Академический Документы

Профессиональный Документы

Культура Документы

Inst Aids Calc CSM93020C1

Загружено:

Lê Hữu NamИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Inst Aids Calc CSM93020C1

Загружено:

Lê Hữu NamАвторское право:

Доступные форматы

OFFICIAL COPY - PDF Generated on 27-Feb-2008

CLIENT: CHARTERER:

7:14AM

PROJECT:

Head Office

5, Route de Fribourg PO Box 152 CH-1723 Marly Switzerland Tel. +41 26 439 99 20 Fax: +41 26 439 99 39 www.singlebuoy.com

Engineering Office

Unit 2B-9-1, Level 9 Block 2B, Plaza Sentral Jalan Stesen Sentral 5 50470 Kuala Lumpur Malaysia Tel. (+603) 2773 5300 Fax: (+603) 2773 5399

SU TU VANG FIELD DEVELOPMENT

SO17560 CS M 93 020 Rev. C1 A

CLIENT NUMBER:

DOCUMENT DESCRIPTION:

TP017-SBM-ST-RE-112

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION

Status/ Revision

C1

Date

(dd-MMM-YYYY)

No. of Pages

18

Written by

JAMIL

Checked by

M. AKMAL

Group Leader Dept. Head

M. AKMAL

EPM Approval for Issue

H. BOTTA

27-Feb-08

INFORMATION ON STATUS:

P I C V A X EPM Preliminary for Information Internal Discipline Checking For Comments and Approval Valid for Construction Approved For Construction As Built Engineering Project Manager or Assigned Substitute

Copyright Single Buoy Moorings Inc 2008

Ex No. : SB 81638

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560 CS M 93 020 C1

PAGE

REVISION STATUS / SUMMARY OF CHANGES

REVISION

C1

REVISED CHAPTERS

REVISION DESCRIPTION

For comments and approval

REASON FOR REVISION

First issue

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560 CS M 93 020 C1

PAGE

TABLE OF CONTENTS

1. GENERAL................................................................................................................................ 4 1.1 INTRODUCTION........................................................................................................ 4 1.2 SCOPE....................................................................................................................... 5 1.3 LAYOUTS .................................................................................................................. 5 1.4 REFERENCE DOCUMENTS..................................................................................... 6 1.5 REFERENCE DRAWING........................................................................................... 6 1.6 MATERIALS CHARACTERISTICS ............................................................................ 6 1.7 ACCEPTABILITY CRITERIA ..................................................................................... 7 1.7.1 Allowable Stress........................................................................................... 7 1.8 DESIGN LOAD........................................................................................................... 7 LIFTING LUG DESIGN............................................................................................................ 7 OVERALL STRUCTURAL INTEGRITY ................................................................................ 10 3.1 FINITE ELEMENT ANALYSIS ................................................................................. 10 3.2 BOUNDARY CONDITION........................................................................................ 11 3.3 LOADING ................................................................................................................. 11 RESULTS SUMMARY........................................................................................................... 12 SHACKLE CATALOGUE ........................................................................................ 14 SMIT DOCUMENTS ................................................................................................ 15

2. 3.

4.

APPENDIX 1) APPENDIX 2)

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560

1.

CS

93

020

C1

PAGE

GENERAL INTRODUCTION

The Su Tu Vang field is located in Block 15-1 offshore SE Vietnam in relatively shallow water of about 51 m depth. The field is part of the Su Tu complex which includes two other areas namely Su Tu Den Southwest and Su Tu Den Northeast. Production from the Su Tu Den Southwest area commenced in October 2003 and remains at full production. The Su Tu Den Southwest production facilities include a wellhead platform (WHP-A) with primary separation facilities, tied back, via 4 pipelines to a Suezmax size FPSO. Facilities on the Su Tu Den FPSO include oil separation and treating, produced water handling, seawater injection and gas lift. The proposed Su Tu Vang development is a Central Production Complex comprising one unit each of the following: A Floating Storage and Offloading (Su Tu Vang FSO) system A Central Processing Platform (CPP) Subsea pipeline end manifold (PLEM) Intra-field flowlines

1.1

Stabilised crude product from the CPP will be transferred to storage on the Su Tu Den FPSO. However, in the short term, the combined production from the existing Su Tu Den and the new Su Tu Vang will be in excess of the FPSO design capability. Therefore, additional storage capacity, the Su Tu Vang FSO, is required for this period. Crude oil is transferred to the Su Tu Vang FSO from the Central Processing Platform (CPP) by a pipeline and a flexible riser. The riser and pipeline are interconnected by a Pipe Line End Manifold (PLEM). Pipeline, flexible riser and rigid piping within the turret will form the fluid transfer system for this purpose. The turret is to be designed for at least 20 years with appropriate safety factors. The planned development has a target first oil date of October 2008.

