Академический Документы

Профессиональный Документы

Культура Документы

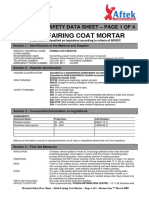

Adhesives and Sealants PDF

Загружено:

Nerinel CoronadoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Adhesives and Sealants PDF

Загружено:

Nerinel CoronadoАвторское право:

Доступные форматы

GS 40

ADHESIVES AND SEALANTS

SPILLAGE & WASTE DISPOSAL Spillages of any type should be attended to immediately. Water-based products can be washed away with water before they dry, provided it is permissible to discharge this type of effluent into the drains. An alternative method is to soak up the Spillage with an inert material, which can be placed in a suitably closed container for disposal. This technique is particularly appropriate for solvent based adhesives, using either sand, clay or powdered limestone as the absorbent material. Care should be taken in the disposal of full or empty containers for solvent-based adhesives in order to avoid a latent explosion and/or fire hazard. The empty containers should be either carefully punctured or left open to ensure that no solvent vapour is trapped under pressure, taking the usual precautions concerning flammable materials. Note: Aerosol packages are pressurised and must not be punctured unless all internal pressure has been relieved. STORAGE The storage of adhesives and sealants should be restricted to 'NO SMOKING' areas since even for non-flammable adhesives there is a risk that vapours can be given off which will be converted by pyrolysis to toxic products by a burning cigarette. All flammable adhesives should be stored in suitable flameproof areas according to the requirements of the appropriate authorities. All adhesives and sealants should be stored in dry conditions and reasonable temperatures, eg. preferably between 50C-300C. Warm drums of solvent-based adhesives should be opened slowly and carefully to allow gradual release of internal pressure. To ensure that the useful shelf life of adhesive products is not exceeded, strict rotation of stock should be observed and possible safety hazards from aging avoided. In all cases, the manufacturer's instructions and directions printed on the label should be observed.

INTRODUCTION This sheet has been prepared as a general guide to safe handling and storage procedures for all users of adhesives and sealants. Specific hazards and precautionary measures are stated, where required, for the various types of adhesives and sealants. However, Material Safety Data (MSDS) Sheets should be provided. HYGIENE The possible ingestion of adhesives and sealants should be avoided and the consumption or storage of food or drink should be prohibited in areas where adhesives are handled or used. Certain adhesives which emit dust or toxic vapours present a hazard from inhalation. Suitable dust masks, respirators and/or adequate ventilation should be provided in these instances. Skin contact should be minimised and manufacturers will advise on barrier and cleansing creams appropriate for their products, as well as suitable protective clothing and eye protection where considered necessary. ALLERGIES There is always the possibility that an individual may be allergic to a substance used in a particular adhesive or sealant. There is generally no easy solution to this problem if physical protection is not adequate. Complete avoidance of exposure to that particular adhesive or sealant may be the only remedy.

This information is provided to offer guidance on a particular aspect of legislation. It is not to be taken as a statement of law and must not be construed to waive or modify any legal obligation

-2-

1.Solvent-bused adhesives solvent-containing types)

(including

maintain the solvent vapour concentration in the working area below the permissible limit. Where necessary, this concentration should be regularly monitored to ensure safe working conditions. 2. Water-based adhesives (including emulsions, latices and solutions) Being water based this class of product is not normally flammable. The dry adhesive film formed when water is removed may be capable of burning but does not usually sustain combustion. Some synthetic polymers depolymerise under heat, liberating volatile, toxic and/or flammable vapours. Solvents are incorporated in many emulsion adhesives for special applications and this may affect toxicity and flammability (see section 1). Synthetic latices or emulsions contain free monomer which, although normally present at low levels, can be a potential hazard to health. Other volatile ingredients such as ammonia, formaldehyde etc can also be troublesome. All such products should therefore be used with adequate ventilation. Contact with the skin should be avoided but if this does occur aqueous adhesives should be washed oft with cold water before they can dry. This is to avoid discomfort rather than injury from adherent polymer. However, repeated contact may cause dermatitis in sensitive individuals and the use of barrier cream and/or protective gloves is advisable. Water-based Adhesives If adhesives dry on unprotected skin some will be found to pull off without inconvenience. Others, particularly pressure sensitive films, are less easy to remove and may require a special skin cleanser. Do not use solvents. Splashes into eyes, mouth or nose should be washed without delay with copious quantities of water and medical advice should be obtained immediately if considered necessary.

