Академический Документы

Профессиональный Документы

Культура Документы

Bab 9 - Condensor Cooling.

Загружено:

masgrahaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bab 9 - Condensor Cooling.

Загружено:

masgrahaАвторское право:

Доступные форматы

PT.

PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

9. CONDENSOR COOLING

9.1 BACKGROUND

In a power plant, the cooling towers, water pumping systems and condensers are involved in condensing the exhaust steam from a steam turbine and transferring the waste heat to the atmosphere.

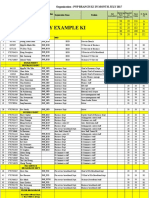

Condensers The condenser is the most important component of the turbine cycle that affects the turbine heat rate. The function of the condenser is to condense exhaust steam from the steam turbine by rejecting the heat of vaporization to the cooling water passing through the condenser. The brief typical specifications of a condenser used in 210 MW power plants are given in the Table 9-1. Table 9-1: Brief specifications of condenser (typical)

Description ID code Type Number of Passes No passes of circulating water Heat load considered for design Cooling water circulation rate Pressure at turbine exhaust Tube length between tube plates Total number of tubes ID of condenser tube Tube material Cooling surface area Cleanliness factor Design press. at tube and water boxes Cooling water temp. raise TTD at Design Cooling water flow and Inlet temp. Units No No Mkcal/hr m /hr kg/cm .abs m No mm m

2 2 3

Value XXXXX Twin shell design 2 2 285.88 2x13500 0.1 10 2x7810 28 Admiralty brass or cupronickel 90/10 depending upon cooling water condition 2x7300 85 6 9 3.4

% Kg/cm abs

O O 2

C C

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Cooling towers Different types of cooling towers are used in the power plants depending upon the location, size, infrastructure and water resources etc. The brief description of different systems is given below: Open cycle or once through systems: Some power stations have an open cycle (once through) cooling water system where water is taken from a water body, such as river, lake or sea pumped through the plant condenser and discharged back to the source. In this case, no cooling tower is required. Close cycle wet cooling systems: In some cases closed cycle wet cooling systems are adopted. In these cases cooling towers are used to reject the heat to the atmosphere with the aid of the cooling tower. The cooling towers can be induced or forced drafted type or natural draft type. Natural draught cooling towers have a large concrete shell. The warm air rises up through the shell by the 'chimney effect', creating the natural draught to provide airflow and operate the tower. These towers therefore do not require fans and have low operating costs. The type of cooling system used is greatly influenced by the location of the plant and on the availability of water suitable for cooling purposes.

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

The selection process is also influenced by the cooling system's environmental impacts. The following Table 9-2 gives typical specifications of cooling tower used in 210 MW power plant: Table 9-2: Brief typical specifications of cooling towers used in a 210 MW plant Manufacturer

Type of Cooling Tower Number of cells No of fans per cell Hot water inlet temperature Wet bulb temperature Dry bulb temperature Atmospheric pressure at power plant Total heat exchange per hour Re-cooled water temperature. Cooling range Fan blade material 12 1 40,3 C 27

O O

xxxx

Induced draft cross flow

C

O

29.67

762 mm Hg 324 x 106 kcal/hr 31,8 9

O O

FRP

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Table 9-3: Specifications of a typical cooling water pump used in a 210 MW

The major energy consuming equipment in the cooling systems are: Cooling towers and fans Cooling water pumps Make up water pumps Condensers

9.2 Steps Involved

The steps involved in conducting energy audit of cooling water and cooling tower are: Data collection Observations and Analysis Exploration for energy conservation measures Report preparation

9.3 Data Collection

9.3.1 Cooling tower specifications

The following Table 9-4 gives the list of cooling tower specifications to be collected for conducting the energy audit study.

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Table 9-4 : Specifications of cooling towers Particulars

Make Type Cooling Capacity, TR (or) Cooling Capacity, kcal/h No of cells Rated water flow, m /h Fill details No of CT fans CT fan kW No of blades per fan Air flow rate, m /h Blade angle Diameter of the blade assembly Blade material (FRP/Al/other) L / G Ratio Inlet water temperature, C Outlet water temperature, C Dry bulb temperature, C Wet bulb temperature, C Atmospheric pressure at the plant Range, OC Approach, C Drift losses

O O O O O

3 3

Cooling Tower #1 Operating

Cooling tower # 2 Design Operating

9.3.2 Specification of water pumps and motors

The following Table 9-5 gives the list of specifications of the pumps and pumping systems to be collected before conducting the energy audit.

