN: 2278 1129, Volume-1, Issue-3,4, 2012 91

Method for Monitoring of Distribution Transformer

characteristics and specifications). Consequently, these features also lead to reducing vendor monopoly and dependence in the implementation I expansion of the DA system in phased manner. The proposed software structure has been successfully implemented in field.. 2. DEVELOPMENT OF NOVEL DISTRIBUTION AUTOMATION SYSTEM (DAS) ON CUSTOMER SIDE DISTRIBUTION SYSTEM This research work has been done in designing and developing a Novel Distribution Automation System (DAS) in an open loop customer side distribution system. The research has utilized an automation techniques in both hardware and software environment using a communication network and embedded controllers along with power meters which has utilized the possible best solution for the fault operation and control tasks remotely. All hardware and software components have been developed and integrated together. Data exchange mechanism has been developed between the host computer and the embedded controllers that function in two way data exchanges between the two. The remote hardware controllers such as remoter terminal units (RTUs) are enabled to the communication modules to operate the substation remotely. The metering equipment is used as real time data restoration tool and gathers the customer's consumption energy information. Thus a multipurpose power meter is used as hand of the electrical utility at the customer side. IsaGraf provides communication GSM (Global system for Mobile Communications) function blocks such as SMS (Short Message Service) operating functions SMS_send, SMS_test, SMS_gets and developed SMS usage functions. These are functions are created for GSM based messaging system to communicate with the person in charge to operate the system at anytime and anywhere remotely. Fabrication testing has been done on real distribution system and

2.1 SYSTEM ARCHITECTURE First step is to check the power input whether it is turned on or turned off. The power input is referred to relay output of MK2200 (multifunction relay).If no fault condition is detected by MK2200, the power input is turned on (Normally Close (NC)). When MK2200 detects the fault condition, power input is turned off (Normally Open (NO)). In this case, the MK2200 is re-set by using a delay timer and power input is turned on automatically.

System Architecture The contribution of this research includes developing a complete fault isolation algorithm based on an open loop distribution system. In an open loop distribution system, two feeders are used to provide electricity supply to the loads. During fault conditions, any section of the feeder can be isolated without interruption. The algorithm is developed to check the fault point starting from the one of the section feeders or OLUC algorithm and repeated with another section feeders or OLDC algorithm. At the beginning, this algorithm needs to clarify with which point is the fault point by supplying the power to each load after the fault is detected by the MK2200 (combined earth leakage relay and over current relay). When the fault point is being activated, the MK2200 detects the fault and trip mechanism is operated. The algorithm will find the false point and reset the MK2200 to restore the power supply to the loads. this time, only the unfaulted point will be restored. 3. WIRELESS DISTRIBUTED MONITORING AND CENTRALIZEDCONTROLLING SYSTEM FOR PREFABRICATED SUBSTATIONS IN CHINA Online monitoring of the distribution transforners is very difficult to realize because of the large number and dispersed distribution of the prefabricated substations. To solve this problem, this paper has proposed a novel monitoring and controlling system integrating the GSM communication technology and the latest PIC microprocessor technology. The paper introduces the whole architecture and working principle of the GSM based remote monitoring system for prefabricated substations in China. Then it explicates the hardware architecture and software flow of the RTU. The application of the proposed system will also promote power automation to a

Undergraduate Academic Research Journal (UARJ), ISSN: 2278 1129, Volume-1, Issue-3,4, 2012 92

Method for Monitoring of Distribution Transformer

higher level by using the microprocessor-based RTU with smart architecture.A trial was given on the implemented system for testing, and the results came out as expected. Improvements are needed for software programming to implement the controlling functions of the control station. The object oriented programming language Visual C++ was used to develop the controlling program with a utility manPC interface. The software architecture consists of three functional modules[5].

4. INTELLIGENT TRANSFORMER SUBSTATIONS IN MODERN MEDIUM VOLTAGE NETWORKS AS PART OF SMART GRID Increasing demand for reliable electricity and achieving the climate protection targets lead to promote the renewable energies with points of infeed in the medium-voltage and low-voltage systems. Maintaining the necessary power quality and network stability requires an active distribution system with intelligent transformer substations. Possible measures reach from pure monitoring via remote control up to targeted load flow control, and are different in the companies or countries. There is everything from zero level up to complete remote control of the transformer substations. Incentive systems to minimize outage times, and necessary measures to secure the voltage quality are the drivers. Presently, the fault detection with monitoring and remote control with shifting of the open isolating point with the sectionalizer are still in the foreground.

