Академический Документы

Профессиональный Документы

Культура Документы

Paper 1

Загружено:

Mohamed SaidОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Paper 1

Загружено:

Mohamed SaidАвторское право:

Доступные форматы

Implementation of Different Types of Patterns using Propeller Display through Microcontroller

Mohit K. Ajani, 2 Bhavin R. Dethadiya,3Hardik P. Modi Assistant Professor, Charotar University of Science and TechnologyChanga-388221, Gujarat, India 3 modi8584@yahoo.com

Abstract: In this application we have implemented a special kind of circular LED display. With the help some mechanical assembly, LED count, hardware requirement, and hence overall cost is cut to very affordable price. Also, maintenance and repairing of the display is so easy, that anyone having electronics knowledge can take care of this. All the synchronizing can be implemented through software. This application uses the principle of PERSISTENCE OF VISION (POV). A glowing object if rotated in a circle at fast speed, it shows a continuous circle. By modifying this basic idea, 8 LEDs can be rotated in a circle, showing 8 concentric circles. This propeller display is mechanically scanned and displays the characters in digital format. Made from scrap it can be used anywhere and everywhere and the most amazing fact about this display is its crystal clear display. This display consists of just 8 bright LEDs which are rotated to show the display. Keywords: Microcontroller, Propeller Display, Persistence of Vision (POV), Interrupt, LED, Sensor I.

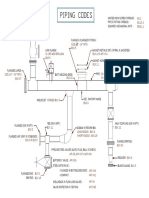

Fig.1 Block Diagram Propeller is a term associated with a circular rotating object. As this application needs to rotate whole circuit assembly, there must be some prime mover attached to it. So, the term Propeller is used here. This application is using bright light emitting diodes for displaying the characters and symbols on its assembly. POV (Persistence of Vision) is the phenomenon which is related to vision capability of human eye by which an after- image is thought to persist for approximately 1/25th of a second. If someone is observing the images at a rate of 25 images per second, then they appear to be continuous. The best example of this property is the red circle we observe when we rotate the firecracker or incense stick in circle. The propeller display consists of following blocks, as shown in the fig.1. A. B. C. D. E. A. Interrupter Module Microcontroller LED module DC motor DC power supply Interrupter Module

INTRODUCTION

This application was started with a simple principle which is frequently encountered in our everyday life, which is Persistence of Vision. This phenomenon makes one feel fast moving/changing objects to appear continuous. A television is a common example; in which image is re-scanned every 25 times, thereby appear continuous. A glowing object if rotated in a circle at fast speed, it shows a continuous circle. By modifying this basic idea, 8 LEDs can be rotated in a circle, showing 8 concentric circles. But if these LEDs are switched at precise intervals, a steady display pattern can be shown. Existing systems do employ POV principle, but for displaying each pixel, individual LED is used. This results in a huge number of LEDs even for small sized displays. By using a propeller type display, LED count can be kept to a bare minimum. Even 8 LEDs can perform a task of over 525 LEDs. Applications can find their way into cost effective solutions for large public displays, information systems. It can directly replace Railway station information displays, bus stands and many more places. [4, 6]

II.

THEORITICAL FRAMEWORK

Interrupter module is our sensor module, consisting of the IR interrupt sensor MOC7811, from Motorola Inc. This sensor was selected from a variety of other alternatives, because of its small size, precise interrupt sensing, and sturdy casing. One great advantage of using this module is, interfacing it with the microcontroller is just a matter of two resistors and a general purpose transistor. Following is the complete circuit diagram of our interrupter module. B. Microcontroller AT89C2051

This application is based around the microcontroller AT89C2051, which is a derivative of 8051 family[5], from Atmel Inc. This is a 20 pin IC packaged in DIP package. This small sized IC is used, mainly because of its reduced weight. This improves the performance of the display, because reduced weight gives advantage of increased RPM. [1, 2] C. LED MODULE

LED module consisting of 8 bright LED is fixed in another side of the arm of our application. These LEDs are connected with each of the port pin of microcontroller, with a series current limiting resistor of 470 ohm. D. DC Motor Fig.3 Circuit Diagram Mechanical assembly plays a vital role in proper functioning of this application. The display is scanned each time, by rotating the whole assembly in a circular path. The basic idea we developed is on our own, by implementing and modifying different ways to do this.Fig.4 shows mechanical assembly diagram.

