Академический Документы

Профессиональный Документы

Культура Документы

E5907 ws08z01-1

Загружено:

raul20132013Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

E5907 ws08z01-1

Загружено:

raul20132013Авторское право:

Доступные форматы

38 l/min 350 bar

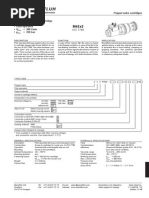

2/2 Solenoid Directional Valve Poppet Type, Pilot-Operated Normally Closed SAE-08 Cartridge 350 bar WS08Z-01

zz External surfaces zinc-plated and corrosion-proof zz Hardened and ground internal valve components to ensure minimal wear and extended service life zz Coil seals protect the solenoid system zz Wide variety of connections available zz Excellent switching performance by high power HYDAC solenoid zz Low pressure drop due to CFD optimized flow path

FUNCTION

FEATURES

SPECIFICATIONS

Operating pressure: Nominal flow: Leakage: Media operating temperature range: Ambient temperature range: Operating fluid: Viscosity range: Filtration: MTTFd: Installation: Materials: max. 350 bar max. 38 l/min Leakage-free (max. 5 drops 0,25 cm/min at 350 bar) min. -20 C to max. +100 C min. -20 C to max. +60 C Hydraulic oil to DIN 51524 Part 1 and 2 min. 7.4 mm/s to max. 420 mm/s Class 21/19/16 according to ISO 4406 or cleaner 150 years (see "Conditions and instructions for valves" in brochure 5.300) No orientation restrictions Valve body: steel Closing hardened and ground elements: steel Seals: NBR (standard) FKM (optional, media temperature range -20 C to 120 C) Back-up rings: PTFE FC08-2 Valve complete 0.33 kg Coil only 0.19 kg energized: approx. 35 ms de-energized: approx. 50 ms DC solenoid, AC voltage is rectified using a bridge rectifier built into the coil 1.5 A at 12 V DC 0.8 A at 24 V DC 15% of the nominal voltage Continuous up to max. 115% of the nominal voltage at 60 C ambient temperature Coil-40-1836

Cavity: Weight: Electrical data: Switching time: Type of voltage: Current draw at 20 C:

When the solenoid coil is not energized, the valve is closed from port 2 to port 1. There is free flow from port 1 to 2. When energized, there is free flow through the valve from port 2 to port 1. Flow from port 1 to 2 is prevented.

E 5.907.3/01.13

Voltage tolerance: Coil duty rating: Coil type:

298

DIMENSIONS

torque 5+2 Nm After loosening knurled nut, coil can be rotated through 360 and removed.

MODEL CODE

WS08Z 01 M C N 24 DG

hex. 7/8" torque 25+5 Nm

After loosening knurled nut, manual operation is possible by twisting button anticlockwise.

torque 4+2 Nm max. without man. override

Basic model Directional poppet valve, UNF Type 01 = standard Manual override No details = without manual override M = manual override Body and ports* C = Cartridge only SB3 = G3/8 ports, steel body AB3 = G3/8 ports, aluminium body Versions with line bodies on request Seals V = NBR (standard) N = FKM (optional) Coil voltage DC voltages 12 = 12 V DC 24 = 24 V DC AC voltages (bridge rectifier built into the coil) 115 = 115 V AC 230 = 230 V AC Other voltages on request Coil connectors (type 40-1836) DC: DG = DIN connector to EN 175301-803 DK = KOSTAL threaded connection M27x1 DL = 2 flying leads, 457 mm long, 0.75 mm DN = Deutsch connector, 2-pole, axial DT = AMP Junior Timer, 2-pole, radial AC: AG = DIN connector to EN 175301-803 other connectors on request

thick

millimeter (inch) subject to technical modifications

Standard models

Model code WS08Z-01-C-N-24DG WS08Z-01-C-N-230AG Other models on request Part No. 561579 3043403

CAVITY

FC08-2

* Standard in-line bodies

Code FH082-SB3 Part No. 560919 Material Steel, zinc-plated Aluminium, clear anodized Ports G3/8 G3/8 Pressure 420 bar 210 bar FH082-AB3 3011423 Other housings on request

Seal kits

Code FH082-N SEAL KIT FH082-V SEAL KIT Material NBR FKM Part No. 3033920 3051756

PERFORMANCE

Measured at = 34 mm/s, Toil = 46 C

Pressure drop

2 1 energized 1 2 de-energized

Flow rate

E 5.907.3/01.13

Form tools Tool Countersink FC08-2 Reamer FC08-2 Part No. 175473 175474

NOTE

millimeter (inch) subject to technical modifications

The information in this brochure relates to the operating conditions and applications described. For applications or operating conditions not described, please contact the relevant technical department. Subject to technical modifications.