1) Alarm charge are listed on the computer's screen. If one of substations sends alarm signal, its mark will be blinking on the screen with alarm sound. ersonnel at the control station can know about the abnornality of any substation in time. 2) Acquire and analyze the status parameters This functional module is used to inquire about the substations status periodically or when accidents happens. By analyzing the data package received, control station can help the mobile operator find the fault location quickly and decrease the repair and restoration time. The analysing result will be displayed on the PC screen. 3) Administer the mobile phones This function module is used to administer the mobile phones within the control area of the station. It includes the function of adding new mobile phones and canceling existed mobile phones by sending AT commands to rewrite appointed phone numbers.

Utilization of inverters from the wind power and photovoltaic systems to ensure and improve the power quality will increase in the future. Moreover, distribution transformers with tap changers will be

Undergraduate Academic Research Journal (UARJ), ISSN: 2278 1129, Volume-1, Issue-3,4, 2012 93

Method for Monitoring of Distribution Transformer

used at critical points in the secondary distribution system. In addition to this there are possibilities for minimization of losses in the grid and monitored utilization of the operational equipment even in the overload range. The advantages resulting from remote control and active load management are: - Faster fault localization - Shorter interruption times - Measuring/signaling of operational data - Reduced network losses - Possibility of compensation of reactive power / harmonics - Monitored transformer operation during overload - Higher transmission power; thus: postponement of network extensions - Remote object supervision For the upcoming tasks, Siemens has a consistent concept and the suitable equipment: - Medium-voltage switchgear 8DJH with the necessary sensors and actors [5] - RTU telecontrol system with SICAM TM 1703 [6] - Communication via IEC 60870-5-101/104 or IEC 61850 protocols; conventionally via wire, radio or in future via WiMAX or BBDL - Telecontrol node / substation automation systems SICAM PAS [7] or SINAUT Power CC - Application/consulting competence through our network planning department [8] The answer to the question Intelligent transformer substation: a need or luxury? is: Intelligent substations and an intelligent distribution network are a must in order to meet the requirements of the future. The objective of Siemens is to continue developing intelligent solutions for the management of secondary distribution systems, thus contributing to reliable and efficient power supply.

5.Online Monitors Keep Transformers in Service

Sensor

Undergraduate Academic Research Journal (UARJ), ISSN: 2278 1129, Volume-1, Issue-3,4, 2012 94

Method for Monitoring of Distribution Transformer

Hardware

Software

6. CONCLUSION In this paper, we have described an advanced remote monitoring system for distribution transformers utilizing the existing GSM communication network, which has low investment and operation costs. It is also easy to install and use. For this purpose, we have introduced a novel software (DTMAS) and used it for three different types of distribution transformers in order to analyze voltage unbalance condition. REFERENCES

[1]. M. M. Ahmed, W. L. Soo, A Robust Distribution Automation System (DAS) Development for Automatic Meter Reading (AMR), 2010. [2]. ICP DAS, 7188E/843X/844X/883X/884X TCP/IP Library Users Manual, Ver. 1.0 Copyright 2002. Available at: www.icpdas.com

