Академический Документы

Профессиональный Документы

Культура Документы

Design Chart

Загружено:

gendadeyu552625Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design Chart

Загружено:

gendadeyu552625Авторское право:

Доступные форматы

Appendix IX.

SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P1

CORCON

Design, Construction and Technical Information Manual

SIMPLE DESIGN CHART & SAMPLE CALCULATIONS

INDEX

DESIGN CONSIDERATIONS

P2

SIMPLE DESIGN LOAD AND SPAN CHARTS FOR CORCON

P3

SAMPLE CALCULATION

P6

BEAM DESIGN P15

REFERENCE FIGURES FOR DESIGN

P24

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P2

CORCON

Design, Construction and Technical Information Manual

DESIGN CONSIDERATIONS

CORCON

is a hybrid moltiribbed slab +beam system using the best properties of a slab

coupled with all the advantages of the beam used to stiffen the slab in deflection.

CORCON

is a flexible system that can be applied to any span and loading

configuration by the use of inserts which can be used to vary the depth of the CORCON

rib beams - from a nominal 50 m

2

depression to 300 m

2

deep for extra heavy loads and or

long Spam over 8 to 9m. Also by reducing the (c to c) centre to centre spacing from 1200

m

2

and continuity the spam can be increased to 26m using post-tensioning.

Small spans - say 3m- use CORCON

with "FLAT" insert mould (see the Figure below):

If require structural primary beams could always use upstand beams subject to

requirements. (see the Figure below):

This upstand systems allows continuous layting of CORCON

ribs.

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P3

CORCON

Design, Construction and Technical Information Manual

SIMPLE DESIGN LOAD AND SPAN CHARTS FOR CORCON

Beams @ 1200 Centres

Single Span

Allowable superimposed live load (KPa)

C to C spans metres

Beam

Depth

d mm

Reqd

bar

size

overla

p

Avg

Conc

.

vol

m3/

m2*

Total

depth

mm

4.0 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 10.0 11.0 14.0

50 2Y12 0.12 184 3

75 2Y12 0.12 209 5 .5^

100 2Y12 0.12 234 5 1.5

150 2Y12 0.12 284 5 2.5 1

200 2Y12 0.12 334 4 4 2 1^

250 2Y16 0.13 384 5 5 3.5 2 0.3 3**

300 2Y16 0,14 414 5 5 4 2 1^ 5** 3** 2***

1.5 hour fire rating, stc 49, min cover 85mm,

f62 mesh top & 1/250 deflection

* based on 20m2 room

^ roof loads

** post tensioned

*** continuous post tensioned built in primary beam

Single Span

Allowable superimposed live load (KPa)

C to C spans metres

Beam

Depth

d mm

Reqd

bar

size

overlap

Avg

Conc.

vol

m3/m2*

Total

depth

mm

3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5

50 2Y12 0.10 164 5 5 3 1 1

100 2Y12 0.10 214 5 4.5 2.5 .05

150 2Y12 0.10 264 5 3.5 1.5

200 2Y12 0.11 314 4 2 1

250 2Y16 0.11 364 5 5 4 2 1.5 0.5

300 2Y16 0.12 414 5 5 5 3.5 2 1

0.5-hour fire rating, min cover 65mm,

f62 mesh top & 1/250 deflection

* based on 20m2 room

^ roof loads

Continuous Span

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P4

CORCON

Design, Construction and Technical Information Manual

Allowable superimposed live load (KPa) and

deflection to span ratio.

C to C spans metres

Beam

Depth

d mm

Reqd

bar

size

overlap

Avg

Conc.

vol

m3/m2*

Total

depth

mm

5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5

10.

0

10.

5

11.

0

50 2Y12 0.12* 184

2

1/2

70

75 2Y12 0.12* 209

2

1/2

75

100 2Y12 0.12* 234

2

1/3

00

150 2Y12 0.12* 284

2

1/2

75

200 2Y12 0.13* 334

2

1/2

75

250 2Y16 0.13* 384

2

1/3

50

2

1/3

00

300 2Y16 0.13* 434

2

1/3

50

2

1/3

00

2

1/2

50

1.5 hour fire rating, stc 49, min cover 85mm,

f62 mesh & y16 @ 1200mm top

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P5

CORCON

Design, Construction and Technical Information Manual

SELECTED SECTION PROPERTIES

b = 110mm

B = 155Mm

D = 485mm

d = 300mm

Fck = 30N/mm2

Fy = 460N/mm2

Conc. Cover = 25mm

Rib Spacing = 900mm

Cross sectional Area = 177954.57mm

2

Moment of Inertia Ixx = 2468.22E6 mm

4

Reinforcement at Mid-Span = 2 * T16 mm Dia.

