Академический Документы

Профессиональный Документы

Культура Документы

Formulation and Evaluation of Mucoadhesive Microcapsules of Rifampicin

Загружено:

IOSR Journal of PharmacyИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Formulation and Evaluation of Mucoadhesive Microcapsules of Rifampicin

Загружено:

IOSR Journal of PharmacyАвторское право:

Доступные форматы

IOSR Journal Of Pharmacy (e)-ISSN: 2250-3013, (p)-ISSN: 2319-4219 Www.Iosrphr.

Org Volume 3, Issue 4 (May 2013), Pp 10-14

Formulation and Evaluation of Mucoadhesive Microcapsules Of Rifampicin

Gottapu Prashanti1

(A.U. College of Pharmaceutical Sciences, Visakhapatnam, Andhra Pradesh-530003)1

Abstract: Mucoadhesive microcapsules of rifampicin were prepared by orifice ionic gelation technique for a

novel controlled release product. Sodium alginate, sodium carboxy methyl cellulose and chitosan were used as coating polymers in different ratios to obtain elegant microcapsules. The formulations were characterized for encapsulation efficiency, SEM analysis and invitro release studies. The microcapsules were discrete, large almost spherical and free flowing with encapsulation efficiency in the range 75 to 88% and size ranging from 780 to 882nm. Rifampicin release from these microcapsules was slow and extended over longer periods of time depending on polymer coat. Drug release was diffusion controlled and followed first order kinetics. The formulation F11 with coating ratio1:2:2 of sodium alginate and chitosan was found to be suitable for oral controlled release. Keywords: Rifampicin, tuberculosis, sodium alginate, sodium carboxy methyl cellulose, chitosan.

I.

INTRODUCTION

Microcapsules are one of the multiparticulate delivery systems and are prepared to obtain prolonged or controlled drug delivery, to improve bioavailability, stability and target drug to specific sites. These can also offer advantages like limiting fluctuation within therapeutic range, reducing side effects, decreasing the dosing frequency and improving patient compliance. Tuberculosis is a chronic communicable disease caused by the bacterium Mycobacterium tuberculosis that infects over 1.8 billion people worldwide and is responsible for 1.5 million deaths annually. Rifampicin is a first-line drug for being used in the therapy of tuberculosis and is included in the list of recommended drug regimens for the treatment of latent M. tuberculosis infection in adults. Rifampicin is the semi-synthetic hydrazine derivative of Rifampicin B. In the last several years, many different types of rifampicin controlled release formulations have been developed to improve clinical efficacy of drug and patient compliance.

II.

MATERIALS AND METHOD OF PREPARATION

Rifampicin drug was a gift sample from Lupin laboratories,. All other chemicals and solvents used were of analytical grade. Paddle stirrer, dissolution apparatus, and UV-visible spectrophotometer, were the equipments used in this study. Microcapsules of rifampicin were prepared by using ionotropic gelation technique employing sodium alginate/sodium cmc/chitosan as coat material. Three sets of microcapsules were prepared. In the first set microcapsules of rifampicin were prepared using only sodium alginate in different ratios(1:1), (1:2),(1:3). In the second set, microcapsules of the drug were prepared using sodium alginate and sodium carboxymethyl cellulose polymers in different ratios(1:1:1),(1:1:2),(1:2:1),(1:2:2) and in the third set microcapsules of the drug were prepared in combination of polymers like sodium alginate and chitosan (1:1:1),(1:1:2),(1:2:1),(1:2:2).

III.

CHARACTERISTICS OF THE PREPARED MICROCAPSULES

3.1 Size And Shape Of Microcapsules Size of the rifampicin microcapsules was determined by sieve analysis. The microcapsules were separated in to different size fractions by sieving using standard sieves. The particle size distributions of the microcapsules were determined to know the mean particle size of microcapsules. All readings are average of three trials SD. The shape and surface morphology of the rifampicin microcapsules were investigated using a HitachiS5-20, scanning electron microscope at room temperature using the required magnification. The sample was deposited on aluminium stubs and coated with gold in HUS-5GB vacuum evaporator, to render it electrically conductive. Encapsulation efficiency was calculated using the formula, Encapsulation efficiency= (estimated percent drug content/theoretical percent drug content)100.