Repeated scanning of the display is must for continuous vision. This task is achieved using circular rotation of the whole circuit assembly. So, we used a DC motor as the prime mover. E. DC Power Supply

For microcontroller, as well as the DC motor, a regulated DC power supply is required. We have to provide +5V to the microcontroller, while +12V to the motor.

III. HARDWARE DESIGN MOC7811 is the sensing part of the interrupter module, while rest of the circuitry works as signal conditioning circuit. Three wires emerge out from the module, respectively Vcc, Signal and Ground. Output of the module is LOW, if interrupt occurs, otherwise it remains HIGH.

Fig.4 Mechanical Assembly Diagram One major challenge was how to bring +5V supply to the spinning circuit. We tried the same by adopting two-three different methods, but finally concluded on the method, as shown in the fig.4.Most critical objective was to achieve pristine balance and overall good mechanical strength. For weight adjustment, we have provided one long screw, and weight can be attached or removed by adding / removing metallic bolts. If the assembly is balanced perfect, then it can achieve stability, and rotate at high RPMs too. This will improve the overall efficiency of this display.

Fig.2.interrupter module moc7811 It consists of IR (Infra Red) LED and Photodiode mounted facing each other enclosed in plastic body. When light emitted by the IR LED is blocked because of some completely opaque object, logic level of the photo diode changes. This change in the logic level can be sensed by the microcontroller or by discrete hardware. This sensor is used to give position feedback.INT0 pin of our microcontroller is Active Low. That means, occurrence of each interrupt is should be signaled with Low logic level. So, we must invert the output of the sensor. Transistor 2N3904 is a general purpose silicon NPN transistor. It is connected in the CE inverting amplifier configuration. It inverts the output of the photodiode, and also improves the transient response.Fig.3 shows circuit diagram of this application [3, 4].

Fig.5.Power Supply Circuit

A fixed voltage power supply producing constant +5V consists of step down transformer, a bridge rectifier, filter capacitors C1 and 3 terminal regulator IC LM7805. A step down transformer is selected in such a way that it produces 9V at the input of IC. This power supply is capable of supplying +5v and load current up to 500m A. The capacitor C2 connected between output terminal and ground cancels out any inductive effect due to long distribution leads. Input capacitor C1 is used to improve transient response of the regulator IC, i.e. response of regulator to sudden changes in load. It is also helpful in reducing the noise present in the output. Dropout voltage (Vin-Vout) needs to be at least 2V under all operating conditions for proper operation of regulator. IV. SOFTWARE DESIGN Software Design has two routines. Main Routine and Interrupt Routine.[5,7] A. 1. 2. 3. 4. 5. 6. 7. 8. B. 1. Main routine: Load proper value in IE register, so that the interrupts INT0 and T0 are enabled. (IE = 83H) Offer higher priority to the INT0 (External) interrupt. (IP = 01H) Configure timer 1 as 16-bit timer, and timer 0 as 8-bit auto reload mode timer. ( TMOD = 12H) INT0 should be configured as edge interrupt. (IT0 = 1) Configure port 3 as input port. (P3 = 0FFH) Move input string to the video RAM area. (call ramc function) Start the timers. Initiate an infinite loop. Interrupt Routine External Interrupt: 1. 2. 3. 4. 5. 6. 7. 2. Stop the timers. Move th1 and tl1 into convenient registers. Divide this 16 bit value by our total number of segments. Subtract the answer from 256, and load the result in th0. Now, reset the video RAM pointer and character segment pointers to their initial respective positions. Start the timers. Return from interrupt.

