Академический Документы

Профессиональный Документы

Культура Документы

CFRP Strengthened System

Загружено:

Gelbert SilotАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CFRP Strengthened System

Загружено:

Gelbert SilotАвторское право:

Доступные форматы

A Review on environmental durability of CFRP strengthened system

S. Fawzia* and M.H. Kabir* * Department of Civil Engineering and The Built Environment, Science & Engineering Faculty, Queensland University of Technology, 2 George Street, Brisbane, QLD 4001, Australia (E-mail: sabrina.fawzia.@qut.edu.au; md.kabir@student.qut.edu.au; ripon94033@gmail.com)

ABSTRACT Recently the use of the carbon fibre reinforced polymer (CFRP) composites appears to be an excellent solution for retrofitting and strengthening of concrete and steel structures because of its superior physical and mechanical properties through the integration of other materials. However, the overall functionality and durability under various environmental conditions of the system has not yet been well documented. This paper reviews the environmental durability of CFRP strengthened system that has received only small coverage in previous review articles. Future research topics have also been indentified, such as durability of steel circular hollow section under various environmental conditions subjected to bending. Environment of interests are moisture/solution, alkalinity, creep/relaxation, fatigue, fire, thermal effects (including freeze-thaw), and ultraviolet exposure.

KEYWORDS CFRP; Durability; Concrete Structures; Steel Structures; Environmental Conditions.

INTRODUCTION Compared to conventional construction materials, carbon fiber reinforced polymer (CFRP) exhibits some unique advantages such as excellent resistance to corrosion and environmental degradation, high longitudinal strength, high fatigue endurance and reduced weight. Furthermore, it is very flexible and forms all kind of shapes, and is easy to handle during construction (Alsayed et al., 2000; Moy, 2001; Teng et al., 2002). Due to these advantages, CFRP composites have been increasingly used in various fields such as aerospace, automotive, athletic, recreational equipment, military and civil engineering infrastructure applications. The term Durability of CFRP is defined as its ability to resist cracking, oxidation, chemical degradation, debonding, wear, fatigue, and the effects of damage from foreign objects for a specified period of time under appropriate load conditions and under service exposure conditions (ACI 440L, 2005). This all-encompassing definition has been broadly adopted making studies of durability remarkably diverse and each one necessarily specific. In strengthening systems, the CFRP materials typically have excellent resistance against environmental conditions (Cromwell et al., 2011); however, the performance of adhesive between CFRP and steel/concrete may be affected by various environmental conditions. A number of studies have been conducted on durability of CFRP strengthened concrete structures, however, comparably a little is known about the environmental durability of the bond between CFRP materials and steel surfaces. The lack of a comprehensive data base on durability of CFRP strengthened steel structures, makes it difficult for the practicing civil engineer and designer to use CFRP composites as a guideline. Recently the output of some research related to durability of CFRP strengthened steel structures, has been published but it has not covered all aspects of durability considerations. This paper summarizes the concept of durability of CFRP strengthened system and results of such efforts to find out the durability gap that would lead to further research on this field.