Adhesives of this class represent the most obvious hazard to users. Storage Store in a cool dry moderate condition at temperatures from 5' to 30' unless otherwise specified by the manufacturer. Usage Avoid inhaling the vapours - use in wellventilated areas - avoid contact with the skin. The use of suitable barrier creams for protection of the skin and/or gloves is recommended. Removal of adhesives from the skin should be done with suitable antiseptic cleaning agents rather than straight solvents. When handling low- viscosity adhesives, suitably approved goggles or face shields should be worn to protect the eyes from splashes. Wherever possible, build up of solvent vapours in the work atmosphere should be controlled by adequate ventilation using flameproof exhaust fans where necessary. If this is not practicable, then suitable breathing apparatus, such as respirators, should be worn. Spillage Clean up immediately using sand or powdered limestone to absorb the adhesive before scraping up the residues and disposing of them according to the local regulations. Fire Risk If the adhesive contains flammable solvents DO NOT store or use near naked flames and avoid sparks and non-flameproof equipment. The manufacturer should be consulted concerning the best methods of extinguishing any fire involving his products. Toxicity Although toxicity of solvent vapours from adhesives vary considerably the breathing of appreciable quantities of solvent-laden air should be avoided. The Threshold limit Values (TLV) of a wide variety of chemicals (including solvents) is listed in an Occupation Health Guide published and periodically reviewed by the National Health and Medical Research Council of Australia. The lower the quoted TLV value the higher the toxicity of the material and consequently, more effective ventilation is required to

Safeguard GS40 - Adhesives and Sealants continued

3. Hot melt adhesives The greatest hazards associated with the use of hot melt adhesives occur when they are molten. Severe burns can result if skin contact occurs and adequate protective clothing should therefore be worn. Suitably approved eye and face protection should also be used if molten adhesive is being used or transferred or if there is a danger of splashing. If burns do occur the recommended procedure is as follows: (a) Immerse the affected area in cold clean water immediately for several minutes. (b) Do not attempt to remove the cold adhesive from the skin.

This information is provided to offer guidance on a particular aspect of legislation. It is not to be taken as a statement of law and must not be construed to waive or modify any legal obligation

-3-

(c) Cover the affected area with a wet compress and obtain medical advice immediately. Hot melts may fume during operation. The vapours given off are not normally considered to be toxic but they should not be inhaled and suitable, preferably forced draught, ventilation should be provided. Hot melt adhesives should be used at their recommended operating temperatures. If overheating occurs there could be a fire risk as the vapours evolved might be ignitable by a spark. If a fire does start a dry powder extinguisher should be used and under no circumstances should water be allowed to come into contact with the molten adhesive. 4. Powder adhesives This covers a very wide range of products from powdered starch and animal glues, which are relatively innocuous, to the more hazardous synthetic resin powders. Under certain circumstances dust can present an explosion hazard. This risk can be avoided by paying careful attention to good housekeeping and maintaining low dust levels. Inhalation of dust is another potential hazard and exposure should be minimised with suitable respirators being worn where necessary. Some powdered glues are acknowledged to be dermatitic and in such cases manufacturer's recommendations must be strictly followed. As a general precaution in all cases strict attention should be paid to personal hygiene and direct handling should be avoided. The use of barrier creams and/or protective gloves is recommended. As some powder adhesives can contain caustic or acidic material, approved eye protective goggles should be worn when handling these products. 5. Other Adhesives This group contains such products as epoxies, polyurethanes, reactive acrylics, cyano-acrylates, anaerobics and other 100% solid liquid resin adhesives. Most of these require to be mixed with a reactive hardener to promote curing of the adhesive and these hardeners can be more toxic than the base resin so care must be exercised in handling them as well as the resin. Some of these liquid resin adhesives contain flammable solvents so the normal precautions as stated for solvent-based adhesives should also be observed. The handling technique should ensure that uncured resin or hardener does not come in contact with the skin. Operators should be provided with suitable gloves, the insides of which

