Академический Документы

Профессиональный Документы

Культура Документы

Based On Liquids Not Exceeding 200 CST Viscosity and 71

Загружено:

patrik710Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Based On Liquids Not Exceeding 200 CST Viscosity and 71

Загружено:

patrik710Авторское право:

Доступные форматы

Home >> Products >> Pumps >> Rotary Gear Pumps

Rotary Gear Pumps

APPLICATIONS

Transfer of various grades of oils like light Diesel Oils, Fuel Oils, Transformer oils, lube oils, castor oils, Grease , wax etc. Transfer of chemicals like sodium silicate, caustic soda, resins, enamels, adhesives, fatty acids, paints and varnish, pulp, juices, Syrups, Alcohol, Kerosene, etc. Atomising of fuel oil at high pressure for burners and boilers. Lubrication of gear boxes, cranes, Machine tools, etc. Cooling and filtering in machine tools. Heat transfer liquids for chemical vessels. Hydraulic systems for presses, power pack units etc.

These pumps are simple in design and robust and sturdy in construction. Only tested materials are used to give them long life. They are built in various sizes and versions to suit every possible industrial application. These pumps available either foot mounted or flange mounted. Pressure range - 0 Kg./cmto 10 Kg./cm Capacity - upto 4000 LPM Size - 3/8" to 8" Inlet - outlet

SPECIAL FEATURES Direction of rotation can be given as per client's requirements. Suction and delivery have threaded connections upto 20" BSP.

Flange connections can be given on request. 3" & above pumps have integral flange connection. As per clients requirement pump is provided with electric motor, gear box, diesel engine, base plate, coupling, guard, flanges, pulley & Belt Drive, Trolley Mounted, etc. Pump are also available in steam jacketed design specially suitable for liquids which solidify or become highly viscous at room temperature like LSHS, Wax, Coal Tar, Adhesives, etc. Pumps are fitted with Mech. Seal, Gland Packing or oil seal as per client's requirements. Pumps are available under Low pressure range (0 to 10 Kg/cm) as well as High pressure range (11 to 40 Kg/cm) On the basis of requirements. Pumps are available in SS 304, SS 316, A 216 Gr. WCB, mild steel, gun metal, Aluminium Material also. Pumps can be offered with external bearing design suitable for liquids which do not have lubricating property like molasses, high

temp. oil, Corrosive abrasive liquid, Pharmaceutical Products, etc. Pumps are designed, mfd. & tested as per API Std. 676. A builtin relief wall is provided in Pump Back Cover. It can be adjusted externally to ensure that the pump does not build up pressure above certain preset limit. This prevents overloading of the motor as well as probable damage to the pump.

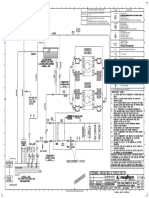

Standard Pumps Specification for rotary Gear Pumps

Based on liquids not exceeding 200 CST viscosity and 70C maximum temperature.

Pump Max cap.in model LPM at 0 Kg./cm MSL 10 MSL 15 MSL 20 MSL 35 MSL 60 MSL 100 MSL 150 MSL 200 MSL 350 MSL 500 MSL 800 5 12 25 45 60 125 175 250 325 450 TO 750 800 TO 1300 Pump RPM size Table for Pressure V/s Power (HP) Kg./ cm 5 0.5 0.75 1 1.5 2 3 5 7.5 12.5 7.5 0.5 1 1.5 2 2 5 7.5 10 15 10 0.5 1 1.5 2 3 5 7.5 12.5 20 Table for Pressure V/s Capacity (LPM) Kg. / cm 3.5 5 11 23 42 57 120 175 240 315 5 4.5 10 22 38 55 115 170 230 305 7.5 4 9 21 35 52 110 165 215 290 10 3.5 8 20 30 50 100 160 200 275 -

3/8" " " /" " 1" 1"

3.5 1440 0.5 1440 0.5 1440 1 1440 1.5 1440 2 1440 3 5

1" 1440 2"

