Академический Документы

Профессиональный Документы

Культура Документы

ED 2002 125NexgenieBaseUnitNG16DLNG14RLInstallationManual

Загружено:

Amit ChaturvediАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ED 2002 125NexgenieBaseUnitNG16DLNG14RLInstallationManual

Загружено:

Amit ChaturvediАвторское право:

Доступные форматы

INSTALLATION MANUAL FOR Base Units

NG16DL, NG14RL

POWER SUPPLY CONNECTOR

PIN 1 PIN 2 PIN 3 24V+ DC 24V DC EARTH

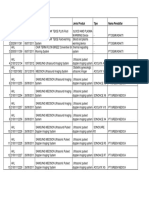

CONFIGURATIONS AVAILABLE

System options and ordering information for product and accessories (range offered). The VAW is the Visual Access Window recommended for effective use of the PLC BASE

Fig. 2

MESSUNG SYSTEMS - Headquarters :

Kohinoor House, EL-2, J- Block, MIDC, Bhosari, Pune - 411026. (INDIA)

AUTOMATION PEOPLE

INSTALLATION

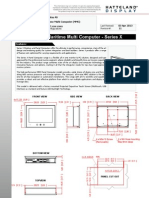

DIMENSION DETAILS

!

WARNING

The figure below shows base unit views from different side with dimensions.

58 118 1 mm 35 mm

This Installation Guide is intended to be used for installation of the Nexgenie series Programmable Logic Controllers (PLCs). It includes general Specifications, specific electrical specifications, installation, wiring and first level trouble shooting. For details refer the product catalog. The unit supply is DC. Utmost precaution is required to be taken to avoid connection of AC mains to the supply or any of the DC input or Output terminals. Connecting mains to supply may damage the unit permanently

With VAW NG16DL NG14RL EXPANSION NE14RX NE16DX NE08IX NE06RX NE08DX

Model Without VAW NG16DN NG14RN x x x x x

Digital Inputs / High Speed Counters 8DC inputs or 2 Enc/ 6 HSC, 4 inputs 20 KHz, 2 inputs 5 KHz Sink/Source Inputs

Outputs Transistor Relay 8 0 0 6 0 8 0 0 8 6 0 0 6 0

8 DC inputs Sink/Source Inputs 0 0

STANDARD ACCESSORIES AVAILABLE

S/N 1 2 3 4 5 6 7 8 9 10 Ordering Used for purpose Code Programming cable for the series :3meters 1910 PLC Programming and monitoring online Pre-wired Cable 300 mm 1911 For interfacing 3rd Party devices to Serial Ports Serial Link Cable with loose conductors 3 meters 1912 Description

1911 1912

This product does not contain any intentionally added mercury or cadmium .In case this product is required to be disposed off it should be done treating it as 'Industrial Waste' and disposed off adhering to all relevant local and national laws of the concerned country.

Fig. 4

97

The Relay wiring if on AC should be effectively isolated from DC wiring physically.

7.5 mm

OVERVIEW

Fig. 3

The Nexgenie series is another 'first' from the Messung stable of innovative small sized PLCs. An unbelievable amount of features and combinations have been made available in a compact and ergonomic unit This PLC doubles as a PLC with limited function Human Machine Interface (HMI) (optional) and has around 4 basic variants of base unit and 5 variants of expansion units .Up to 4 expansion units can be cascaded to add more I/Os to any base unit The base unit comprises of minimum 14 I/Os and can be expanded up to 80 I/Os The PLC can be mounted on a standard DIN rail (35 mm x 7.5mm). Programming is achieved with the internationally acclaimed CoDeSys software that is compliant to the requirements of the PLC 'product standard' IEC/EN 61131-3. Users conversant with any of the following languages: Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL) and Sequential Function Charts (SFC), Continuous Function Charts (CFCs) can comfortably program this PLC.

The figure 4 above shows recommended standard DIN rails TS 35 / 7.5 mm and figure 5 below shows back side view of base unit along with DIN clip.

MOUNTING

To mount the PLC on the DIN rail, 1) the DIN clip is to be pulled downwards till it clicks, 2) then the PLC is hooked on the rail and pressed down on the rail 3) and the DIN clip to be pushed upwards again till it clicks The unit will clamp on the rail with only slight horizontal slide movement. To prevent horizontal dislocation in transit or in anticipated vibration in the installation, the DIN rail mounted units may be locked in place using end clamps on either side. Recommended types: - ELMEX: SCKU / SCUN or CONNECTWELL: CA702/802/202 or WAGO 249-116/117

HOOKS on PLC

The DIN Rail

Memory Cassette 256 KB Programming Software CoDeSys Power supply connector 3 Pin I/O connector 10pin screw type 9 pin D connector shell 20 meter Expansion Kit Terminator Plug

9904 9920 1951 1952 1953 1954 1955

Transport and download PLC projects PLC programming and documentation For 24V supply connection to PLC For I/O wiring connection Will be available soon Will be available soon A mandatory termination network