Safeguard GS40 - Adhesives and Sealants continued

must be kept scrupulously clean, and care should be taken to prevent cuffs becoming contaminated. Damaged gloves must be replaced. Barrier creams applied to the skin before work begins offers additional protection. If, despite all precautions, the skin does become contaminated, the affected area should be washed with a suitable antiseptic hand cleanser and disposable towels used for drying. Do not use solvents. Extra care should be taken with cyano-acrylates to prevent splashing into eyes or bonding of skin. If contaminated, the eyes should be irrigated immediately with copious amounts of water and bonded skin should be soaked in warm water or acetone if water is not effective. The mixing of adhesive formulations should only be carried out in suitably ventilated areas. As a precaution the wearing of approved dust or vapour respirators is advised when handling powder or liquid fillers and/or hardeners in order to avoid inhalation. Cleanliness and tidiness in the working area are of the utmost importance. Benches should be covered with replaceable paper which should be removed and destroyed when contaminated. Containers should be kept as far as practicable in a clearly marked-off area of the workspace. Spillages and contamination of tools and equipment or of the outside of containers are naturally to be avoided. If these occur, the affected area must be cleaned up immediately. Medical attention should be obtained for severe cases of over exposure. 6. Sealants The main type of sealants in current use are: silicones polysulphides polymercaptans urethanes acrylics butyl mastics polychloroprenes oil-based caulks.

None of the above materials is considered to be toxic or present any special hazards in their storage or handling. However, some may be acidic or alkaline in nature or allergenic, thus continuous exposure could cause skin or eye irritation. It is advisable to avoid eye contamination by using protective goggles where necessary, and to prevent repeated or prolonged contact with the skin by using gloves etc.

For further information contact: Dept for Administrative & Information Services Workplace Services GPO Box 465 ADELAIDE SA 5001 Ph: 1300 365 255 (If calling from a mobile phone or from interstate ph: (08) 8303 0400) Website: www.eric.sa.gov.au Issue Date: May 2000

This information is provided to offer guidance on a particular aspect of legislation. It is not to be taken as a statement of law and must not be construed to waive or modify any legal obligation

Вам также может понравиться

- SDS447 Dulux Trade Diamond Matt Safety Data SheetДокумент8 страницSDS447 Dulux Trade Diamond Matt Safety Data SheetjustinОценок пока нет

- Dulux Water BasedДокумент7 страницDulux Water BasedDya PratamaОценок пока нет

- MSDS Dulux Brilliant WhiteДокумент9 страницMSDS Dulux Brilliant WhiteDya PratamaОценок пока нет

- MSDS TELLUS S2 M68aДокумент5 страницMSDS TELLUS S2 M68amflorian69Оценок пока нет

- Corena Oil PДокумент5 страницCorena Oil Pmingyu parkОценок пока нет

- Shell Tellus S22 M22Документ5 страницShell Tellus S22 M22Hafifi IsmailОценок пока нет

- SDS 54/56Документ4 страницыSDS 54/56perret.yap.weilunОценок пока нет

- Pertua Exello Engine Oils - Material Safety Data SheetДокумент5 страницPertua Exello Engine Oils - Material Safety Data SheetPertua Marketing CorporationОценок пока нет

- Material Safety Data Sheet: Titan Performance Excel 15W40Документ8 страницMaterial Safety Data Sheet: Titan Performance Excel 15W40andi permanaОценок пока нет