[3]. Customized Non-interruptible Distribution Automation System, Short Term Project No. PJP/2006/FKE (1) , UTeM, 2005-2006 [4]. Intelligent Distribution Automation System: Customized SCADA Based RTU For istribution Automation System, M.Sc. Research Project, UTeM, 2005-2007. [5]. Pabla, A.S. (2005). Electric Power Distribution, 2nd ed., New York: McGraw-Hill, 723 p. ISBN 0-07-144783-0 [6]. Rubin, L., Bricker, S. & Gonen, T. (2001). Substation Automation Technologies and Advantages. IEEE Transactions on Power Delivery, 489 p. ISSN 0895-0156 [7]. Lee, H.J. & Park, Y.M. (1996). A Restoration Aid Expert System for Distribution Substations. IEEE Transactions on Power Delivery, Vol.11,pp.1765 -1769 [8]. Kezunovic, M. (2003). Data Integration and Information Exchange for Enhanced Control and Protection of Power Systems. In Proceedings of the 36th Hawaii International Conference on System Sciences. TX 77843-3128. 33p. [9]. Customized Non-interruptible Distribution Automation System, Short Term Project No. PJP/2006/FKE (1) , UTeM, 2005-2006 [10]. Intelligent Distribution Automation System: Customized SCADA Based RTU For Distribution Automation System, M.Sc. Research Project, UTeM, 2005-2007. [11]. John D. McDonald,Substation and Smart Grid, The World Market for Substation Automation and Integration Programs in Electric Utilities: 2005-2007; Newton-Evans Research Company, Inc. [12]. L.Boquete, I.Bravo, "Telemetry and control system with GSM communications", Microprocessors and microsystems, Vol. 27, pp. 1-8, February 1, 2003. [13]. Abdul-Rahman Al-Ali, Abdul Khaliq, "GSM-based distribution transformer monitoring system", Electrotechnical Conference, 2004. Proceedings of the 12th IEEEMediterranean, Vol. 3, pp.999 - 1002, May 12-15, 2004. [14]. PIC16F87X Data Sheet, 2001 Microchip Technology Inc. DS30292C [15]. CMS91-900/1800 GSM/GPRS Module-AT Commands Specification, Hardware Specification. www.CELLon.com [16]. Zhu Wangui, "Designing and implementing SMS-based remote monitoring system", anufacturing Automatic Control, Vol. 25, pp. 32-34, December, 2003. [17]. EEG Erneuerbare-Energien-Gesetz; Website des Bundesministerium fr Umwelt, Naturschutz und Reaktorsicherheit http://www.erneuerbare-energien.de/inhalt/ June 14th, 2010 [18]. Internationaler ETG (Energietechnische Gesellschaft)Kongress 2009; Fachtagung 1: Intelligente Netze ETGFachbericht 118; VDE Verlag, Berlin [19]. [19] Smart Grid, Siemens Internet Website: http://www.energy.siemens.com/hq/en/energytopics/ smartgrid/, June 10th, 2010 [20]. Brochure: Intelligent transformer substations in smart grids Siemens AG, Power Distribution Division, Order No. E50001-D710-A370-X-4A00, 2010 [21]. Detailled product information on Siemens 8DJH: http://www.energy.siemens.com/hq/en/powerdistribution/ medium-voltage-switchgear/

Undergraduate Academic Research Journal (UARJ), ISSN: 2278 1129, Volume-1, Issue-3,4, 2012 95

Вам также может понравиться

- SCADA in POWER DISTRIBUTION SYSTEMSДокумент10 страницSCADA in POWER DISTRIBUTION SYSTEMSrohinibhaskar0% (1)

- Buku PUIL PDFДокумент133 страницыBuku PUIL PDFGalang Pratama100% (1)

- Time America, Inc. TA520/530: Technical Reference ManualДокумент55 страницTime America, Inc. TA520/530: Technical Reference Manualsujithnair143Оценок пока нет

- Electrical Panel InspectionДокумент16 страницElectrical Panel InspectionjvieiraoliveiraОценок пока нет

- Mid 216 (LCM) VNL Fault Codes Pv776-20033682Документ82 страницыMid 216 (LCM) VNL Fault Codes Pv776-20033682Андрей100% (6)

- Architecture of A Fault Diagnosis Expert System For Power Plants ProtectionДокумент5 страницArchitecture of A Fault Diagnosis Expert System For Power Plants Protectionserg6007Оценок пока нет

- Wireless Transformer MonitoringДокумент8 страницWireless Transformer MonitoringKamlesh Motghare100% (1)

- Theft Detection Based GSM Prepaid Electricity System Project ReportДокумент21 страницаTheft Detection Based GSM Prepaid Electricity System Project ReportAkhil TupiliОценок пока нет

- Substation Automation Basics - The Next GenerationДокумент8 страницSubstation Automation Basics - The Next GenerationAlly RaxaОценок пока нет

- GSM Based Distribution Transformer Monitoring and Controlling System Ijariie1748Документ3 страницыGSM Based Distribution Transformer Monitoring and Controlling System Ijariie1748Velu SamyОценок пока нет