DIN CLIP

5

Fig. 5

SPECIFICATIONS OF CPU SECTION

NG16D(L/N), NG14R(L/N) 0.3 s for Bool instruction, 0.3 s for Word instruction 128 K bytes flash 1MB flash, Can store project file with symbolic names, comments, visualization screens 4 K bytes 24 K bytes Stored in FRAM, battery free operation 300 bytes of marker memory (%MB3700 to %MB3999) and 700 bytes of data memory as per user choice Unlimited (limited only by program and data memory), With resolution of 1ms Can be declared as retentive selectively. Unlimited (limited only by program and data memory) Can be declared as retentive selectively Available for application program back up and transport User can transfer application program to CPU through serial Port1 without any need of programming software 14 (can be expanded up to 80) 6, 4 inputs (I0.0, I0.1, I0.3 and I0.4) with 20 KHz max; 2 inputs (I0.2 and I0.5) with 5 KHz max 2, 10 KHz max. With 1 s resolution, Configurable for all high speed inputs individually Sum of frequencies for all enabled channels, for "Time Period" measurement shall not exceed 10KHz. Whereas sum of frequencies for all enabled channels, for "Pulse ON Time" measurement shall not exceed 5KHz. Built-in, backed up by super capacitor for duration of 2 weeks nominal 2, Both ports support open protocol Port1: RS232/ 485/ Modem interface Port2: RS232/422/485 / Modem interface Buit-in: Nexgen Slave and Modbus RTU Slave 2", 128 X 64 graphics LCD with white backlit, 4 system keys for parameter settings and display navigation. Back light life is 10,000 hours. 64 user messages, Useful for monitoring and setting PLC data, monitoring machine status and alarm messages Software FB, unlimited loops (limited only by program and data memory) IEC 61131-3 compatible programming software CoDeSys ver. 2.3.9.13 onwards 6 : Ladder Diagram (LD), Function Block Diagram (FBD), Sequential Function Chart (SFC), Continuous Function Chart (CFC), Instruction List (IL), Structured Text (ST) Off line simulation, Single cycle mode, Break point, Data flow, Sampling trace, Visualization, Watch and receipt Remote programming and online monitoring possible via Modem, LAN

GENERAL SPECIFICATIONS OF THE SERIES

Power Supply Protection Overcurrent Reverse Polarity Noise Immunity As required by EN 61131-2 24V DC (18 to 30 V ripple included) at 85 mA: 2 W nominal. Fuse : Common for base and expansions 630 mA Type 372 Littlefuse. Protected by series diode up to 40V Electro Static Discharge (ESD) (IEC 61000-4-2) : 8KV Air Discharge 4KV contact. Electrical Fast Transient (EFT) (IEC 61000-4-4) : Power Line: 2KV, Digital I/O : 1KV, Analog & Communication I/O : 1KV Radiation Susceptibility (RS)(IEC 61000-4-3) : 80MHz~2.7GHz, 10V/m to 1V/m 5 C to 55 C 10 to 95 % RH non condensing , pollution degree 2 As required by EN 61131-2.IEC 60068-2-6 (test Fc), IEC 60068-2-27 test Ea Open type , to be used inside protective panels IP 20 CoDeSys Software compliant to IEC / EN 61131-3 Base Unit -118 x 97 x 58 mm. Height is 102 mm inclusive of DIN clip Clamps on to Standard TS 35 DIN rail 0.5 mm square copper, single or multi strand For 0.5 mm square, insertion length 8 mm; Jainson Type 58-508-L8 or equivalent Flat blade screwdriver 1.5 mm wide such as Taparia 933 Base unit: 300 grams, Expansion unit: 175 grams nominal CE

Nexgenie CPU speed Application program memory Source code memory Marker memory Data memory Retained memory

To remove unit from the rail the reverse of process given above is to be followed.

RECOMMENDATIONS

The PLC assembly is required to be panel mounted taking care of the following points Only horizontal mounting is permitted. Vertical or suspended from panel roof or floor mounting is not allowed for thermal considerations. The required clearances around the unit are given in figure 6 below. A 50 mm clearance is also required on the front side of the unit.

on Ceiling D

O O O O

Operating Temperature Humidity Vibration, Shock Class of equipment IP Protection Programming Software Dimensions (W x H x D) Mounting Recommended I/O wires Termination lugs for I/O wiring Suggested tool for I/O wiring Weight Approvals

Number of Timers Number of counters Memory cassette (Optional) (Ordering code 9904)

D D

I/O points High speed counter inputs

Horizontal Vertical on Floor Fig. 6

D = 50 mm

Encoder ABZ interface Time duration measurement

1. 2. 3.