10

Formulation And Evaluation Of Mucoadhesive Microcapsules Of Rifampicin

3.2 Estimation Of Rifampicin Rifampicin content in the microcapsules was estimated by using UV spectrophotometer method. A quantity of microcapsules equivalent to 100 mg were powdered and transferred into a 100 ml volumetric flask, sufficient amount of methanol was added to produce 100 ml, shaken for 20 min and filtered. Two milliliters of the filtrate was diluted to 100 ml with phosphate buffer (pH 7.4) and HCl buffer (pH 1.2) containing ascorbic acid (200 g/ml) and the drug content was analyzed at 475 n m. Three determinations were carried out for each fraction. 3.3 INVITRO STUDIES 3.3.1 MUCOADHESIVE STUDY OF MICROCAPSULES The mucoadhesive property of the microcapsules was evaluated by an in vitro adhesion testing method known as the wash-off method. Freshly excised pieces of intestinal mucosa (2 2 cm) from sheep were mounted onto glass slides (3 1inch) with cyanoacrylate glue. Two glass slides were connected with a suitable support. About 50 microcapsules were spread onto each wet rinsed tissue specimen, and immediately thereafter the support was hung onto the arm of a USP tablet disintegrating test machine. When the disintegrating test machine was operated, the tissue specimen was given a slow, regular up-and-down movement in the test fluid at 37C contained in a 1 L vessel of the machine. At the end of 30 minutes, at the end of 1 hour, and at hourly intervals up to 12 hours, the machine was stopped and the number of microcapsules still adhering to the tissue was counted. The test was performed at both gastric pH (0.1N HCl, pH 1.2) and intestinal pH (phosphate buffer, pH 7.4). 3.3.2 DISSOLUTION STUDIES Dissolution studies were carried out using USP XXIII rotating basket method. The stirring rate was 75 rpm. 900 ml of pH 7.4 phosphate buffer having ascorbic acid (200 g/ml) was used as dissolution medium and maintained at 371. Samples of 5 ml each were withdrawn at regular time intervals, filtered, diluted suitably, analyzed using double beam UV spectrophotometer at 475 nm and an equal volume of fresh medium was immediately added to maintain the dissolution volume. Dissolution studies were carried out up to 100% release of the drug. The drug release experiments were conducted in triplicate. IR studies (not shown) indicated that the qualitative composition of the drug formulation and verified the identity of each of the components. No drug interaction or complexation occurred during the manufacturing process.

IV.

RESULTS AND DISCUSSION

A standard calibration curve for the drug was obtained by measuring absorbance at 475nm, and by plotting the graph of absorbance V/s concentration in triplicate pH 1.2, pH 7.4 between 2 to 10 g/ml concentrations. Estimation of drug content and in-vitro drug release studies are based on this standard curve. The particle size distribution of all the formulations were determined and the Mean average particle size of rifampicin mucoadhesive microcapsules as showm in table no.1 was found to be in the range of 780 to 882m. Table no.1 Average particle size of microcapsules Sl no. FORMULATIONS Mean particle size(m) 1 F1 792 2 F2 780 3 F3 840 4 F4 832 5 F5 840 6 F6 865 7 F7 882 8 F8 810 9 F9 800 10 F10 840 11 F11 825 The drug entrapment efficiency of all the formulations were in the range between 75% to 88%. Drug entrapment efficiency of microparticles increases with increase in concentration of Sodium cmc and chitosan. The percentage encapsulation yield of the formulations are given in table no.2 shows percentage yield from 67 to 72%.

11

Formulation And Evaluation Of Mucoadhesive Microcapsules Of Rifampicin

Table no.2 Encapsulation yield of all formulations Formulations % percentage yield F1 670.65 F2 68.50.79 F3 69.40.87 F4 70.111.01 F5 72.30.45 F6 73.20.73 F7 710.91 F8 72.090.82 F9 71.431.1 F10 70.640.71 F11 71.920.96 The swelling ratio of microcapsules were determined was higher in pH 7.4 than pH 1.2. among the all formulations, the chitosan alginate microcapsules are having the low swelling indices. In vitro wash off test was conducted to assess mucoadhesive properties of prepared microcapsules. Mucoadhesion test was carried out with everted sheep intestinal sac in the presence of pH 1.2 and pH 7.4. The washoff was faster at intestinal pH than at gastric pH. The rapid wash-off observed at intestinal pH was due to ionization of carboxyl and other functional groups in the polymers at this pH. The results of the wash-off test indicated that the microcapsules had fairly good mucoadhesive property. 4.1 INVITRO DISSOLUTION STUDIES Dissolution studies of all the formulations were carried out using dissolution tester USP XXIII.The dissolution studies were conducted by using two different dissolution medias, pH 1.2 & pH 7.4. Formulations F1, F2, F3 containing drug and sodium alginate polymer in different ratios i.e, 1:1, 1:2, 1:3 have shown drug release of 100%, 99.99% &100% in 25, 26 & 27hrs respectively as shown in fig no.1. This shows that more sustained release was observed with increase in percentage of sodium alginate.

Fig no.1 Zero order kinetics for F1,F2,F3 In formulations F4, F5, F6, F7 containing sodium alginate and sodium cmc in ratios 1:1:1, 1:1:2, 1:2:1, 1:2:2 the drug released completely in 26, 28, 28,30hrs of time period shown in fig no.2. This shows that the release rate is retarted.

12

Formulation And Evaluation Of Mucoadhesive Microcapsules Of Rifampicin

Fig no.2 Zero order kinetics for F4,F5,F6,F7 Similarly the time period was further increased when chitosan was replaced to sodium cmc following same ratios. For formulation F11 it took 46hrs for complete release of the drug and for F10, F9, F8 the time period was 44, 43&41 hrs as shown in fig no.3. This indicates that the release rate time period was further increased with the addition and increase in concentration of chitosan because of strong bonds between chitosan and sodium alginate.