1440 7.5

2" 1440 10 3" 4" 1440 1440 -

RECOMMENDED PUMP SPEED AND POWER REQUIREMENTS WHEN PUMPING LIQUID HAVING VISCOSITY OF 200 CST TO 50000 CST

Permissible pump speed with reference to max. Rated speed from table 100% 75% 75% Additional Power required 3.5 5.0 Kg/cm Kg/cm 50% 35% 50% 60% 35% 50% Viscosity of liquid CST Recommended Pump Speed RPM

Viscosity of liquid CST 200 to 500 500 to 1500 1500 to 2500

200 to 5000 5000 to 15000 15000 to 50000

750 500 200

Pump capacity is directly proportional to pump speed

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- PETAL Sentence StartersДокумент1 страницаPETAL Sentence StartersSnip x Hunt manОценок пока нет

- If Your Actions Inspire Others To Dream MoreДокумент3 страницыIf Your Actions Inspire Others To Dream Morepatrik710Оценок пока нет

- Bearing 6202 and 6203 ConsumptionДокумент2 страницыBearing 6202 and 6203 Consumptionpatrik710Оценок пока нет

- Rev - 00 - Open Loop Water Circuit - 3250kwДокумент1 страницаRev - 00 - Open Loop Water Circuit - 3250kwpatrik710Оценок пока нет

- Organgram of Shyam MetalicДокумент1 страницаOrgangram of Shyam Metalicpatrik710Оценок пока нет

- Hardness Shore C C MN MN Si P S Ni CRДокумент2 страницыHardness Shore C C MN MN Si P S Ni CRpatrik710Оценок пока нет

- PO Box 1010, Liverpool L70 1NL, United KingdomДокумент2 страницыPO Box 1010, Liverpool L70 1NL, United Kingdompatrik710Оценок пока нет

- Observation ChartДокумент5 страницObservation Chartpatrik710Оценок пока нет

- Based On Liquids Not Exceeding 200 CST Viscosity and 70Документ1 страницаBased On Liquids Not Exceeding 200 CST Viscosity and 70patrik710Оценок пока нет

- Sti 2062Документ6 страницSti 2062patrik710Оценок пока нет

- Gear Teeth Chemical CompositionДокумент1 страницаGear Teeth Chemical Compositionpatrik710Оценок пока нет

- Facility of Pipe PlantДокумент3 страницыFacility of Pipe Plantpatrik710Оценок пока нет

- Crompton Greaves LetterДокумент1 страницаCrompton Greaves Letterpatrik710Оценок пока нет

- Technotherma Furnace PVT - LTD: 206, Hallmark Commercial Complex, L.B.S. Mar9, N4ulund (West), N4umbai-400 080. IndiaДокумент1 страницаTechnotherma Furnace PVT - LTD: 206, Hallmark Commercial Complex, L.B.S. Mar9, N4ulund (West), N4umbai-400 080. Indiapatrik710Оценок пока нет

- V Pully DimensionДокумент1 страницаV Pully Dimensionpatrik710Оценок пока нет

- Tata SteelДокумент32 страницыTata Steelpatrik710Оценок пока нет

- Misc Pipe and Grade For Iph & OphДокумент1 страницаMisc Pipe and Grade For Iph & Ophpatrik710Оценок пока нет

- Efficient Furnace Operation1Документ7 страницEfficient Furnace Operation1patrik710Оценок пока нет

- Chemical Quality of TMT Bars: View Previous Topic View Next TopicДокумент6 страницChemical Quality of TMT Bars: View Previous Topic View Next Topicpatrik710Оценок пока нет

- Subhrajit Swain 123Документ3 страницыSubhrajit Swain 123patrik710Оценок пока нет

- RK Bansal JP Hollman RK Bansal RS Khurmi Shigley WD Callister O P Khanna Gere TimoshenkoДокумент4 страницыRK Bansal JP Hollman RK Bansal RS Khurmi Shigley WD Callister O P Khanna Gere Timoshenkopatrik710Оценок пока нет

