Академический Документы

Профессиональный Документы

Культура Документы

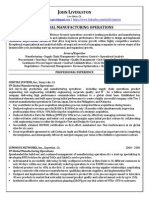

Vice President Manufacturing Operations in Chicago IL Resume Timothy Kelleher

Загружено:

TimothyKelleherОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Vice President Manufacturing Operations in Chicago IL Resume Timothy Kelleher

Загружено:

TimothyKelleherАвторское право:

Доступные форматы

TIMOTHY KELLEHER Long Grove, IL 60047 Email: tkelleher1012@aol.

com Phone: 847-478-8931 VICE PRESIDENT OF MANUFACTURING OPERATIONS

Continuous Improvement / Lean Manufacturing / Business Strategy / Global Multi-Plant Start-Ups / Team Building / Consolidations / Supply Chain / Cost Reduction / Distribution Manufacturing Operations Executive with progressive leadership experience in all aspects of global manufacturing and supply chain/distribution operations. Expertise in Continuous Improvement, Lean Six Sigma, turning around problem operations, cost reduction and improving gross margins. Strong background in all phases of plant start-ups, supply chain, inventory management, quality assurance, process development, ERP implementations, EHS, acquisitions and consolidations and self-directed team development. Experience encompasses high and low volume operations.

CAREER HISTORY & HIGHLIGHTS GENERAL MANAGER, WD Allen Group, Crystal Lake, IL, 06/12-12/12 Full P & L responsibility for this global supply chain service provider. Led business until sale of company at the end of 2012

Formalized business development process with visible 1 3 year goals to ensure business growth, expansion, and competitiveness to double sales volume over the next 6 years. Identified and pursued global supply chain partners in emerging markets to strategically position WD Allen as a broad, competitive supply chain player. Successfully reduced duplicative supply chain functionality within machining and fabrication commodities by 23% within 6 months while realizing an 18% aggregate cost improvement.

VP/DIRECTOR OF MANUFACTURING, PCTEL, Bloomingdale, IL, 2005-2012 Led global manufacturing activities including production, supply chain, inventory management, contract manufacturers, distribution, logistics, manufacturing engineering, facilities and safety for this wireless communication equipment manufacturer. Initiated Lean Manufacturing initiative that reduced production cycle times by 88%, improved on-time shipping from 87% to 98%, increased labor productivity by 17% and reduced direct labor costs by 32%. Saved $5.5M in material and labor costs and improved the gross margin from 26% to 35% by implementing a comprehensive cost reduction program. Improved product quality by 83% from 2700 ppm to 460 ppm by organizing cross-functional teams, identifying and correcting root causes, error-proofing operations, redefining process control roles and instituting a range of preventative actions. Automated packaging operations at PCTEL that reduced indirect labor costs by 50% and improved shipping quality from 1200 ppm to 208 ppm. Improved inventory record accuracy by 29% to 98% within 2 years. Led successful plant start-up and consolidated production of four (4) antenna manufacturers into one plant without customer service interruption.

Timothy Kelleher MANAGER, MANUFACTURING OPERATIONS, Texas Instruments / Power Trends Division, Warrenville, IL,1998-2005 Managed production, technical support, process control, planning, inventory management, shipping and customer service for this electronics manufacturer.

Implemented pull manufacturing that reduced production cycle times by 70%. Successfully planned and executed the transition of six (6) high volume SMT and assembly product lines to TI plant in Mexico without customer impact. Utilized pareto analysis of late shipments reasons and implemented countermeasures that resulted in a 14% improvement in customer delivery. Deployed automated order acknowledgement/capacity management process within SAP ERP integration that decreased production planning/ customer service man-hours by 80%.

OPERATIONS MANAGER, Bell & Howell, Durham, NC, 1994-1998 Managed plant output in terms of revenue, quality results, cost and delivery for this electromechanical capital equipment solutions provider.

Developed and implemented cellular manufacturing processes, performance measurement systems, plant-wide quality systems and safety and training processes. Reduced lead time by 50% from 4 weeks to 10 days on complicated system machines. Utilized quality improvement processes that reduced functional field problems by 83%. Spearheaded plant relocation from Charlotte to Durham NC without customer impact, and selected and trained self-directed workforce that grew operation to $48M within 4 years. Created core safety management processes; recognized across the corporation as the outstanding benchmark across the corporation.