Fig no.3 Zero order kinetics for F8,F9,F10,F11 The highest time period taken by the optimized formulation F11 which is about 46 hrs for complete drug release.Further these drug releases were subjected for mathematical treatment to check whether it is following first order or zero order. Based on the co-efficient of correlation (r) values in table no.3 it was observed that the drug release is following zero order kinetics. The plots of amount of drug released vs square root of time were found to be linear indicating that the drug release mechanism is diffusion controlled. In the present system, based on the calculated values rifampicin follows non-fickian transport and zero order kinetics.

13

Formulation And Evaluation Of Mucoadhesive Microcapsules Of Rifampicin

Table no.3 Calculated values of various kinetic models Formulations Zero order First order Higuchi Peppas F1 r=0.806 r=0.834 r=0.947 r=0.851 n=0.590 F2 r=0.834 r=0.843 r=0.954 r=0.862 n=0.653 F3 r=0.847 r=0.913 r=0.970 r=0.871 n=0.673 F4 r=0.865 r=0.853 r=0.947 r=0.860 n=0.599 F5 r=0.874 r=0.856 r=0.973 r=0.863 n=0.607 F6 r=0.909 r=0.858 r=0.989 r=0.872 n=0.635 F7 r=0.945 r=0.923 r=0.992 r=0.875 n=0.650 F8 r=0.935 r=0.920 r=0.983 r=0.870 n=0.600 F9 r=0.954 r=0.934 r=0.984 r=0.877 n=0.675 F10 r=0.968 r=0.930 r=0.987 r=0.878 n=0.690 F11 r=0.989 r=0.951 r=0.991 r=0.921 n=0.697

V.

CONCLUSION

Mucoadhesive microcapsules of rifampicin were formulated by ionotropic gelation technique using sodium alginate, sodium cmc & chitosan. The IR spectras revealed that, there was no interaction between polymers and drug. All the polymers used were compatible with the drug. From the study it is evident that a promising controlled release microcapsules drug delivery of rifampicin can be developed. Further in-vivo investigation required to establish efficacy of these formulations.The study also indicated that the time required for drug release increases with an increase in the polymer concentration.

REFERENCES

[1]. [2]. [3]. [4]. [5]. [6]. [7]. [8]. [9]. [10]. [11]. Ain, Q.U; Sharma, S; Khuller, G.K; Garg, S.K,Alginate-based oral drug delivery system for tuberculosis: pharmacokinetic and therapeutic effects, J Antimicrob Chemother ,2003, 51, 931938. Shaik R., Singh T.R.R., Garland M.J., A David Woolfson, and Ryan F.Donnely, mucoadhesive drug delivery system J.Phaem Bioadhesion Sciences 2011 Jan-Mar;3(1):89-100 Edsman K., Hagerstrom H., Pharmacetical Applications of mucoadhesion for the oral routes.J.Pharm pharmocol.2005 Jan;57(1):3-22 Jiang L., Gao L., Wang X.,Tang L.,The applications of mucoadhesive polymers in drug delivery. Drug delivery in pharmacy.2010 Mar; 36(3):323-36 Labana, S; Pandey, R, Sharma, S; Khuller, G.K,Chemotherapeutic activity against murine tuberculosis of once weekly administered drugs (INH and RIF)encapsulated in liposomes, Int J Antimicrob Agents,.2002, 20, 301 304. Quenelle, D. C; Winchester, G. A; Staas, J. K.Treatment of tuberculosis using a combination of sustained-release rifampinloaded microspheres and oral dosing with isoniazid,. Antimicrobial Agents and Chemotherapy, 2001, 45, 163744. Tonnesen, H. H; Karlsen, J. Alginate in drug delivery systems. Drug Development and Industrial Pharmacy, 2002, 28, 621 30. Hejazi, R; Amiji, M. Chitosan-based gastrointestinal delivery systems. Journal of Controlled Release, 2003, 89, 151 65. Manekar N.C. and Joshi, S.B., Microencapsulation Technique". The Eastern Pharmacist, 1998; 47-49. Chowdary K.P.R. and Suresh Babu K.V.V., "Studies on Micro encapsulation by Calcium Alginate". The Eastern Pharmacist, 1989; 2 : 125-126. Pilley V. and C. M. Dangor, Ionotropic Gelation : encapsulation of indomethacin in calcium alginate gel discs. J. of microencapsulation: 1998; 15(2):215-26.

