Академический Документы

Профессиональный Документы

Культура Документы

Rules of Thumb - Fluid Flow

Загружено:

Alex Kramer100%(1)100% нашли этот документ полезным (1 голос)

441 просмотров14 страницRules of thumb for chemical engineering

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документRules of thumb for chemical engineering

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

441 просмотров14 страницRules of Thumb - Fluid Flow

Загружено:

Alex KramerRules of thumb for chemical engineering

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 14

12 Rules of Thumb for Chemi

Nomenclature

D = pipe inside diameter, mm or in

¢ = efficiency, dimensionless

gas specific gravity

dimensionless

OG (Hh—M) Pe

ZaTs

= head correction, kPa or psia

(compared to air),

Where C2 = 0.0375 for US units, and 0.06835 for SI units

elevation of pipeline at origin, m or ft

elevation of pipeline at terminus, m or ft

L = pipe length, km or miles

nF (PR)

= average pressure for calculating H. and Z,

P,, = pressure base, standard conditions, kPa or psia

inlet pressure, kPa or psia

*» = outlet pressure, kPa or psia

Q = flow rate, standard m'/day or standard f'/day

average temperature, K or R

temperature base, standard conditions, K or R

Z, = average compressibility factor, dimensionless

Compressible Flow - Adiabatic

This section gives equations for computing pressure

drop due to friction for adiabatic flow [17]. An iterative

solution is required, but this is easy using the Solver tool

in Excel, or in a VBA subroutine. Use the following

procedure to solve for the flow rate (given upstream and

downstream pressures) or one of the pressures (given the

flow rate and the other pressure).

1. Calculate the Mach number, defined as the ratio of

the velocity of the gas in a pipe to the speed of sound.

in the gas at flowing conditions (temperature and

pressure). Use the upstream (given) temperature for

itil guess ofthe downstream temperature.

Nuw = vw 1.16)

i= \ RTE 16)

2. Calculate an intermediate value for each of the two

‘Mach numbers:

(17)

(1-18)

4, Solve the following equation by iteration of the

unknown flow or pressure, simultaneously with

equations 1-16, 1-17, and 1-18,

i)

(1-19)

‘The next section includes a VBA function that sol-

ves this problem,

Visual Basic Subroutines for Pressure Drop Due to Friction

‘The VBA functions listed here are used in conjunction

with an Excel spreadsheet to solve for pressure drop due to

friction in circular pipes running full, There are three

functions, designed to work in SI units. Incompressible

and adiabatic compressible flow problems are modeled in

single function, with two of three values as input and the

third as output (P), P2, or W). The functions and

examples are provided in the accompanying Excel

workbook.

After entering the code into a VBA Module, call the

functions from an Excel worksheet using the syntax given.

Each function returns a single value as described.

Syntax ROS| Wn dp EMP)

Returns: Reynolds number

Requires ‘ass flow rate, viscosity, pipe diameter

Either density or temperature, molecular weight and pressure

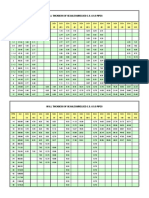

Example: Figure 1-1

Listing

Function NReSI(K, mu,

Optional Mw, Optional p)

“w= Flowrate in kg/h

+ nu = Viscosity fnmPa-s

4, Optional ro, Optional Tin,

+ d=Pipelo inam

* ro = density in kg/m (required for liquid

in-= temperature, deg C (required for gas) - default

20degc

“Hy =nolecular weight (requi red for gas) - default 29

* p=pressure, kPa (required for gas) - default 1000 kPa

+ Re = ro u L/nw

+ r= density

*u=velocsty

+ L=length (or pipe diameter)

mu = viscosity

* Convert viscosity to units kg/mh

su =mu* 0.001 * 3600,

* Convert pipe diameter to meters

a=a/000

Ps =3.141592654

RL = 8214.47 * gas constant

f IsMissing(ro) Then * assune this 1s. gas cal eulation

Is ssing(Tin) Then Tin

# Ist ssingcMw) Then Hh

3]

2. pats

7 Parameter Unite

8) Mass Flow Rate —_kgih

3 Vesoosey mPa

40) PpeDameter mm

al Densty kira

2 Temperature

78] Noecuar Weight — kkgmo

ie) Presi We ere

45)

48)

Sopa

18 Reynlss Number _dmensioness

19)

20

Bl

zy

Figure 1

|-NRes\08.08,010,011)

Fluid Flow 13

If Ist ssing(p) Then p = 1000 "kPa

Convert tenperature to deg k

Tin=Tin + 273.15

Convert pressure to Pa

papel

ro=p*Mw/(R1* Tin)