- Transmission Oil TO30 MSDSДокумент4 страницыTransmission Oil TO30 MSDSAltoz DequitoОценок пока нет

- 201 Rubber Cement SolutionДокумент7 страниц201 Rubber Cement Solutionapi-265234726Оценок пока нет

- SDS Safety SODIUM HYDROSULPHIDE - 2020Документ10 страницSDS Safety SODIUM HYDROSULPHIDE - 2020KASHISH RAHEJAОценок пока нет

- MSDS Norwaytex Anti Fouling 2100 Material Safety Data SheetДокумент10 страницMSDS Norwaytex Anti Fouling 2100 Material Safety Data Sheetcem jakartaОценок пока нет

- Safety Data Sheet: Spotcheck SKC-S - AerosolДокумент6 страницSafety Data Sheet: Spotcheck SKC-S - AerosolChandrasekhar SonarОценок пока нет

- Safety Data Sheet for Molten SulfurДокумент9 страницSafety Data Sheet for Molten SulfurGerome EugenioОценок пока нет

- MSDS Kyoso Cutting OilДокумент4 страницыMSDS Kyoso Cutting Oilachwan febriantoОценок пока нет

- Original MSDS SolidifierДокумент6 страницOriginal MSDS SolidifierSaad IqbalОценок пока нет

- MSDS (Anti Malarial Oil)Документ4 страницыMSDS (Anti Malarial Oil)FaizalОценок пока нет

- Raycol Asphalt Company Limited: Material Safety Data SheetДокумент3 страницыRaycol Asphalt Company Limited: Material Safety Data SheetKongsak AkkharawongwhatthanaОценок пока нет

- Sigmadur Semigloss HardenerДокумент7 страницSigmadur Semigloss HardenerSelvakpm06Оценок пока нет

- Polyurethane Hardener - SDS 090317Документ8 страницPolyurethane Hardener - SDS 090317Pammy JainОценок пока нет

- Umeguard SX White Cs-651Документ12 страницUmeguard SX White Cs-651Mugilrajan DevarajanОценок пока нет

- OLIN - Curing Agent Easy-Fit AДокумент9 страницOLIN - Curing Agent Easy-Fit ABoyet BaldeОценок пока нет

- Eco 303a SDSДокумент9 страницEco 303a SDSSunny OoiОценок пока нет

- 03 - Safety PrecautionsДокумент3 страницы03 - Safety PrecautionsChrisDanger2Оценок пока нет

- 1 - Identification of The Material and Supplier Marine Naval Fuel F76Документ5 страниц1 - Identification of The Material and Supplier Marine Naval Fuel F76Ashwani KumarОценок пока нет

- Marine Paint Guide: 5. Safety PrecautionsДокумент3 страницыMarine Paint Guide: 5. Safety PrecautionsPolaris BridgemanОценок пока нет

- Material Safety Data Sheet: Version No.01 - Revision Date 12/07/2010Документ10 страницMaterial Safety Data Sheet: Version No.01 - Revision Date 12/07/2010shulhan nstОценок пока нет

- Safety Policy (Administrative)Документ89 страницSafety Policy (Administrative)salamon2tОценок пока нет

- MIRR ALMA SUPER API SL SAE 15W-40 Safety Data SheetДокумент8 страницMIRR ALMA SUPER API SL SAE 15W-40 Safety Data SheetAbdul GhafoorОценок пока нет

- DGLP660 MSDSДокумент7 страницDGLP660 MSDSAbadОценок пока нет

- Safety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Документ5 страницSafety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Chanchai PrugpadeeОценок пока нет

- 2016 (3) Anionic Slow Setting EmulsionДокумент6 страниц2016 (3) Anionic Slow Setting EmulsionRanmal AbhaОценок пока нет

- Komatsu Hydraulic Oil HO46 MSDSДокумент5 страницKomatsu Hydraulic Oil HO46 MSDSruan.morenoОценок пока нет