14

Вам также может понравиться

- Evaluation of Micro CapsulesДокумент6 страницEvaluation of Micro CapsulesPeeyush_Sharma_5529Оценок пока нет

- Guru Nanak Institute of Pharmacy, Ibrahimpatnam, Hyderabad-501506, Dist-Ranga Reddy, Andhra PradeshДокумент9 страницGuru Nanak Institute of Pharmacy, Ibrahimpatnam, Hyderabad-501506, Dist-Ranga Reddy, Andhra PradeshNur Aini IktikhafsariОценок пока нет

- Enkapsulasi KetoprofenДокумент5 страницEnkapsulasi KetoprofenFitria NugrahaeniОценок пока нет

- LC method for ampicillin and dicloxacillinДокумент10 страницLC method for ampicillin and dicloxacillincarbouОценок пока нет

- A Study On The Effects of Different Surfactants On Ethylcellulose MicrospheresДокумент6 страницA Study On The Effects of Different Surfactants On Ethylcellulose Microspheres'Satria Putra PenarosaОценок пока нет

- Formulasi Sediaan FarmasiДокумент11 страницFormulasi Sediaan FarmasiKukuh PermadiОценок пока нет

- DESIGN AND EVALUATION OF MUCOADHESIVE MICROCAPSULES OF ACECLOFENAC BY SOLVENT EMULSIFICATION METHOD Gangotri Yadav, Resma Jadhav, Vaishali Jadhav, Ashish JainДокумент7 страницDESIGN AND EVALUATION OF MUCOADHESIVE MICROCAPSULES OF ACECLOFENAC BY SOLVENT EMULSIFICATION METHOD Gangotri Yadav, Resma Jadhav, Vaishali Jadhav, Ashish JainiajpsОценок пока нет

- Mucoadhesive MicrospheresДокумент20 страницMucoadhesive MicrospheresRam C DhakarОценок пока нет

- Micro Sphere ThesisДокумент26 страницMicro Sphere ThesisPeter SamОценок пока нет

- Analisis Cipro Dengan UVДокумент8 страницAnalisis Cipro Dengan UVGhina Rahimah Az-zahraОценок пока нет

- 26537-Article Text-147230-1-10-20190103 PDFДокумент4 страницы26537-Article Text-147230-1-10-20190103 PDFSoheil JafariОценок пока нет

- 26537-Article Text-147230-1-10-20190103 PDFДокумент4 страницы26537-Article Text-147230-1-10-20190103 PDFSoheil JafariОценок пока нет

- Martins 2019Документ7 страницMartins 2019Hasna NoerОценок пока нет

- Delivery of Ofloxacin Hydrochloride Using Chitosan-Sodium Alginate IPN BeadsДокумент28 страницDelivery of Ofloxacin Hydrochloride Using Chitosan-Sodium Alginate IPN BeadsEpha Lumban GaolОценок пока нет

- Nadifloxacin - HPTLC Stability Indicating PDFДокумент8 страницNadifloxacin - HPTLC Stability Indicating PDFNájla KassabОценок пока нет

- Formulation and Evaluation of Ciprofloxacin Microspheres for Nasal Drug DeliveryДокумент6 страницFormulation and Evaluation of Ciprofloxacin Microspheres for Nasal Drug DeliveryNela SharonОценок пока нет

- Development and Validation of A Dissolution Test With Spectrophotometric Analysis For Gemifloxacin in Tablet Dosage FormДокумент6 страницDevelopment and Validation of A Dissolution Test With Spectrophotometric Analysis For Gemifloxacin in Tablet Dosage FormwiracanaОценок пока нет

- 6 Sy Comparative Evaluation of Niosome Formulations Prepared by Different TechniquesДокумент6 страниц6 Sy Comparative Evaluation of Niosome Formulations Prepared by Different Techniquesgrvgr8Оценок пока нет

- A A A A C CC C A A A A D D D D Eeee M M M M IIII C CC C S S S S C CC C IIII Eeee N N N N C CC C Eeee S S S SДокумент5 страницA A A A C CC C A A A A D D D D Eeee M M M M IIII C CC C S S S S C CC C IIII Eeee N N N N C CC C Eeee S S S SvouudaosuОценок пока нет

- 10 1 1 509 9662 PDFДокумент5 страниц10 1 1 509 9662 PDFRizky AdyaОценок пока нет

- 11 ArticleДокумент10 страниц11 ArticleBaru Chandrasekhar RaoОценок пока нет

- Amoxicillin Mucoadhesive Microspheres Manage H. PyloriДокумент11 страницAmoxicillin Mucoadhesive Microspheres Manage H. PyloriYuda ArifОценок пока нет

- Analytical Method Development and Validation of Caffeine in Tablet Dosage Form by Using UV-SpectrosДокумент5 страницAnalytical Method Development and Validation of Caffeine in Tablet Dosage Form by Using UV-SpectrosKrisna Raditya PОценок пока нет

- AsdasdasdasdДокумент7 страницAsdasdasdasdduarupiahОценок пока нет

- ASSAY METHOD DEVELOPMENT AND VALIDATION FOR THE ESTIMATION OF SOLIFENACIN SUCCINATE IN TABLETS BY UV SPECTROPHOTOMETRY N.J.R. Hepsebah, A. Ashok KumarДокумент6 страницASSAY METHOD DEVELOPMENT AND VALIDATION FOR THE ESTIMATION OF SOLIFENACIN SUCCINATE IN TABLETS BY UV SPECTROPHOTOMETRY N.J.R. Hepsebah, A. Ashok KumariajpsОценок пока нет

- Cephalexine Spectro VisДокумент0 страницCephalexine Spectro VisVictor Purnama Agung FanggidaeОценок пока нет