B. DC MOTOR RPM TESTING DC Motor used in this application is 12 V dc motor which is tested by using digital contact-less tachometer. Arrangement was made so that the sensing circuit gives high to low pulse for each completion of revolution. By measuring the time difference between two successive pulses RPS can be calculated which further provide RPM value, as shown below: Power supply given to DC Motor = 9V Time interval between two successive pulses as seen on CRO = 30.4ms RPS = 1 / (30.4ms)=32.89 RPS = 33 RPM= 33x60=1980 C. GENERATED PATTERNS Fig.8 and Fig.9 shows generated patterns.

Fig.8. Displaying an alternate pattern circle

Timer 0 Interrupt: 1. 2. 3. Call the display routine. Clear timer overflows flag. Return from interrupt. V.

RESULTS AND DISCUSSIONS

A. INTERRUPTER MODULE TESTING This Interrupt module testing is required for detecting exact position of wheel on which whole circuit assembly is mounted. Supply voltage given to Pin. No. 1(Collector) and Pin.No.3 (Anode) of MOC7811=5.5V.Output voltage obtained at Pin.No.1 of MOC 7811 without interrupt=5.21v.Output voltage obtained at Pin.No.1 of MOC7811 with interrupt=0.08V.

Fig.9. Displaying an feather like pattern

VI CONCLUSION AND FUTURE SCOPES

In this application we implemented different patterns using propeller display through microcontroller. By using this propeller display we can implement real rime clock as well as calendar. We can generate scrolling messages. We may also connect it through computer to display direct message through keyboard. It can be also used to show real time price list at shopping malls or at railway station and bus station to display time of routes. In future we will expand this application for more than 8 LEDs and will implement message display through propeller display.

ACKNOWLEDGEMENTS

We would like to thank Charotar institute of technology,changa and Charotar University of Science and Technology for their consistent support throughout our implementation of this application.

REFERENCES

[1] [2] [3] [4] [5] [6] [7] Muhammad Ali Mazidi, Janice Gillispie Mazidi The 8051 microcontrollers & Embedded Systems pp. 183-203 Kennaeth J.Aayala The 8051 Microcontroller: Architecture, Programming, and Applications Richard Barnett The 8051 Family of Microcontrollers Raj Kamal The concepts and features of microcontrollers includes programmable logic controllers pp.76-145 Ted Van Sickle Programming Microcontrollers in C pp. 65121,211-285 Chris Braithwaite, fred cowan, Hassan Archizaddeh 8051 an application based microcontroller introduction pp 66-82 Gerhard Schmidt Introduction to the Assembly Language of ATMEL AVR Microprocessors pp. 45-60

BIBLIOGRAPHY

Mohit K Ajani is pursuing the bachelor of Engineering in Electronics and Communication from Charotar Institute of Technology. His areas of interest are embedded systems, Networking and Communication.

Bhavin R. Dethadiya is pursuing the bachelor of Engineering in Electronics and Communication from Charotar Institute of Technology. His areas of interest are embedded systems and automation.

Hardik P Modi has received the B.E. degree in Electronics and Communication Engineering from Sardar Patel University and M.E. in Electronics and Communication System engineering from Dharmsinh Desai University. Presently he is doing Ph.D. from Charotar University of Science & Technology. He is also working as Assistant Professor in Department of Electronics and Communication Engineering of Charotar University of Science & Technology, Changa, Gujarat. His research interests are in Microcontroller and Image Processing

Вам также может понравиться

- Lesson1Notes PDFДокумент32 страницыLesson1Notes PDFMohamed SaidОценок пока нет

- IC16 Official Rules and Regulations - Innovation Competition-0b264c213850Документ9 страницIC16 Official Rules and Regulations - Innovation Competition-0b264c213850Mohamed SaidОценок пока нет