In case of small sized panels care shall be taken to keep more clearances on right side so as to facilitate proper viewing of the label on the underside of the flap. The unit is designed as an 'open type unit' which requires it to be installed in a suitable panel protecting from heat, dust and water. If only base unit (without any expansion unit) is installed, ensure that the terminator plug is fitted on expansion connector on its right side. The expansion units should be connected to the base unit in tandem with the supplied flat cables. It is necessary to remove terminator plug from Base unit and fix it on the last unit on its right side. This is mandatory for system operation. In case of possible vibrations/shocks to the panels in use, the unit shall be required to be protected from sliding movement in the rail by use of clamps from both sides of the unit to avoid dislocation of wires and connectors causing malfunction. Real Time Clock (RTC) Serial ports

NOMENCLATURE

LCD of VAW (optional) CPU Status Indicators System keys of VAW (optional) I/O terminal block flap with wiring label (removed )

4.

Terminator plug

Removable I/O terminal blocks Flap Fuse protection I/O status LEDs 24 VDC power connector (3 pin removable) Two Serial port connectors P1 & P2 (9 pin D male connectors) DIN Clip Fig. 1 Connector for expansion unit (bottom side) or terminator plug interface I/O terminal block ejector

5.

Serial protocol FBs Visual Access Window (VAW) (optional )

Fig. 7

6.

For performance that is least susceptible to external EMI the low voltage and high voltage noise prone wires should be physically isolated and laid out separately in the panel. In cases where crossing is found to be inevitable the cables should cross at right angles to avoid cross talk. A strip of paper of width 50mm or so is recommended to be wrapped around the unit sides during installation and wiring to avoid small pieces of wire ends or strands or washers or drilling burr et cetera from falling into the unit and getting trapped on boards causing severe damage mechanical or electrical shorts in the miniature electronic components on the boards. The paper should be removed without fail before putting the system in use Individual connector wires may be dressed to leave the unit from top and bottom sides so as to give natural isolation between input and output sides or clubbed together to leave from one side of unit.

PID Programming software Programming languages

7.

8.

Diagnostics, debugging and online monitoring features Remote programming

SERIAL PORT CONNECTIONS

5 4 3 2 1

9 8 7 6

9 pin D male connector solder side view

1 2 3 4 5 6 7 8 9

PORT P1 terminations Carrier Detect RS232C RxD (RS232C) TxD (RS232C) VCC+ (+ 5V) GND TR Select D- (RS485) Reserved D+ (RS485)

1 2 3 4 5 6 7 8 9

PORT P2 terminations Carrier Detect (RS232C) RxD (RS232C) TxD (RS232C) TX+ (RS422) GND TR Select TX- (RS422) RX- (RS422) RX+ (RS422)

The figure shows the connection details for transistor output

Q 00 Q 01 CURRENT Load Load

FAULT FINDING

= Power ON R = PLC in RUN mode C IO M S = = = = CPU error I/O error Memory error Power supply improper/super capacitor discharged

First level fault finding can be read from the status of the LEDs positioned above the Visual Access Window (VAW)

Q 06 Q 07 V G

Load Load 24 V+

Connection details as shown are provided on the back side of the connector cover

SPECIFICATIONS OF DIGITAL INPUTS

8, 2 groups of 4 inputs each 24VDC (18 to 30V including ripple) ON voltage:18 V DC minimum; OFF voltage: 5 VDC maximum 7mA max at 24 V DC 1.5 mA max 3.9 K Sink or source. All inputs in one group to be in same mode Optical 1.5 KV between input and internal bus, 1.5KV between groups, Nil: between input points in a group Permitted external cable length Maximum 100 meters nominal Recommended wire specifications 0.5 mm sq. max single / multi-strand Method of termination Removable screw type 10 pin terminal block Transition delay: Digital filter 7ms to 14 ms Status Indicator Independent green LED per point Special Supplementary functions of Inputs Single phase counters Quadrature encoders 6 input points, 20 KHz for inputs I0.0, I0.1, I0.3 and I0.4, 5 KHz for inputs I0.2 and I0.5 2 channels, ABZ inputs, 10 KHz max Number of Inputs Voltage rating ON / OFF voltage Current rating OFF current Input impedance Mode Isolation

Number of outputs Voltage rating Type of output / Device LED indication for output Contact rating (Resistive load) Response time Minimum load Contact life Isolation Connection Voltage Current Type of load Resistive Inductive Resistive Inductive

6; grouped as 2+2+2 24 to 250 VAC, 47-53 Hz , 30 VDC max Non latching normally open (NO) contact / Electro- mechanical relay Red LED for individual output 500 mA at 250 VAC and 20 VDC, 1 Amp max current through common terminals OFF to ON: 10 ms, ON to OFF: 5 ms 1 mA Electrical life : Refer below, Mechanical life : 20,000,000 (180 cpm) Galvanic 10-pin removable screw type terminal blocks Electrical life (20 cpm) 5,00,000 30,000 10,00,000 80,000 Voltage 30 VDC Current 1 Amp 500 mA Type of load Resistive Inductive Resistive Inductive Electrical life (20 cpm) 6,00,000 1,50,000 10,00,000 3,80,000

Power Supply

User can select terminator resistor in RS485 network, by connecting pin 6 (TR selection) and pin 7 (D-RS485) together on D connector whenever required. Powering any external devices using VCC is not recommended.