- Scad AДокумент10 страницScad AKhaddavi KhalifОценок пока нет

- IOT-Based Transformer MonitoringДокумент9 страницIOT-Based Transformer MonitoringSuparna DebОценок пока нет

- XBEE Based Transformer Protection and Oil TestingДокумент3 страницыXBEE Based Transformer Protection and Oil TestingijsretОценок пока нет

- AptdДокумент28 страницAptdrudresh singhОценок пока нет

- Power Quality Analysis A Distributed Measurement SystemДокумент6 страницPower Quality Analysis A Distributed Measurement SystemtamsideОценок пока нет

- SCADA-Based Control System For Distribution SubstationДокумент8 страницSCADA-Based Control System For Distribution SubstationThan Htike AungОценок пока нет

- Lecture 6 - Power System AutomationДокумент15 страницLecture 6 - Power System AutomationAweSome, ST,MTОценок пока нет

- Substation Load ShareДокумент6 страницSubstation Load ShareRaghul Ramasamy100% (1)

- Monitor Generators Remotely via SMSДокумент6 страницMonitor Generators Remotely via SMSyassine moujbaniОценок пока нет

- IAS 2009 Vfinal2Документ7 страницIAS 2009 Vfinal2Cinthya BorgesОценок пока нет

- Creating A Microgrid Energy Management System Using NI LabVIEW and DAQДокумент7 страницCreating A Microgrid Energy Management System Using NI LabVIEW and DAQtunghtdОценок пока нет

- IoT Based Industrial Production Monitoring System Using Wireless Sensor NetworksДокумент8 страницIoT Based Industrial Production Monitoring System Using Wireless Sensor NetworksIJAERS JOURNALОценок пока нет

- Automated Meter Reading and SCADA Application For Wireless Sensor NetworkДокумент12 страницAutomated Meter Reading and SCADA Application For Wireless Sensor NetworkliameiОценок пока нет

- Supervisory SystemsДокумент23 страницыSupervisory Systemspotugaadu1Оценок пока нет

- SCADA-Optimized Electricity BillingДокумент13 страницSCADA-Optimized Electricity BillingNorton KingОценок пока нет

- Fuzzy Logic Approach For Fault Diagnosis of Three Phase Transmission LineДокумент5 страницFuzzy Logic Approach For Fault Diagnosis of Three Phase Transmission LineJournal 4 ResearchОценок пока нет

- Scada in Power Distribution Systems SeminarДокумент2 страницыScada in Power Distribution Systems Seminarsumitsinha89100% (1)

- The Essentials of Automation Applied To Distribution Systems Via PLCs SCADA IEDs and RTUsДокумент17 страницThe Essentials of Automation Applied To Distribution Systems Via PLCs SCADA IEDs and RTUsBruno SamosОценок пока нет

- Substation Automation Basics - The Next Generation: By: By: John Mcdonald, P.EДокумент5 страницSubstation Automation Basics - The Next Generation: By: By: John Mcdonald, P.ELaxman VeerepalliОценок пока нет

- A Solution To Remote Detection of Illegal Electricity Usage Via Power Line CommunicationsДокумент13 страницA Solution To Remote Detection of Illegal Electricity Usage Via Power Line CommunicationsSai RamОценок пока нет

- Integrating SCADA and Sap Operations For Electricity Process AutomationДокумент3 страницыIntegrating SCADA and Sap Operations For Electricity Process AutomationHakim BenmajidОценок пока нет

- GSM Based Transformer Fault Monitoring SystemДокумент5 страницGSM Based Transformer Fault Monitoring SystemEditor IJTSRDОценок пока нет

- Smart DevicesДокумент16 страницSmart DevicesmanojchandrasekharanОценок пока нет

- 4department 5electronics: Communication System For Controlling Smart Appliances Using Power Line CommunicationДокумент6 страниц4department 5electronics: Communication System For Controlling Smart Appliances Using Power Line CommunicationNeel SomudroОценок пока нет

- Scada in Power Distribution SystemsДокумент10 страницScada in Power Distribution SystemsMike AjayiОценок пока нет

- Advanced Automated Fault Location System For Primary Distribution NetworkДокумент13 страницAdvanced Automated Fault Location System For Primary Distribution NetworkSateesh IamОценок пока нет