MATERIALS/QUALITY MANAGER, 1993-1994 Created and implemented effective quality processes from incoming inspection to final test. Developed master scheduling, order processing, MRP, production scheduling, shop floor control, ECN, stockroom and shipping processes.

Earlier career includes Quality Systems Manager for CYRO Industries (automotive plastics (1990-1993). EDUCATION & PROFESSIONAL DEVELOPMENT Masters in Business Administration and Bachelor of Science in Manufacturing Technology, University of Limerick, Limerick, Ireland (rated among the top three schools in Ireland). Lean Bronze - Society of Manufacturing Engineers, 2011, Lean Manufacturing Certificate-University of Illinois at Chicago, 2004 Certified Quality Manager and Six Sigma Black Belt - American Society for Quality, 2001 & 2004 Certified in Production & Inventory Management - APICS, 2000 Inventory Record Accuracy, Buker Consulting, 2009

Вам также может понравиться

- VP Manufacturing Supply Chain in Denver CO Resume Thomas DespresДокумент3 страницыVP Manufacturing Supply Chain in Denver CO Resume Thomas DespresThomasDespresОценок пока нет

- How to Enhance Productivity Under Cost Control, Quality Control as Well as Time, in a Private or Public OrganizationОт EverandHow to Enhance Productivity Under Cost Control, Quality Control as Well as Time, in a Private or Public OrganizationОценок пока нет

- Professional Resume For Tom RandallДокумент3 страницыProfessional Resume For Tom RandalltomrandallОценок пока нет

- Director of Operations or Plant Manager or Quality Manager or PRДокумент2 страницыDirector of Operations or Plant Manager or Quality Manager or PRapi-78457904Оценок пока нет

- Operations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsДокумент2 страницыOperations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsPaulRoberts2Оценок пока нет

- Production Manager or Production SupervisorДокумент3 страницыProduction Manager or Production Supervisorapi-121382640Оценок пока нет

- Facilities Manager Manufacturing Director in Orange County CA Resume Mark LevitzДокумент2 страницыFacilities Manager Manufacturing Director in Orange County CA Resume Mark LevitzMarkLevitzОценок пока нет

- Director VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuДокумент3 страницыDirector VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuThomasZhu2Оценок пока нет

- VP Quality Operations Executive in Kansas City MO Resume Saul PachecoДокумент3 страницыVP Quality Operations Executive in Kansas City MO Resume Saul PachecoSaulPacheco100% (2)

- VP General Manager in United States Resume Art ChristiansonДокумент2 страницыVP General Manager in United States Resume Art ChristiansonArtChristiansonОценок пока нет

- Vice President Operations in Somerville NJ Resume Vasu MohanДокумент3 страницыVice President Operations in Somerville NJ Resume Vasu MohanVasumohanОценок пока нет

- Alan Miner 2010Документ3 страницыAlan Miner 2010ajminerОценок пока нет

- Charlie Kiss Resume 2016Документ2 страницыCharlie Kiss Resume 2016api-212848086Оценок пока нет

- Plant Manager Director Operations Quality in Washington DC Resume Sanders HolstonДокумент3 страницыPlant Manager Director Operations Quality in Washington DC Resume Sanders HolstonSandersHolstonОценок пока нет

- VP Director Operations Manufacturing in Chicago IL Resume Erik PetersonДокумент2 страницыVP Director Operations Manufacturing in Chicago IL Resume Erik PetersonErikPeterson1Оценок пока нет

- Manufacturing Plant Manager Resume SampleДокумент0 страницManufacturing Plant Manager Resume SamplePrem Singh LaishangbamОценок пока нет

- Director Operations Manufacturing Production in Philadelphia PA Resume Charles AltmanДокумент3 страницыDirector Operations Manufacturing Production in Philadelphia PA Resume Charles AltmanCharlesAltmanОценок пока нет

- Senior Operations Lean Manager in Dallas Fort Worth TX Resume James BirdДокумент2 страницыSenior Operations Lean Manager in Dallas Fort Worth TX Resume James BirdJames BirdОценок пока нет

- Plant Operations Director Manager in Dallas FT Worth TX Resume Kevin HuurmanДокумент2 страницыPlant Operations Director Manager in Dallas FT Worth TX Resume Kevin HuurmanKevinHuurmanОценок пока нет