For RS485 interface, Data+line is formed by connecting pin 4 (Tx+) and pin 9 (Rx+) together. Data- line is formed by connecting pin 7 (Tx-) and pin 8 (Rx-) together. User can select terminating resistor in RS485 network, by connecting pin 6 (TR selection) and pin 7 (Tx-RS422) together whenever required.

Transistor (DC) Output

Load Supply Fig. 9

Problem

RELAY OUTPUTS

Observation on LEDs R C IO M S

Probable cause No power incoming Fuse Blown (if supply is present)

Suggested Action Check for proper 24V on power connector of PLC (pins 1 and 2 in figure 2 ) Replace fuse after checking cause of blowing (like Wrong supply, excessive supply) Get Supply voltage corrected Put PLC in RUN Mode through CoDeSys. Download application program through backup cassette or CoDeSys and put PLC in RUN Mode

Application

Supply 24V is below 18V PLC in "STOP MODE" Application program invalid

PC to PLC down/Upload problem

x x

Operator is forcing I / Q / M Remove force condition through CoDeSys. Communication problem Check loose connection, downloading cable , PC while downloading the port and application project. program RTC data corrupted or Invalid due to longer power OFF Set RTC using VAW or HMI or CoDeSys and keep the PLC powered ON for at least 30 minutes to charge the capacitor Try cycling the power or Contact Service * a) Terminator plug missing or Lose : Fix it b) Check expansion module cable for probable loose connection. C) If "E" LED on any expansion module is ON then this module / cable may be faulty. Try replacing it. d) If any unwanted expansion module/s are connected at power-on and later on removed, then restart the PLC power. Check for proper sensor operation and its wiring. Correct / set as necessary

250 VAC 1 Amp 500 mA

CPU

Local IO

x CPU hardware Problem IO module error

The figure below shows the connection details for relay outputs. Output contacts are grouped as two output contacts with one separate common. So output contacts Q00 and Q01 are with one common C0. Output contacts Q02 and Q03 are with one common C1. Output contacts Q04 and Q04 are with one common C2. Connection details as below are provided on the back side of the connector cover

Fuses External C Load R

WIRING DETAILS

The figures below show how to interface field inputs like potential free push buttons and limit switches for sink and source operation. Either group can be wired for sink or source.

I 00 I 01 I 02 I 03 C0 Common() 24V+ Current Rb () +

PNP type proximity sensor

Q 00 Q 01 C0

Load Load RC snubbers for AC Loads Load Load

I 00 I 01 I 02 I 03

Rb

+ ()

Input LED does not light even though sensor is activated Input LED continuously ON and does not respond to sensor state change Output device not switched ON even though respective LED is ON

Input

Sensor or related wiring faulty Sensor actuation and adjustment disturbed

Q 02

NPN type proximity sensor

Q 03 C1 Q 04 Q 05 C2 RELAY Output

1N 4007 Load

C0 Common(+) Fig. 8

+24V Current

Load Load +

SINK MODE

SOURCE MODE

Output device or wiring faulty External freewheeling diode polarity is reversed or faulty. Fuse may faulty. Missing supply at Output common terminals Required logical conditions not satisfied. Real time setting erronous

Output

Check and correct as necessary. Check relevant supply at the "Q" terminals and respective load common. Use appropriate AC/DC voltage measuring tools. Ensure proper load supply.

OP LED is OFF

The figure shows how to interface PNP and NPN type of 3 wire proximity switches as an example in one of the inputs. In normal course where the proximity switch-off currents are below 1.5 mA the bleeder resistor would not be required. In case the off currents are greater that 1.5 ma typically the excess current would have to be bled through the bleeder resistor [Rb=Vin / (Ioff-1.5)] ( Rb in kilo-ohms Vin in Volts and Ioff in millamperes )

Free wheeling diodes for inductive loads on DC supply. Applicable for transistor output or relay output.

Fig. 10

Number of outputs Voltage rating Current rating Type of output LED indication for output ON voltage drop OFF voltage Response Time Inrush current Off state leakage current Protections

Isolation External power supply Connection

8 24 VDC (18 to 30 VDC including ripple ) 300 mA per output , 1.5 Amp max through common Upto 4 channel can be paralleled at a time MOSFET in Source mode Red LED for individual output 2 V DC maximum 1.5 V DC maximum OFF to ON 0.1 ms, ON to OFF 0.4 ms 600 mA for 700s duration 10 A maximum Reverse voltage Output short circuit protection Fast demagnetization for inductive loads 1.5 KV optical from internal bus 18 to 30 VDC including ripple for control circuit 10-pin removable screw type terminal block

Serial Port related

SPECIFICATIONS OF DIGITAL OUTPUTS TRANSISTOR OUTPUTS

GUIDELINES FOR USING RELAY OUTPUTS

External fuse links or fused terminals are recommended to be used for relay output wiring to avoid any burnout of internal tracks due to excessive current arising out of external short circuits, overloads or inductive surges. The life of relay contacts can be enhanced by the use of RC snubber (spark quenchers) across the AC load. A suggested combination for of the R and C could be R=220E Half watt and C=0.1 F / 1000 Volts. Alternatively, these could be bought out from Messung under order Code HRC1PH. For DC loads a free-wheeling diode such as 1N4007 should be used in reverse polarity as shown to avoid effects of back EMFs generated by inductive load. The diode and the snubber should be positioned and wired up as near as possible to the external loads for maximum effect.