ENVIRONMENTAL DURABILITY STUDY ON CFRP STRENGTHENED CONCRETE STRUCTURES Research on environmental durability of CFRP strengthened concrete structures has been ongoing for more than 15 years. The major areas of durability issues for CFRP strengthened concrete structures have almost been resolved. However, this is not the end of the world. New issues would be expected and research would be continued. Some research works are highlighted below to get an overall idea about environmental durability of CFRP strengthened concrete structures which may widen the research area on durability of CFRP strengthened steel structures. From the experimental investigations of David and Neuner (2001) and Karbhari and Engineer (1996) on the effects of environmental conditions on the response of externally strengthened RC beams, it is concluded that the long-term exposure to humidity may cause a significant decrease in the load carrying capacity of the RC beams. In addition, the study of Karbhari and Engineer (1996) also revealed that even short-term exposure to humidity may cause significant degradation of the CFRP strengthening system depending on the compatibility between the fiber and resin and the resin characteristics. Similarly, Juska et al. (2000) analysed the data related to thermal exposure and freezing-and-thawing conditioning and concluded that elevated temperature and freezing-andthawing cycles have significant effects on the CFRP composite systems. Benmokrane et al. (2000) studied the effects of alkaline solution on the CFRP composites and confirmed that alkaline environment may cause degradation of both the stiffness and strength of various CFRP composites. Leung et al. (2001) investigated the flexural capacity of steel and CFRP-strengthened concrete beams exposed to different environmental conditions. They observed that exposure to water for long periods caused a reduction of the load-carrying capacity as well as an increase in mid span deflection. Zheng and Morgan (1993) investigated the synergistic thermal-moisture damage mechanisms of epoxies and their carbon fiber composites. Reverse thermal effects were investigated after measuring the weight change of the epoxy resins and their carbon fiber composites when immersed in the distilled water at temperatures ranging between 33 and 170 F (0.5 and 80 C). It was determined that a critical temperature regime exists above which the resin has the ability to absorb greater amounts of water. Karbhari et al. (1997) modified the peel test method for assessing changes in bonding between glass fiber-reinforced polymer (GFRP) and CFRP composites and concrete. They concluded that the exposure of GFRP and CFRP composites to aqueous solutions had a significantly deleterious effect, indicating that most of the degradation was at the level of the epoxy layer between composite and concrete. Chin et al. (1998) studied the environmental effects on composite matrix resins used in construction. Specimens were exposed to an alkaline solution combined with a high temperature of 194 F (90 C) for approximately 10 weeks. They observed significant degradation in specimens and changes in glass transition temperature and tensile strength. An extensive research on the durability of the reinforced concrete (RC) beams externally strengthened with CFRP plates and fabrics under adverse environmental conditions has been carried out by Grace and Singh (2005). They dealt with the durability of the reinforced concrete (RC) beams externally strengthened with CFRP plates and fabrics under adverse environmental conditions such as 100% humidity, saltwater, alkali solution, freeze-thaw, thermal expansion, dryheat, and repeated load cycles. It was concluded that the long-term exposure to humidity is the most detrimental factor to the bond strength between CFRP plates and fabrics and RC beams. Based on experimental results, it was concluded that RC beams strengthened with CFRP plates are more susceptible to aggressive environmental conditions than the beams strengthened with CFRP fabrics. In addition the load-carrying capacity of beams strengthened with CFRP plates is reduced after long-term exposure to 100% humidity, dry heat, freezing-and-thawing, and thermal expansion environmental conditionings. The beams strengthened with CFRP plates and exposed to saltwater