- Racing Speed Locking System For Electric VehicleДокумент4 страницыRacing Speed Locking System For Electric VehicleElins JournalОценок пока нет

- End To End TestingДокумент6 страницEnd To End TestingEduardo777_777Оценок пока нет

- Power System Operation and Control NotesДокумент61 страницаPower System Operation and Control Notesanon_613151744100% (1)

- ESAA 1999 Residential School Power Communication StandardsДокумент38 страницESAA 1999 Residential School Power Communication StandardsSubramanyam Arehalli MuniswariahОценок пока нет

- Wireless ARM-Based Automatic Meter Reading & Control System (WAMRCS)Документ6 страницWireless ARM-Based Automatic Meter Reading & Control System (WAMRCS)Muthu KumaranОценок пока нет

- Robotic Monitoring Improves Power System ReliabilityДокумент14 страницRobotic Monitoring Improves Power System ReliabilityHOD EEEОценок пока нет

- Unit 3 IotДокумент17 страницUnit 3 IotKrishna DolasОценок пока нет

- Distribution Automation in Smart GridДокумент33 страницыDistribution Automation in Smart GridOM PRAKASH GURJARОценок пока нет

- Presentation 2Документ23 страницыPresentation 2Suda KrishnarjunaraoОценок пока нет

- Wireless Sensor System Monitors MotorsДокумент5 страницWireless Sensor System Monitors MotorsAbhijeet KeerОценок пока нет

- aUTOMATIC METERINGДокумент12 страницaUTOMATIC METERINGGSK MuhammadОценок пока нет

- Case Study: Power Line Carrier & Programmable Logic Control in Electrical SubstationДокумент12 страницCase Study: Power Line Carrier & Programmable Logic Control in Electrical SubstationTana AzeezОценок пока нет

- REMOTE MONITORING AND CONTROL OF SMART MICRO-GRID SYSTEMДокумент13 страницREMOTE MONITORING AND CONTROL OF SMART MICRO-GRID SYSTEMRahulОценок пока нет

- Project Report 9-07-2013Документ59 страницProject Report 9-07-2013Aravind RameshОценок пока нет

- NI CaseStudy Cs 13453Документ7 страницNI CaseStudy Cs 13453Anonymous C6PQv75QZОценок пока нет

- An Expert System For Power Plants: Department of Elctrical & Electronics EngineeringДокумент10 страницAn Expert System For Power Plants: Department of Elctrical & Electronics EngineeringPVV RAMA RAOОценок пока нет

- Dcs SystemДокумент7 страницDcs SystemJeya Kannan100% (1)

- Automatic Phase Selector Fro, Avilable Three Phase With Use of RelaysДокумент37 страницAutomatic Phase Selector Fro, Avilable Three Phase With Use of RelaysDinesh KumarОценок пока нет

- ERJM Volume 42 Issue 2 Pages 93-98Документ6 страницERJM Volume 42 Issue 2 Pages 93-98ahmed.hossamelden91Оценок пока нет

- Iot Based Transformer Monitoring System.Документ82 страницыIot Based Transformer Monitoring System.ra patОценок пока нет

- CMPS AssignmentДокумент11 страницCMPS AssignmentHemant SharmaОценок пока нет

- Transformer On Line MonitoringДокумент6 страницTransformer On Line MonitoringSiva KumarОценок пока нет

- Paper Ieee PDFДокумент4 страницыPaper Ieee PDFchandanjha2010Оценок пока нет

- Unit 4 - Power System Operation and ControlДокумент25 страницUnit 4 - Power System Operation and ControlSilas StephenОценок пока нет

- Ketentuan Pembuatan Katalog Komponen Listrik: 1. Spesifikasi TeknikДокумент6 страницKetentuan Pembuatan Katalog Komponen Listrik: 1. Spesifikasi TeknikSiswoyo SuwidjiОценок пока нет

- Contract project-2004 With Ministry of Environment, Japan: Air Pollution Control Technology in Thermal Power PlantsДокумент29 страницContract project-2004 With Ministry of Environment, Japan: Air Pollution Control Technology in Thermal Power PlantsPallavi BhattОценок пока нет

- B330-Sistem Kehadiran Perkuliahan OnlineДокумент1 страницаB330-Sistem Kehadiran Perkuliahan OnlineSiswoyo SuwidjiОценок пока нет