- VP Operations Technical Services in Atlanta GA Resume Tammy MatthewsДокумент3 страницыVP Operations Technical Services in Atlanta GA Resume Tammy MatthewsTammyMatthewsОценок пока нет

- Todd ShuderДокумент3 страницыTodd ShuderToddShuderОценок пока нет

- Improvement Manager Chemical Manufacturing in Houston Texas Resume Hans DreikornДокумент2 страницыImprovement Manager Chemical Manufacturing in Houston Texas Resume Hans DreikornHans Dreikorn1Оценок пока нет

- Improvement Manager Chemical Manufacturing in Houston TX Resume Hans DreikornДокумент2 страницыImprovement Manager Chemical Manufacturing in Houston TX Resume Hans DreikornHans DreikornОценок пока нет

- VP Director Operations Supply Chain in Buffalo Niagara NY Resume Glen LongleyДокумент3 страницыVP Director Operations Supply Chain in Buffalo Niagara NY Resume Glen LongleyGlenLongleyОценок пока нет

- Director Manufacturing in Greater Denver CO Resume Erik Van HornДокумент2 страницыDirector Manufacturing in Greater Denver CO Resume Erik Van HornErik Van HornОценок пока нет

- Quality Technical Leader in Marietta GA Resume Wayne BoldenДокумент2 страницыQuality Technical Leader in Marietta GA Resume Wayne BoldenWayneBoldenОценок пока нет

- Resume of WwildmanДокумент3 страницыResume of Wwildmanapi-31967822Оценок пока нет

- Process Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsДокумент2 страницыProcess Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDouglasWilkinsОценок пока нет

- VP Director Operations Semiconductor in San Francisco Bay CA Resume Joel CamardaДокумент3 страницыVP Director Operations Semiconductor in San Francisco Bay CA Resume Joel CamardaJoelCamardaОценок пока нет

- Plant Manager Manufacturing Operations in Syracuse NY Resume Samuel BeamanДокумент3 страницыPlant Manager Manufacturing Operations in Syracuse NY Resume Samuel BeamanSamuelBeamanОценок пока нет

- Senior Project Manager in Dallas TX Resume Phillip HaugДокумент2 страницыSenior Project Manager in Dallas TX Resume Phillip HaugPhillipHaugОценок пока нет

- Manufacturing Plant Manager Operations in Edmonton Canada Resume Francois RoyДокумент2 страницыManufacturing Plant Manager Operations in Edmonton Canada Resume Francois RoyFrancois RoyОценок пока нет

- Lean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichДокумент3 страницыLean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichMichaelMakarewichОценок пока нет

- Manufacturing Manager Aerospace Electronics RF in San Jose CA Resume William CaryДокумент3 страницыManufacturing Manager Aerospace Electronics RF in San Jose CA Resume William CaryWilliamCaryОценок пока нет

- VP Quality Lean Sigma Development in TX OK MO KS Resume Mark FellerДокумент2 страницыVP Quality Lean Sigma Development in TX OK MO KS Resume Mark FellerMark FellerОценок пока нет

- Resume Higdon Joe 2019Документ3 страницыResume Higdon Joe 2019api-469696047Оценок пока нет

- Thomas Clark: - Director of ManufacturingДокумент2 страницыThomas Clark: - Director of ManufacturingHitendra Nath BarmmaОценок пока нет

- Industrial Engineer CV TemplateДокумент2 страницыIndustrial Engineer CV TemplateWasim RashidОценок пока нет

- Vice President Quality Operations in Greater Chicago IL Resume Kevin FredrichДокумент2 страницыVice President Quality Operations in Greater Chicago IL Resume Kevin FredrichKevin Fredrich1Оценок пока нет

- VP Supply Chain Manufacturing in Los Angeles San Diego CA Resume Gary MuellerДокумент3 страницыVP Supply Chain Manufacturing in Los Angeles San Diego CA Resume Gary MuellerGaryMueller1Оценок пока нет

- Change Management Director in Chicago IL Resume John BarkerДокумент2 страницыChange Management Director in Chicago IL Resume John BarkerJohnBarker1Оценок пока нет

- VP Operations Manufacturing Purchasing in Salt Lake City UT Resume Jolene KawaДокумент2 страницыVP Operations Manufacturing Purchasing in Salt Lake City UT Resume Jolene KawaJoleneKawaОценок пока нет