and alkali-solutions, however, exhibit increased load-carrying capacity with respect to that of baseline beams, especially for short-term exposure. A literature (Smith et al., 2005) outlines the durability considerations for CFRP-strengthened RC structures in the Australian Environment. The various issues considered in this paper have been grouped under two main categories, namely Environmental Considerations and Loading Conditions. Environmental Considerations consist of moisture and humidity, chemical attack, alkalinity/acidity, temperature (thermal effects and freeze-thaw), ultraviolet radiation (UV), and fire. Loading considerations consist of creep and relaxation, and fatigue. Several design guidelines have been highlighted in this review. In the Australian service environment, the main factors influencing the durability of CFRP are concrete surface temperature and moisture. In hot and humid environments the hygrothermal aging of the epoxy resin could be significant. They have recommended to follow the Australian Standard for the design of concrete structures (AS 3600 2001) to ascertain how durability in plain (unstrengthened) RC structures has been considered. Finally, a systematic experimental study of the effect of prolonged hot water exposure at various temperatures from 20 to 90 oC is proposed on the effectiveness of the strengthening of CFRP to column specimens will be carried out. It is also necessary to understand the effectiveness of the CFRP strengthening in concrete columns under sustained loading. It is also planned to study the creep behaviour of CFRP strengthened concrete having varying moisture content. The reduction of strength and the subsequent failure of materials subjected to cyclic or sustained loading combined with environmental effects have emerged as some of the most fundamental problems of engineering materials. Some field durability studies, including normal temperature and humidity effects, were undertaken over the past few years (Karbhari and Amanilla, 2007). To overcome this problem, a relatively recent research on durability of CFRP strengthened concrete members under extreme temperature and humidity was conducted by Gamage (2009) in Australia. To find the long-term bond performance of CFRP strengthened concrete members, the specimens were exposed to combination of cyclic temperatures (20-50 oC) and 90% constant humidity and the residual strength was measured using single lap shear test method. It was concluded that the maximum strength reduction observed after 450 temperature cycles (2000 hours exposure) under constant 90% relative humidity was 30% for the specimens subjected to low level sustained loads (up 25% of the ultimate strength). Deterioration of concrete structures in hot, arid climates is mainly due to aggressive environmental conditions characterized by extreme high temperature fluctuations, and high chloride content in the soil and in the concrete materials (El-Hacha et al., 2010). They investigated the behavior of concrete cylinders wrapped with CFRP sheets when subjected to harsh environmental conditions represented by heating and cooling cycles, freezing and thawing cycles, and exposure to fresh and salt water. Thirty-six plain concrete cylinders (150 x 300 mm) were tested. Nine specimens served as unstrengthened controls and the remaining cylinders were strengthened with two layers of CFRP sheets. Cylinders were subjected to high temperatures (45C), to heating and cooling cycles (23 to 45C), and to prolonged heat exposure (45C). Some of the cylinders that were subjected to heating and cooling, were later subjected to freezing and thawing cycles, while others were submerged in fresh water or salt water. It was reported that high temperature exposure was not found to decrease the strength of the wrapped concrete cylinders when compared to unwrapped specimens. In addition, freezing-thawing exposure as well fresh and salt water immersion had a slightly negative effect on the compressive strength of both unwrapped and wrapped cylinders when compared to room temperature and heating and cooling exposure, respectively. A more recent study has been conducted by Cromwell et al. (2011) to investigate the performance of commercially available CFRP materials and CFRP bond to concrete when subjected to nine

different environmental conditioning protocols which are; water exposure, salt water exposure, alkaline exposure, dry heat exposure, diesel fuel exposure, weathering exposure, freeze-heat exposure and freeze-exposure. The effect of environmental conditioning was assessed using four different standard test methods; (i) Tension test, (ii) Short beam shear test, (iii) Bond to concrete and (iv) Beam flexure. Multiple specimens were tested in every case by varying the curing duration of specimens. Three commercially available CFRP systems were included in this study: (1) a preformed unidirectional CFRP plate (CP); (2) a unidirectional carbon fiber fabric (CF); and (3) a unidirectional glass fiber fabric (GF). The test result concluded that CFRP plate performed very well in all conditions. Degradation was particularly pronounced for salt water and alkaline environments, both known to be deleterious to glass fiber. Furthermore, deterioration was often more pronounced on bond properties, possibly due to the critical nature of the adhesive (CFPR plate) or resin layer (fabrics) bond line to the performance of the concrete-CFRP system. Finally, it was proposed that immersion in salt water and immersion in an alkaline solution (9.5 pH CaCO3) at room temperature for the durations considered in this study (up to 10,000 h) are the most broadly appropriate methods for assessing the effects of environmental conditioning on CFRP material and bond properties. Another comprehensive study on the durability of the CFRP concrete bond interface under freezethaw cycling has been investigated very recently by Yanchun and Yu-Fei (2011) and reported here, with exposure condition, concrete grade, and number of freeze-thaw cycles as the parameters considered. A high tensile strength carbon fiber fabric named TORAYCA Cloth with a nominal thickness of 0.167 mm was utilized in the program as the reinforcement. Two types of saturant resin (Sikadur-30 and Sikadur-300) were used as adhesive. The concrete specimens (blocks) had dimensions of 340 (length)150 (depth)150 (width) mm3.After preparing, the specimens were subjected to an accelerated freeze-thaw cycling in an environmental chamber. The CFRP-concrete joint was placed in salt water (4% NaCl) or tap water with the CFRP facing downward and approximately 6 mm of concrete being submerged. A complete freeze-thaw cycle was as follows: starting at +4 C, the temperature decreased to 18 C in 110 min and was held constant for 10 min; it was then increased to +4 C in 115 min and held for 5 min. The behavior of the CFRP-concrete bond interface was investigated with single-face shear tests. The results indicate that the bond strength, bond stiffness, interfacial fracture energy, and maximum slip of the joints decrease with increases in the number of freeze-thaw cycles, and they are also affected by the exposure environment. The depth of cracking and effective bond length increases with increases in cycle number, thus affecting bond stiffness and strength. The deterioration of bond strength can be attributed to the damage caused to the concrete by the freeze-thaw cycling.