- Word CountДокумент3 страницыWord CountLeo LonardelliОценок пока нет

- Arithmetic QuestionsДокумент2 страницыArithmetic QuestionsAmir KhanОценок пока нет

- Test 2-Module 1 12-10-2017: VocabularyДокумент2 страницыTest 2-Module 1 12-10-2017: VocabularySzabolcs Kelemen100% (1)

- Vitamins - CyanocobalaminДокумент12 страницVitamins - CyanocobalaminK PrashasthaОценок пока нет

- Contemporary Strategic ManagementДокумент2 страницыContemporary Strategic ManagementZee Dee100% (1)

- Maths Formulas For IGCSEДокумент2 страницыMaths Formulas For IGCSEHikma100% (1)

- AIIMS 2015 Solved PaperДокумент436 страницAIIMS 2015 Solved PaperSurya TejaОценок пока нет

- 10 1108 - TQM 03 2020 0066 PDFДокумент23 страницы10 1108 - TQM 03 2020 0066 PDFLejandra MОценок пока нет

- The Linguistic Colonialism of EnglishДокумент4 страницыThe Linguistic Colonialism of EnglishAdriana MirandaОценок пока нет

- D25KS Sanvick PDFДокумент4 страницыD25KS Sanvick PDFJiménez Manuel100% (1)

- A Comparative Study of Public Private Life Insurance Companies in IndiaДокумент5 страницA Comparative Study of Public Private Life Insurance Companies in IndiaAkansha GoyalОценок пока нет

- IR2153 Parte6Документ1 страницаIR2153 Parte6FRANK NIELE DE OLIVEIRAОценок пока нет

- SafetyRelay CR30Документ3 страницыSafetyRelay CR30Luis GuardiaОценок пока нет

- Dialectical Relationship Between Translation Theory and PracticeДокумент5 страницDialectical Relationship Between Translation Theory and PracticeEverything Under the sunОценок пока нет

- СV Nestor RodriguezДокумент28 страницСV Nestor RodriguezKate BrownОценок пока нет

- Practice Problems - Electrochemical CellДокумент5 страницPractice Problems - Electrochemical CellYehia IbrahimОценок пока нет

- Toh736 - 84000 The Dharani of Parnasavari PDFДокумент24 страницыToh736 - 84000 The Dharani of Parnasavari PDFJames LeeОценок пока нет

- OM CommandCenter OI SEP09 enДокумент30 страницOM CommandCenter OI SEP09 enGabriely MuriloОценок пока нет

- Studies On Drying Kinetics of Solids in A Rotary DryerДокумент6 страницStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhОценок пока нет

- MFE Module 1 .Документ15 страницMFE Module 1 .Adarsh KОценок пока нет

- SG110CX: Multi-MPPT String Inverter For SystemДокумент2 страницыSG110CX: Multi-MPPT String Inverter For SystemKatherine SmithОценок пока нет

- (Sat) - 072023Документ7 страниц(Sat) - 072023DhananjayPatelОценок пока нет

- Biotech NewsДокумент116 страницBiotech NewsRahul KapoorОценок пока нет

- The Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierДокумент61 страницаThe Ovation E-Amp: A 180 W High-Fidelity Audio Power AmplifierNini Farribas100% (1)

- Quality Control of Rigid Pavements 1Документ58 страницQuality Control of Rigid Pavements 1pranjpatil100% (1)

- Lesson 1 3 Transes in Reading in Philippine HistoryДокумент17 страницLesson 1 3 Transes in Reading in Philippine HistoryNAPHTALI WILLIAMS GOОценок пока нет

- J.K. Brimacombe - Design of Continuous Casting MachinesДокумент13 страницJ.K. Brimacombe - Design of Continuous Casting MachinesJavier GómezОценок пока нет

- Boom-Block Gambit: Redemption'S RiseДокумент44 страницыBoom-Block Gambit: Redemption'S RiseNone OfyourbuisnessОценок пока нет

- Perdarahan Uterus AbnormalДокумент15 страницPerdarahan Uterus Abnormalarfiah100% (1)