Reinforcement at Supports = 3 T 12mm Dia.

Moment Capacity at Mid Span = 69.08KN-m

Section Capacity at Support = 81.03

Actual Deflection = 1.14mm

Shear Capacity = 0.86N/Sq.mm

Shear Reinforcement = Please check CORCON test Results.

Concrete Volume per Sq.m of Plan Area = 0.15Cub.m

Reinforcement per Sq.m of Plan Area = 0.26Kg

B

d

D

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P6

CORCON

Design, Construction and Technical Information Manual

SAMPLE CALCULATION

PROJECT

The Sukhothai Bangkok

JOB REF

DECOIN PTY LTD

ACN 008 625 590

ABN 30 008 625 590

CALCULATION BY

Upul Perera

CHECKED

BY

CALC SHEET

PART OF

STRUCTURE

PRINTED BY

Decoin Pty Ltd

DATE

09/02/2003

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P7

CORCON

Design, Construction and Technical Information Manual

MEMBER

REF

LOAD CALCULATIONS

Loading (Guest Room Area)

(A) Rib Self weight = 3.36

kN/m

2

Screed + Finishes = 1.177

kN/m

2

Services = 0.225

kN/m

2

Ceilings = 0.225

kN/m

2

Partitions =

421 . 8

434 . 3

kN/m

2

- DL

Imposed Lead 1.962

kN/m

2

- LL

n= 14.93 kN/m

2

(ult)

Udl for Ribs DL = 8.421 x 1.2 = 10.1 kN/m

LL = 1.962 x 1.2 = 2.4 kN/m

(B) Plant Room Area

Rib Self wt. = 3.36

Screed = 1.1772

Services =

7622 . 4

225 . 0

kN/m2

- DL

Live Leads = 7.35 8

kN/m

2

- LL

N= 18.439 kN/m

2

(ULT)

Udl for Ribs DL = 5.715 kN/m

LL = 8.829 kN/m

(C ) Storage Room,

Rib self wt. = 3.36 kN/m

2

Screed = 1.177

Services =

7622 . 4

225 . 0

-

kN/m

2

- DL

Imposed Load 4.905 -

kN/m

2

- LL

OUT PUT

R

e

f

e

r

e

n

c

e

s

t

o

B

S

8

1

1

0

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P8

CORCON

Design, Construction and Technical Information Manual

UDL for Ribs, DL = 5.715 kN/m

LL = 5.886 kN/m

MEMBER

REF

Specimen Calculation

Loading for [live load of 300 kg/m2 Area]

Ribbed slab self wt = 0.14 x 24 = 3.36 kN/m2

Screed = 1.18

Services = 0.225

Ceilings = 0.225

4.99 kN/m

2

DL

Live Load = 2.943 kN/m

2

-

LL

Design Ultimate Load n = 4.99 x 1.4 + 2.943

x 1.6

= 11.69 kN/m

2

Uniformly Distributed Load on a Rib

DL = 1.2 x 4.99 = 5.88 kN/m

LL = 1.2 x 2.943 = 3.53 kN/m (service load)

Three load combinations were considered. Please refer

Prokon print out sheets #01 to #03.

The rib beam is designed for max. sagging and hogging

moment for each span, considering BM and SF envelopes.

OUT PUT

MEMBER

REF

BS8110

Cl 3.3.4

CALCULATIONS

A. Durability and Fire Resistance of Rib Slab

Exposure conditions: It is assumed that these rib beams are

used in areas where the concrete surfaces are protected

OUT PUT

R

e

f

e

r

e

n

c

e

s

t

o

B

S

8

1

1

0

Y20 Y20

Area=140561 mm

2

= 0.14 m

2

66

125

400

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P9

CORCON

Design, Construction and Technical Information Manual

BS8110

Table 3.4

BS 8110

Table 3.5

BS 8110

Fig. 3.2

against weather or aggressive conditions.