- MSDS EverstickДокумент7 страницMSDS EverstickDil VasconcelosОценок пока нет

- Construction Chemical Manufacturer Safety Data SheetДокумент6 страницConstruction Chemical Manufacturer Safety Data SheetAfshin EngОценок пока нет

- Alvania EP GreaseДокумент5 страницAlvania EP Greasemingyu parkОценок пока нет

- CASTROL OPTIGEAR SYNTHETIC X 320_SDSДокумент7 страницCASTROL OPTIGEAR SYNTHETIC X 320_SDSHector Martin BarajasОценок пока нет

- MSDS for BP Biodiesel BlendДокумент6 страницMSDS for BP Biodiesel BlendFurkan YamanОценок пока нет

- Material Safety Data Sheet: Toa Thinner # 21Документ5 страницMaterial Safety Data Sheet: Toa Thinner # 21ชินวิช แสงสักОценок пока нет

- Dust Away 1Документ5 страницDust Away 1Season AkhirОценок пока нет

- Heavy Fuel Oil SDS HazardsДокумент9 страницHeavy Fuel Oil SDS Hazardsshishir4870Оценок пока нет

- Material Safety Data SheetДокумент11 страницMaterial Safety Data SheetRenalyn TorioОценок пока нет

- SDS - Jotamastic 87 Standard - Comp. B - Marine - Protective - English (Uk) - SingaporeДокумент6 страницSDS - Jotamastic 87 Standard - Comp. B - Marine - Protective - English (Uk) - SingaporeAmi Terecef Gamboa MirandaОценок пока нет

- FINE BOND SDS Updates Company InfoДокумент4 страницыFINE BOND SDS Updates Company InfoBong CasirОценок пока нет

- TB-09.2 Health & Safety of UV InksДокумент2 страницыTB-09.2 Health & Safety of UV InksAdesh GurjarОценок пока нет

- AFTEK - Penapatch Fairing Coat Mortar SDS 2009Документ4 страницыAFTEK - Penapatch Fairing Coat Mortar SDS 2009Aria NickbakhtОценок пока нет

- Msds - m153 Base - Sds10828Документ7 страницMsds - m153 Base - Sds10828cmkohОценок пока нет

- SDS - Crosstrans 206 - 0Документ6 страницSDS - Crosstrans 206 - 0omidОценок пока нет

- MSDS New CAUSTIC SODAДокумент6 страницMSDS New CAUSTIC SODAAlves EdattukaranОценок пока нет

- MSDS Lube OilДокумент4 страницыMSDS Lube OilMohamed Sayed AbdoОценок пока нет

- MSDS DR-665.02Документ5 страницMSDS DR-665.02I Gede AnggaОценок пока нет

- Poly Ultra Nails Construction Adhesive-Aus SdsДокумент7 страницPoly Ultra Nails Construction Adhesive-Aus SdsGavin PintoОценок пока нет

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingДокумент4 страницыSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthОценок пока нет

- Shutter Oil MSDSДокумент5 страницShutter Oil MSDSMohammad Aquil BegОценок пока нет

- SDS - Fenomastic Emulsion Primer - English (Uk) - Dubai PDFДокумент4 страницыSDS - Fenomastic Emulsion Primer - English (Uk) - Dubai PDFBОценок пока нет

- Msds - m339 Aggregate - Sds11062Документ4 страницыMsds - m339 Aggregate - Sds11062cmkohОценок пока нет

- 110006castrol EDGE 5W-30Документ6 страниц110006castrol EDGE 5W-30amiller1987Оценок пока нет

- Sds Castrol Grease LM 2 BiДокумент4 страницыSds Castrol Grease LM 2 BiengturcompОценок пока нет

- Workplace Vocabulary for Esl Students: With Exercises and TestsОт EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsОценок пока нет

- Site PlanningДокумент18 страницSite PlanningMary Mae Jeremias100% (2)