End tf

If ¥al(ro) =0 Then

If Ist ssing(Tin) Then Tin = 20

If Ist ssing(Ma) Then Hw = 29

If Ist ssing(p) Then p = 1000 "kPa

Convert temperature to deo k

Tin=Tin + 273.15,

Convert pressure to Pa

=p 1000

ro=p*Mw/(R1* Tin)

End tf

Caleulate veloctty

U=wrosiPt * (4/2) *2)

NReSI = ro*U* d/aw

End Funetion

Darcy Friction Factor

Stan = FicionSi Nar a)

eture: Darcy friction factor

Required pipe roughness, Reynolds number pipe dlamoter

Example: Figure 1-2

Listing

Function FrictionS! epsilon, We, d)

epstlon= Surface roughness 1s in units m

= PipelD 1s in units me

| EEE | HPPEPEPE SFT] PEPER CPAP BEPC RP PEE PRP PPS PRTG

Example | Example 2

0,000.0 7400

12 oot

381 266

9610

0

16.04

200

Trast3 1,692,238

|-nReSiE3.£9.510,612,613.614)

14 Rules of Thumb for Chemical Engineers

el SE: MGSES R G

5 Inputs

Ed Pawmeter lun Srampe3

8 Wass Fou Rats fain “0000

Bo] asoaep mos i

40, PreDaneter mm xe

At Denaty ‘om 3610

42, Temperste oc

33 Moteur ght korg

a Preseure i abealte

1s

6 Pree Rouainess o ono0487

7

18 ouput

‘6 Reyolis Number émersoness 77.357

Fa

1 Darcy Picton Facordmersoness 0.0234

Bz

a

_ |-Fretionsi(016 019,010)

Figure 1-2.

convert dtameter fron aa tom

a= a/1000

wrehil1, $.K

Flow Regimes,”

hemical Engineering, 84:24, p9

a = (2.457 * Log(/((7/NRE) *

“Friction Factor Equation Spans 211

1977

9+ (0.27 * epstlon/

ayy) 816

(a7530/NRe) * 16

FeictionS! =8* ((8/WRe) * 124 1/(a +b) 41.5) * (1/12

End Funetion

Pressure Drop Due to Friction

Syntae POW.F Pd La Th Ma)

Function PO(W, Pin, Pout, d, Lf, Optional Density, Optional Tin,

Optional Mw, Optional Gamma)

FRetums: Downstream pressure, upstream pressure, or ow

Required: Two ofthe three parameters: downstream pressure,

upstream pressure, or ow

Pipe parameters diameter, equivalent length, and friction

factor. When sohing fr flow, an adttiona tration is

‘needed on the Reynolds number. See the example for

{an explanation

Ether density o temperature, molecular weight

and gamma

Note: As written, limited to perfect gas behavior. The

compressibility factor, Z, could be added wherever the

term R * T appears (change to R * T* Z); in this case, add

Z to the list of arguments.

Example, see Figure 1-3:

Create a cell formula that computes the difference

between the guess and the calculated (E26) flow rate.

‘Then, use Goal Seek to find a value for Guess that equals

the calculated rates.

‘Actually, this is overkill given the inherent uncertainty

in the friction factor to begin with. There is nothing wrong

with calculating a friction factor based on an initial guess

then just going with it, An example flow rate calculation is

shown in Figure 1-4

Listing

Function PDSI(W, Pin, Pout. d. L, f, Opttona? Density.

Optional Tin, Optional Hx, Optional Ganma, Optional

sotheraal)

* Pressure Drop due to friction ina round pipe

“with the fol lowing arguments

* Specify two of the following three: function W111

compute the third

“Wamass flow rate, kg/h

* Pin= inlet, or upstream, pressure, kPa

* Pout = outlet, or downstream pressure, kPa

* Pipe properties

“d= pipe dianeter, an

*L=pipe length, m

+f =barcy friction factor

+ Fluld properties

* Density (optional)

“Tin (optional )

deg ¢ (default to 20

* Hoc (optional

(default to 29 for air)

* Gamma (opt onal)