RTC dependent functions does not match with Real Time Clock During programming PLC shows communication error

RTC

Check the required conditions on Input LEDs or diagnose via VaW / CoDeSys OR contact Machine manufacturer. Re-set Real time setting by VAW/CoDeSys

Communication setting wrong Cable faulty or loose connection PC port faulty PLC port faulty Cable faulty or loose connection Third part device port faulty PLC port faulty PLC power is < 18VDC Right from start up. Also indicated by 'SYS' LED ON. VAW not configured and programmed.

Check cable and ensure healthy connection Check cable and ensure healthy connection Change Port or get corrected Contact service* Check cable and ensure healthy connection Check device and get corrected Contact service* Get supply voltage corrected.

Third part device connected on serial port of PLC is not working VAW display blank

CROSS REFERENCES

Hard copy 6319 Soft copy* ED-2002-126 ED-2002-127 ED-2002-128 Codesys _V23_E.pdf

VAW

Document 1) Product Brochure 2) Nexgenie PLC User Manual 3) VAW programming manual 4) Digital I / O Expansion module Manuals 5) Programming Software *Soft copies are downloadable from www.messung.com

Confirm the programming of 'VAW_PRG' and other requirements as per VAW programming manual. * service could mean Company Service Centers, Your dealer or distributor depending upon your location. - LED off, - LED on continuously, X - ' Don't care' condition, - LED Flashing Specifications are subject to change without prior notice. Copyright Messung Systems Document PD-2002-125 Rev. 1

VAW display showing 'nexgenie'

PD-2002-128

July 2009

Вам также может понравиться

- 13 - SIGA IM - Isolator Module PDFДокумент2 страницы13 - SIGA IM - Isolator Module PDFPrakash SelvarajОценок пока нет

- Datakom d700tft Installation ManualДокумент179 страницDatakom d700tft Installation ManualJaime Calmet0% (1)

- Optimho Static Distance Protection RelaysДокумент22 страницыOptimho Static Distance Protection RelaysShahzad BhattiОценок пока нет

- Especificación Tecnica V350-35-R34Документ5 страницEspecificación Tecnica V350-35-R34Germaín Hernández GómezОценок пока нет

- TD - Datasheet TK400 NDДокумент4 страницыTD - Datasheet TK400 NDSocaciu VioricaОценок пока нет

- 3 LCDAnnДокумент4 страницы3 LCDAnnDidit HendarminОценок пока нет

- Simplex 4100-0031Документ10 страницSimplex 4100-0031vlaya1984Оценок пока нет

- Model G306A - Graphic Color LCD Operator Interface Terminal With TFT Qvga Display AND TouchscreenДокумент8 страницModel G306A - Graphic Color LCD Operator Interface Terminal With TFT Qvga Display AND TouchscreenJoche K'stilloОценок пока нет

- ControlДокумент5 страницControlamerquipОценок пока нет

- Secure Data CommunicationДокумент11 страницSecure Data CommunicationNeela ChennurОценок пока нет

- BTT SKR V1.4 Instruction ManualДокумент12 страницBTT SKR V1.4 Instruction ManualMaruf HasanОценок пока нет

- G308a HmiДокумент8 страницG308a HmiJuan Diego Chavarría RojasОценок пока нет

- XFC EspecificacionsДокумент19 страницXFC Especificacionsadesa2013Оценок пока нет

- MS 9200 (C) MS 9200E Fire Lite Alarms DF 51276Документ4 страницыMS 9200 (C) MS 9200E Fire Lite Alarms DF 51276Miguel PerezОценок пока нет

- 74 3441Документ104 страницы74 3441GUZMANОценок пока нет

- Intel D965GF Quick Start GuideДокумент21 страницаIntel D965GF Quick Start GuidesamuzaferОценок пока нет

- Traffic LightДокумент18 страницTraffic LightHarish KhanОценок пока нет

- 7SG22 Iota Catalogue SheetДокумент12 страниц7SG22 Iota Catalogue Sheetbaskaranjay5502Оценок пока нет

- IED670 Getting Started Guide: Mounting and InstallationДокумент10 страницIED670 Getting Started Guide: Mounting and InstallationunorulezОценок пока нет

- Program FRT12 Flow Rate Totaliser for Accurate Flow MeasurementДокумент12 страницProgram FRT12 Flow Rate Totaliser for Accurate Flow Measurementvallolet_sb5185Оценок пока нет