Therefore treat as mild Exposure Conditions.

For Grade 30 Concrete (30 Mpa) the Nominal cover

requirement is as 25 mm, for Durability requirement,

Note: Above cover requirement is including links

Nominal cover for Ribbed slab for : -

01 hr. Fire Period = 20 mm

02 hr. Fire Period = 35 mm for continuous beams

45 mm for Simply Supported beams

use 35 mm cover for bottom bars

Minimum member Dimensions regeared for Ribbed

beams, is 125 mm and Slab thickness of 95 mm for 1 hr

fire rating?

Same for 2-hr fire rating is 125 mm ribs & 125 mm slab

thickness.

MEMBER

REF

BS 8110

Cl.3.4.4.4

CALCULATIONS

Design for bending.

Max

M

+ re moment in the span = 71.1 kNm.

Effective Depth (d) = 400 (35+6+15) = 344 mm

OUT PUT

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P10

CORCON

Design, Construction and Technical Information Manual

BS 8110

Table 3.27

K= =

cu

f bd

M

2

30 344 1179

10 1 . 71

2

6

=0.017 < k = 0.156

Hence Compression R/F is not required.

Z=d [0.5 + |

.

|

\

|

9 . 0

25 . 0

k

] < 0.95d

=344 x [0.5+ |

.

|

\

|

9 . 0

017 . 0

25 . 0 ]

=344 x 0.98 >0.95d

Z=0.95d=0.95x344=327mm

Depth to Neutral axis x = (d-z)/0.45

=(344-327)/0.45

=37.8mm <100mm min. flange thickness

Hence, Neutral airs is within flange thickness.

area of tension R/F,

As = =

fyz

M

87 . 0

2

6

555

327 450 87 . 0

10 1 . 71

mm =

( )

h b

As

w

min

100

=0.18 for 4 . 0 08 . 0

1179

5 . 95

< = =

b

b

w

(As)

min

=

2 2

555 7 . 68

100

400 5 . 95 18 . 0

mm mm < <

Minimum Steel requirement is satisfactory.

As =555 mm

2

MEMBER

REF

CALCULATIONS

Max

m

Support (at 1

st

intention Support) = -63 kNm

Effective depth to tension R/F; d=400-

(25+6+25+20/2)=334mm

Effective depth to compression R/F; d=35+6+15=

56mm

OUT PUT

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P11

CORCON

Design, Construction and Technical Information Manual

BS 8110

Table 327

M/bd

2

f

cu

=

30 334 66

10 63

2

6

= 0.285 > k=0.156

Compression Steel is required.

Z=d [0.5 +

|

.

|

\

|

9 . 0

'

25 . 0

k

]

= 334[0.5 + |

.

|

\

|

9 . 0

156 . 0

25 . 0 ]

= 334 x 0.776

= 259 mm

x= (d-z)/0.45 = (384-259) / 0.45 = 166.6 mm

Area of compression Reinforcements:

A'

s

=(k-k') f

cu

bd

2

/0.87 f

y

(d-d')

=

( )

( ) 56 334 450 87 . 0

334 66 30 156 . 0 285 . 0

2

=261.8 mm

2

Area of tension R/F : A

s

= k' f

cu

bd

2

/ 0.87f

y

z +A'

s

A

s

=

259 450 87 . 0

334 66 30 156 . 0

2

+261.8 = 601.6 mm

2

minimum tension R/F

h b

As

w

. min

100

=0.26

A

smin.

=

100

400 5 . 95 26 . 0

= 99.3 mm

2

<601.6 mm

2

minimum steel requirement is satisfactory.

