Академический Документы

Профессиональный Документы

Культура Документы

EMCO - Pneumatic Caliper Disc Brake: Emco Dynatorq Pvt. LTD

Загружено:

Srini KumarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

EMCO - Pneumatic Caliper Disc Brake: Emco Dynatorq Pvt. LTD

Загружено:

Srini KumarАвторское право:

Доступные форматы

EMCO - Pneumatic Caliper Disc Brake

Licensee: Carlson Company Inc. Wichita, Kansas, USA

EL

Emco Dynatorq Pvt. Ltd.

( Formerly Emco Lenze Pvt. Ltd. )

( ISO 9001 : 2008 Company )

CBAA - Air Applied Spring Release Caliper Disc Brake

101 12.7

BRAKING RADIUS

60.3 O.D. OF DISC 38.1

9.5

19 56.3

111.3

39.6

51.5

MOUNTING BOLTS M12, 4 Pcs. 330.2

CBAA20 STATIC BRAKING FORCE 8450N AT 80 PSI WITH FULL LINING

CYLINDER & PISTON ARE STAINLESS STEEL

Brake torque depends upon disc size

Force ( N ) X Torque ( Nm ) = ( mm ) _ 38.1 ] [ Disc dia 2 1000

Note :- Caliper Brakes are to be operated with solenoid valve

98.4 182.5

AIR INLET 1/4"-18, NPT

Disc Size in Inches ( mm ) 12 14 16 18 24 36 ( 305 ) ( 356 ) ( 406 ) ( 457 ) ( 610 ) ( 914 )

Static Torque at 80 PSI ( Nm ) 950 1180 1400 1600 2260 3650

Weight

Representative Mounting Arrangement

Rotor / Disc

13.6 Kg ( Approx )

NOTE : Dynamic torque is approximately 85% of static torque

CBAA20

* Additional brakes can be mounted at 90 to increase torque. * 1-4 Brake can be mounted depending on disc size.

The Model CBAA20 is air applied, spring released caliper brake which is used in stopping applications of industrial equipment. It has a unique design, using an actuator located between two caliper arms. This allows the brake to have a compact physical size in relation to its high torque capacity. Friction linings are changed by pulling the clip pin and removing the caliper shoe. The CBAA20 unit comes assembled and ready for mounting.

Application Areas:Steel mills, Cranes, Conveyors, Wind turbines, Textile machinery, Paper industries, Wire drawing machinery, Test rigs, Tyre industries, Printing machines, Mines,Specialpurpose machines, Bulk material handling equipment, Cable machinery, Sugarcentrifuges, Ball mills, Nuclear power plants, Cement mills and plants, Hydro

CBSA - Spring Applied Air Release Caliper Disc Brake

CBSA20 STATIC BRAKING FORCE 8450N WITH FULL LINING

Brake torque depends upon disc size

Force ( N ) X Torque ( Nm ) = ( mm ) _ 38.1 ] [ Disc dia 2 1000

Note :- Caliper Brakes are to be operated with solenoid valve

Representative Mounting Arrangement

Disc Size in Inches ( mm ) 12 14 16 18 24 36 ( 305 ) ( 356 ) ( 406 ) ( 457 ) ( 610 ) ( 914 ) Static Torque ( Nm ) 950 1180 1400 60 PSI 1600 2260 3650 15.5 Kg ( Approx ) Minimum Release Pressure Weight

Rotor / Disc

NOTE : Dynamic torque is approximately 85% of static torque

* Additional brakes can be mounted at 90 to increase torque. * 1-4 Brake can be mounted depending on disc size.

CBSA20

The Model CBSA20 is spring applied, air released caliper brake which is used in stopping and holding applications of industrial equipment. It has a unique design, using an actuator located between two caliper arms. This allows the brake to have a compact physical size in relation to its high torque capacity. Friction linings are changed by pulling the clip pin and removing the caliper shoe. The CBSA20 unit comes assembled and ready for mounting.

Application Areas:Steel mills, Cranes, Conveyors, Wind turbines, Textile machinery, Paper industries, Wire drawing machinery, Test rigs, Tyre industries, Printing machines, Mines, Specialpurpose machines, Bulk material handling equipment, Cable machinery, SugarCentrifuges, Ball mills, Nuclear power plants, Cement mills and plants, Hydro turbines.