- Rückenbreite Bis 10 MM (1 Blatt 0,106 MM) : Hardware and EngineeringДокумент94 страницыRückenbreite Bis 10 MM (1 Blatt 0,106 MM) : Hardware and EngineeringAdilson DominguesОценок пока нет

- 4007ES Fire Control PanelsДокумент8 страниц4007ES Fire Control PanelsJorge Renato Chirinos QuiñonezОценок пока нет

- FX2N 4AD TC - UserGuide - JY992D65501 G PDFДокумент8 страницFX2N 4AD TC - UserGuide - JY992D65501 G PDFTam DangОценок пока нет

- Automation Component AK 1703 ACP: Answers For EnergyДокумент6 страницAutomation Component AK 1703 ACP: Answers For EnergybepperigaОценок пока нет

- Manual DigitalView SVP-1280Документ25 страницManual DigitalView SVP-1280elotilloОценок пока нет

- Ps4-200 Hardware h1184gДокумент94 страницыPs4-200 Hardware h1184gEmmanuel PatryОценок пока нет

- A29040B Series: 512K X 8 Bit CMOS 5.0 Volt-Only, Preliminary Uniform Sector Flash MemoryДокумент29 страницA29040B Series: 512K X 8 Bit CMOS 5.0 Volt-Only, Preliminary Uniform Sector Flash MemoryMirta PurkОценок пока нет

- Fiber Optic Ieee c37.94 g.703 E1 Multiplexer Pdf2 133Документ18 страницFiber Optic Ieee c37.94 g.703 E1 Multiplexer Pdf2 133nnt236Оценок пока нет

- UPCX 530 controller firmwareДокумент8 страницUPCX 530 controller firmwareuongquocvuОценок пока нет

- Master Control Unit Installation GuideДокумент28 страницMaster Control Unit Installation GuideFelipe MejiasОценок пока нет

- 7SA511 CatalogueДокумент4 страницы7SA511 CatalogueKenneth YanulaqueОценок пока нет

- User'S Guide: JY992D65601DДокумент8 страницUser'S Guide: JY992D65601DEdgar LojanОценок пока нет

- Agilent 34970A Data Acquisition / Switch Unit: Convenient Data Logging FeaturesДокумент34 страницыAgilent 34970A Data Acquisition / Switch Unit: Convenient Data Logging FeaturesRocío NapanОценок пока нет

- Ultra-Thin Industrial Computers W/ I-Processors User's GuideДокумент24 страницыUltra-Thin Industrial Computers W/ I-Processors User's Guidejroyal692974Оценок пока нет

- Ds Hd08t21mmc XXX XXXXДокумент2 страницыDs Hd08t21mmc XXX XXXXbbbru1Оценок пока нет

- 1 Megabit (128 K X 8-Bit) CMOS 5.0 Volt-Only, Uniform Sector Flash MemoryДокумент31 страница1 Megabit (128 K X 8-Bit) CMOS 5.0 Volt-Only, Uniform Sector Flash MemoryJavier BendekОценок пока нет

- Android Based Wireless Home Appliances Control SystemДокумент44 страницыAndroid Based Wireless Home Appliances Control SystemShahzad SaifОценок пока нет

- DRS-L Short Techn Description e Rev5Документ18 страницDRS-L Short Techn Description e Rev5yuy0607Оценок пока нет

- KRONOS USER MANUAL V4.21 GUIDEДокумент56 страницKRONOS USER MANUAL V4.21 GUIDENguyễn Viết NhuОценок пока нет

- Standard Eeprom Ics: SLX 24C164 16 Kbit (2048 8 Bit) Serial Cmos-Eeprom With C Synchronous 2-Wire BusДокумент25 страницStandard Eeprom Ics: SLX 24C164 16 Kbit (2048 8 Bit) Serial Cmos-Eeprom With C Synchronous 2-Wire BusLong Bụng Bớt PhệОценок пока нет

- Service Manual 969HQT PDFДокумент56 страницService Manual 969HQT PDFJose QuiscaОценок пока нет

- LDДокумент38 страницLDfeliprolОценок пока нет

- Allen Bradley Catalog Wiring SystemsДокумент189 страницAllen Bradley Catalog Wiring SystemsAlphaОценок пока нет

- Freescale's S08 Ultra-Low-Power MCU With LCD DriverДокумент6 страницFreescale's S08 Ultra-Low-Power MCU With LCD DriverIonela100% (1)

- A1000 Installation ManualДокумент12 страницA1000 Installation ManualMuti FutiОценок пока нет

- Tidu 160Документ47 страницTidu 160engamin_sОценок пока нет

- Ai 708P PDFДокумент29 страницAi 708P PDFAnthony CasasОценок пока нет

- Melsec-Q Ethernet (UDP) Driver: Mitsubishi Electric CorpДокумент13 страницMelsec-Q Ethernet (UDP) Driver: Mitsubishi Electric CorpJansen SoejarsonoeОценок пока нет