(default to 1.4

"Isothermal (optional) ~- any value forces tsothermal

compressible cale, Sf missing then adiabatic

"Establish constants

spect fy for

specify for gas

squids, ka/n3

inlet tenperature

specify for gas, molecular weight

specify for gas, ratio of Cp/cy

gc=1" conversion constant, m/sec2

RL = 8314.47 * gas constant, &3-Pa/kgnol-K

Pi = 3.1415926

convert d tometers

a= a/i000

* convert temperature to deg k

f IsMissing(Tin

in =Ting 273.15

Determine which unknoxn to solve for ~ Flow,

Pressure, or Outlet Pressure

On Error Resume Next

# IsMissing(W) Then

hen Pin =0

hen Pout =

hen Tin = 20

Inlet

f IsMissingcPin

# IsMissing(Pout)

On Error GoTo 0

0 Then opt

0 Then opt

Input Ere*

GoTo PoEnd

End If

* Limited input checking

Вам также может понравиться

- 4.mechanical (Qa)Документ22 страницы4.mechanical (Qa)Osama AzaiemОценок пока нет

- Other Pumps Sumps For Solids-Bearing Waters: 12-6. Summary of Trench-Type Wet Well CharacteristicsДокумент29 страницOther Pumps Sumps For Solids-Bearing Waters: 12-6. Summary of Trench-Type Wet Well Characteristicsshady mohamedОценок пока нет

- 13aДокумент15 страниц13ashady mohamedОценок пока нет

- Ammonia B PDFДокумент9 страницAmmonia B PDFmehrdad_k_rОценок пока нет

- Previous Page: 13-9. InsulationДокумент15 страницPrevious Page: 13-9. Insulationshady mohamedОценок пока нет

- Carl N. Anderson Bayard E. Bosserman Il Charles D. Morris Contri Butors Casi Cadrecha Joseph E. Lescovich Harvey W. Taylor John VuncannonДокумент15 страницCarl N. Anderson Bayard E. Bosserman Il Charles D. Morris Contri Butors Casi Cadrecha Joseph E. Lescovich Harvey W. Taylor John Vuncannonshady mohamedОценок пока нет

- Em - 1110 3 136Документ203 страницыEm - 1110 3 136Real VinchenzoОценок пока нет

- ICARUS ReferenceДокумент66 страницICARUS Referencerylar999Оценок пока нет

- Minor Loss Coefficients in Pipes and Tubes ComponentsДокумент2 страницыMinor Loss Coefficients in Pipes and Tubes ComponentsSurendra ReddyОценок пока нет

- Cost Estimation and Weight Calculation for Vessel DimensionsДокумент46 страницCost Estimation and Weight Calculation for Vessel Dimensionsshankarbt83Оценок пока нет

- CHAPTER 8 Sizing and CostingДокумент20 страницCHAPTER 8 Sizing and CostingNurul Amelia Mustaffa0% (1)

- Capital Cost EstimatorДокумент14 страницCapital Cost Estimatoramirho3einОценок пока нет

- SMWWTPGLДокумент161 страницаSMWWTPGLPremasiri KarunarathnaОценок пока нет

- Measuring Concrete Work 1Документ19 страницMeasuring Concrete Work 1Akbar RafeekОценок пока нет

- Pipe Wall ThicknessДокумент2 страницыPipe Wall ThicknessTomi Kazuo0% (1)

- S Telp RDB 5279259Документ14 страницS Telp RDB 5279259Pablo NuñezОценок пока нет

- 10 State Standards - Waste Water FacilitiesДокумент178 страниц10 State Standards - Waste Water Facilitiesblin254Оценок пока нет

- Bilfinger Water Technologies - Solutions For Fine and Micro-SievingДокумент8 страницBilfinger Water Technologies - Solutions For Fine and Micro-SievingmohamedОценок пока нет

- Nm-Dairy Planning Data SheetДокумент16 страницNm-Dairy Planning Data SheetRicardo NapitupuluОценок пока нет

- Overhead Guidance PDFДокумент9 страницOverhead Guidance PDFanuarОценок пока нет

- Nps Table Welded Seamless Stainless Steel PipeДокумент3 страницыNps Table Welded Seamless Stainless Steel PipeOmar HasounОценок пока нет

- Design Guidelines FOR Wastewater FacilitiesДокумент20 страницDesign Guidelines FOR Wastewater FacilitiesAbbi UnoОценок пока нет

- Bill's Conversion Spreadsheet Revision GuideДокумент20 страницBill's Conversion Spreadsheet Revision GuidesudhirbmaliОценок пока нет

- Pages From Rules of Thumb For Chemical Engineers, 4th EdДокумент10 страницPages From Rules of Thumb For Chemical Engineers, 4th EdRicardo RamírezОценок пока нет

- Art's Process Spec SheetsДокумент27 страницArt's Process Spec SheetsSaid Alauddeen FaiszОценок пока нет

- Falling Film Heat Transfer CoefficientДокумент22 страницыFalling Film Heat Transfer CoefficientZarra FaktОценок пока нет