ENVIRONMENTAL DURABILITY STUDY ON CFRP STRENGTHENED STEEL STRUCTURES Research on durability of CFRP strengthened reinforced concrete (RC) structures are fairly satisfactory based on literatures highlighted above. However, till now a few number of literatures are available on durability of CFRP strengthened steel structures which are summarised accordingly. An extensive study of the rehabilitation of deteriorated steel bridge members (Mertz and Gillespie, 1996) covered two major issues concerning the use of composites for rehabilitating steel girders: its effectiveness and its durability. For the first part of the investigation, a series of wedge tests using different bonding agents and surface preparation procedures were performed. Four different environmental conditions were employed: hot water, salt water, de-icing solution and freeze-thaw conditions. It was found that the specimens using epoxy as adhesive and treated with silane performed better under the four different environments. Next, several number of steel beams were

strengthened and repaired using different schemes of composites and adhesives to increase or restore flexural characteristics. The strengthening or repairing technique adopted here was perfect enough to meet the objectives but this system did not prove whether it is suitable under different environmental conditions subjected to bending. They also pointed out that galvanic corrosion could occur between the carbon and the steel that may reduce the durability of a strengthening system and, to prevent this, a layer of E Glass FRP material was recommended to electrically insulate the two materials. The feasibility of using CFRP materials for strengthening of tubular steel members subjected to bending for underwater application has been performed in another study (Seica and Packer, 2007). Six numbers of steel tubes were wrapped using Sika and Fyfe fibre systems and cured under standard conditions and under sea water conditions. Two layers of sheets with the fibres oriented longitudinally to the length of the tube were first adhered to each beam and then these were confined with a third layer with the fibres oriented transversely to the tube axis. The circumferential layer was used to confine the longitudinal layers whilst subjected to compressive stresses during bending. It was reported that the ultimate bending strength, flexural stiffness and rotation capacity of the wrapped beams, relative to the reference beam, were increased for both performance parameters under study; however, the composite members wrapped and cured underwater were not able to attain the flexural capacity of those cured in air. Finally no serious debonding problems were found in any of the specimens, suggesting that the fibres bonded adequately regardless of the application and curing conditions involved. This is a promising research that has been conducted recently to enhance the data base for the suitability of using CFRP and adhesives under marine environment. However, galvanic corrosion which significantly reduces the long-term durability of a strengthening system, can occur when two materials are coupled together and submerged in an electrolyte is neglected in this study. Moreover, the orientation and variation of number of layers may also affect the durability of CFRP strengthened system has not been addressed here. A recent research has been carried out by Al-Shawaf et al. (2008) to determine the environmental durability of CFRP strengthened steel Double-STRAP Joints under elevated temperature in Australia. A series of tensile tests was carried out on CFRP/steel plates specimens joined together in double-lap shear joints and subjected to a range of environmental temperatures of 20C, 40C and 60C. High modulus (640 GPa) unidirectional carbon fibre plies were used in wet lay-up fabrication method to strengthen the composite matrix using three types of epoxy resins as bonding materials which are (1) Araldite 420 A/B, (2) Mbrace Saturant and (3) Sikadur-30. It was reported that adhesive microstructural and / rheological composition plays the key role in the overall bond trend. Based on visual assessment and comparison of the average experimental ultimate load capacities for the three series at each conditioning temperature, it is believed that the MBrace Saturant epoxy is inherently more brittle, glassy and has higher microcracking propensity, flaws and imperfections, than the others. This in turn will, inevitably, weaken the interfacial adhesive layer, thus enhancing the probability of the debonding failure. This is a fantastic research that has been carried out to choose a suitable commercially available adhesive under elevated temperature for strengthening of steel plate subjected to tension. On the other hand, it is still required to do the same research but for those sections which are subjected to compression and bending to fulfil the gaps that have not been done yet. Another research has been conducted by Dawood and Rizkalla (2010) recently to evaluate the environmental durability of the bond of the proposed CFRP strengthening system to steel plate surfaces. The program consisted of testing 44 steel-CFRP double-lap shear specimens with four different bond configurations and tested in tension. The specimens were exposed to severe environmental conditions for different durations, up to 6 months. Different methods to enhance the bond durability were studied including pre-treating the steel surface with a silane coupling agent,