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Table 9-5: Design Specifications of pumps & motors Particulars

ID code Location No of pumps installed No of pumps operated Make Type of the pump Model No of stages Rated pressure, kg /cm Rated flow, m /h Rated efficiency, % Input kW of the pump Speed of the pump Year of commissioning Motor kW Motor make Motor voltage Rated current of motor Motor rpm Rated motor efficiency

3 2

Collect the following information for all pumps in the cooling water circuit Performance characteristics of all pumps and motors Compile design, P. G. Test, previous best and last energy audit value with respect to cooling tower and cooling water system along with the condensers If the pumps are operated in parallel then it is advised to collect the performance curve for the parallel operation Schematic diagram of Water pumping network (which depict the source, pumps in operation & stand by, line sizes and users) Water and pressure equipment at the users as per the design requirements Brief description of the system with the key specifications in which pumps are used (for example, if pumps are used for supplying water to condenser, then add a brief write up about the cooling water system)

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

9.3.3 Condenser specifications

Collect the condenser design specifications in respect of the following key parameters Heat load considered for design Design inlet cooling water temperature Design TTD Cleanliness factor Cooling water temperature raise Condenser back pressure Cooling water flow Cooling water side pressure drop No of cooling water pass Total heat transfer area Condenser no of tubes: Condensing zone Air cooling zone Tube dimensions Tube OD x thickness Length of tube for ordering Tube material Condensing zone Air cooling zone Water box design pressure

9.4 Instruments Required

The following instruments are required for conducting the water pumping energy audit: Power Analyzer: Used for measuring electrical parameters of motors such as kW, kVA, pf, V, A and Hz Temperature Indicator & Probe Pressure Gauge: To measure operating pressure and pressure drop in the system Stroboscope: To measure the speed of the driven equipment and motor Ultra sonic flow meter or online flow meter Sling hygrometer or digital hygrometer Anemometer In addition to the above calibrated online instruments can be used PH meter 7

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

9.5 Measurements & Observation to Be Made

While conducting the audit, the following measurements and observations are necessary Energy consumption pattern of pumps and cooling tower fans Motor electrical parameters (kW, kVA, Pf, A, V, Hz, THD) for pumps and cooling tower fans Pump operating parameters to be measured/monitored for each pump are: Discharge Head (suction & discharge) Valve position (observation) Temperature Load variation Power parameters of pumps Pumps operating hours and operating schedule Pressure drop in the system (between discharge and user point) Pressure drop and temperatures across the users (heat exchangers, condensers, etc) Cooling water flow rate to users Pump /Motor speed Actual pressure at the user end User area pressure of operation and requirement Cooling tower parameters to be monitored Inlet temperature Outlet temperature Dry bulb temperature Wet bulb temperature or relative humidity Water flow to cooling tower Air flow rate of cooling tower Range, C L/G ratio Approach, C Fan speed, rpm Fan power consumption (kW/cell)

O O

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

While conducting the measurement or performance simultaneously the following need to be noted Unit load of the plant Date & time of measurement Instruments used of measurement Frequency of the measurement

evaluation

any

system

9.6 Observations and Analysis

9.6.1 System familiarization and operational details

Detailed interactions with the plant personnel have to be carried out to get familiarization for system detail and operational details. The brief details of the entire system have to be given in the report

9.6.2 Energy consumption Pattern

If the plant is monitoring the energy consumption, it is suggested to record the data and monitor the daily and monthly consumption pattern. Collect the past energy consumption data (month wise for at least 12 months, daily consumption for about a week for different seasons, daily consumption during the audit period). Work out the total consumption of cooling water and cooling tower system to arrive at percentage to the total consumption of the auxiliary consumption. If the energy meters are not installed to water pumps and cooling tower fans & its auxiliary units of, instantaneous measurements can be carried out, based on the loading pattern the daily consumption can be worked out (as shown in Table 9-6). Table 9-6: Energy consumption pattern Equipment

Cooling water pumps Make up water pumps Cooling tower fans Others Total

Instantaneous kW

Daily consumption, kWh

The energy consumption of cooling water and associated system: kWh/day Total auxiliary power consumption: kWh/Day