- Strengthening 49 km of NH-2B in West BengalДокумент102 страницыStrengthening 49 km of NH-2B in West BengalOllie BhattОценок пока нет

- Charts of Stainless Steel Pipe Fittings' WeightsДокумент6 страницCharts of Stainless Steel Pipe Fittings' WeightsHao ZhouОценок пока нет

- Modern Cost Engineering PDFДокумент38 страницModern Cost Engineering PDFbertan dağıstanlı100% (1)

- Head Loss CalculationДокумент7 страницHead Loss CalculationCuong VuОценок пока нет

- MS Piping and Fittings Rates ListДокумент12 страницMS Piping and Fittings Rates Listshawanqureshi1706160Оценок пока нет

- Tank Spreadsheet V 6 AДокумент88 страницTank Spreadsheet V 6 Aace1205100% (1)

- Option-2-Piping Support Structural BOQДокумент12 страницOption-2-Piping Support Structural BOQMaqsood Ibn Shaikhul ArfeenОценок пока нет

- Claus Process CalculationДокумент105 страницClaus Process CalculationDaniel SetyadiОценок пока нет

- Water Tank Estimation and CostingДокумент1 страницаWater Tank Estimation and CostingrayguntanОценок пока нет

- Wall Thickness11Документ1 страницаWall Thickness11Mohammad ghanaatpisheОценок пока нет

- Productivity TablesДокумент18 страницProductivity TablesabcОценок пока нет

- Engineering Art Rev1Документ42 страницыEngineering Art Rev1Mahesh KumarОценок пока нет

- WELCOME To Cost & Evaluation Workbook by Peters, Timmerhaus and West. Accompanying Plant Design and Economics For Chemical Engineers, 5th EditionДокумент15 страницWELCOME To Cost & Evaluation Workbook by Peters, Timmerhaus and West. Accompanying Plant Design and Economics For Chemical Engineers, 5th Editionxhche7Оценок пока нет

- BOPL Project Cost Centres ListДокумент94 страницыBOPL Project Cost Centres ListDawood khan100% (1)

- Calculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pump For A Non-Newtonian LiquidДокумент5 страницCalculation of Friction Losses, Power, Developed Head and Available Net Positive Suction Head of A Pump For A Non-Newtonian Liquidt_i_f_anoОценок пока нет

- Previous Page: 11-4. Overhung-Lmpeller PumpsДокумент25 страницPrevious Page: 11-4. Overhung-Lmpeller Pumpsshady mohamedОценок пока нет

- Delft Management of Engineering ProjectsДокумент222 страницыDelft Management of Engineering ProjectsEirinaios ChatzillariОценок пока нет

- Energy conversion factors and density ranges for petroleum productsДокумент2 страницыEnergy conversion factors and density ranges for petroleum productslutfi awnОценок пока нет

- Resistance Equivalent LengthДокумент3 страницыResistance Equivalent LengthATUL SONAWANEОценок пока нет

- Pipe Fabrication and Welding Project Cost BreakdownДокумент2 страницыPipe Fabrication and Welding Project Cost BreakdownRuelОценок пока нет

- Air Stripping: The Removal of Volatile Contaminants From Water and Contaminated SoilsДокумент39 страницAir Stripping: The Removal of Volatile Contaminants From Water and Contaminated SoilsMohammed Al-DahlanОценок пока нет

- OneSteel Data Charts - FinalДокумент20 страницOneSteel Data Charts - FinalDaniel CheesmanОценок пока нет

- Design of Reactor 1Документ13 страницDesign of Reactor 1Nelykah Rianne MartijaОценок пока нет

- Clarke CL430-500m Parts DiagramДокумент20 страницClarke CL430-500m Parts Diagrampr8Оценок пока нет

- CT Deep Boiler Emissions CalculatorДокумент8 страницCT Deep Boiler Emissions Calculatorsissam.adilОценок пока нет

- S ProjectDefinitionOnOffshore PetrofacДокумент4 страницыS ProjectDefinitionOnOffshore PetrofacDiego1980bОценок пока нет

- Pump Rules of ThumbДокумент5 страницPump Rules of Thumbaquileslima100% (1)

- Purpose: The Purpose of This Document Is To Carry Out Hydraulic CalculationДокумент14 страницPurpose: The Purpose of This Document Is To Carry Out Hydraulic CalculationEkundayo John100% (1)

- Unit Operations Thumb RulesДокумент9 страницUnit Operations Thumb RuleshibhavuОценок пока нет

- Reducing-Tee Mechanical Piping PDFДокумент4 страницыReducing-Tee Mechanical Piping PDFanjargoklithОценок пока нет