HYDAC Fluidtechnik GmbH Justus-von-Liebig-Str. D-66280 Sulzbach/Saar Tel: 0 68 97 /509-01 Fax: 0 68 97 /509-598 E-Mail: flutec@hydac.com

299

Вам также может понравиться

- 3100 GemsДокумент6 страниц3100 GemsJoão PauloОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- 2011 Hyundai Service FiltersДокумент18 страниц2011 Hyundai Service FiltersTan JaiОценок пока нет

- FBL ManualДокумент12 страницFBL Manualaurumstar2000Оценок пока нет

- Case Study 1Документ2 страницыCase Study 1asad ee100% (1)

- E5924 ws08w01Документ2 страницыE5924 ws08w01Inkanata SacОценок пока нет

- Solenoid Bidirectional ValveДокумент2 страницыSolenoid Bidirectional Valveman_y2kОценок пока нет

- DSG ValvesДокумент17 страницDSG ValvesChris RoederОценок пока нет

- 2/2-Way Valves DN 20 To DN 50Документ4 страницы2/2-Way Valves DN 20 To DN 50Oscar CurimanyaОценок пока нет

- s270 MCB CatalogueДокумент1 страницаs270 MCB CatalogueManu PillaiОценок пока нет

- Accessories AC Current Transformer (max 23mm φ cable) Type CTD-1XДокумент2 страницыAccessories AC Current Transformer (max 23mm φ cable) Type CTD-1Xน็อต ซุบเปอร์ไรเดอร์Оценок пока нет

- Datasheet G RelaysДокумент10 страницDatasheet G RelaysthomaswangkoroОценок пока нет

- DEIF TCM 2 Datasheet 4921240329ukДокумент6 страницDEIF TCM 2 Datasheet 4921240329ukAnonymous T3qDfvОценок пока нет

- N en en 5 8 120 82090Документ2 страницыN en en 5 8 120 82090refaeОценок пока нет

- Proportional Reducing ValveДокумент8 страницProportional Reducing ValvediabalziabОценок пока нет

- Irrigation Solenoid ValveДокумент1 страницаIrrigation Solenoid ValveAtul KalaskarОценок пока нет

- Moeller Datasheet MCS4 019711Документ5 страницMoeller Datasheet MCS4 019711mihai37Оценок пока нет

- Position Switches FR Series: Selection DiagramДокумент12 страницPosition Switches FR Series: Selection DiagramMehmetLeventÖzsinanОценок пока нет

- Ca3kn22bd Telemecanique - Unit5.relayДокумент8 страницCa3kn22bd Telemecanique - Unit5.relaykapenziОценок пока нет

- Electro Válvula Del CompresorДокумент4 страницыElectro Válvula Del CompresorneumaticoОценок пока нет

- Rele Tyco Rt424024sДокумент3 страницыRele Tyco Rt424024sJose G. Cantillo L.Оценок пока нет

- TX Relays: Features Typical ApplicationsДокумент7 страницTX Relays: Features Typical ApplicationszakioОценок пока нет

- At The End of This Document You Will Find Links To Products Related To This Catalog. You Can Go Directly To Our Shop by ClickingДокумент5 страницAt The End of This Document You Will Find Links To Products Related To This Catalog. You Can Go Directly To Our Shop by ClickingAhmad Aliyan Alif Bin IsmailОценок пока нет

- Pressure Transmitter For General Industrial Applications Model A-10Документ7 страницPressure Transmitter For General Industrial Applications Model A-10brunotavernaОценок пока нет

- MK 2 PiДокумент7 страницMK 2 PiA Whick Bumbum TralalaОценок пока нет

- H25 Incremental EncoderДокумент4 страницыH25 Incremental EncoderEdgar AllamОценок пока нет

- RAMC GS E Ed26 Pub21112016Документ28 страницRAMC GS E Ed26 Pub21112016Alvaro Quinteros CabreraОценок пока нет

- Pizzato Elettrica Position Switches FR Series - Catalog 2011-2012Документ12 страницPizzato Elettrica Position Switches FR Series - Catalog 2011-2012IBJSC.comОценок пока нет