- CSE 451: Operating Systems Winter 2012: ProcessesДокумент14 страницCSE 451: Operating Systems Winter 2012: ProcessesMohamed SaidОценок пока нет

- How Are We Doing?: General EvaluationДокумент1 страницаHow Are We Doing?: General EvaluationMohamed SaidОценок пока нет

- Transform Together Application Form Final 2015 16Документ3 страницыTransform Together Application Form Final 2015 16Mohamed SaidОценок пока нет

- Society of Petroleum Engineers: Student Chapter Resources Request FormДокумент1 страницаSociety of Petroleum Engineers: Student Chapter Resources Request FormMohamed SaidОценок пока нет

- EE482 - Optical Communications: Projects (+2) Mid-Term (+1.5)Документ5 страницEE482 - Optical Communications: Projects (+2) Mid-Term (+1.5)Mohamed SaidОценок пока нет

- 8086 - 88 Device SpecificationsДокумент16 страниц8086 - 88 Device SpecificationsMohamed SaidОценок пока нет

- MIPS CheatsheetДокумент2 страницыMIPS CheatsheetMohamed SaidОценок пока нет

- Employee Performance Review FormДокумент1 страницаEmployee Performance Review FormMohamed SaidОценок пока нет

- Electronics II Lab 1 Assignment: Experiment 1: Common Emitter AmplifierДокумент7 страницElectronics II Lab 1 Assignment: Experiment 1: Common Emitter AmplifierMohamed SaidОценок пока нет

- Dance O'clock' Quiz Feedback FormДокумент1 страницаDance O'clock' Quiz Feedback FormMohamed SaidОценок пока нет

- SampleДокумент3 страницыSampleMohamed SaidОценок пока нет

- Signals Report On Memristors: Prepared By: Mohamed Said Abdullah HammadДокумент3 страницыSignals Report On Memristors: Prepared By: Mohamed Said Abdullah HammadMohamed SaidОценок пока нет

- 2015 Competition Mission Spec Briefing FINALДокумент6 страниц2015 Competition Mission Spec Briefing FINALMohamed SaidОценок пока нет

- Embedded: Universities o Public o Private (E-Just, Aast, Nile, AUC, ..)Документ2 страницыEmbedded: Universities o Public o Private (E-Just, Aast, Nile, AUC, ..)Mohamed SaidОценок пока нет

- VHDL Project Universal RegisterДокумент5 страницVHDL Project Universal RegisterMohamed SaidОценок пока нет

- Serial Data ReceiverДокумент10 страницSerial Data ReceiverMohamed Said100% (1)

- Devices Lab Report Reverse Diode Bias: Prepared By: Mohamed Saeed Abdullah Hammad 207Документ9 страницDevices Lab Report Reverse Diode Bias: Prepared By: Mohamed Saeed Abdullah Hammad 207Mohamed SaidОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Low Voltage Products: Fusegear Switch Fuses OSДокумент80 страницLow Voltage Products: Fusegear Switch Fuses OSSalehОценок пока нет

- Mini Project Report IRABДокумент10 страницMini Project Report IRABNaveenkondi100% (1)

- Especificaciones Terex T340Документ9 страницEspecificaciones Terex T340anmec20Оценок пока нет

- High Bay 16" Aluminum BAYLIGHTERДокумент1 страницаHigh Bay 16" Aluminum BAYLIGHTEREliasОценок пока нет

- Breaker Failure Protection RAICAДокумент8 страницBreaker Failure Protection RAICAGeorge AsuncionОценок пока нет

- Service Manual: ForewordДокумент2 364 страницыService Manual: ForewordredОценок пока нет

- 6d KEP Technology UpdateДокумент4 страницы6d KEP Technology UpdatecuongckОценок пока нет