- Production Supervisor Planner Aviation in Atlanta GA Resume Nancy CashДокумент2 страницыProduction Supervisor Planner Aviation in Atlanta GA Resume Nancy CashNancyCashОценок пока нет

- Facilities Maintenance Consultant in Detroit MI Virtual Resume Robert MillerДокумент2 страницыFacilities Maintenance Consultant in Detroit MI Virtual Resume Robert MillerRobertMiller1Оценок пока нет

- Director of Operations or Manufacturing Manager or ManufactringДокумент2 страницыDirector of Operations or Manufacturing Manager or Manufactringapi-77726818Оценок пока нет

- VP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonДокумент2 страницыVP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonJohn Livingston2Оценок пока нет

- Customer Service Operations Manager in Calgary AB Canada Resume Randy ScottДокумент3 страницыCustomer Service Operations Manager in Calgary AB Canada Resume Randy ScottRandyScottОценок пока нет

- TPM / Lean / Maintenance / Operations MGRДокумент4 страницыTPM / Lean / Maintenance / Operations MGRapi-121351425Оценок пока нет

- Manufacturing Engineer Production Manager in New York City Resume Ivan DominguezДокумент2 страницыManufacturing Engineer Production Manager in New York City Resume Ivan DominguezIvanDominguezОценок пока нет

- Director Quality Operational Excellence in Orlando FL Resume Douglas NorkusДокумент3 страницыDirector Quality Operational Excellence in Orlando FL Resume Douglas NorkusDouglasNorkus2Оценок пока нет

- Derrell James CVДокумент5 страницDerrell James CVapi-78745273Оценок пока нет

- Quality DirectorДокумент3 страницыQuality Directorapi-78871699Оценок пока нет

- Head Manufacturing - ResumeДокумент6 страницHead Manufacturing - Resumerkgnanduri100% (4)

- Continuous Process Improvement Leader in Columbia SC Resume Jeff SheetzДокумент2 страницыContinuous Process Improvement Leader in Columbia SC Resume Jeff SheetzJeffSheetzОценок пока нет

- Name Mobile Phone Email Address Linkedin: EngineeringДокумент2 страницыName Mobile Phone Email Address Linkedin: EngineeringdannyОценок пока нет

- Ajay Kumar: Experience SummaryДокумент4 страницыAjay Kumar: Experience SummarySAMSON GLOBALОценок пока нет

- VP of Manufacturing or OperationsДокумент4 страницыVP of Manufacturing or Operationsapi-79310704Оценок пока нет

- VP Supply Chain in Columbus OH Resume Belinda SalsbureyДокумент2 страницыVP Supply Chain in Columbus OH Resume Belinda SalsbureyBelinda Salsburey100% (1)

- Oracle Warehouse Management System Rules Engine: An Oracle White Paper October 2000Документ22 страницыOracle Warehouse Management System Rules Engine: An Oracle White Paper October 2000Ron DeLongОценок пока нет

- ACFrOgC3ap IsdwuxtEJ5MGSg 6Co9vDg1-DSyHV2glL1tO WWhGCRh-t7 ASS BNnVcP81mcNrzk0aEBZuDa-iEDL638Dofbm7MKfW-SmIfrCeQZBWuTSl3az1drvYДокумент4 страницыACFrOgC3ap IsdwuxtEJ5MGSg 6Co9vDg1-DSyHV2glL1tO WWhGCRh-t7 ASS BNnVcP81mcNrzk0aEBZuDa-iEDL638Dofbm7MKfW-SmIfrCeQZBWuTSl3az1drvYjleafe8957Оценок пока нет

- Documentation Procedure of An Export HouseДокумент17 страницDocumentation Procedure of An Export HousePooja SikariaОценок пока нет

- CusdecFinalSAD TaiheiyoДокумент5 страницCusdecFinalSAD TaiheiyoYre de los Reyes100% (1)

- Equipment/Material Requisition: Document No. Requisition of Fire Fighting PumpДокумент6 страницEquipment/Material Requisition: Document No. Requisition of Fire Fighting PumpGunturMudaAliAkbarОценок пока нет

- Dan Gardner TPM22ManagingDemurrageDetentionДокумент40 страницDan Gardner TPM22ManagingDemurrageDetentionSwapnil PatilОценок пока нет