inserting a glass fiber layer within the adhesive and a combination of both methods of protection. The research findings indicate that the use of a silane coupling agent significantly enhanced the bond durability. While the presence of the glass fibers helped to enhance the initial bond strength of the system, it did not improve the durability of the bond. The use of both techniques enhanced both the overall bond strength and the environmental durability of the strengthening system. Here the durability has been tested for steel plate under tension only but a huge range of steel sections available (I-section, Hollow section etc.) which may subject to bending, tension and compression also. Therefore, measures of structural integrity in terms of durability for variety of sections under different loading conditions have now become imperative. CONCLUSIONS This paper has provided a review of current research on durability of CFRP strengthened concrete and steel structures. A quite satisfactory number of research on durability of CFRP strengthened concrete structures have been conducted and some important guidelines have been documented. On the other hand, research on durability of CFRP strengthened steel structures is very minimal. Therefore, now it is very urgent for researchers to carry on more research on this field to enhance the data base as well as to give guidelines to industrys personnel for efficient use of CFRP and resins under various environmental conditions. Future research topics have been identified as: (i) Durability study of CFRP strengthened steel structures for various environmental conditions, such as moisture/solution, alkalinity, creep/relaxation, fatigue, fire, thermal effects (including freeze-thaw), and ultraviolet exposure. (ii) By keeping environmental parameters constant, same study can be done by changing loading conditions, such as, bending, bending plus compression and bending plus tension. (iii) The CFRP wrapping orientation has a significance effect on enhancement of flexural strength of steel tubular member (Haedir et al., 2009). Therefore, by changing CFRP wrapping condition, study can be conducted under various environmental conditions. (iv) Finally, the research topics can further be extended by doing same test under cyclic loading conditions. ACKNOWLEDGEMENT The authors would like to thank, Queensland University of Technology (QUT) for providing support to carry out research on environmental durability study of CFRP strengthened steel tubular structures subjected to bending. REFERENCES Alsayed S. H., Al-Salloum Y. A. and Almusallam T.H. (2000). Fibre-reinforced polymer repair materials-some facts. Proceedings of the Institution of Civil Engineers, Civil Engineering, 138(3), 131-4. ACI 440L. (2005). Durability of fiber reinforced polymer (FRP) composites used with concrete. American Concrete Institute (ACI), Committee 440, Draft Report. Al-Shawaf R., Al-Mahaidi, Zhao X. (2008). Effect of elevated temperature on bond behaviour of high modules CFRP/Steel double-STRAP joints. Australian Structural Engineering Conference (ASEC), Melbourne, Australia, ISBN 9781877040702. Benmokrane B., Faza S., Gangarao H. V. S., Karbhari V. M. and Porter M. (2000). Effects of alkaline environment, gap analysis for durability of fiber reinforced polymer composites in civil infrastructure. ASCE Publications, 24-28.