- Technical Data Sheet CM24-T-..: Type OverviewДокумент4 страницыTechnical Data Sheet CM24-T-..: Type OverviewAnh GiàОценок пока нет

- 30 22 7 012 0010-Finder-Datasheet-548493Документ2 страницы30 22 7 012 0010-Finder-Datasheet-548493Tony RodriguezОценок пока нет

- High-Speed DC Circuit-Breaker PDFДокумент8 страницHigh-Speed DC Circuit-Breaker PDFfassina01Оценок пока нет

- BremasErsce Catalogue 2011 - Cam Switches CR SeriesДокумент24 страницыBremasErsce Catalogue 2011 - Cam Switches CR SeriesTan Ren ZongОценок пока нет

- Informacion General: Mostrar TodoДокумент4 страницыInformacion General: Mostrar TodoMarisol MartinezОценок пока нет

- Spare List KP InstДокумент4 страницыSpare List KP InstRaju SkОценок пока нет

- Rotary Type Installation Switches 16... 160 A, 500 VДокумент8 страницRotary Type Installation Switches 16... 160 A, 500 VFlo MircaОценок пока нет

- Containing 2 To 12 Valves 2/2 Normally Closed, Direct Operated 1/8Документ8 страницContaining 2 To 12 Valves 2/2 Normally Closed, Direct Operated 1/8Urip S. SetyadjiОценок пока нет

- DS PV2201 GB 10873Документ6 страницDS PV2201 GB 10873eeghbaliОценок пока нет

- K01 TypeДокумент10 страницK01 TypeHenry PalОценок пока нет

- Small Relay D2: Product InformationДокумент9 страницSmall Relay D2: Product InformationGus Gus GusОценок пока нет

- Features: 46 Series - Miniature Industrial Relays, 8 - 16 AДокумент6 страницFeatures: 46 Series - Miniature Industrial Relays, 8 - 16 AThomas GonzalezОценок пока нет

- 5493 F 38 e 2849 CДокумент3 страницы5493 F 38 e 2849 Cben_aizziОценок пока нет

- Manual - Dvp48eh00r PDFДокумент2 страницыManual - Dvp48eh00r PDFMauro KowalczukОценок пока нет

- Relee Din Gama 38Документ6 страницRelee Din Gama 38andy175Оценок пока нет

- Ordering Information: Sealed Snap Action SwitchДокумент6 страницOrdering Information: Sealed Snap Action SwitchG Sandeep KumarОценок пока нет

- RE18136Документ4 страницыRE18136Ahmed Abd ElhakeemОценок пока нет

- Pune Techtrol FGTДокумент2 страницыPune Techtrol FGTBenjamin StricklandОценок пока нет

- Relay 5vДокумент2 страницыRelay 5vNgoc Loi Nguyen HoОценок пока нет

- Hawe Pressure Dt11 d5440t2 enДокумент4 страницыHawe Pressure Dt11 d5440t2 enАндрей дронОценок пока нет

- Model Number Structure: Enclosed SwitchДокумент10 страницModel Number Structure: Enclosed SwitchJavierОценок пока нет

- 1 Year Spares MasterДокумент30 страниц1 Year Spares MasternalasekaranОценок пока нет

- MIL Control Valve Specification and Sizing CalculationДокумент34 страницыMIL Control Valve Specification and Sizing CalculationRahulTewari67% (3)

- Micro Flow Meter DatasheetДокумент4 страницыMicro Flow Meter DatasheetLuanLTОценок пока нет

- 064 Elektrix 2012 WebДокумент72 страницы064 Elektrix 2012 WebСања БанковићОценок пока нет

- Flow Measurement of Liquids and Gases: OperationДокумент8 страницFlow Measurement of Liquids and Gases: Operationابزار دقیقОценок пока нет

- Miniature General Purpose Relay: Operation in Any PositionДокумент8 страницMiniature General Purpose Relay: Operation in Any PositiondalmohvacОценок пока нет

- DirectionalControlValves NACHIДокумент47 страницDirectionalControlValves NACHICarlos Mauricio Guerrero Aguilar100% (1)

- p10 3283pdfДокумент4 страницыp10 3283pdfsrinuvoodiОценок пока нет

- LS200 Series Liquid Level SwitchesДокумент4 страницыLS200 Series Liquid Level SwitchesJavy PantojaОценок пока нет

- Solinoid Popet ValveДокумент3 страницыSolinoid Popet ValvesaqureshОценок пока нет