- Xport TCP IpДокумент5 страницXport TCP IpKarthick Vijayan100% (1)

- V350 35 R6 - Tech SpecДокумент5 страницV350 35 R6 - Tech Specchrobakpeter12345Оценок пока нет

- BLN 95 9041Документ5 страницBLN 95 9041marsh2002Оценок пока нет

- M0000528 Inst200 Ing v1.6Документ84 страницыM0000528 Inst200 Ing v1.6Farzad SagharchiОценок пока нет

- SICAM AK - Hardware Based SASДокумент6 страницSICAM AK - Hardware Based SASsavijolaОценок пока нет

- Altronic Loop Controller Installation & Operating Manual MODEL DE-1500 FORM DE-1500 IOI 8-03Документ25 страницAltronic Loop Controller Installation & Operating Manual MODEL DE-1500 FORM DE-1500 IOI 8-03wcuevasmОценок пока нет

- 03 13003 enДокумент4 страницы03 13003 enImam MunandarОценок пока нет

- Numerical Overcurrent Protection Relay - Argus 1Документ4 страницыNumerical Overcurrent Protection Relay - Argus 1sulemanchОценок пока нет

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142От EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142Оценок пока нет

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.От EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.Оценок пока нет

- Assignment-29 10 18Документ14 страницAssignment-29 10 18Amit ChaturvediОценок пока нет

- Doli Capax - Capable of Crime or TortДокумент1 страницаDoli Capax - Capable of Crime or TortAmit ChaturvediОценок пока нет

- IPC AssignmentДокумент21 страницаIPC AssignmentAmit ChaturvediОценок пока нет

- GP 1Документ5 страницGP 1neepubrarОценок пока нет

- Document For Global Venture ABCDДокумент1 страницаDocument For Global Venture ABCDAmit ChaturvediОценок пока нет

- NuisanceДокумент5 страницNuisanceAmit ChaturvediОценок пока нет

- Admin Law Assignment 16Документ1 страницаAdmin Law Assignment 16Amit ChaturvediОценок пока нет

- The Doctrine of Necessity and CompulsionДокумент4 страницыThe Doctrine of Necessity and CompulsionAmit ChaturvediОценок пока нет

- Admin Law Assignment 14Документ1 страницаAdmin Law Assignment 14Amit ChaturvediОценок пока нет

- Admin Law Assignment 13Документ1 страницаAdmin Law Assignment 13Amit ChaturvediОценок пока нет

- Admin Law Assignment 14Документ1 страницаAdmin Law Assignment 14Amit ChaturvediОценок пока нет

- Wrongful Restrain & Wrongful ConfinementДокумент1 страницаWrongful Restrain & Wrongful ConfinementAmit ChaturvediОценок пока нет

- GST Concept Status Ason01052017Документ15 страницGST Concept Status Ason01052017Amit ChaturvediОценок пока нет

- Working Capital ConceptsДокумент42 страницыWorking Capital Conceptsdabloo_3sep86% (7)

- Doctrine of Mens ReaДокумент1 страницаDoctrine of Mens ReaAmit ChaturvediОценок пока нет

- 33118ipcc Idtc Rev Nov14 Pm1Документ77 страниц33118ipcc Idtc Rev Nov14 Pm1Rocker FarmerОценок пока нет

- Document For Global Venture ABCDДокумент1 страницаDocument For Global Venture ABCDAmit ChaturvediОценок пока нет

- Airborne Particle Size Chart - Engineering Design Micron ChartДокумент3 страницыAirborne Particle Size Chart - Engineering Design Micron ChartAmit ChaturvediОценок пока нет

- What NPS Changes Mean For You - The Economic Times PDFДокумент2 страницыWhat NPS Changes Mean For You - The Economic Times PDFAmit ChaturvediОценок пока нет

- Myth Booklet English Compressed PDFДокумент28 страницMyth Booklet English Compressed PDFAmit ChaturvediОценок пока нет

- Trade/Industry:: (I) Reduction in Multiplicity of TaxesДокумент1 страницаTrade/Industry:: (I) Reduction in Multiplicity of TaxesAmit ChaturvediОценок пока нет

- Golden Peacock Award Winning Jeevan Saral PlanДокумент6 страницGolden Peacock Award Winning Jeevan Saral PlanAmit ChaturvediОценок пока нет

- Letter of Credit - Wikipedia, The Free EncyclopediaДокумент10 страницLetter of Credit - Wikipedia, The Free EncyclopediaAmit ChaturvediОценок пока нет

- Chauhans Need To Streamline Investments, Increase Equity Exposure - The Economic TimesДокумент4 страницыChauhans Need To Streamline Investments, Increase Equity Exposure - The Economic TimesAmit ChaturvediОценок пока нет