- Energy and Process Optimization for the Process IndustriesОт EverandEnergy and Process Optimization for the Process IndustriesОценок пока нет

- Literature Review PDFДокумент12 страницLiterature Review PDFpoudelОценок пока нет

- 2-Plant Layout - Pipeway DesignДокумент25 страниц2-Plant Layout - Pipeway DesignLaxmikant SawleshwarkarОценок пока нет

- CE142P-2 Experiment 7Документ7 страницCE142P-2 Experiment 7Faye AnneОценок пока нет

- Troubleshooting Hydraulic PumpsДокумент1 страницаTroubleshooting Hydraulic PumpsALEXANDER MUGABEОценок пока нет

- Viscosity Converting ChartДокумент3 страницыViscosity Converting ChartMaria Victoria Morales GalindezОценок пока нет

- VALVULA CHECK Dorot PDFДокумент1 страницаVALVULA CHECK Dorot PDFGustavo RomanОценок пока нет

- M6b Water Surface Profiles PDFДокумент10 страницM6b Water Surface Profiles PDFEftima KredanОценок пока нет

- Catálogo de Electroválvulas SMCДокумент0 страницCatálogo de Electroválvulas SMCjoseluisrosglz100% (1)

- Preliminary - MITTEN HPU Only Rev DДокумент120 страницPreliminary - MITTEN HPU Only Rev DFabyano BrittoОценок пока нет

- Cavitation and Pipe DetailsДокумент34 страницыCavitation and Pipe DetailsSANDIP ROYОценок пока нет

- Glass Lined PipingДокумент6 страницGlass Lined PipingPawel MielnikОценок пока нет

- Technical Data: 150x100 CNJA 5 30Документ5 страницTechnical Data: 150x100 CNJA 5 30سمير البسيونىОценок пока нет

- Diw InstДокумент1 страницаDiw InstJeonghyeon KimОценок пока нет

- Nptel: Computational Fluid Dynamics For Turbomachinery - Web CourseДокумент3 страницыNptel: Computational Fluid Dynamics For Turbomachinery - Web CourseAissa AMOURОценок пока нет

- Hydraulic Calculation of Pipe Culvert: 1/1 345566782.xlspipe CVДокумент1 страницаHydraulic Calculation of Pipe Culvert: 1/1 345566782.xlspipe CVDenBagoesОценок пока нет

- Chapter 4 - Compressible FlowДокумент32 страницыChapter 4 - Compressible FlowNicholas EmildasОценок пока нет

- Hydraulic Jump Lab ReportДокумент8 страницHydraulic Jump Lab ReportAhmed ZarkhaizОценок пока нет

- Mech Pgcet 2013 Que BankДокумент88 страницMech Pgcet 2013 Que BankEr Keval PatelОценок пока нет

- Aero 311Документ6 страницAero 311Hamza AshrafОценок пока нет

- Fluid Mechanics Lab Venturi MeterДокумент11 страницFluid Mechanics Lab Venturi MeterLawrence Martin Laus100% (1)

- Piping Material Specification Client: Sterlite IndustriesДокумент4 страницыPiping Material Specification Client: Sterlite Industriessomeshangale100% (1)

- MGF and Softner ControlДокумент1 страницаMGF and Softner ControlSameer WareОценок пока нет

- Open Channel Laboratory ExperimentДокумент3 страницыOpen Channel Laboratory ExperimentJohn Ceasar PascoОценок пока нет

- Pleasant Street Hydraulic ManualДокумент607 страницPleasant Street Hydraulic ManualbadralislamОценок пока нет

- Introduction To ValvesДокумент6 страницIntroduction To ValvesMohamed Al-OdatОценок пока нет

- HPI Mini Pump-Motor Combinations CatalogДокумент18 страницHPI Mini Pump-Motor Combinations CatalogEdison David GomezОценок пока нет

- How To Size A PumpДокумент90 страницHow To Size A PumpDaani Olora100% (5)

- Hydraulic Calculation For Fire FightingДокумент15 страницHydraulic Calculation For Fire FightingΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥОценок пока нет

- Fire Hydrants - Loop TestingДокумент9 страницFire Hydrants - Loop TestingNikita KadamОценок пока нет

- 2018 Experimental Investigation of Flow Patterns and External Performance of A Centrifugal Pump That Transports Gas-Liquid Two-Phase MixturesДокумент10 страниц2018 Experimental Investigation of Flow Patterns and External Performance of A Centrifugal Pump That Transports Gas-Liquid Two-Phase Mixturesrl leeОценок пока нет