- 4.kalpana ArticleДокумент5 страниц4.kalpana ArticleBaru Chandrasekhar RaoОценок пока нет

- Formulation And Evaluation Of Sustained Release Sodium Alginate Microbeads Of CarvedilolДокумент8 страницFormulation And Evaluation Of Sustained Release Sodium Alginate Microbeads Of CarvedilolDelfina HuangОценок пока нет

- Saiful 2016Документ7 страницSaiful 2016skkbd415Оценок пока нет

- Spectrophotometric Determination of Isoxsuprine in Pure and Pharmaceutical FormsДокумент7 страницSpectrophotometric Determination of Isoxsuprine in Pure and Pharmaceutical FormsIOSRjournalОценок пока нет

- Simultaneous Estimation of Sulfamethoxazole and Pyrimethamine in Bulk and Combined Tablet Dosage FormДокумент10 страницSimultaneous Estimation of Sulfamethoxazole and Pyrimethamine in Bulk and Combined Tablet Dosage FormSaravanan RamОценок пока нет

- Simple Fluorimetric Method for Estimating MoxifloxacinДокумент3 страницыSimple Fluorimetric Method for Estimating MoxifloxacinVindhy MulyaОценок пока нет

- BP 181212054815Документ74 страницыBP 181212054815Ahmad AinurofiqОценок пока нет

- Preparation and Evaluation of Wound Healing Activity of Ursolic Acid Nanoemulgel Formulations in RatsДокумент11 страницPreparation and Evaluation of Wound Healing Activity of Ursolic Acid Nanoemulgel Formulations in RatsRAPPORTS DE PHARMACIEОценок пока нет

- Ashraf M. Mahmoud, Saad A. Alqahtani: American Journal of Analytical Chemistry, 2016, 7, 179-191Документ13 страницAshraf M. Mahmoud, Saad A. Alqahtani: American Journal of Analytical Chemistry, 2016, 7, 179-191DrGajanan VaishnavОценок пока нет

- Micro SphereДокумент4 страницыMicro SphereDrAmit VermaОценок пока нет

- 7.formulation and Evaluation of Lycopene Emulgel PDFДокумент15 страниц7.formulation and Evaluation of Lycopene Emulgel PDFYuppie RajОценок пока нет

- International Journal of Innovative Pharmaceutical ResearchДокумент8 страницInternational Journal of Innovative Pharmaceutical ResearchDavid GuzmanОценок пока нет

- Análise de Nicarbazina em RaçãoДокумент9 страницAnálise de Nicarbazina em RaçãoCarol MicalliОценок пока нет

- Development and Evaluation of Mucoadhesive Vaginal Tablet of Sertaconazole For Vaginal CandidiasisДокумент8 страницDevelopment and Evaluation of Mucoadhesive Vaginal Tablet of Sertaconazole For Vaginal CandidiasisAnugrah ElfaОценок пока нет

- Degradation PramipexoleДокумент9 страницDegradation Pramipexoleclaudiamaniac7Оценок пока нет

- 2 51 1584357062 5ijmpsapr20205Документ12 страниц2 51 1584357062 5ijmpsapr20205TJPRC PublicationsОценок пока нет

- 1246 PDFДокумент4 страницы1246 PDFPrima RiyandiОценок пока нет

- Preparation and Evaluation of Sustained Release Microbeads of Norfloxacin Using Sodium AlginateДокумент5 страницPreparation and Evaluation of Sustained Release Microbeads of Norfloxacin Using Sodium AlginateRajesh KumarОценок пока нет

- Formulation and Evaluation of Niosome-Encapsulated Levofloxacin For Ophthalmic Controlled DeliveryДокумент11 страницFormulation and Evaluation of Niosome-Encapsulated Levofloxacin For Ophthalmic Controlled Deliverynurbaiti rahmaniaОценок пока нет

- EJCHEM - Volume 65 - Issue 11 - Pages 155-162Документ8 страницEJCHEM - Volume 65 - Issue 11 - Pages 155-162Gustavo D.B.Оценок пока нет

- Estimation of Meropenem in Human Plasma by HPLC-UV and Its Application in Comparative Bioavailability StudyДокумент8 страницEstimation of Meropenem in Human Plasma by HPLC-UV and Its Application in Comparative Bioavailability Studyayand2005Оценок пока нет

- Available Online Through Dissolution Enhancement of Atorvastatin Calcium by Nanosuspension TechnologyДокумент4 страницыAvailable Online Through Dissolution Enhancement of Atorvastatin Calcium by Nanosuspension TechnologyChandarana ZalakОценок пока нет

- Jourraal of Chromatography, 421 (1988) 257-267 Biomedical ApplicationsДокумент11 страницJourraal of Chromatography, 421 (1988) 257-267 Biomedical Applicationsarunkumar76Оценок пока нет

- Services On DemandДокумент13 страницServices On DemandaKureishiОценок пока нет

- Jurnal Formulasi Rifampicin PDFДокумент15 страницJurnal Formulasi Rifampicin PDFKris Natalia ManihurukОценок пока нет