- 2301D and 2301D-EC Digital Load Sharing and Speed Controls For EnginesДокумент148 страниц2301D and 2301D-EC Digital Load Sharing and Speed Controls For EnginesJoe D'AmatoОценок пока нет

- Piping 1685957422Документ1 страницаPiping 1685957422Doğuhan DenizgezОценок пока нет

- Brochure - ASKA Mobile Light Tower - V5Документ8 страницBrochure - ASKA Mobile Light Tower - V5cool.boys4200Оценок пока нет

- Hydraulic System:: R. Qasim Abbas D Automatic Control I 4Документ5 страницHydraulic System:: R. Qasim Abbas D Automatic Control I 4علي حسين علاوي ثوينيОценок пока нет

- Stainless Series S115-2 or S6115-2 (Globe), S1115-2 or S61115-2 (Angle) Installation InstructionsДокумент1 страницаStainless Series S115-2 or S6115-2 (Globe), S1115-2 or S61115-2 (Angle) Installation InstructionsWattsОценок пока нет

- Fisa Tehnica Produs: Circuit Breaker Compact NS1000N - 4 Poles - 1000 A - Fixed - Without Trip UnitДокумент2 страницыFisa Tehnica Produs: Circuit Breaker Compact NS1000N - 4 Poles - 1000 A - Fixed - Without Trip UnitGolovatii NicolaeОценок пока нет

- Essotrans Extra, Multigrade 30, 10W, 30, 50 Essotrans Extra, Multigrade 30, 10W, 30, 50Документ2 страницыEssotrans Extra, Multigrade 30, 10W, 30, 50 Essotrans Extra, Multigrade 30, 10W, 30, 50Kaly7Оценок пока нет

- CATALOGO - DIXON VALVE Petrochemical - 1 - Exploration - 2017Документ24 страницыCATALOGO - DIXON VALVE Petrochemical - 1 - Exploration - 2017Hector Luis MejiaОценок пока нет

- KR-G11 User Guider AlarmДокумент21 страницаKR-G11 User Guider AlarmJuan DuqueОценок пока нет

- AIR Conditioner: Owner'S ManualДокумент31 страницаAIR Conditioner: Owner'S Manualnoriko5463Оценок пока нет

- MkIV Failure CodesДокумент12 страницMkIV Failure Codesjaypc1050% (2)

- IRFP450Документ8 страницIRFP450Erick DavidОценок пока нет

- Manual Lavadora Ge EspañolДокумент52 страницыManual Lavadora Ge Españoltavaelromo8475% (4)

- Ee - Module 3 - April 2012Документ3 страницыEe - Module 3 - April 2012Znevba Quintano100% (2)

- MTL 9461-ET: Intrinsically Safe Serial To Ethernet GatewayДокумент2 страницыMTL 9461-ET: Intrinsically Safe Serial To Ethernet GatewayTulia Concepcion PerezОценок пока нет

- Manual de Motores Vol 4Документ75 страницManual de Motores Vol 4Gabriel Piñon Conde100% (1)

- U151E U250E VacTestДокумент5 страницU151E U250E VacTestbyungchul kimОценок пока нет

- Electric Drive Technology Trends Challenges and Opportunities For Future Electric VehiclesДокумент21 страницаElectric Drive Technology Trends Challenges and Opportunities For Future Electric Vehiclespathfinder tamlukОценок пока нет

- Basic Components of ElectronicsДокумент77 страницBasic Components of ElectronicshardzoneОценок пока нет

- Alto Mistral 2500, 4000Документ46 страницAlto Mistral 2500, 4000wacawaca100% (1)

- Zelio Timer Relays - RUZC2MДокумент5 страницZelio Timer Relays - RUZC2MFredy Aparco IngaОценок пока нет

- Byd DolphinДокумент6 страницByd DolphinGervásio OliveiraОценок пока нет

- Atlet XLLДокумент4 страницыAtlet XLLMiguel MartínezОценок пока нет