- Genst KatalogДокумент5 страницGenst KatalogSiswoyo SuwidjiОценок пока нет

- CH 04Документ62 страницыCH 04Praveen KumarОценок пока нет

- 05 BearingДокумент70 страниц05 BearingSiswoyo SuwidjiОценок пока нет

- Variable AC Voltage Supply Using Variac & Isolation TransformerДокумент10 страницVariable AC Voltage Supply Using Variac & Isolation TransformerSiswoyo SuwidjiОценок пока нет

- Genst KatalogДокумент2 страницыGenst KatalogSiswoyo SuwidjiОценок пока нет

- Genst KatalogДокумент2 страницыGenst KatalogSiswoyo SuwidjiОценок пока нет

- Digital Logic FundamentalsДокумент25 страницDigital Logic FundamentalsSiswoyo SuwidjiОценок пока нет

- Autotransformer StarterДокумент22 страницыAutotransformer StarterSiswoyo SuwidjiОценок пока нет

- Chapter 5 - : Total Quality ManagementДокумент53 страницыChapter 5 - : Total Quality ManagementSiswoyo SuwidjiОценок пока нет

- What Types of TransformerДокумент2 страницыWhat Types of TransformerSiswoyo SuwidjiОценок пока нет

- Ac Servo Motor Principal PDFДокумент26 страницAc Servo Motor Principal PDFAman Deep86% (7)

- Draf Kurikulum Sebaran Pol AmbonДокумент2 страницыDraf Kurikulum Sebaran Pol AmbonSiswoyo SuwidjiОценок пока нет

- Synchronous GeneratorsДокумент50 страницSynchronous GeneratorsRajAnandОценок пока нет

- Body of Knowledge ElectricalДокумент11 страницBody of Knowledge ElectricalSiswoyo SuwidjiОценок пока нет

- Bab 09 SKK RevisiДокумент19 страницBab 09 SKK RevisiSiswoyo SuwidjiОценок пока нет

- Megger - The Complete Guide To Electrical Insulation TestingДокумент24 страницыMegger - The Complete Guide To Electrical Insulation Testingnutchai2538100% (1)

- 5 Power System ControlДокумент18 страниц5 Power System ControlSiswoyo SuwidjiОценок пока нет

- 4 Utilization of Electric EnergyДокумент15 страниц4 Utilization of Electric EnergySiswoyo SuwidjiОценок пока нет

- The Transmission of Electric Energy: ET2105 Electrical Power System EssentialsДокумент39 страницThe Transmission of Electric Energy: ET2105 Electrical Power System EssentialsSiswoyo SuwidjiОценок пока нет

- 08 Silabus SCM Best PracticeДокумент2 страницы08 Silabus SCM Best PracticeSiswoyo SuwidjiОценок пока нет

- 13 Voltage CurrentДокумент7 страниц13 Voltage CurrentSiswoyo SuwidjiОценок пока нет

- Lecture 13Документ29 страницLecture 13Andrew GoulderОценок пока нет

- 14 Seri CircuitДокумент7 страниц14 Seri CircuitSiswoyo SuwidjiОценок пока нет

- 13 Voltage CurrentДокумент7 страниц13 Voltage CurrentSiswoyo SuwidjiОценок пока нет

- 12 ResistansiДокумент7 страниц12 ResistansiSiswoyo SuwidjiОценок пока нет

- 12 ResistansiДокумент7 страниц12 ResistansiSiswoyo SuwidjiОценок пока нет

- RK600 Manual 7010Документ24 страницыRK600 Manual 7010Dave JacksonОценок пока нет

- MATLAB Based Simulations Model For Three Phases Power System NetworkДокумент9 страницMATLAB Based Simulations Model For Three Phases Power System NetworkMuket AgmasОценок пока нет

- Data Sheet 6ES7214-1HG40-0XB0: General InformationДокумент10 страницData Sheet 6ES7214-1HG40-0XB0: General InformationNikola PerencevicОценок пока нет

- Truealarm Analog Sensing: FeaturesДокумент4 страницыTruealarm Analog Sensing: FeaturesEduardo Villanueva PríncipeОценок пока нет