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

9.6.3 Operating efficiency and performance evaluation of the pumps

All operating pumps in cooling water circuit needs to be studied for its operating efficiency (As run performance test) with the aid of sophisticated energy audit instruments. In addition to these portable instruments online valid calibrated instruments can also be used during the energy audits. The parameters to be studied in detailed are: Water flow rate and pressure of pumps/headers Velocity in the main headers and pumps and major lines (to verify adequacy of line sizes) Power consumption of pumps (for estimating the operating efficiency of the pumps) Monitor present flow control system and frequency of control valve variation if any (for application of variable speed drives) Fill up the following data sheet for every pump for comparison with the design/PG test values The following Table 9-7 gives the list of parameters to be considered for performance evaluation. Table 9-7: Performance parameters for water pumps Particulars

Pump ID code Pump application Fluid pumped No of stages Suction head Discharge head Total head developed by pump Water flow Speed of the pump/ motor Hydraulic kW Input kW to the motor Combined efficiency Motor efficiency (Refer to motor performance curve) Pump efficiency

Unit

Design/PG test value

Actual

Remarks

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

10

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Type of discharge flow control mechanism Discharge throttle valve position (% open) Flow control frequency and duration if any % load of pump on flow % load of pump on head % load on motor Specific energy, kW/m /h

3

The above analysis and comparison will help in arriving at various energy efficiency improvement measures. Hydraulic power can be calculated by using the following: Q(m/s) x Total head.(hd - hs)m x .(kg/m ) x g.(m/s ) Hydraulic kW = 1000

3 2

Where:

Q Total head g

Water flow rate Difference between discharge head (hd) and suction head (hs ) Density of the water or fluid being pumped Acceleration due to gravity

m3/s m kg/m m/s

2 3

If the pumps are operating in parallel, it is advised to measure all above parameter for every pump separately to evaluate the individual pump performance. However combined parameters of flow and head need to be verified with Performance curve for parallel operation. Compare the actual values with the design/performance test values if any deviation is found, investigate for the contributing factors and arrive at appropriate suggestions. The investigations for abnormality are to be carried out for problems. Enlist scope of improvement with extensive physical checks/observations.

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

11

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Based on the actual operating parameters, enlist recommendations for action to be taken for improvement, if applicable such as: Replacement of pumps Impeller replacement Impeller trimming Variable speed drive application, etc

Compare the specific energy consumption with similar type of pumps and latest energy efficient pumps Cost analysis with savings potential for taking improvement measures.

9.6.4 Flow distribution to the major users and cooling towers

Measure the flow at the individual pump discharge side, main header, at the users (for the major and large users) along with the pressure and velocity. Depict these values in schematic diagram. The following Figure 9-1 gives the typical distribution network where measurements need to be carryout. Figure 9-1: Water balance

= Indicates where all flow measurements needs to be carried out The above measurement will help is comparing the design values/PG values with the present operating parameters. The above detailed measurements will help in checking for uniform distribution of water as per the design or rated parameters. While evaluating the system also look for the: Line adequacy (by measuring the velocity in the major pipe lines), Pressure drop in the distribution network Specific water flow rate

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

12

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

9.6.5 Performance of condensers

Evaluate the performance of the condenser by measuring the following parameters and comparing the same with design/PG test values. The following Table 9-8 list of the parameters to be considered while evaluating the condenser performance Table 9-8 : Parameters for condenser performance

Particulars Unit load Frequency Condenser back pressure, mmwg Cooling water flow, m3/h Cooling water inlet temperature, OC Cooling water outlet temperature, OC Cooling water temperature raise, OC Cooling water in /out pressure Pressure drop across the condenser Condenser heat load (estimated) Pressure Temperature Enthalpy Flow Condensate site (outlet of condenser) Pressure Temperature Enthalpy Saturation temperature Saturation and inlet water temperature difference LMTD TTD Condenser effectiveness Design/ PG test value Actual (@ different interval) 1 2 3 4 Avg Remarks

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

13

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

The following needs to be computed: a. Condenser heat load Condenser heat load = Q x T x Cp Q T Cp Water flow rate Average CW temperature rise Specific heat kg/h

O

kcal/kgOC

Expected condenser vacuum can be calculated from the performance curves of condenser as given by manufacturer.