- VP Distribution Operations Logistics in Boise ID Resume Bruce WolvertonДокумент2 страницыVP Distribution Operations Logistics in Boise ID Resume Bruce WolvertonBruceWolvertonОценок пока нет

- Director Operations Ecommerce Fulfillment in Boston MA Resume Brian BishopДокумент1 страницаDirector Operations Ecommerce Fulfillment in Boston MA Resume Brian BishopBrianBishop2Оценок пока нет

- Sea Way BillДокумент3 страницыSea Way BillzadgoОценок пока нет

- Technical Vocabulary: Observe Al Ejemplo #1Документ4 страницыTechnical Vocabulary: Observe Al Ejemplo #1Emilse AlvarezОценок пока нет

- Mindanao Terminal and Brokerage Service, Inc. vs. PhoenixДокумент2 страницыMindanao Terminal and Brokerage Service, Inc. vs. PhoenixKrizzia GojarОценок пока нет

- Issue11 MNZ Safety Bulletin June 2007Документ2 страницыIssue11 MNZ Safety Bulletin June 2007enigma102Оценок пока нет

- 60 Saludo, Jr. vs. CAДокумент6 страниц60 Saludo, Jr. vs. CAluigi vidaОценок пока нет

- 5 Loadicator Tricks That Can Ease Your Life During Cargo OperationДокумент17 страниц5 Loadicator Tricks That Can Ease Your Life During Cargo OperationKunal Singh100% (2)

- Logistics Industry in IndiaДокумент6 страницLogistics Industry in IndiabharatОценок пока нет

- Welcome To The Presentation On: ICD Pithampur & RatlamДокумент23 страницыWelcome To The Presentation On: ICD Pithampur & Ratlammanasphadnis100% (1)

- Australia AND New Zealand: Standard Operation Procedures For Air and Oceanfreight Shipments ToДокумент13 страницAustralia AND New Zealand: Standard Operation Procedures For Air and Oceanfreight Shipments ToSalman MunawarОценок пока нет

- File ôn trắc nghiệm TACN1Документ15 страницFile ôn trắc nghiệm TACN1phmtrang307Оценок пока нет

- UNIT-5 Harbour EngineeringДокумент20 страницUNIT-5 Harbour EngineeringsuryaОценок пока нет

- SA Port Benchmarking Report 2015 16Документ37 страницSA Port Benchmarking Report 2015 16Vagner JoseОценок пока нет

- Factory Price Laminate Bamboo Lumber 100% Solid Bamboo Beams - Buy Laminated Bamboo Lumber, Laminated Bamboo, Bamboo Beams Product OnДокумент12 страницFactory Price Laminate Bamboo Lumber 100% Solid Bamboo Beams - Buy Laminated Bamboo Lumber, Laminated Bamboo, Bamboo Beams Product OnJhake Bayuga PascuaОценок пока нет

- Bab II Internship ReportДокумент5 страницBab II Internship ReportArnaz Asa SholehОценок пока нет

- Assignment-1: Topic Assignment Direction & Requirement/SДокумент3 страницыAssignment-1: Topic Assignment Direction & Requirement/ShamzaОценок пока нет

- Revised ThesisДокумент44 страницыRevised ThesisKyle Jezrel GimaoОценок пока нет

- VAT Guideline Sea Land AirДокумент24 страницыVAT Guideline Sea Land AiraliОценок пока нет

- Customer Service RepresentativeДокумент1 страницаCustomer Service Representativeapi-121451947Оценок пока нет

- Mareva Sample AffidavitДокумент3 страницыMareva Sample AffidavitAisyah BalkisОценок пока нет

- 21 Phil Charter Insurance V ChemoilДокумент2 страницы21 Phil Charter Insurance V Chemoilkmand_lustregОценок пока нет

- SAP Sales Business Objectives Risk & Control MatrixДокумент4 страницыSAP Sales Business Objectives Risk & Control Matrixmani197100% (3)

- Sage X3 - User Guide - SE - Reports - Sales-US000Документ153 страницыSage X3 - User Guide - SE - Reports - Sales-US000caplusincОценок пока нет

- The Supply Chain Revolution: Innovative Sourcing and Logistics for a Fiercely Competitive WorldОт EverandThe Supply Chain Revolution: Innovative Sourcing and Logistics for a Fiercely Competitive WorldОценок пока нет