- Research Article: Received: 23 July 2016, Revised and Accepted: 30 September 2016Документ7 страницResearch Article: Received: 23 July 2016, Revised and Accepted: 30 September 2016AndreyОценок пока нет

- New Spectrophotometric Assay of Pyrantel Pamoate in Pharmaceuticals and Spiked Human Urine Using Three Complexing AgentsДокумент2 страницыNew Spectrophotometric Assay of Pyrantel Pamoate in Pharmaceuticals and Spiked Human Urine Using Three Complexing AgentsNurul FatimahОценок пока нет

- 213 SharmaДокумент4 страницы213 SharmaFaradies ArijaОценок пока нет

- Experiment KumudДокумент8 страницExperiment KumudSudeep KothariОценок пока нет

- J. Antimicrob. Chemother. 2004 Pandey 635 40Документ6 страницJ. Antimicrob. Chemother. 2004 Pandey 635 40Mark del RosarioОценок пока нет

- Método de Análisis Colorimétrico para AzitromicinaДокумент8 страницMétodo de Análisis Colorimétrico para AzitromicinaAmatista CanteОценок пока нет

- Formulation Development and Evaluation of TransferДокумент10 страницFormulation Development and Evaluation of TransferOktavia Rahayu AОценок пока нет

- Experimental approaches to Biopharmaceutics and PharmacokineticsОт EverandExperimental approaches to Biopharmaceutics and PharmacokineticsОценок пока нет

- Practical Handbook of Pharmaceutical Chemistry for M.PharmОт EverandPractical Handbook of Pharmaceutical Chemistry for M.PharmОценок пока нет

- The Comprehensive Review On Fat Soluble VitaminsДокумент17 страницThe Comprehensive Review On Fat Soluble VitaminsIOSR Journal of PharmacyОценок пока нет

- Total Phenol and Antioxidant From Seed and Peel of Ripe and Unripe of Indonesian Sugar Apple (Annona Squamosa L.) Extracted With Various SolventsДокумент6 страницTotal Phenol and Antioxidant From Seed and Peel of Ripe and Unripe of Indonesian Sugar Apple (Annona Squamosa L.) Extracted With Various SolventsIOSR Journal of PharmacyОценок пока нет

- Analytical Study of Urine Samples For Epidemiology of Urinary Tract Infections by Using Urine R/E in Local Population of Abbottabad, PakistanДокумент7 страницAnalytical Study of Urine Samples For Epidemiology of Urinary Tract Infections by Using Urine R/E in Local Population of Abbottabad, PakistanIOSR Journal of PharmacyОценок пока нет

- Chest Sonography Images in Neonatal R.D.S. and Proposed GradingДокумент3 страницыChest Sonography Images in Neonatal R.D.S. and Proposed GradingIOSR Journal of PharmacyОценок пока нет

- A Review On Step-by-Step Analytical Method ValidationДокумент13 страницA Review On Step-by-Step Analytical Method ValidationIOSR Journal of Pharmacy100% (1)

- A Case of Allergy and Food Sensitivity: The Nasunin, Natural Color of EggplantДокумент5 страницA Case of Allergy and Food Sensitivity: The Nasunin, Natural Color of EggplantIOSR Journal of PharmacyОценок пока нет

- Fibrolipomatous Hamartoma of Ulnar Nerve: A Rare Case ReportДокумент3 страницыFibrolipomatous Hamartoma of Ulnar Nerve: A Rare Case ReportIOSR Journal of PharmacyОценок пока нет

- Sulphasalazine Induced Toxic Epidermal Necrolysis A Case ReportДокумент3 страницыSulphasalazine Induced Toxic Epidermal Necrolysis A Case ReportIOSR Journal of PharmacyОценок пока нет

- Evaluation The Efficacy of IVIgG in Treatment of Hemolytic Disease of NewbornДокумент5 страницEvaluation The Efficacy of IVIgG in Treatment of Hemolytic Disease of NewbornIOSR Journal of PharmacyОценок пока нет

- Complete NMR Assignment of MogrosidesII A2, II E andIII A1Isolated From Luo Han GuoДокумент6 страницComplete NMR Assignment of MogrosidesII A2, II E andIII A1Isolated From Luo Han GuoIOSR Journal of PharmacyОценок пока нет

- Clinico-Haematological Profile of Falciparum Malaria in A Rural Hospital of Triputa.Документ3 страницыClinico-Haematological Profile of Falciparum Malaria in A Rural Hospital of Triputa.IOSR Journal of PharmacyОценок пока нет

- A Cross Sectional Study of Ethnic Differences in Occurrence and Severity of Adverse Drug Reactions (ADRs) Due To NSAIDs in SikkimДокумент6 страницA Cross Sectional Study of Ethnic Differences in Occurrence and Severity of Adverse Drug Reactions (ADRs) Due To NSAIDs in SikkimIOSR Journal of PharmacyОценок пока нет