- CL 8A Install GuideДокумент6 страницCL 8A Install GuidePeque DMОценок пока нет

- Functional Competency Directory For CTC Roles: Damodar Valley CorporationДокумент7 страницFunctional Competency Directory For CTC Roles: Damodar Valley Corporationlaloo01Оценок пока нет

- LS Starvert Is7 ManualДокумент299 страницLS Starvert Is7 ManualMiguel Angel Lopez PeñaОценок пока нет

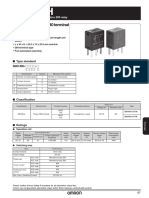

- G8V-RH: High Current Micro 280 Terminal LayoutДокумент3 страницыG8V-RH: High Current Micro 280 Terminal Layoutchrdue1Оценок пока нет

- RXZE2S108M: Product Data SheetДокумент3 страницыRXZE2S108M: Product Data SheetAntonio Valdes Jr.Оценок пока нет

- Execution of Hydro Power Plant - PLANNING AND OPERATIONДокумент49 страницExecution of Hydro Power Plant - PLANNING AND OPERATIONkapolaОценок пока нет

- Automatic Power Saving System Using PLC (Programmable Logic Controller)Документ3 страницыAutomatic Power Saving System Using PLC (Programmable Logic Controller)Hamza QadirОценок пока нет

- Fisa Tehnica Centrala Adresabila de Alarmare La Incendiu UTC Fire Security FP1216C-45 2-4 Bucle 128 Adrese-Bucla 16 ZoneДокумент2 страницыFisa Tehnica Centrala Adresabila de Alarmare La Incendiu UTC Fire Security FP1216C-45 2-4 Bucle 128 Adrese-Bucla 16 ZoneMariusОценок пока нет

- Dse705 Installation InstДокумент2 страницыDse705 Installation Instjaimesilva1972Оценок пока нет

- Installation and Maintenance Manual (Ebara Submersible Pump)Документ27 страницInstallation and Maintenance Manual (Ebara Submersible Pump)tm_20100% (5)

- Manual SWGR BloksetДокумент5 страницManual SWGR BloksetibrahimОценок пока нет

- RER615 Operation ManualДокумент148 страницRER615 Operation ManualРоман ВоеводаОценок пока нет

- 1MRK505176-SEN en Busbar Protection IED REB 670Документ4 страницы1MRK505176-SEN en Busbar Protection IED REB 670vsrikala68Оценок пока нет

- Instructions 95-8676: Infrared Carbon Dioxide Gas Detector Pointwatch Eclipse Model PireclДокумент54 страницыInstructions 95-8676: Infrared Carbon Dioxide Gas Detector Pointwatch Eclipse Model PireclJrОценок пока нет

- User Manual: HGM96XX Series (HGM9610/HGM9620) Automatic Genset ControllerДокумент78 страницUser Manual: HGM96XX Series (HGM9610/HGM9620) Automatic Genset Controllernhocti007Оценок пока нет

- MK2200 Microprocessor-Based Relay Protection FunctionsДокумент4 страницыMK2200 Microprocessor-Based Relay Protection Functionstalha0703097Оценок пока нет

- Brochure - Sirius - Selection Data For Fuseless Load Fedders - January 2009Документ80 страницBrochure - Sirius - Selection Data For Fuseless Load Fedders - January 2009Pablo MarajОценок пока нет

- OMC-140 Multifunctional NMEA Display Operators' Manual: Version 1.04 - 2015Документ39 страницOMC-140 Multifunctional NMEA Display Operators' Manual: Version 1.04 - 2015Laur IriОценок пока нет

- 3516C 4160V 2250 KW Tier 4 PrimeДокумент6 страниц3516C 4160V 2250 KW Tier 4 PrimesprikitОценок пока нет

- VW Passat b4 Abs Edl Teves Diagnosis EngДокумент81 страницаVW Passat b4 Abs Edl Teves Diagnosis Engdradubuh002Оценок пока нет

- Distance ProtectionДокумент14 страницDistance ProtectionBrenda Naranjo MorenoОценок пока нет

- Rev AДокумент56 страницRev ADimitris KokkinosОценок пока нет

- EPRI - Life Cycle Management Volume 4 Large Power TransformerДокумент110 страницEPRI - Life Cycle Management Volume 4 Large Power TransformerAri FirmansyahОценок пока нет