- The Goal: A Process of Ongoing Improvement - 30th Aniversary EditionОт EverandThe Goal: A Process of Ongoing Improvement - 30th Aniversary EditionРейтинг: 4 из 5 звезд4/5 (684)

- Working Backwards: Insights, Stories, and Secrets from Inside AmazonОт EverandWorking Backwards: Insights, Stories, and Secrets from Inside AmazonРейтинг: 4.5 из 5 звезд4.5/5 (14)

- Process!: How Discipline and Consistency Will Set You and Your Business FreeОт EverandProcess!: How Discipline and Consistency Will Set You and Your Business FreeРейтинг: 4.5 из 5 звезд4.5/5 (5)

- Working Backwards: Insights, Stories, and Secrets from Inside AmazonОт EverandWorking Backwards: Insights, Stories, and Secrets from Inside AmazonРейтинг: 4.5 из 5 звезд4.5/5 (44)

- The E-Myth Chief Financial Officer: Why Most Small Businesses Run Out of Money and What to Do About ItОт EverandThe E-Myth Chief Financial Officer: Why Most Small Businesses Run Out of Money and What to Do About ItРейтинг: 5 из 5 звезд5/5 (13)

- Toyota Supply Chain Management: A Strategic Approach to the Principles of Toyota's Renowned SystemОт EverandToyota Supply Chain Management: A Strategic Approach to the Principles of Toyota's Renowned SystemОценок пока нет

- Results, Not Reports: Building Exceptional Organizations by Integrating Process, Performance, and PeopleОт EverandResults, Not Reports: Building Exceptional Organizations by Integrating Process, Performance, and PeopleОценок пока нет

- PMP Exam Prep: How to pass the PMP Exam on your First Attempt – Learn Faster, Retain More and Pass the PMP ExamОт EverandPMP Exam Prep: How to pass the PMP Exam on your First Attempt – Learn Faster, Retain More and Pass the PMP ExamРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Design Thinking for Beginners: Innovation as a Factor for Entrepreneurial SuccessОт EverandDesign Thinking for Beginners: Innovation as a Factor for Entrepreneurial SuccessРейтинг: 4.5 из 5 звезд4.5/5 (7)

- The Red Pill Executive: Transform Operations and Unlock the Potential of Corporate CultureОт EverandThe Red Pill Executive: Transform Operations and Unlock the Potential of Corporate CultureОценок пока нет

- Self-Discipline: The Ultimate Guide To Beat Procrastination, Achieve Your Goals, and Get What You Want In Your LifeОт EverandSelf-Discipline: The Ultimate Guide To Beat Procrastination, Achieve Your Goals, and Get What You Want In Your LifeРейтинг: 4.5 из 5 звезд4.5/5 (662)

- The Supply Chain Revolution: Innovative Sourcing and Logistics for a Fiercely Competitive WorldОт EverandThe Supply Chain Revolution: Innovative Sourcing and Logistics for a Fiercely Competitive WorldРейтинг: 4 из 5 звезд4/5 (32)

- The Machine That Changed the World: The Story of Lean Production-- Toyota's Secret Weapon in the Global Car Wars That Is Now Revolutionizing World IndustryОт EverandThe Machine That Changed the World: The Story of Lean Production-- Toyota's Secret Weapon in the Global Car Wars That Is Now Revolutionizing World IndustryРейтинг: 4.5 из 5 звезд4.5/5 (40)

- The Influential Product Manager: How to Lead and Launch Successful Technology ProductsОт EverandThe Influential Product Manager: How to Lead and Launch Successful Technology ProductsРейтинг: 5 из 5 звезд5/5 (2)

- Summary of The Goal: by Eliyahu M. Goldratt and Jeff Cox | Includes AnalysisОт EverandSummary of The Goal: by Eliyahu M. Goldratt and Jeff Cox | Includes AnalysisРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Kaizen: The Step-by-Step Guide to Success. Adopt a Winning Mindset and Learn Effective Strategies to Productivity Improvement.От EverandKaizen: The Step-by-Step Guide to Success. Adopt a Winning Mindset and Learn Effective Strategies to Productivity Improvement.Оценок пока нет

- The Influential Product Manager: How to Lead and Launch Successful Technology ProductsОт EverandThe Influential Product Manager: How to Lead and Launch Successful Technology ProductsРейтинг: 4.5 из 5 звезд4.5/5 (11)