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560

1.2 SCOPE

The purpose of this document is to show the adequacy of the padeye and the surrounding structure to hold the pulling load from the snatch block during the installation. All primary structural elements are checked for compliance with the requirement of the international standards and regulations as mentioned in Ref. [4].

CS

93

020

C1

PAGE

1.3

LAYOUTS

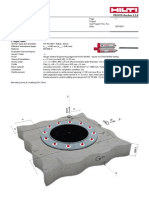

Figure 1.0: Plan View of Snatch Block Layout from Ref. [3].

Figure 2.0: Elevation View of Snatch Block Layout from Ref. [3].

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560 CS M 93 020 C1

PAGE

1.4

REFERENCE DOCUMENTS

[1] SO17560 SSM 92010 SBM Standard steel plates and profiles specification.

[2] AISC Allowable Stress Design Ninth Edition [3] 07.429-002 Smit Engineering Memo: Dimensions, Positioning and Design Loads FSO Deck Equipment [4] American Bureau of Shipping Guide for building and classing: Floating production, storage and offloading system (May 2004)

1.5

REFERENCE DRAWING

[i] SO17560 [ii] SO17560 [iii] SO17560 DSM 02017 DSM 02001 DSM 82031 Vessel Insert Padeye for Snatch Block Tanker Insert General Arrangement Rigid Arm General Arrangement

1.6

MATERIALS CHARACTERISTICS

The lifting lugs are made from high strength steel (Grade 36) in accordance with Ref.[1] and the summary of the yield stress reduction with respect to the plate thickness is shown in table below. Properties Material Designation Thickness (mm) t 16 16 < t 40 40 < t 63 63 < t 80 80 < t 100 E (GPa)

High strength steel Grade 36

210

0.3

yield (MPa) 355 345 335 325 315

Table 1: Requirement for minimum yield strength

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560

1.7

1.7.1

CS

93

020

C1

PAGE

ACCEPTABILITY CRITERIA Allowable Stress

The following table shows the maximum allowable combined comparative stresses according to Ref. [4] chapter 5 sections 4.13. Condition Safety Condition Minimum Yield Strength fy (N/mm2) 355 345 335 325 315 Allowable Stress (N/mm2) 213 207 201 195 189

Operating

0.6

Table 2: Allowable yield stress

1.8

DESIGN LOAD

The design load of 100 tons acting on the snatch block is based on Ref. [3]. It is assumed that the design load given has included all the necessary factors and that maximum line tension between the snatch block and the gantry sheave is 170 tons..

2.

LIFTING LUG DESIGN

Refer to Ref. Dwg. [i] for the lifting lug details. Allowable stress is in accordance to Ref. [4]. Design load = Assumed shackle size used Pin diameter Bow width Bow clear height Check Shear on Padeye Shear area = 2[(200-50)(30) + 2(200-75)(25)] = 21,500 mm2 100t (1,000 kN) = 3 Bolt Type Anchor Shackle (See Appendix 1) = 3.76 (96mm) = 5.25 (133mm) = 14.63 (372mm)

= 1,000 E3 / 21,500 = 46.5 N/mm2 = 0.4 Fy = 0.4 (345) = 138 N/mm2

Allowable shear stress

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560

Check Bearing Bearing area bearing = = = = 96(25+30+25) 7,680 mm2 1 E6 / 7,680 130.2 N/mm2

CS

93

020

C1

PAGE

Allowable bearing stress = 0.9 Fy = 0.9 (345) = 310.5 N/mm2 Check Welding on Cheek Plate Weld leg length Throat length Weld length Weld area = 15mm = 15/2 =10.6mm = 2(175)(2) =2,200mm = 10.6 x 2,200 = 23,320mm2