Compression steel

area at support

A'

s

= 261.8 mm

2

Tension steel area

at support

A

s

= 601.6mm

2

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P12

CORCON

Design, Construction and Technical Information Manual

MEMBER

REF

BS 8110

Table 3.9

Or from

equation:

BS 8110

Table 3.8

BS 8110

cl.3.4.56

Table 3.8

CALCULATIONS

Check for Shear

Max

m.

shear force at 1

st

interior support = 60.6 kN,

Take Max

m

shear force at d away from face of the

support:

V=54.8 kN

Tension Steel provided 2 Y 20 (628 mm

2

)

bd

As 100

=

334 5 . 95

628 100

=1.968 v =

334 5 . 95

10 8 . 54

3

=1.718 N/

mm

2

Design concrete shear stress v

c

v

c

= 0.79

3

1

100

|

.

|

\

|

bvd

As

4

1

400

|

.

|

\

|

d

/

m

3

1

25

|

.

|

\

|

cu

f

= 0.79

3

1

628 100

|

.

|

\

|

bvd

4

1

25 . 1

334 / 400

|

.

|

\

|

3

1

25

30

|

.

|

\

|

v

c

= 0.79 1.250 |

.

|

\

|

25 . 1

046 . 1

1.0625 = 0.878 N/ mm

2

A

sv

>b

v

s

v

(v-v

c

) / 0.87 f

yv

s

v

s

( )

c v

sv yv

v v b

A f

87 . 0

s

( )

( ) 898 . 0 718 . 1 5 . 95

2 3 . 28 250 87 . 0

s

v

s153mm provide R6-150 c/c

max shear link spacing 0.75d= 0.75 x 334 = 250 mm

minimum link requirement A

sv

> 0.4 b

v

s

v

/ 0.87 f

yv

s

v

s

v

sv yv

b

A f

4 . 0

87 . 0

s

( )

5 . 95 4 . 0

2 3 . 28 250 87 . 0

= 322 mm

OUT PUT

Provide Shear links

at 1

st

interior

support

R6-150 mm c/c.

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P13

CORCON

Design, Construction and Technical Information Manual

provide nominal links @ R6 -225 c/c

Provide Nominal

links R6-225 mm

c/c.

MEMBER

REF

Ref. BS 8110

Table 3.10

CALCULATIONS

Check for Deflection, (250mm Rib -n = 11.69kN/m

2

|

.

|

\

|

b

b

w

= |

.

|

\

|

1179

5 . 95

= 0.081

basic span/Depth ratio = 16.76 (Value between simply

supported & continuous)

f

s

=

b sprov

req s

y

A

A

f

1

8

5

.

.

= 1

629

538

450

8

5

= 240 N/

mm

2

M/bd

2

=

2

6

344 1179

10 1 . 71

= 0.509

Modification factor = 0.55 +

( )

0 . 2

9 . 0 120

477

2

s

|

.

|

\

|

+

bd

M

f

s

M.F. = 0.55 +

( )

( )

0 . 2 95 . 1

509 . 0 9 . 0 120

240 477

s =

+

Allowable span = 16.76 x 1.95 x 344 mm

=11,242 mm > actual span 7,258 mm

Hence: Deflection is satisfactory.

OUT PUT

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P14

CORCON

Design, Construction and Technical Information Manual

CHECK FOR DEFLECTION (BS8110)

DATA

Bending moment at mid span = 114 kNm (Ultimate)

Average web width (b

w

) = 95.5 mm

Effective Flange width (b) = 1179 mm

Effective depth at mid span (d) = 394 mm

Actual span of rib = 7525 mm

Strength of reinforcement (f

y

) = 450 N/mm

2

Area of steel required (As

req

.) = 778 mm

2

Area of steel provided (As

pro.)

= 805 mm

2

Moment redisribution ratio = 1

CALCULATIONS

Basic Span/Span Depth ratio = 16.76

The design service stress (f

s

) = 271.82 N/mm

2

Modification factor = 1.67 1.673

Allowable Span = 11,046 mm

Deflection is Satisfactory

Table 3.10 of BS8110

See the BS 8110- Table 3.10 Support Conditions

Rectangular

Sections

Flanged Beams with b

w

/b

<=0.3

Cantilever 7 5.6

b

w

/b = 0.1 Simply Supported 20 16

Continuous 26 20.8

Note: Linear Interpolation between values given above

can be used.