b. Calculated condenser vacuum Calculated condenser vacuum = Atmospheric pressure - Condenser back pressure c. Deviation in condenser vacuum Deviation in vacuum = Expected condenser vacuum - Measured condenser vacuum d. Condenser TTD Condenser TTD = Saturation temperature - cooling water outlet temperature e. Condenser Effectiveness Rise in cooling water temperature Condenser Effectiveness = Saturation temperature - cooling water inlet temperature f. Condenser heat duty Condenser heat duty (kcal/h) can be computed by: Condenser heat duty is in kcal/h Condenser heat duty = heat added by main steam + heat added by reheater + heat added by SH attemperation + Heat added by RH attemperation + Heat added by BFP 860 (Pgen + Pgen.

losses

+ Heat loss due to radiation)

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

14

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Heat added by main steam, where: Heat added by main steam (MS) = Flow MS x (hMS - hFW), kcal/hr Flow MS = Flow of Main Steam excluding SH Attemperation in kg/hr

hMS hFW = Enthalpy of Main Steam in kcal/kg = Enthalpy of Feed Water in kcal/kg

Heat added by Reheater = Flow Reheater x (hHRH hCRH), kcal/hr Flow Reheater hHRH hCRH = Flow Cold Reheat Steam, kg/hr = Enthalpy of Hot Reheat Steam in kcal/ kg = Enthalpy of Cold Reheat Steam in kcal/kg

Heat added by BFP = Flow FW x (hBFP Out hBFP In) kcal/hr Flow FW hBFP Out hBFP In = Total FW flow kg/hr = (Enthalpy of FW at BFP Outlet), kcal/kg = (Enthalpy of FW at BFP Inlet), kcal/kg

Heat added by RH attemperation = Flow RH Attemperation x (hHRH hRHATT) kcal/ h hRHATT Flow RH Attemp = Enthalpy of RH Attemperation in kcal/kg = kg/hr

Heat added by SH Attemperation = Flow SH Attemp * (hMS hSHATT ) kcal/hr hSHATT Flow SH Attemp = (Enthalpy of SH Attemp ), kcal/kg = kg/hr

Heat Loss rad Pgen Pgen Losses*

)

= 0.1% of Pgen (Radiation Losses) kW = (Gross Generator Output), kW = (Mech. Losses + Iron Losses + Stator Current Losses), kW *) Values to be taken from Generator Loss Curve

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

15

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

g. Condenser tube velocity Tube velocity is given by: Cooling water flow rate x 10 Tube velocity = 3600 x Tube area x (No of tubes per pass - No of tubes plugged per pass)

6

where:

- Cooling water flow is in m /h - Tube velocity is in m/s - Tube area in mm

2

h. Determination of actual LMTD Actual LMTD is given by:

Where - LMTD is in OC - Tsat is saturation temperature in pressure

O

C corresponding to condenser back

- Tin is cooling water in let temperature OC - Tout is cooling water outlet let temperature OC i. Determination of expected LMTD

Correction for cooling water inlet temperature (ft) is given by Expected LMTD is given by: LMTD expected = LMTD test * ft * fw * fq

Correction for cooling water flow rate (fw) is given by

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

16

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Correction for cooling water heat load (fq) is given by

While conducting the energy audit of condensers, the following observations need to be carried out: Tubes in operation Vs total installed Cleaning system operation Filtering system for cooling water Regular monitoring system for performance Comparison of LMTD, TTD, heat load, condenser vacuum, flow, temperatures, pressures with design / PG test- arriving the factors causing deviation Modifications carried out in the recent past Cooling water flow Pressure drop on water side and choking Affect of present performance of cooling tower Accurate metering of vacuum Absolute back pressure deviation from expected value Sub cooling of air steam mixture and condensate Circulation water temperature raise Effectiveness of cleaning the tubes Circulating water velocity in tubes

9.6.6 Performance of cooling towers

Cooling tower performance can be evaluated by measuring/monitoring the following parameters given in the Table 9-9 for each cell of the cooling tower:

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

17

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Table 9-9: performance of a cooling tower Particulars Cooling water flow Cooling water inlet temperature Cooling water outlet temperature Dry bulb temperature Wet bulb temperature Air flow rate L/G ratio No of fans operated Power consumption of fan Fan speed Range Approach TR Evaporation losses Make up water requirement Design/PG test value 1 Actual 2 3 4 Avg Remarks

While conducting the cooling tower, visual observations need to be made with respect to: Adequate water level in the trough Cross flow air from other cooling towers (which are under maintenance) Nozzle condition and operation Fill condition Change of blade angles during change of seasons The CT airflow shall be measured using an anemometer and compared with calculated airflow derived from fan characteristic curves of CT fans with actual power measurements. Calculate range, approach, L/G (Liquid to gas) ratio and effectiveness for design and operating conditions for each tower

C.T.Range

= Water inlet temperature - Water outlet temp.