CB Caliper Brake Pneumatic Caliper Disc Brake

A D E Mounting Bolts Air Inlet 1/8"NPT

Brake torque depends upon disc size

Force ( N ) X Torque ( Nm ) = ( mm ) _ Lining radius ( mm ) [ Disc dia ] 2 1000

Model CB100 CB200

A 63.5 73

B 66.7 95

C 57 79

D 41.3 57

E 12.7 16

F 9.5 10

Mounting Bolts M10 M12

Static Tangential Force @ 80 PSI 556 N 1100 N

Lining Area 21.3 cm 52 cm

Wearable Lining Volume 5.4 cm 16 cm

Rotor / Disc Specifications Static Torque Ratings @ 80 PSI With Full Lining

3 Plcs. Eq. Spcd. B.C.D.

C D

Representative Mounting Arrangement

Rotor / Disc

Dia.

* Additional brakes can be mounted at 60 to increase torque. * 1-6 Brake can be mounted depending on disc size.

CB100 Part Number Dia. ( mm ) A B C D B.C.D. CB200 CB100 CB200 Static Torque Ratings @ 80 PSI Air Pressure 31 Nm 50 Nm Static Torque Ratings @ 160 PSI Hydraulic Pressure 61 Nm 99 Nm

Note :- Caliper Brakes are to be operated with solenoid valve

6161

152

50.8

34.9

15.8

9.5

42

6162 6163

229 305

68.2 98.4

47.5 71.4

22.2 31.7

9.5 9.5

57.1 84.1

52 Nm 73 Nm

92 Nm 134 Nm

104 Nm 147 Nm

183 Nm 269 Nm

Application Areas:Steel mills, Cranes, Conveyors, Wind turbines, Textile machinery, Paper industries, Wire drawing machinery, Test rigs, Tyre industries, Printing machines, Mines, Specialpurpose machines, Bulk material handling equipment, Cable machinery, SugarCentrifuges, Ball mills, Nuclear power plants, Cement mills and plants, Hydro turbines.

CSB Caliper Brake Spring Applied / Air Release

A D Mounting Bolts E

1

Air Inlet 8" NPT

Brake torque depends upon disc size

B

Force ( N ) X Torque ( Nm ) = ( mm ) _ Lining radius ( mm ) [ Disc dia ] 2 1000

Model

Mounting Bolts M10 M12

Static Tangential Force 330 N 660 N

Lining Area

Wearable Lining Volume 4.9 cm 13.6 cm

Note :- Caliper Brakes are to be operated with solenoid valve

CBS100 CBS200

79.4 85.7

67.5 95

57.1 79

41.3 57

12.7 16

11 11

21.3 cm 52 cm

Rotor / Disc Specifications Static Torque Ratings at Full Lining Release Pressure 70 PSI

3 Plcs. Eq. Spcd. B.C.D.

C D

Part Number

Dia. ( mm )

CSB100 A B C D B.C.D.

CSB200

Release Pressure @ 70 PSI 18 Nm 30 Nm

6161

152

50.8

34.9

15.8

9.5

42

B Dia.

6162 6163

229 305

68.2 98.4

47.5 71.4

22.2 31.7

9.5 9.5

57.1 84.1

31 Nm 44 Nm

55 Nm 81 Nm

Torque Selection Guideline

Representative Mounting Arrangement

Rotor / Disc Torque (Nm) = 9550 X ( Motor kW / RPM ) X Safety factor (K)

Load Condition Low masses, equal loading & non - intermittent operation Low masses, light shock load & intermittent operation Medium masses, light shock load & intermittent operation Large masses, light shock load & intermittent operation Diesel engine drive Compressor drive Safety Factor (K) 2.0 2.5 3.0 3.0 4-5 5-6 2-3 3-4

* Additional brakes can be mounted at 60 to increase torque. * 1-6 Brake can be mounted depending on disc size.

Application Areas:-

Non overhauling loads Overhauling loads

Steel mills, Cranes, Conveyors, Wind turbines, Textile machinery, Paper industries, Wire drawing machinery, Test rigs, Tyre industries, Printing machines, Mines, Specialpurpose machines, Bulk material handling equipment, Cable machinery, SugarCentrifuges, Ball mills, Nuclear power plants, Cement mills and plants, Hydro turbines.