- Sal Sheet MetroДокумент3 страницыSal Sheet MetroAmit ChaturvediОценок пока нет

- CH 18Документ7 страницCH 18Amit ChaturvediОценок пока нет

- CSRF 1 FormДокумент4 страницыCSRF 1 FormAbhishek KrОценок пока нет

- The Payment of Gratuity Act 1972Документ13 страницThe Payment of Gratuity Act 1972KijanjooОценок пока нет

- Test DocumentДокумент1 страницаTest DocumentAmit ChaturvediОценок пока нет

- Book 1Документ2 страницыBook 1Amit ChaturvediОценок пока нет

- 1MRK505344-UEN B en Technical Manual Line Differential Protection RED670 2.1 IEC PDFДокумент1 324 страницы1MRK505344-UEN B en Technical Manual Line Differential Protection RED670 2.1 IEC PDFjackelynОценок пока нет

- Electrical Circuit Analysis Test 1 Semester I 2017 2018Документ5 страницElectrical Circuit Analysis Test 1 Semester I 2017 2018Andy QklОценок пока нет

- TecsunДокумент26 страницTecsunlarry thomasОценок пока нет

- Ahb Faqs FAQsnewДокумент10 страницAhb Faqs FAQsnewKrunal ModiОценок пока нет

- Stonex Laser PDFДокумент19 страницStonex Laser PDFxavierОценок пока нет

- How To Manufacture A Free Energy Device (Perpetual Motion)Документ12 страницHow To Manufacture A Free Energy Device (Perpetual Motion)leechster100% (1)

- Lec 13 Radiographic Grids IIДокумент27 страницLec 13 Radiographic Grids IIwaelОценок пока нет

- MOSPEC General Purpose Silicon RectifierДокумент4 страницыMOSPEC General Purpose Silicon RectifierIvan JmePhotographyОценок пока нет

- I Ma 3010.71 1320 622 Huy 067 - A - ComДокумент140 страницI Ma 3010.71 1320 622 Huy 067 - A - ComValério de Oliveira Santos100% (1)

- Instant Power Supply (IPS) System With Load PriorityДокумент60 страницInstant Power Supply (IPS) System With Load PriorityTania Marzia100% (3)

- ECE 5380 / 6380 Power Electronics Syllabus Spring 2012Документ7 страницECE 5380 / 6380 Power Electronics Syllabus Spring 2012Ref DocsОценок пока нет

- Digital Logic Design Chapter 1Документ55 страницDigital Logic Design Chapter 1መሰረቴ ግርማይОценок пока нет

- Apple Technician Guide For LED Cinema Display (24-Inch)Документ92 страницыApple Technician Guide For LED Cinema Display (24-Inch)addai262Оценок пока нет

- Miyano Model Lz-02Ry2 Quick Loading CNC Lathe Turning Center W/Y - Axis and Revolving Tool AttachmentДокумент18 страницMiyano Model Lz-02Ry2 Quick Loading CNC Lathe Turning Center W/Y - Axis and Revolving Tool AttachmentFidel Eduardo Luque Percka100% (1)

- 1383817411Документ610 страниц1383817411ryanrahman0% (2)

- Semiconductors Physics ConceptsДокумент10 страницSemiconductors Physics ConceptsHari Vardhan ChowdharyОценок пока нет

- How To Convert An OEM Pansat 2500 To A Pansat 2700Документ3 страницыHow To Convert An OEM Pansat 2500 To A Pansat 2700jayduvОценок пока нет

- Audacity. User Guide PDFДокумент13 страницAudacity. User Guide PDFRusber A. Risco OjedaОценок пока нет

- Trane TCIДокумент12 страницTrane TCIReinerio Praxedes Castillo CespedesОценок пока нет

- SPN4526 U4Документ8 страницSPN4526 U4Raj NayakОценок пока нет

- Lighting Lighting: Slimblend Square, RecessedДокумент3 страницыLighting Lighting: Slimblend Square, RecessedAhmed YahiaОценок пока нет

- Question Bank BEEДокумент5 страницQuestion Bank BEEK.Sushita VISTASОценок пока нет

- Automatic Night Lamp With Morning AlarmДокумент7 страницAutomatic Night Lamp With Morning Alarm152ISSHIKA SINHAОценок пока нет

- 34018@motoДокумент16 страниц34018@motomseoane321Оценок пока нет

- Service: LCD-TVДокумент95 страницService: LCD-TVCarlos GonçalvesОценок пока нет

- Yasser Auda CCIEv5 EPC OverviewДокумент5 страницYasser Auda CCIEv5 EPC OverviewQuang AnhОценок пока нет

- Linear TransformerДокумент44 страницыLinear TransformerRonmark AbinoОценок пока нет

- EwfdasdsДокумент206 страницEwfdasdsadam ibnu100% (1)

- 1.5.1 Intro To MicromachiningДокумент24 страницы1.5.1 Intro To MicromachiningAshish MishraОценок пока нет

- USSTP Student OJT ProgramДокумент4 страницыUSSTP Student OJT ProgramKim RyanОценок пока нет