C.T. Approach = Water Outlet temperature - Wet bulb temp.

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

18

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

range x 100 Effectiveness % = {range + approach}

Water flow in kg L/G ratio = Air flow in kg

Fan airflow actual (Nm /h)/cell Rated fan flow in Nm /h x (Fan input kW actual) = (Fan input rated)

1/3

3

1/3

Air mass flow/cell = flow x density of air CW flow (m /hr) x CT Range in OC Evaporation losses = 675

3

Evaporation losses Makeup water consumption = (COC 1)

The above readings may be taken on daily basis for three days on different atmospheric conditions say during midsummer, winter & monsoon period. Once in the mid-day and once in the mid night time and a record duly maintained. Collect unit load (MW), frequency, and condenser vacuum condition while taking the cooling tower measurement

9.6.7 Power consumption of CT fans

All fans power consumption (Table 9-10) to be measured and to be compared with the airflow and blade angles.

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

19

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Table 9-10: Power consumption of fans CT Fan # Blade angle setting KW Drawn

9.6.8 Application and matching of pump

Installed pump has to be thoroughly verified for its application, whether the pump is best suited for the application, duty, load variation, etc. The various options to be considered to improvement energy efficiency are: Replacement of present pump with best suited energy efficient pump Replace of trim the impeller, if the pump is throttled to reduce the flow by 10-20%. (Where a smaller impeller is not available, the impeller may be trimmed in consultation with the manufacturers) Retrofit with variable speed drives pumps if the pumps are serving variable loads

9.6.9 Exploration of energy conservation possibilities

While conducting the energy audit of the condenser and cooling water system, the following need to be explored in detail for Condenser Possibility of Improvement in condenser vacuum Turbine heat rate Reduction possibilities Improving the effectiveness of condenser and TTD Cooling water flow adequacy and flow optimization Air ingress Increasing the TTD of the condenser Fouling of tubes Water pumping and cooling tower Improvement of systems and drives. Use of energy efficient pumps Replacement of inefficient pumps

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

20

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Trimming of impellers Correcting inaccuracies of the Pump sizing Use of high efficiency motors Integration of variable speed drives into pumps: The integration of adjustable speed drives (VFD) into compressors could lead to energy efficiency improvements, depending on load characteristics. High Performance Lubricants: The low temperature fluidit and high temperature stability of high performance lubricants can increase energy efficiency by reducing frictional losses. Improvements in condenser performance Improvement in cooling tower performance Application potential for energy efficient fans for cooling tower fans Measuring and tracking system performance: Measuring water use and energy consumption is essential in determining whether changes in maintenance practices or investment in equipment could be cost effective. In this case it is advised to monitor the water flow rate and condenser parameters, cooling tower parameters periodically i.e. at least once in a three months and energy consumption on daily basis. This will help in identifying the Deviations in water flow rates Heat duty of condenser and cooling towers Measures to up keep the performance

System Effect Factors Equipment cannot perform at its optimum capacity if fans, pumps, and blowers have poor inlet and outlet conditions. Correction of system effect factors (SEFs) can have a significant effect on performance and energy savings. Elimination of cavitation: Flow, pressure, and efficiency are reduced in pumps operating under cavitation. Performance can be restored to manufacturers specifications through modifications. This usually involves inlet alterations and may involve elevation of a supply tank. Internal Running Clearances: The internal running clearances between rotating and non-rotating elements strongly influence the turbo machine's ability to meet rated performance. Proper set-up reduces the amount of leakage (re-circulation) from the discharge to the suction side of the impeller.

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

21

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

CONDENSOR COOLING

Reducing work load of pumping: Reducing of obstructions in the suction / delivery pipes thereby reduction in frictional losses. This includes removal of unnecessary valves of the system due to changes. Even system and layout changes may help in this including increased pipe diameter. Replacement of components deteriorated due to wear and tear during operation, Modifications in piping system

After the identification of energy conservation measures, detailed techno-economic evaluation has to be carried out.