- Technical Data Sheet CM24G-..: Type OverviewДокумент4 страницыTechnical Data Sheet CM24G-..: Type OverviewAnh GiàОценок пока нет

- C4 R30datasheetДокумент2 страницыC4 R30datasheetsimbugowriОценок пока нет

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesОт EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesРейтинг: 4.5 из 5 звезд4.5/5 (7)

- ColgateДокумент32 страницыColgategargatworkОценок пока нет

- BPV ApproachДокумент13 страницBPV ApproachfwfsdОценок пока нет

- Tugas-MPSI-P1-P14 - Kelompok 2 - 19.4A.04Документ29 страницTugas-MPSI-P1-P14 - Kelompok 2 - 19.4A.04gilang putraОценок пока нет

- Business Ethics Final Work Brief 2Документ6 страницBusiness Ethics Final Work Brief 2KALIZA TRESSY MEGHANОценок пока нет

- Sydney Boys 2017 2U Accelerated Prelim Yearly & SolutionsДокумент26 страницSydney Boys 2017 2U Accelerated Prelim Yearly & Solutions黄心娥Оценок пока нет

- Land Surveying Chapter 2 Leveling p1Документ66 страницLand Surveying Chapter 2 Leveling p1Azrul ZulwaliОценок пока нет

- Questionnaire On EthnocentrismДокумент14 страницQuestionnaire On Ethnocentrismkalpa vrikshaОценок пока нет

- Orphanage Project ProposalДокумент3 страницыOrphanage Project ProposaldtimtimanОценок пока нет

- Green Tyre TechnologyДокумент4 страницыGreen Tyre TechnologyAnuj SharmaОценок пока нет

- Pecson Vs CAДокумент3 страницыPecson Vs CASophiaFrancescaEspinosaОценок пока нет

- Cylinder Clamp For N2 Cylinder 84L and FM-200 Cylinder 82.5LДокумент1 страницаCylinder Clamp For N2 Cylinder 84L and FM-200 Cylinder 82.5LNguyễn Minh ThiệuОценок пока нет

- LTE ID RNP StandardizationДокумент9 страницLTE ID RNP Standardizationahdanizar100% (1)

- Catalog Electrical Products en - 339 - 1Документ20 страницCatalog Electrical Products en - 339 - 1H 8CОценок пока нет

- Module 9 School AgeДокумент16 страницModule 9 School AgeMichelle FactoОценок пока нет

- Lust V Animal Logic MSJ OppositionДокумент34 страницыLust V Animal Logic MSJ OppositionTHROnlineОценок пока нет

- Maxillofacial Trauma and Management - Dental Ebook & Lecture Notes PDF Download (Studynama - Com - India's Biggest Website For BDS Study Material Downloads)Документ24 страницыMaxillofacial Trauma and Management - Dental Ebook & Lecture Notes PDF Download (Studynama - Com - India's Biggest Website For BDS Study Material Downloads)Vinnie SinghОценок пока нет

- Ten Rules of NetiquetteДокумент11 страницTen Rules of NetiquetteAriel CancinoОценок пока нет

- Corality ModelOff Sample Answer Hard TimesДокумент81 страницаCorality ModelOff Sample Answer Hard TimesserpepeОценок пока нет

- MCMCHistoryДокумент18 страницMCMCHistoryAli S.Оценок пока нет

- Picasso OperatingInstructions Manual 211018 WEBДокумент27 страницPicasso OperatingInstructions Manual 211018 WEBBill McFarlandОценок пока нет

- Editing Packs I Maybe Will NeedДокумент3 страницыEditing Packs I Maybe Will NeedMijo SusićОценок пока нет

- Lesson Worksheet: 6.1A MeanДокумент7 страницLesson Worksheet: 6.1A Meanwaiman fuОценок пока нет

- MetalsMagazine 2 2018 PDFДокумент116 страницMetalsMagazine 2 2018 PDFJack 123Оценок пока нет

- Unilift de DGDДокумент36 страницUnilift de DGDLove SemsemОценок пока нет

- Intel Core - WikipediaДокумент16 страницIntel Core - WikipediaEEBB0% (1)

- PSA Technology-More Than A Hydrogen Purifier: TOBIAS KELLER and GOUTAM SHAHANI, Linde EngineeringДокумент2 страницыPSA Technology-More Than A Hydrogen Purifier: TOBIAS KELLER and GOUTAM SHAHANI, Linde EngineeringChem.EnggОценок пока нет

- Aling MODEДокумент29 страницAling MODEBojan PetronijevicОценок пока нет