Emco & Emco - Carlson

Making machines friendly

The brands emco & emco - carlson stand for uncompromised quality in products as well the services. Products that are safe & reliable and service that makes our products and your machines perform efficiently.

Regd. Office :

1st Floor, Sita Mauli, above Bank of Maharashtra, Madanlal Dhingra Road Panch Pakhadi, Thane ( West ), 400 602, INDIA Tel : +91 (0) 22 2540 5490/2545 2244/2541 5913/2541 5914 Fax : +91 (0) 22 2545 2233 Email : mktg@emco-dynatorq.in

Unit I :

Shivam Industrial Estate, Bldg. No. 3, Gala No. 12A & 12B Tungareshwar Phata Road, Sativali, Vasai (E), Thane - 401 208 Tel : +91 (0) 250 2480 489 / 2480 490 Fax : +91 (0) 250 2481 086 Email : vasai@emco-dynatorq.in

Unit II :

1002 - 1003, GIDC, Waghodia, Dist. Baroda 391 760, Gujarat Tel : +91 (0) 2668 262186 / 263089 / 262187 Telefax : +91 (0) 2668 262180 Email : dynatorq@gmail.com

Unit III :

Gala No. 6A & 8, Kedarnath Bldg. Tungareshwar Indl. Estate, Sativali, Vasai (E) Tel : +91 (0 ) 250 2480 178 / 2480 921

Upcoming Unit IV :

1426, GIDC, Waghodia, Dist. Baroda 391 760, Gujarat

Website : www.emco-dynatorq.in

EL

Emco Dynatorq Pvt. Ltd.

( Formerly Emco Lenze Pvt. Ltd. )

ISO 9001 : 2008 Company

Вам также может понравиться

- Is 8531 1986Документ6 страницIs 8531 1986Srini KumarОценок пока нет

- Engineering Drawing - Lettering and Lines PresentationДокумент67 страницEngineering Drawing - Lettering and Lines PresentationSrini KumarОценок пока нет

- Bentley-Openplant Isometrics Manager V8i Product-Data-SheetДокумент2 страницыBentley-Openplant Isometrics Manager V8i Product-Data-SheetSrini KumarОценок пока нет

- Re-Profiling Tripper Conveyors ...Документ2 страницыRe-Profiling Tripper Conveyors ...Srini KumarОценок пока нет

- Engineering Drawings and Symbols: 16-1 © 2011 Cengage Learning Engineering. All Rights ReservedДокумент41 страницаEngineering Drawings and Symbols: 16-1 © 2011 Cengage Learning Engineering. All Rights ReservedSrini KumarОценок пока нет

- Duplicate Bill: For Any Queries On This Bill Please Contact Sdo4602@ho - Mahadiscom.inДокумент1 страницаDuplicate Bill: For Any Queries On This Bill Please Contact Sdo4602@ho - Mahadiscom.inSrini KumarОценок пока нет

- Rotating Steel ShaftsДокумент3 страницыRotating Steel ShaftsSrini KumarОценок пока нет

- Ilogic Inventor APIДокумент29 страницIlogic Inventor APISrini KumarОценок пока нет

- Duplicate Bill: For Any Queries On This Bill Please Contact Sdo4602@ho - Mahadiscom.inДокумент1 страницаDuplicate Bill: For Any Queries On This Bill Please Contact Sdo4602@ho - Mahadiscom.inSrini KumarОценок пока нет

- BMH Offering Guide 2010Документ15 страницBMH Offering Guide 2010Srini KumarОценок пока нет

- Inv 10 CH QДокумент15 страницInv 10 CH QSrini KumarОценок пока нет

- Rack and Pinion Gear DesignДокумент32 страницыRack and Pinion Gear DesignSrini KumarОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Tosaca Catalogue PDFДокумент16 страницTosaca Catalogue PDFgabОценок пока нет

- PoloniumДокумент12 страницPoloniumIan Brunia OranioОценок пока нет

- 1 s2.0 S1359431199000496 Main PDFДокумент14 страниц1 s2.0 S1359431199000496 Main PDFWILLIAMCARABALIОценок пока нет

- Comparison Between - MB - BE - FDДокумент5 страницComparison Between - MB - BE - FDSoumajit DasОценок пока нет