Chin J., Haight M., Hughes W. and Nguyen T. (1998). Environmental effects on composite matrix resins used in construction. Proceedings of CDCC, Sherbrooke, Canada, 229-242. Cromwell J. R., Harries K. A., Shahrooz B.M. (2011). Environmental durability of externally bonded FRP materials intended for repair of concrete structures. Construction and Building Materials, 25, 2528-2539. David E. and Neuner J. D. (2001). Environmental durability studies for FRP systems: definitions of normal conditions of use of FRP for structural strengthening applications. Proceedings of the International Conference of FRP Composites in Civil Engineering, Hong Kong, China, 1551-1558. Dawood M. and Rizkalla S. (2010). Environmental durability of a CFRP system for strengthening steel structures. Construction and Building Materials, 24, 1682-1689. El-Hacha R., Green M. F. and Gordon R. Wight G. R. (2010). Effect of severe environmental exposures on CFRP wrapped concrete columns. Journal of Composites for Construction, 14(1), 8393 Grace Nabil F., Singh S. B. (2005). Durability evaluation of carbon fiber-reinforced polymer strengthened concrete beams: Experimental Study and Design. ACI Structural Journal, 102(1), 40+. Gamage JCPH., Al-Mahaidi R. and Wong MB. (2009). Durability of CFRP-strengthened concrete members under extreme temperature and humidity. Australian Journal of Structural Engineering, 9(2), 111-118. Haedir J., Bambach M. R., Zhao X.-L. and Grzebieta R. H. (2009). Strength of circular hollow sections (CHS) tubular beams externally reinforced by carbon FRP sheets in pure bending. ThinWalled Structures, 47, 11361147. Juska T., Dutta P., Carlson L. and Weitsman J. (2000).Thermal effects, gap analysis for durability of fiber reinforced polymer composites in civil infrastructure. ASCE Publications, 40-45. Karbhari V. M., and Engineer, M. (1996). Effect of environmental exposure on the external strengthening of Cconcrete with composites-short-term bond durability. Journal of Reinforced Plastics and Composites, 1194-1216. Karbhari V. M., Engineer M. and Eckel D. (1997). On the durability of composite rehabilitation schemes for concrete: use of peel test. Journal of Material Science, 147-156. Karbhari V. M. and Amanilla M. A. (2007). Design factors, reliability, and durability prediction of wet layup carbon/epoxy used in external strengthening. Composites: Part B, 38, 10-23. Leung H., Balendran R., and Lim C. (2001). Flexural capacity of strengthened concrete beam exposed to different environmental conditions. Proceedings of the International Conference of FRP Composites in Civil Engineering, Hong Kong, China, 1597-1606. Moy S. (2001). ICE design and practice guides-FRP composites life extension and strengthening of metallic structures. London (UK), Thomas Telford Publishing.

Mertz D. R. and Gillespie J. W. (1996). Rehabilitation of steel bridge girders through the application of composite materials. NCHRP Report No. 93-ID11, Washington, DC: Transportation Research Board, 120. Smith S. T., Kaul R., Sri Ravindrarajah R. and Otoom O. M .A. (2005). Durability considerations for FRP-strengthened RC structures in the Australian Environment. Conference Proceeding; Australian Structural Engineering Conference, 952 - 961 Seica M. V. and Packer J. A. (2007). FRP materials for the rehabilitation of tubular steel structures for underwater applications. Composite Structures, 80, 440-450. Teng J. G., Chen J. F., Smith S.T. and Lam L. (2002). FRP-strengthened RC structures. West Sussex (UK), John Wiley and Sons Ltd. Yanchun Y. and Yu-Fei W. (2011). Durability of CFRP-concrete joints under freezethaw cycling. Cold Regions Science and Technology, 65, 401-412. Zheng Q. and Morgan R. (1993). Synergistic thermal-moisture mechanics of epoxies and their carbon fiber composites. Journal of Composite Materials, 465-1478.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- mt1173 Vle PDFДокумент287 страницmt1173 Vle PDFKhushal JhajahriaОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- f6ea499c37d63b3801dee6dd82a4aaf2_320a9a62d020a9964c64b2c44de68cf1Документ2 страницыf6ea499c37d63b3801dee6dd82a4aaf2_320a9a62d020a9964c64b2c44de68cf1Hardik Gupta0% (1)