- IsmДокумент1 страницаIsmLam-ang MagitingОценок пока нет

- Planning Notes 1Документ36 страницPlanning Notes 1Nerinel CoronadoОценок пока нет

- Site PlanningДокумент51 страницаSite PlanningNerinel CoronadoОценок пока нет

- Structural Notes NewДокумент5 страницStructural Notes NewArki Tekture100% (1)

- Mixed Questions With Some AnswersДокумент5 страницMixed Questions With Some AnswersBrian Risma ObedencioОценок пока нет

- Guidelines for Planning and Designing HospitalsДокумент6 страницGuidelines for Planning and Designing HospitalsDeven Garcia86% (7)

- Definition of TermsДокумент2 страницыDefinition of TermsAndreamarie BringasОценок пока нет

- Ancient Egyptian Pyramids and ArchitectureДокумент28 страницAncient Egyptian Pyramids and ArchitectureJun de OcampoОценок пока нет

- Modern ArchitectureДокумент13 страницModern ArchitecturercdpreludeОценок пока нет

- Handbook on Water Supply and Drainage with Emphasis on PlumbingДокумент181 страницаHandbook on Water Supply and Drainage with Emphasis on PlumbingHolly Hart91% (11)

- Arki ReviewerДокумент17 страницArki ReviewerCarlo Emozero IbuyanОценок пока нет

- Essentials Skills Manual Plumber PDFДокумент264 страницыEssentials Skills Manual Plumber PDFNerinel CoronadoОценок пока нет

- Plumbing Abbreviations, Definitions and SymbolsДокумент15 страницPlumbing Abbreviations, Definitions and SymbolsWahib Tannoury100% (1)

- Fastening MaterialsДокумент4 страницыFastening MaterialsArki TektureОценок пока нет

- UtilitiesДокумент1 страницаUtilitiesKali SarzonaОценок пока нет

- Partial AIRPORT ModelДокумент1 страницаPartial AIRPORT ModelNerinel CoronadoОценок пока нет

- Auditorium Acoustics 101: The Quieter, the BetterДокумент8 страницAuditorium Acoustics 101: The Quieter, the BetterCharles NukesevenОценок пока нет

- Planning 2 HW 8Документ9 страницPlanning 2 HW 8Nerinel CoronadoОценок пока нет

- BT ReviewerДокумент5 страницBT ReviewerNerinel Coronado0% (1)

- RA 9514 SSC Presentation Rule 10Документ154 страницыRA 9514 SSC Presentation Rule 10GabrielGalpoSolano100% (4)

- PRC Requirements For Master Plumbers ExamДокумент2 страницыPRC Requirements For Master Plumbers ExamDick Anthony Mabao86% (22)

- Arch QaДокумент56 страницArch QaNerinel CoronadoОценок пока нет

- Planning 2 HW 3Документ2 страницыPlanning 2 HW 3Nerinel CoronadoОценок пока нет

- Planning 2 HW 12Документ8 страницPlanning 2 HW 12Nerinel CoronadoОценок пока нет

- Planning 2 HW 6Документ10 страницPlanning 2 HW 6Nerinel CoronadoОценок пока нет

- Planning2 HW 1Документ2 страницыPlanning2 HW 1Nerinel CoronadoОценок пока нет

- Street Addressing SystemДокумент2 страницыStreet Addressing SystemNerinel CoronadoОценок пока нет

- Planning 2 HW 3Документ2 страницыPlanning 2 HW 3Nerinel CoronadoОценок пока нет

- Street Addressing SystemДокумент2 страницыStreet Addressing SystemNerinel CoronadoОценок пока нет

- Numerical Methods Chapter 10 SummaryДокумент8 страницNumerical Methods Chapter 10 SummarynedumpillilОценок пока нет

- FR Post-10Документ25 страницFR Post-10kulich545Оценок пока нет

- Agricultural Engineering Comprehensive Board Exam Reviewer: Agricultural Processing, Structures, and Allied SubjectsДокумент84 страницыAgricultural Engineering Comprehensive Board Exam Reviewer: Agricultural Processing, Structures, and Allied SubjectsRachel vОценок пока нет