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P15

CORCON

Design, Construction and Technical Information Manual

BEAM DESIGN

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P16

CORCON

Design, Construction and Technical Information Manual

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P17

CORCON

Design, Construction and Technical Information Manual

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P18

CORCON

Design, Construction and Technical Information Manual

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P19

CORCON

Design, Construction and Technical Information Manual

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P20

CORCON

Design, Construction and Technical Information Manual

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P21

CORCON

Design, Construction and Technical Information Manual

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P22

CORCON

Design, Construction and Technical Information Manual

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P23

CORCON

Design, Construction and Technical Information Manual

Created with novaPDF Printer (www.novaPDF.com)

Appendix IX. SIMPLE DESIGN CHART & SAMPLE CALCULATIONS P24

CORCON

Design, Construction and Technical Information Manual

REFERENCE FIGURES FOR DESIGN

Created with novaPDF Printer (www.novaPDF.com)

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 18R 97Документ16 страниц18R 97Manoj Singh100% (4)

- Beam Deflection FormulaeДокумент2 страницыBeam Deflection Formulae7575757575100% (6)

- BambooДокумент52 страницыBamboohksmallray100% (2)

- Differentiating Project Management From Program ManagementДокумент3 страницыDifferentiating Project Management From Program ManagementMosab BakryОценок пока нет

- Organizational Behaviour & Change GuideДокумент19 страницOrganizational Behaviour & Change GuideSureshbabu SugumaranОценок пока нет

- 105508Документ56 страниц105508dox4printОценок пока нет

- JK Erectrors & FsbricatorsДокумент3 страницыJK Erectrors & FsbricatorskrmcharigdcОценок пока нет

- Epack Polymers (P) LTDДокумент20 страницEpack Polymers (P) LTDcharibackupОценок пока нет

- Kirby Building Systems India LTDДокумент5 страницKirby Building Systems India LTDdox4printОценок пока нет

- Wienerberger-NZEB - May 2011Документ7 страницWienerberger-NZEB - May 2011dox4printОценок пока нет

- Radiant Enterprises ProfileДокумент5 страницRadiant Enterprises Profiledox4printОценок пока нет

- Chakri PEBДокумент8 страницChakri PEBdox4printОценок пока нет

- Letter From RathakrishnanДокумент1 страницаLetter From Rathakrishnandox4printОценок пока нет

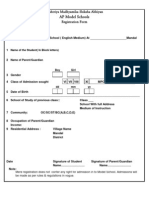

- AP Model Schools Registration FormДокумент1 страницаAP Model Schools Registration Formdox4printОценок пока нет

- Simplex Engineering&FOundary WorksДокумент9 страницSimplex Engineering&FOundary Worksdox4printОценок пока нет

- Brick Mesh and Corner Bead for Wall ConstructionДокумент1 страницаBrick Mesh and Corner Bead for Wall Constructiondox4printОценок пока нет

- TS For Civil WorkДокумент43 страницыTS For Civil WorkKinfe MehariОценок пока нет

- Navayuga Enterprises (Aerocon)Документ2 страницыNavayuga Enterprises (Aerocon)dox4printОценок пока нет

- L&T Buildings at FactoriesДокумент36 страницL&T Buildings at FactoriesSreekanth PSОценок пока нет

- News ViewsДокумент20 страницNews Viewsdox4printОценок пока нет

- MR K Ramakrishnan Managing Infrastruc Proj RiskДокумент22 страницыMR K Ramakrishnan Managing Infrastruc Proj Riskdox4printОценок пока нет

- 06 Weekly Progress Report For Jun ' 13Документ1 страница06 Weekly Progress Report For Jun ' 13dox4printОценок пока нет

- PW 371Документ150 страницPW 371Patrick SilberbauerОценок пока нет

- Gulf Opening2009 PDFДокумент6 страницGulf Opening2009 PDFAvijit DashОценок пока нет

- Ethical Governance in The Indian Construction Industry - A Case STДокумент19 страницEthical Governance in The Indian Construction Industry - A Case STdox4printОценок пока нет

- State Bank of India Bike Loan For Honda ActivaДокумент2 страницыState Bank of India Bike Loan For Honda Activadox4printОценок пока нет

- Mail Elevation A, B, C& D A0Документ1 страницаMail Elevation A, B, C& D A0dox4printОценок пока нет

- इंटरनेट मानक और जानकारी का अधिकारДокумент14 страницइंटरनेट मानक और जानकारी का अधिकारdox4printОценок пока нет

- ch13Документ13 страницch13asokan80Оценок пока нет

- Metal FormsДокумент6 страницMetal Formsdox4printОценок пока нет