Note: Assumed 50% of weld area is effective. = 1,000 E3 / (23,320 / 2) = 85.8 N/mm2 Allowable shear stress = 0.4 Fy = 0.4 (345) = 138 N/mm2

Check Padeye Base Inline Moment = 1000 kN x 0.5m = 500 kN.m

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560 CS M 93 020 C1

PAGE

Off plane moment

= 5% x 1000kN x 0.92m = 46 kN.m

25

25

30 600

500 900

Inline Section Modulus Off plane Section modulus Shear area

= 7.96 E6 mm3 = 3.01 E6 mm3 = 900 x 30 = 27,000 mm2

in line off plane

= 500 E6 / 7.96 E6 = 62.81 N/mm2 = 46 E6 / 3.01 E6 = 15.3 N/mm2

= 1,000 E3 / 27,000 = 37.1 N/mm2

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560

combined

CS

2

M

2

93

020

C1

PAGE

10

= (62.81 + 15.3) + 3(37.1) = 101.14 N/mm2

Allowable combined stress

= 0.6 Fy = 0.6 (345) = 207 N/mm2

3.

OVERALL STRUCTURAL INTEGRITY

Considered loading is as per Section 1.8.

3.1

FINITE ELEMENT ANALYSIS

The structure is modelled using the finite element method (NX Nastran version 4.1 as solver and FEMAP version 9.3 as pre and post processor). The original model used on has been modified to reflect the current design arrangement. Longitudinal extend of the model is from bulkhead frame 122 to rigid arm at 5850 forward of frame 122. Transverse extend is from longitudinal bulkhead at 4800 at starboard side to 4800 at port side. Vertical extend is from 31225 above base line to 34655 above base line. The model has been carried out and presented in the following image

Figure 3.0: 3 - Dimensional view of the model.

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560

3.2

CS

93

020

C1

PAGE

11

BOUNDARY CONDITION

The turret structure is model as pinned at deck at elevation 31225, rigid arm frame at 5850 forward of frame 122, bulkhead at 4800 of centreline at starboard and bulkhead at 4800 of centreline at port side.

3.3

LOADING

Considered loading is as per Section 2. 1000 kN load is distributed onto 5 nodes. The distribution values are assumed to be as follows.

Figure 4.0: Load Distribution. Pont load at a =

=268 kN Pont load at b =

50 1000 [50 + 2(43.3) + 2(25)] 43.3 1000 [50 + 2(43.3) + 2(25)]

=232 kN

Pont load at c

=134 kN

25 1000 [50 + 2(43.3) + 2(25)]

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560 CS M 93 020 C1

PAGE

12

Figure 5.0: Load Application.

4.

RESULTS SUMMARY

Figure 6.0: Von-Mises Stress On Padeye

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560 CS M 93 020 C1

PAGE

13

Figure 7.0: Von-Mises Stress Existing Structure

Von Mises Stress Result Maximum Von Mises Stress, eq = 159.3 MPa < 0.6 (345) = 207 MPa Unity Check, UC = 0.77 OK

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560

APPENDIX 1)

CS

93

020

C1

PAGE

14

SHACKLE CATALOGUE

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560

APPENDIX 2)

CS

93

020

C1

PAGE

15

SMIT DOCUMENTS

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560 CS M 93 020 C1

PAGE

16

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560 CS M 93 020 C1

PAGE

17

OFFICIAL COPY - PDF Generated on 27-Feb-2008

7:14AM

VESSEL INSTALLATION AIDS: SNATCH BLOCK PADEYE CALCULATION SO17560 CS M 93 020 C1

PAGE

18

Вам также может понравиться

- Continuous Concrete Beam Design To Bs 81101997 Table 3.5Документ8 страницContinuous Concrete Beam Design To Bs 81101997 Table 3.5sarv_kishoreОценок пока нет

- DBR Lightning Protec ArarДокумент9 страницDBR Lightning Protec Ararsrigirisetty208Оценок пока нет

- Wind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsОт EverandWind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsОценок пока нет

- Design CalcДокумент308 страницDesign CalcPeja Jusoh100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- Rcc95 Continuous Beams (Tables)Документ8 страницRcc95 Continuous Beams (Tables)Steve JsobОценок пока нет