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta NilaiNilai-Nilai Perusahaan

22

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Exfoliation TestexДокумент26 страницExfoliation TestexmasgrahaОценок пока нет

- Session VI EHa and LTR Mechanical Equipment and Operation and MaintenanceДокумент59 страницSession VI EHa and LTR Mechanical Equipment and Operation and MaintenancemasgrahaОценок пока нет

- Innovation For Boiler TubeДокумент2 страницыInnovation For Boiler TubemasgrahaОценок пока нет

- Journal of Power Engineering and Power Equipment Ppchem-02-2008-5-Errata PDFДокумент6 страницJournal of Power Engineering and Power Equipment Ppchem-02-2008-5-Errata PDFmasgrahaОценок пока нет

- Exfoliation TestexДокумент26 страницExfoliation TestexmasgrahaОценок пока нет

- Geothermal Energy Status ReportДокумент64 страницыGeothermal Energy Status ReportmasgrahaОценок пока нет

- Boiler Management EPRIДокумент3 страницыBoiler Management EPRImasgrahaОценок пока нет

- 2011 TB WB Merged PDFДокумент115 страниц2011 TB WB Merged PDFthequranthekoranОценок пока нет

- Boiler Feed Water Treatment Oxgenated Power Plant in ChinaДокумент11 страницBoiler Feed Water Treatment Oxgenated Power Plant in Chinamasgraha100% (1)

- Boiler Management Reliable & AvailableДокумент3 страницыBoiler Management Reliable & AvailablemasgrahaОценок пока нет

- Sustaining Power Plant Life Through Rehabilitation As A Part of Life Cycle Management Program r02Документ14 страницSustaining Power Plant Life Through Rehabilitation As A Part of Life Cycle Management Program r02masgrahaОценок пока нет

- PASS55 WorkshopДокумент9 страницPASS55 WorkshopmasgrahaОценок пока нет

- When Generator Rewind in GeneralДокумент4 страницыWhen Generator Rewind in GeneralmasgrahaОценок пока нет

- Boiler Maintenance Management SystemДокумент3 страницыBoiler Maintenance Management SystemmasgrahaОценок пока нет

- PASS55 - QuestionsДокумент2 страницыPASS55 - QuestionsmasgrahaОценок пока нет

- Air Heater PerformanceДокумент6 страницAir Heater PerformancemasgrahaОценок пока нет

- Incipient & Hidden Failure From Relevance ReferencesДокумент3 страницыIncipient & Hidden Failure From Relevance ReferencesmasgrahaОценок пока нет

- PAS55 Assessment ExerciseДокумент28 страницPAS55 Assessment ExercisemasgrahaОценок пока нет

- Handout Pass55Документ27 страницHandout Pass55masgrahaОценок пока нет

- Asset Management: Review and CloseДокумент3 страницыAsset Management: Review and ClosemasgrahaОценок пока нет

- Asset Management: Review and CloseДокумент3 страницыAsset Management: Review and ClosemasgrahaОценок пока нет

- Asset Management: Review and CloseДокумент3 страницыAsset Management: Review and ClosemasgrahaОценок пока нет

- PASS55 WorkshopДокумент9 страницPASS55 WorkshopmasgrahaОценок пока нет

- Air Heater Powermag 101 - CoalДокумент36 страницAir Heater Powermag 101 - CoalmasgrahaОценок пока нет

- Pass55 ChartДокумент4 страницыPass55 ChartmasgrahaОценок пока нет

- Pass 55 CBRM2Документ33 страницыPass 55 CBRM2masgrahaОценок пока нет

- PASS55 - PerformanceДокумент16 страницPASS55 - PerformancemasgrahaОценок пока нет

- PAS 55 ReviewДокумент8 страницPAS 55 ReviewmasgrahaОценок пока нет

- Pass 55 CBRMДокумент18 страницPass 55 CBRMmasgrahaОценок пока нет

- Tools, Facilities and EquipmentДокумент3 страницыTools, Facilities and EquipmentmasgrahaОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Presenters: Horace M. Estrella Jay Mart A. Lazana Princess Camille R. HipolitoДокумент23 страницыPresenters: Horace M. Estrella Jay Mart A. Lazana Princess Camille R. HipolitoHorace EstrellaОценок пока нет

- Reaction Paper FinalДокумент5 страницReaction Paper FinalJelo RoxasОценок пока нет

- Cool Fire Manual 45M620N2UK 01 PDFДокумент198 страницCool Fire Manual 45M620N2UK 01 PDFPaun MihaiОценок пока нет