- RACI Matrix: Phase 1 - Initiaton/Set UpДокумент3 страницыRACI Matrix: Phase 1 - Initiaton/Set UpHarshpreet BhatiaОценок пока нет

- Ensayo Bim - Jaime Alejandro Martinez Uribe PDFДокумент3 страницыEnsayo Bim - Jaime Alejandro Martinez Uribe PDFAlejandro MartinezОценок пока нет

- Electronics Project Automatic Bike Controller Using Infrared RaysДокумент16 страницElectronics Project Automatic Bike Controller Using Infrared RaysragajeevaОценок пока нет

- John Hay People's Alternative Coalition Vs Lim - 119775 - October 24, 2003 - JДокумент12 страницJohn Hay People's Alternative Coalition Vs Lim - 119775 - October 24, 2003 - JFrances Ann TevesОценок пока нет

- International Certificate in WealthДокумент388 страницInternational Certificate in Wealthabhishek210585100% (2)

- AATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsДокумент3 страницыAATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsAdrian CОценок пока нет

- Logic and Set Theory PropositionДокумент3 страницыLogic and Set Theory PropositionVince OjedaОценок пока нет

- Table of Specification for Pig Farming SkillsДокумент7 страницTable of Specification for Pig Farming SkillsYeng YengОценок пока нет

- PROF ED 10-ACTIVITY #1 (Chapter 1)Документ4 страницыPROF ED 10-ACTIVITY #1 (Chapter 1)Nizelle Arevalo100% (1)

- Nokia MMS Java Library v1.1Документ14 страницNokia MMS Java Library v1.1nadrian1153848Оценок пока нет

- Pom Final On Rice MillДокумент21 страницаPom Final On Rice MillKashif AliОценок пока нет

- C6030 BrochureДокумент2 страницыC6030 Brochureibraheem aboyadakОценок пока нет

- Difference Between Mark Up and MarginДокумент2 страницыDifference Between Mark Up and MarginIan VinoyaОценок пока нет

- Sysmex Xs-800i1000i Instructions For Use User's ManualДокумент210 страницSysmex Xs-800i1000i Instructions For Use User's ManualSean Chen67% (6)

- Artist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheДокумент2 страницыArtist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheUy YuiОценок пока нет

- Break Even AnalysisДокумент4 страницыBreak Even Analysiscyper zoonОценок пока нет

- Skuld List of CorrespondentДокумент351 страницаSkuld List of CorrespondentKASHANОценок пока нет

- Marine Engineering 1921Документ908 страницMarine Engineering 1921Samuel Sneddon-Nelmes0% (1)

- The Impact of School Facilities On The Learning EnvironmentДокумент174 страницыThe Impact of School Facilities On The Learning EnvironmentEnrry Sebastian71% (31)

- Prof Ram Charan Awards Brochure2020 PDFДокумент5 страницProf Ram Charan Awards Brochure2020 PDFSubindu HalderОценок пока нет

- Astera Data Integration BootcampДокумент4 страницыAstera Data Integration BootcampTalha MehtabОценок пока нет

- Level 3 Repair PBA Parts LayoutДокумент32 страницыLevel 3 Repair PBA Parts LayoutabivecueОценок пока нет

- 15142800Документ16 страниц15142800Sanjeev PradhanОценок пока нет

- EIN CP 575 - 2Документ2 страницыEIN CP 575 - 2minhdang03062017Оценок пока нет

- 08 Sepam - Understand Sepam Control LogicДокумент20 страниц08 Sepam - Understand Sepam Control LogicThức Võ100% (1)

- Mtle - Hema 1Документ50 страницMtle - Hema 1Leogene Earl FranciaОценок пока нет

- Polyol polyether+NCO Isupur PDFДокумент27 страницPolyol polyether+NCO Isupur PDFswapon kumar shillОценок пока нет