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1От EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Рейтинг: 3.5 из 5 звезд3.5/5 (3)

- CSM Adac L&T 0h02 1 DesignДокумент27 страницCSM Adac L&T 0h02 1 Designtamim2014Оценок пока нет

- Pre - FabricationДокумент23 страницыPre - FabricationMahaveer Singh100% (1)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisОт EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- Re 500Документ15 страницRe 500mazmamrefОценок пока нет

- Cylinder Head - Install: Disassembly and AssemblyДокумент8 страницCylinder Head - Install: Disassembly and AssemblyMahmoud AliОценок пока нет

- Flat Panel Display ManufacturingОт EverandFlat Panel Display ManufacturingJun SoukОценок пока нет

- Design of Anchor BoltДокумент16 страницDesign of Anchor BoltLaxmikant ChauhanОценок пока нет

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIОт EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiОценок пока нет

- PROFIS Anchor 2.2.0: WWW - Hilti.deДокумент6 страницPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguОценок пока нет

- S-6011 - DC Asdasd Asda Dad AДокумент268 страницS-6011 - DC Asdasd Asda Dad APeja JusohОценок пока нет

- Design Calculations For Light MastДокумент23 страницыDesign Calculations For Light Mastjobees7850Оценок пока нет

- 5890 000 SP 5103 001 - A PDFДокумент164 страницы5890 000 SP 5103 001 - A PDFrazormeback100% (2)

- Pump Foundation DesignДокумент18 страницPump Foundation DesignSourav92% (12)

- GCMT 13 MS CN FLR 001 1 Jun Rev.2 Flare Stack CalculationДокумент28 страницGCMT 13 MS CN FLR 001 1 Jun Rev.2 Flare Stack CalculationMedyRiomaОценок пока нет

- CAS & CRT FoundationsДокумент10 страницCAS & CRT Foundationsmasarriam1986Оценок пока нет

- Menaa M-03 4110-002R4 (Main Stadium-Sectors A&B Precast Structural Calculations - Rev4) 2012 - 1012 PDFДокумент176 страницMenaa M-03 4110-002R4 (Main Stadium-Sectors A&B Precast Structural Calculations - Rev4) 2012 - 1012 PDFErnest NavarroОценок пока нет

- Continuous Concrete Beam Design To Bs 81101997 Table 3.5Документ8 страницContinuous Concrete Beam Design To Bs 81101997 Table 3.5Victor AndradeОценок пока нет

- M2 CV ST D 002 (R0)Документ13 страницM2 CV ST D 002 (R0)ksshashidhar100% (1)

- RCC94 Two-Way Slabs (Tables) GGGДокумент3 страницыRCC94 Two-Way Slabs (Tables) GGGThomas OluwafemiОценок пока нет

- PSC Design (EC2) Tutorial PDFДокумент49 страницPSC Design (EC2) Tutorial PDFGeorge LazarОценок пока нет

- Sarpanta LemnДокумент4 страницыSarpanta LemnEla TeodorescuОценок пока нет

- Design Calculations For Light MastДокумент24 страницыDesign Calculations For Light Mastjobees7850100% (17)

- Calculation Sheet For Q-Pipe Rack Steel StrcutureДокумент66 страницCalculation Sheet For Q-Pipe Rack Steel StrcutureclarkgaguiОценок пока нет

- COPNO AKER Pipe Support ProcedureДокумент51 страницаCOPNO AKER Pipe Support Procedurejeddij100% (3)

- PR-10 Report Rev. B (Arkonin)Документ179 страницPR-10 Report Rev. B (Arkonin)Adrianus Hindradjaja100% (1)

- Actuator Blast CalcДокумент10 страницActuator Blast Calcviv0102Оценок пока нет

- PROFIS Anchor 2.4.6: WWW - Hilti.luДокумент6 страницPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliОценок пока нет

- How To Review PV Elite Design ReportДокумент9 страницHow To Review PV Elite Design ReportBhaskar Shankar Chowdhury100% (2)

- Atlas - Tech Data SheetsДокумент20 страницAtlas - Tech Data SheetsJAY PARIKHОценок пока нет

- PROFIS Anchor 2.4.6: WWW - Hilti.luДокумент6 страницPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliОценок пока нет