- SavannahHarbor5R Restoration Plan 11 10 2015Документ119 страницSavannahHarbor5R Restoration Plan 11 10 2015siamak dadashzadeОценок пока нет

- 300u Specs Diodo 300 Amps. 25 Dolares RadiosurtidoraДокумент6 страниц300u Specs Diodo 300 Amps. 25 Dolares RadiosurtidorarepelindОценок пока нет

- Essentials: Week by WeekДокумент18 страницEssentials: Week by WeekHirenkumar ShahОценок пока нет

- Oceanarium: Welcome To The Museum Press ReleaseДокумент2 страницыOceanarium: Welcome To The Museum Press ReleaseCandlewick PressОценок пока нет

- Research Group 3 11abmb1Документ32 страницыResearch Group 3 11abmb1arianeОценок пока нет

- SecurityFund PPT 1.1Документ13 страницSecurityFund PPT 1.1Fmunoz MunozОценок пока нет

- Nfpa 1126 PDFДокумент24 страницыNfpa 1126 PDFL LОценок пока нет

- Bossypants Autobiography and Womens SelvesДокумент26 страницBossypants Autobiography and Womens SelvesCamila Paz GutiérrezОценок пока нет

- BSH 7005-15Документ129 страницBSH 7005-15Mark InnesОценок пока нет

- [18476228 - Organization, Technology and Management in Construction_ an International Journal] Adaptive Reuse_ an Innovative Approach for Generating Sustainable Values for Historic Buildings in Developing CountriesДокумент15 страниц[18476228 - Organization, Technology and Management in Construction_ an International Journal] Adaptive Reuse_ an Innovative Approach for Generating Sustainable Values for Historic Buildings in Developing Countrieslohithsarath bethalaОценок пока нет

- Chapter 2.3.3 History of Visual Arts Modernism Post ModernismДокумент17 страницChapter 2.3.3 History of Visual Arts Modernism Post ModernismKim Ashley SarmientoОценок пока нет

- EZ Water Calculator 3.0.2Документ4 страницыEZ Water Calculator 3.0.2adriano70Оценок пока нет

- Artificial Intelligence Practical 1Документ5 страницArtificial Intelligence Practical 1sadani1989Оценок пока нет

- Dessler HRM12e PPT 01Документ30 страницDessler HRM12e PPT 01harryjohnlyallОценок пока нет

- Report DR JuazerДокумент16 страницReport DR Juazersharonlly toumasОценок пока нет

- Introduction To Password Cracking Part 1Документ8 страницIntroduction To Password Cracking Part 1Tibyan MuhammedОценок пока нет

- Openvpn ReadmeДокумент7 страницOpenvpn Readmefzfzfz2014Оценок пока нет

- RSC Article Template-Mss - DaltonДокумент15 страницRSC Article Template-Mss - DaltonIon BadeaОценок пока нет

- LFF MGДокумент260 страницLFF MGRivo RoberalimananaОценок пока нет

- Taoist Master Zhang 张天师Документ9 страницTaoist Master Zhang 张天师QiLeGeGe 麒樂格格100% (2)

- Benedict Anderson, Imagined CommunitiesДокумент2 страницыBenedict Anderson, Imagined CommunitiesMonir Amine0% (1)

- Case Study - Montana Mountain BikingДокумент6 страницCase Study - Montana Mountain Bikingbonny MishОценок пока нет

- Pelayo PathopyhsiologyДокумент13 страницPelayo PathopyhsiologyE.J. PelayoОценок пока нет

- PNP Ki in July-2017 AdminДокумент21 страницаPNP Ki in July-2017 AdminSina NeouОценок пока нет

- Animal Health ChecklistДокумент4 страницыAnimal Health ChecklistcapsfastОценок пока нет

- IMDSI22Документ82 страницыIMDSI22Dang JinlongОценок пока нет

- Muscles of The Dog 2: 2012 Martin Cake, Murdoch UniversityДокумент11 страницMuscles of The Dog 2: 2012 Martin Cake, Murdoch UniversityPiereОценок пока нет

![[18476228 - Organization, Technology and Management in Construction_ an International Journal] Adaptive Reuse_ an Innovative Approach for Generating Sustainable Values for Historic Buildings in Developing Countries](https://imgv2-2-f.scribdassets.com/img/document/422064728/149x198/344a5742a7/1565947342?v=1)