- Self Medication Practices For Oral Health Problems Among Dental Patients in Bangalore: A Cross Sectional StudyДокумент8 страницSelf Medication Practices For Oral Health Problems Among Dental Patients in Bangalore: A Cross Sectional StudyIOSR Journal of PharmacyОценок пока нет

- Indonesian Wild Ginger (Zingiber SP) Extract: Antibacterial Activity Against Mycoplasma GallisepticumДокумент6 страницIndonesian Wild Ginger (Zingiber SP) Extract: Antibacterial Activity Against Mycoplasma GallisepticumIOSR Journal of PharmacyОценок пока нет

- Nanoemulsion and Nanoemulgel As A Topical FormulationДокумент5 страницNanoemulsion and Nanoemulgel As A Topical FormulationIOSR Journal of PharmacyОценок пока нет

- Pharmacokinetics of High-Dose Methotrexate in Egyptian Children With Acute Lymphoblastic Leukemia: Impact of Interpatient VariationsДокумент10 страницPharmacokinetics of High-Dose Methotrexate in Egyptian Children With Acute Lymphoblastic Leukemia: Impact of Interpatient VariationsIOSR Journal of PharmacyОценок пока нет

- A Case of Allergy and Food Sensitivity: The Nasunin, Natural Color of EggplantДокумент5 страницA Case of Allergy and Food Sensitivity: The Nasunin, Natural Color of EggplantIOSR Journal of PharmacyОценок пока нет

- Epidemiology of Tuberculosis (TB) in Albania 1998-2009Документ7 страницEpidemiology of Tuberculosis (TB) in Albania 1998-2009IOSR Journal of PharmacyОценок пока нет

- Nanoemulsion and Nanoemulgel As A Topical FormulationДокумент5 страницNanoemulsion and Nanoemulgel As A Topical FormulationIOSR Journal of PharmacyОценок пока нет

- Complete NMR Assignment of MogrosidesII A2, II E andIII A1Isolated From Luo Han GuoДокумент6 страницComplete NMR Assignment of MogrosidesII A2, II E andIII A1Isolated From Luo Han GuoIOSR Journal of PharmacyОценок пока нет

- Clinico-Haematological Profile of Falciparum Malaria in A Rural Hospital of Triputa.Документ3 страницыClinico-Haematological Profile of Falciparum Malaria in A Rural Hospital of Triputa.IOSR Journal of PharmacyОценок пока нет

- Self Medication Practices For Oral Health Problems Among Dental Patients in Bangalore: A Cross Sectional StudyДокумент8 страницSelf Medication Practices For Oral Health Problems Among Dental Patients in Bangalore: A Cross Sectional StudyIOSR Journal of PharmacyОценок пока нет

- Indonesian Wild Ginger (Zingiber SP) Extract: Antibacterial Activity Against Mycoplasma GallisepticumДокумент6 страницIndonesian Wild Ginger (Zingiber SP) Extract: Antibacterial Activity Against Mycoplasma GallisepticumIOSR Journal of PharmacyОценок пока нет

- Pharmacokinetics of High-Dose Methotrexate in Egyptian Children With Acute Lymphoblastic Leukemia: Impact of Interpatient VariationsДокумент10 страницPharmacokinetics of High-Dose Methotrexate in Egyptian Children With Acute Lymphoblastic Leukemia: Impact of Interpatient VariationsIOSR Journal of PharmacyОценок пока нет

- Total Phenol and Antioxidant From Seed and Peel of Ripe and Unripe of Indonesian Sugar Apple (Annona Squamosa L.) Extracted With Various SolventsДокумент6 страницTotal Phenol and Antioxidant From Seed and Peel of Ripe and Unripe of Indonesian Sugar Apple (Annona Squamosa L.) Extracted With Various SolventsIOSR Journal of PharmacyОценок пока нет

- Epidemiology of Tuberculosis (TB) in Albania 1998-2009Документ7 страницEpidemiology of Tuberculosis (TB) in Albania 1998-2009IOSR Journal of PharmacyОценок пока нет

- A Review On Step-by-Step Analytical Method ValidationДокумент13 страницA Review On Step-by-Step Analytical Method ValidationIOSR Journal of Pharmacy100% (1)

- Hematological and Biochemical Alterations in Malaria and Their Correlation With Parasitic Index.Документ4 страницыHematological and Biochemical Alterations in Malaria and Their Correlation With Parasitic Index.IOSR Journal of PharmacyОценок пока нет

- A Cross Sectional Study of Ethnic Differences in Occurrence and Severity of Adverse Drug Reactions (ADRs) Due To NSAIDs in SikkimДокумент6 страницA Cross Sectional Study of Ethnic Differences in Occurrence and Severity of Adverse Drug Reactions (ADRs) Due To NSAIDs in SikkimIOSR Journal of PharmacyОценок пока нет

- Treatment of Uthiravatha Suronitham (Rheumatoid Arthritis) With A Siddha Compound Formulation - A Case Study.Документ3 страницыTreatment of Uthiravatha Suronitham (Rheumatoid Arthritis) With A Siddha Compound Formulation - A Case Study.IOSR Journal of Pharmacy100% (1)