- Organisational Culture and ChangeДокумент49 страницOrganisational Culture and ChangeMahima Rojith100% (1)

- Industrial Attachment ReportДокумент82 страницыIndustrial Attachment ReportNiyibizi Promesse100% (9)

- Documentation On Setting Up SPI Protocol For ADE7878Документ8 страницDocumentation On Setting Up SPI Protocol For ADE7878phamvan_tuong100% (1)

- Reinforcing Steel Bars Price List: StructuralДокумент1 страницаReinforcing Steel Bars Price List: StructuralGelbert SilotОценок пока нет

- (ANALYSIS) Why Filipinos Need To Stay at Home Until June (Or Even Longer) PDFДокумент13 страниц(ANALYSIS) Why Filipinos Need To Stay at Home Until June (Or Even Longer) PDFGelbert SilotОценок пока нет

- Social Security System: SSS SeminarsДокумент2 страницыSocial Security System: SSS SeminarsGelbert Silot100% (2)

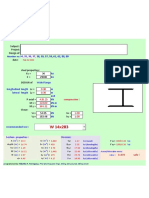

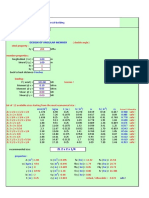

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsДокумент26 страниц2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsGelbert SilotОценок пока нет

- Latest FormДокумент27 страницLatest FormGelbert SilotОценок пока нет

- A Ultimate Load CombinationsДокумент1 страницаA Ultimate Load CombinationsGelbert SilotОценок пока нет

- Two Way SlabДокумент1 страницаTwo Way SlabGelbert SilotОценок пока нет

- Columnsteel 1Документ1 страницаColumnsteel 1Gelbert SilotОценок пока нет

- SFB 2Документ1 страницаSFB 2Gelbert SilotОценок пока нет

- Design of Angular Member: Top CHPRDДокумент2 страницыDesign of Angular Member: Top CHPRDGelbert SilotОценок пока нет

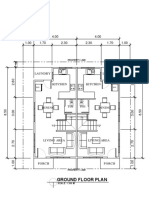

- Laundry Laundry: Ground Floor PlanДокумент1 страницаLaundry Laundry: Ground Floor PlanGelbert SilotОценок пока нет

- 12 Date:: 20 Footing Dimension: 230 97.5 16Документ1 страница12 Date:: 20 Footing Dimension: 230 97.5 16Gelbert SilotОценок пока нет

- Column Design/Analysis Software: (Based On The NSCP 2015 Code)Документ2 страницыColumn Design/Analysis Software: (Based On The NSCP 2015 Code)Gelbert SilotОценок пока нет

- Column Design/Analysis Software: (Based On The NSCP 2015 Code)Документ2 страницыColumn Design/Analysis Software: (Based On The NSCP 2015 Code)Gelbert SilotОценок пока нет

- Application Special Member PDFДокумент20 страницApplication Special Member PDFGelbert SilotОценок пока нет

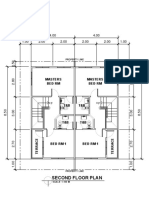

- Masters Bed RM Masters Bed RM: Second Floor PlanДокумент1 страницаMasters Bed RM Masters Bed RM: Second Floor PlanGelbert SilotОценок пока нет

- Admixtures For Concrete, Mortar and Grout Ð Test Methods: Part 6. Infrared AnalysisДокумент10 страницAdmixtures For Concrete, Mortar and Grout Ð Test Methods: Part 6. Infrared AnalysisWasimuddin SheikhОценок пока нет