- 3M Textool Open-Top Sockets For QFN Applications: QFN Test Socket, 0.5Mm 48 Pos, EVEN ROW, 7x7 PKG With TPДокумент2 страницы3M Textool Open-Top Sockets For QFN Applications: QFN Test Socket, 0.5Mm 48 Pos, EVEN ROW, 7x7 PKG With TPPradeeban NОценок пока нет

- Cylinder Head Instalation ProceduresДокумент9 страницCylinder Head Instalation ProceduresNasser AyoubОценок пока нет

- RCC94 Two-Way Slabs (Tables)Документ4 страницыRCC94 Two-Way Slabs (Tables)Zayyan RomjonОценок пока нет

- Calculation Report For Monorail and Hatch Cover REV.0Документ15 страницCalculation Report For Monorail and Hatch Cover REV.0Tran Van DaiОценок пока нет

- Cylinder Head Instalation Procedures (Converted)Документ9 страницCylinder Head Instalation Procedures (Converted)Nasser AyoubОценок пока нет

- IC Data SheetДокумент14 страницIC Data SheetAnugrah AjyОценок пока нет

- 300-5617 Cooler AssemblyДокумент13 страниц300-5617 Cooler Assemblyharikrishnanpd3327Оценок пока нет

- B4B13Документ7 страницB4B13HanTeongОценок пока нет

- E-6012 - DC Ad Adasd Ad Adqwe Adas DaДокумент159 страницE-6012 - DC Ad Adasd Ad Adqwe Adas DaPeja JusohОценок пока нет

- Tutorial Pressure VesselДокумент19 страницTutorial Pressure Vesseltahseenahsan100% (1)

- 13 - Copes-Vulcan ValvesДокумент7 страниц13 - Copes-Vulcan ValvesshalegpОценок пока нет

- 320C Assemble Final DriveДокумент15 страниц320C Assemble Final DriveLuis ValenzuelaОценок пока нет

- ZzazazazzzzzaaДокумент14 страницZzazazazzzzzaaDenstar Ricardo Silalahi100% (2)

- IsometricsДокумент4 страницыIsometricsMuhammedHafisОценок пока нет

- Mediciones de Valvulas y Resortes de Valvula - C15Документ4 страницыMediciones de Valvulas y Resortes de Valvula - C15Andres Josue Rodriguez Santa CruzОценок пока нет

- 32.0 M Dia Roof Design ReportДокумент124 страницы32.0 M Dia Roof Design ReportsndpinОценок пока нет

- Porta Batumi Facade Structural Analysis Report RP16-001Документ39 страницPorta Batumi Facade Structural Analysis Report RP16-001ismail TORLAK100% (1)

- Pbadupws - Nrc.gov Docs ML0731 ML073190432Документ57 страницPbadupws - Nrc.gov Docs ML0731 ML073190432Ashish MahtoОценок пока нет

- Bok:978 1 4471 2879 3Документ576 страницBok:978 1 4471 2879 3Lê Hữu NamОценок пока нет

- Multi-Menu Delivery Project: 1. Business Opportunities Why Saudi Arabia?Документ28 страницMulti-Menu Delivery Project: 1. Business Opportunities Why Saudi Arabia?Lê Hữu NamОценок пока нет

- MGT104 Assignment 3Документ11 страницMGT104 Assignment 3Lê Hữu Nam0% (1)

- Restaurant InnovationДокумент25 страницRestaurant InnovationLê Hữu Nam100% (1)

- AUT Vice-Chancellor's Doctoral Scholarships - April and October RoundsДокумент4 страницыAUT Vice-Chancellor's Doctoral Scholarships - April and October RoundsLê Hữu NamОценок пока нет

- 6 Examination ProceduresДокумент5 страниц6 Examination ProceduresLê Hữu NamОценок пока нет

- Iron Kingdoms - Gun MageДокумент8 страницIron Kingdoms - Gun MageLê Hữu NamОценок пока нет

- ChernobylДокумент55 страницChernobylFacundo BaróОценок пока нет

- Elasto-Seal-Pro Bullbond Tds 2017rДокумент4 страницыElasto-Seal-Pro Bullbond Tds 2017rMark VillafloresОценок пока нет

- ENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)Документ4 страницыENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)m khaeronОценок пока нет