- Fulhold Pharma Investor Update Regulatory ProgressДокумент5 страницFulhold Pharma Investor Update Regulatory ProgresstopwineОценок пока нет

- Dr. Arya Govinda - Management of OAB in ElderlyДокумент36 страницDr. Arya Govinda - Management of OAB in ElderlyCOVID RSHJОценок пока нет

- Dosage - Chapter 7Документ6 страницDosage - Chapter 7kaukau4everОценок пока нет

- MEROPENEMДокумент1 страницаMEROPENEMJust now0% (1)

- Contraception and FertilityДокумент11 страницContraception and FertilityWil LesterОценок пока нет

- Group 3 Assignment 1.Документ10 страницGroup 3 Assignment 1.Tinke WinkeОценок пока нет

- Technical Information 1414 - AEROPERL® 300 Pharma Improving The Dissolution of Poorly Soluble APIs PDFДокумент16 страницTechnical Information 1414 - AEROPERL® 300 Pharma Improving The Dissolution of Poorly Soluble APIs PDFvinayОценок пока нет

- Lithium Intoxication: A Case Report and Review of PharmacokineticsДокумент4 страницыLithium Intoxication: A Case Report and Review of PharmacokineticsDHIVYAОценок пока нет

- tcrm0301 003Документ11 страницtcrm0301 003paulОценок пока нет

- Pharmacological Science Adverse Effects Pharmaceutical Products Etymological Adverse Drug Reactions Prophylaxis Medication ErrorsДокумент27 страницPharmacological Science Adverse Effects Pharmaceutical Products Etymological Adverse Drug Reactions Prophylaxis Medication ErrorsSuchita HenrageОценок пока нет

- Sinus tachycardia to digitalis toxicity drug commentsДокумент6 страницSinus tachycardia to digitalis toxicity drug commentssaharamichaelОценок пока нет

- Cytochrome P450Документ17 страницCytochrome P450Abdul QuyyumОценок пока нет

- Herbal Medicine Current Status and The FutureДокумент8 страницHerbal Medicine Current Status and The FutureCarlos TobarОценок пока нет

- Size, Shape, and Other Physical Attributes of Generic Tablets and Capsules PDFДокумент11 страницSize, Shape, and Other Physical Attributes of Generic Tablets and Capsules PDFJoe Luis Villa MedinaОценок пока нет

- Provider Type Network Name Card Governorate CityДокумент2 256 страницProvider Type Network Name Card Governorate CityOsama Os OsОценок пока нет

- Hydrocodone/Acetaminophen Tablets & Capsules: Media ImagesДокумент9 страницHydrocodone/Acetaminophen Tablets & Capsules: Media ImagesjavasoloОценок пока нет

- Harga Sudah Termasuk PPN Dan PPHДокумент2 страницыHarga Sudah Termasuk PPN Dan PPHAditya listyo subagyoОценок пока нет

- Neurotoxicity of Ecstasy (MDMA) : An OverviewДокумент10 страницNeurotoxicity of Ecstasy (MDMA) : An OverviewArian JafariОценок пока нет

- Obat IhcДокумент3 страницыObat IhcyolandaОценок пока нет

- Use of Antibiotic and Analgesic Drugs During LactationДокумент11 страницUse of Antibiotic and Analgesic Drugs During LactationpinakshiОценок пока нет

- Cefuroxime Drug StudyДокумент4 страницыCefuroxime Drug StudyJC LumayaОценок пока нет

- uk-pl-casodex-excipients-guideline-ONC 20 0015Документ5 страницuk-pl-casodex-excipients-guideline-ONC 20 0015Deisy ClerkeОценок пока нет

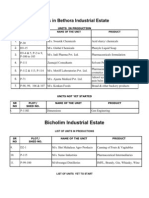

- Goa Industrial Estates 1Документ11 страницGoa Industrial Estates 1Vishal SalveОценок пока нет

- Essential of Rational Medicines UseДокумент30 страницEssential of Rational Medicines UseJareena BegumОценок пока нет

- NPPA PRICE LIST UPDATED AS ON 13/2/2018Документ208 страницNPPA PRICE LIST UPDATED AS ON 13/2/2018anil karnОценок пока нет

- Mycitracin - Google SearchДокумент1 страницаMycitracin - Google SearchKomal KhanОценок пока нет

- ICH E2F Step 4 October 2010Документ34 страницыICH E2F Step 4 October 2010SravyaОценок пока нет

- Saturation Kinetics: Prepared and Presented by Mohammed Muzammil 1 Year Mpharm Department of PharmacologyДокумент28 страницSaturation Kinetics: Prepared and Presented by Mohammed Muzammil 1 Year Mpharm Department of PharmacologyMaaz Uddin SiddiquiОценок пока нет

- List Napza, Oot, Prekusor All Terdaftar PomДокумент54 страницыList Napza, Oot, Prekusor All Terdaftar PomIrsan SyarifuddinОценок пока нет

- CTOC-v122update-Final-USFDA eCTD StructureДокумент25 страницCTOC-v122update-Final-USFDA eCTD StructureCHENFU LlUОценок пока нет