- Advanced Quality ControlДокумент38 страницAdvanced Quality ControlSantosh VemulaОценок пока нет

- Metodologi of NIEДокумент21 страницаMetodologi of NIEStevanus Gabriel PierreОценок пока нет

- Globalization and MediaДокумент24 страницыGlobalization and MediaCyka Blyat0% (2)

- DAAD WISE Summer Internship ReportДокумент2 страницыDAAD WISE Summer Internship ReportVineet Maheshwari100% (1)

- STM ProcessДокумент7 страницSTM Processyadavpankaj1992Оценок пока нет

- B2+ UNIT 10 Test Answer Key HigherДокумент2 страницыB2+ UNIT 10 Test Answer Key HigherMOSQUITO beats100% (1)

- Uum MSC Individual Project Guide Bpmn6073 Sem A161 CywДокумент15 страницUum MSC Individual Project Guide Bpmn6073 Sem A161 CywgohkhenghoОценок пока нет

- Math 1220 Calculus 2 Final Sample 2 - Summer 01Документ2 страницыMath 1220 Calculus 2 Final Sample 2 - Summer 01Tyler CameronОценок пока нет

- 2-General Physics 1-Uncertainties in MeasurementДокумент22 страницы2-General Physics 1-Uncertainties in MeasurementLiza Macalinao MangalimanОценок пока нет

- English: Quarter 3 - Module 5Документ21 страницаEnglish: Quarter 3 - Module 5Maria Qibtiya100% (3)

- Opening Image in MFC Dialog With OpenCVДокумент9 страницOpening Image in MFC Dialog With OpenCVJuan José CárdenasОценок пока нет

- Hospital Information SystemДокумент2 страницыHospital Information SystemManpreetaaОценок пока нет

- Valve Stem SealsДокумент2 страницыValve Stem SealsBinny Samuel Christy100% (1)

- Acta Scientiarum. Biological Sciences 1679-9283: Issn: Eduem@Документ12 страницActa Scientiarum. Biological Sciences 1679-9283: Issn: Eduem@paco jonesОценок пока нет

- A Paradox in The Interpretation of Group Comparisons: Frederic M. LordДокумент2 страницыA Paradox in The Interpretation of Group Comparisons: Frederic M. Lordajax_telamonioОценок пока нет

- Killiliisa StrategyДокумент49 страницKilliliisa StrategyNunatsiaqNewsОценок пока нет

- Investigation of Post Processing Techniques To Reduce The Surface Roughness of Fused Deposition Modeled PartsДокумент14 страницInvestigation of Post Processing Techniques To Reduce The Surface Roughness of Fused Deposition Modeled PartsIAEME PublicationОценок пока нет

- Constructivist Approach To Teaching and LearningДокумент2 страницыConstructivist Approach To Teaching and LearningLen-Len CobsilenОценок пока нет

- Theatre at HierapolisДокумент7 страницTheatre at HierapolisrabolaОценок пока нет

- Engendered Orange-Fleshed Sweetpotato Project Planning, Implementation, Monitoring and Evaluation: A Learning Kit. Volume 5: Workshop Evaluation, PAPA and AnnexesДокумент107 страницEngendered Orange-Fleshed Sweetpotato Project Planning, Implementation, Monitoring and Evaluation: A Learning Kit. Volume 5: Workshop Evaluation, PAPA and Annexescip-libraryОценок пока нет

- Western Oregon University: CSE 617 Open Source ToolsДокумент5 страницWestern Oregon University: CSE 617 Open Source ToolszobelgbОценок пока нет

- QTDM Unit-2 Correlation & Regression AnalysisДокумент12 страницQTDM Unit-2 Correlation & Regression AnalysisAishwarya ManishОценок пока нет

- More More SymcliДокумент10 страницMore More SymcliSrinivas Gollanapalli100% (1)

- Auto-Gate ReportДокумент21 страницаAuto-Gate Reportstamford_bridgeОценок пока нет