- How To Use A Gas RegulatorДокумент2 страницыHow To Use A Gas RegulatorJustin ChongОценок пока нет

- Developerguides Typical Manhole Detail Drawings 2022Документ7 страницDeveloperguides Typical Manhole Detail Drawings 2022Arnold HernandezОценок пока нет

- Teaching Dossier 20190301 - ULFG IIДокумент11 страницTeaching Dossier 20190301 - ULFG IIElie OtayekОценок пока нет

- N2xy Sni IecДокумент4 страницыN2xy Sni IecirfanОценок пока нет

- KF Components VacotecДокумент13 страницKF Components Vacotecaldo2306Оценок пока нет

- Butterfly ValveДокумент4 страницыButterfly ValveFlowBiz Exports Pvt. Ltd.Оценок пока нет

- A 615 A615M-96aДокумент5 страницA 615 A615M-96aipkm123Оценок пока нет

- CPVC Fire Sprinkler Products: Installation Instructions & Technical HandbookДокумент93 страницыCPVC Fire Sprinkler Products: Installation Instructions & Technical HandbookLuiz Fernando SilvaОценок пока нет

- Effect of Using Saturated Lime Water in The Production of Concrete Using Pozzolanic Cement Cem II B-PДокумент18 страницEffect of Using Saturated Lime Water in The Production of Concrete Using Pozzolanic Cement Cem II B-PKellymax olakitarОценок пока нет

- Lecture 23Документ83 страницыLecture 23Robert Andy WoodОценок пока нет

- 016 - Attachment For Full Scale Shear Pads - 01 Mar 11Документ54 страницы016 - Attachment For Full Scale Shear Pads - 01 Mar 11nadraОценок пока нет

- Earthen DamДокумент11 страницEarthen Dam20CE015 Swanand DeoleОценок пока нет

- APS Hydro Private LimitedДокумент14 страницAPS Hydro Private LimitedHema LathaОценок пока нет

- Shape Memory Alloy (SMA) Fluid Fitting System: Product Handbook & Engineering DataДокумент84 страницыShape Memory Alloy (SMA) Fluid Fitting System: Product Handbook & Engineering DatajcОценок пока нет

- Metal Ceramic Crown Lab ManualДокумент25 страницMetal Ceramic Crown Lab ManualchusbОценок пока нет

- DDDDДокумент185 страницDDDDJosé FernándezОценок пока нет

- Metal: Ferrous and Mild SteelДокумент74 страницыMetal: Ferrous and Mild SteelRoshan MauryaОценок пока нет

- Three Storey Commercial Building (Concrete) - 18-009 - PinagsamaДокумент21 страницаThree Storey Commercial Building (Concrete) - 18-009 - PinagsamaJohn Michael TalanОценок пока нет

- 31003Документ4 страницы31003Elliott RussellОценок пока нет

- Aula Estrutura 01Документ85 страницAula Estrutura 01Wanessa MoraisОценок пока нет

- Circle Rates Rev04 Effective 010709Документ42 страницыCircle Rates Rev04 Effective 010709giridharrajug1Оценок пока нет

- Kinlong-2021Door Control Hardware Typical Product Catalogue (Thuy Luc)Документ154 страницыKinlong-2021Door Control Hardware Typical Product Catalogue (Thuy Luc)vantanbkdnОценок пока нет

- Progress Report-December 2017 PDFДокумент17 страницProgress Report-December 2017 PDFCivil EngineerОценок пока нет

- Seismic Slope StabilityДокумент27 страницSeismic Slope StabilityMUHAMMAD ALIОценок пока нет

- Bolt Tightening-Torques PDFДокумент4 страницыBolt Tightening-Torques PDFSH1961100% (2)

- Booklet Tier I I PhaseДокумент48 страницBooklet Tier I I PhaseAkhlaq HussainОценок пока нет

- Submitted To The Department of Civil Engineering of CGC Technical Campus Jhanjeri, MohaliДокумент46 страницSubmitted To The Department of Civil Engineering of CGC Technical Campus Jhanjeri, MohaliBipinОценок пока нет

- Defining Titles and Career Paths in BIMДокумент7 страницDefining Titles and Career Paths in BIMjon_kasilagОценок пока нет