- Navidi Ch07 4e Linear RegressionДокумент68 страницNavidi Ch07 4e Linear RegressionAmin ZaquanОценок пока нет

- Cambridge IGCSE (9-1) : Physics 0972/11Документ20 страницCambridge IGCSE (9-1) : Physics 0972/11michael nanlohyОценок пока нет

- 01 Cleveland Ruth 1997 PDFДокумент21 страница01 Cleveland Ruth 1997 PDFMarianne Zanon ZotinОценок пока нет

- Physics of SoundДокумент33 страницыPhysics of SoundijahsmkutОценок пока нет

- JUL1990 JPL Reliability Analysis HandbookДокумент169 страницJUL1990 JPL Reliability Analysis HandbookKanwal Jit Singh100% (1)

- Face Detection RecognitionДокумент21 страницаFace Detection RecognitionkamendersinghgangwarОценок пока нет

- Tutorial On Structural Analysis Using BEAM Elements of CAEPIPEДокумент5 страницTutorial On Structural Analysis Using BEAM Elements of CAEPIPEFRANCISCOОценок пока нет

- 3-Case Study Understanding and Improving ESP Reliability in SAGD Wells With High Dogleg SeverityДокумент7 страниц3-Case Study Understanding and Improving ESP Reliability in SAGD Wells With High Dogleg SeverityDorianОценок пока нет

- Terminology of Helical SpringДокумент4 страницыTerminology of Helical Springsandeep c sОценок пока нет

- Strings, Chains, and Ropes: SIAM Review December 2006Документ12 страницStrings, Chains, and Ropes: SIAM Review December 2006Hemendra PrasannaОценок пока нет

- Seminar On Wireless Charging of Mobile DevicesДокумент24 страницыSeminar On Wireless Charging of Mobile DevicesGourish Amonkar100% (1)

- SOALAN BiologiДокумент12 страницSOALAN BiologiLoong Wai FamОценок пока нет

- Vehicle Dynamics Lecture05Документ28 страницVehicle Dynamics Lecture05Rahul KadbeОценок пока нет

- RDM-chapter 1Документ35 страницRDM-chapter 1Mat MatttОценок пока нет

- Antenna Radiation Electromagnetic Electrical Resistance Ohm MeterДокумент6 страницAntenna Radiation Electromagnetic Electrical Resistance Ohm Meterbiswa217Оценок пока нет

- Mechanical Properties OF Dental MaterialsДокумент40 страницMechanical Properties OF Dental MaterialsRamnarayan MeenaОценок пока нет

- Attachment PDFДокумент2 страницыAttachment PDFYunita RamadhantiОценок пока нет

- 2015-05 Alto Motorcycle CatalogДокумент97 страниц2015-05 Alto Motorcycle CatalogGeorgi AleksievОценок пока нет

- Revista Domus 771Документ10 страницRevista Domus 771Claudia TecuceanuОценок пока нет

- Neodymium MagnetДокумент42 страницыNeodymium MagnetpraveenОценок пока нет

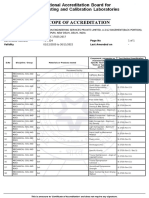

- Scope TC 9124Документ1 страницаScope TC 9124Esscon Engineering Services Pvt. Ltd.Оценок пока нет

- Colonial ZF SeriesДокумент2 страницыColonial ZF SeriesmndmattОценок пока нет

- DuPlessis F Skripsie2020Документ81 страницаDuPlessis F Skripsie2020lovejoy mhishiОценок пока нет

- ST-130 - Manual PDFДокумент27 страницST-130 - Manual PDFJean TorreblancaОценок пока нет

- 87716166b1472fd3f7a6a47ea68960afДокумент410 страниц87716166b1472fd3f7a6a47ea68960afPedroОценок пока нет

- Pengaruh Kandungan Frekuensi Gempa Terhadap Simpangan Dan Drift Ratio 2 Arah Struktur Bangunan Set-Back Bertingkat BanyakДокумент9 страницPengaruh Kandungan Frekuensi Gempa Terhadap Simpangan Dan Drift Ratio 2 Arah Struktur Bangunan Set-Back Bertingkat BanyakIvan MuhammadОценок пока нет