Академический Документы

Профессиональный Документы

Культура Документы

Med Air and Surgical Air Catalog

Загружено:

zampacaanasАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Med Air and Surgical Air Catalog

Загружено:

zampacaanasАвторское право:

Доступные форматы

16/11/11 Page 1 of 7 Issue 1

mAIR Medical Air, cAIR Combined Air & sAIR Surgical Air Systems EN ISO 7396-1/HTM 02-01 and HTM2022 EurPh 380V 60Hz, 4 Bar, 7 Bar & 10 Bar Outlet SPECIFICATION

Air Plant System

The Medical Air system shall conform to EN ISO 7396-1 and NHS Health Technical Memorandum HTM02-01. Medical quality air to the European Pharmacopoeia monograph shall be delivered at pressures of 400 kPa (4 bar), 700kPa (7 bar) or 1000 kPa (10 bar) gauge for supply of the hospital medical or surgical air systems. The entire system shall be duplexed such that any single functional component failure will not affect the integrity of the medical compressed air supply. Surgical air systems shall have a duplexed dryer system and a simplex compressor. Additional compressors shall be available to fully duplex the surgical air system, such that any single functional component failure will not affect the integrity of the air supply.

Compressors

Compressors shall be oil injected rotary screw compressors suitable for both continuous and frequent start/stop operation at a nominal outlet pressure of 700 kPa (7 bar), 950 kPa (9.5 bar) or 11500 kPa (11.5 bar) gauge. Compressors shall be supplied with a block and fin style after cooler with a dedicated quiet running fan to maximise cooling and efficiency. A multistage oil separator capable of achieving 2ppm oil carry over shall be fitted to minimise contamination and maintenance. EFF1 (CEMEP) rated TEFC, IP55 class F electric motors shall be used and incorporate maintenance-free greased for life bearings. Motors with lower efficiency ratings are not acceptable. Each screw compressor shall be supplied with a motor control unit which incorporates a user friendly 3.5 high-definition colour display with clear pictograms and LED indicators, providing easy access to system operational information. Visualisation of compressor outputs and status shall be available through a web browser, using a simple Ethernet connection. Compressors are to be individually hard-piped to the receiver manifold as standard.

Sources Of Supply - HTM02-01/EN ISO 7396-1

Triplex or quadruplex compressor configurations will produce the primary supply with two compressors in standby. Each compressor will be capable of supplying the specified volumetric flow for duplex and triplex plant, and half flow for quadruplex. For duplex plant the secondary supply shall be from an automatic manifold capable of supplying at average demand for 4 hours. For triplex and quadruplex plant the standby compressors will form the secondary supply.

Variable Speed Drive Option

Sources Of Supply - HTM2022 EurPh

Duplex, triplex or quadruplex compressor configurations will produce the primary supply with one compressor on standby. A secondary supply shall be from an automatic manifold capable of supplying at average demand for 4 hours.

Variable Speed Drive (VSD) shall be available on compressor. By including an AC to DC converter, along with associated control hardware and software it will enable the compressor to match its running speed on a 1:1 ratio with the flow demand required by hospital. By using such technology energy of savings of up to 35% shall be achievable as well as prolonged machine life. Start currents will be removed and the motor will run from 0-100% speed increasing or decreasing its speed as necessary to continuously match the required demand. The compressor shall operate from 400-1300kPa (4-13 bar) gauge.

Control System

The central control system shall provide an intelligent human machine interface incorporating on board flash memory and real-time clock for recording operational parameters in the in built event log. The central control system shall operate at low voltage and include BMS connection for plant fault, plant emergency, reserve fault and pressure fault. Visualisation of plant inputs, outputs and status through a web browser, using a simple Ethernet connection shall be available. The central control unit shall incorporate a user friendly 5.7 high-definition colour display with clear pictograms and LED indicators, providing easy access to system operational information. A mechanical back-up facility shall ensure continued operation in the event of a control system malfunction. The control system shall normally employ automatic rotation of the lead compressor to maximise life and ensure even wear.

Dryer/Filter/Regulator System

The duplexed filter and dryer module shall incorporate high efficiency water separators, oil filters, heatless regenerative desiccant dryer, dust/activated carbon filters, hopcolite filters and bacterial filters with autoclavable element. Contaminants in the delivered air downstream of the bacterial filters shall be maintained at levels below those shown in the following table: Contaminant H2O Dry particulates Oil (droplet or mist) CO CO2 SO2 NO NO2 Threshold 67 ppm v/v Free from visible particulates in a 75 litre sample 0.1 mg/m 5 ppm v/v 500 ppm v/v 1 ppm v/v 2 ppm v/v 2 ppm v/v

Optional Control Equipment

An advanced monitoring system shall be available to give immediate access to valuable information such as system status, trends, historical data and system performance. Data collected from all pumps shall be made available in real-time visualisation pages and shall be accessed through the hospitals LAN, such that total data security is assured. The Airconnect monitoring system shall also include : Logging and trending for an accurate performance status of the system. Desktop event notification to avoid constant status checking. E-mail and SMS event notification for additional convenience.

The dryer control system shall incorporate a Purge Saver Energy Management system that freezes the regeneration of the desiccant once adequate dew point is reached in the inactive tower. Only when the dewpoint level in the active tower deteriorates to an unacceptable level will the intelligent controller switch towers. This shall be achieved by including an additional dew point sensor and associated software in the dryer controller to effectively manage the system as well as providing on screen measurements of purge savings.

BeaconMeds Telford Crescent, Staveley, Derbyshire S43 3PF Tel: +44 (0) 1246 474 242 Fax: +44 (0) 1246 472 982

Company Reg No. 2957933 (English) Company VAT Reg No. 598612590 www.beaconmedaes.com gbn.info@beaconmedaes.com Constructionline Reg No. 75463 CHAS accredited contractor SAFEcontractor Reg No. N00184450

mAIR MEDICAL AIR SYSTEMS

In an effort to continuously improve our products, the right is reserved to change the specification of the items described herein at any time. Please contact us for further information and up to date specifications.

2005629

In an effort to continuously improve our products, the right is reserved to change the specification of the items described herein at any time. Please contact us for further information and up to date specifications.

2005629

16/11/11 Page 2 of 7 Issue 1

Dew Point Monitoring

The dryer shall incorporate a ceramic dew point hygrometer with an accuracy of 10C in the range -20 to -800C atmospheric dew point and 4-20mA analogue output. Aluminium oxide or palladium wire sensors are not acceptable. An alarm condition shall trigger on the dryer control panel if the dew point exceeds a -460C atmospheric set point. The plant control unit shall incorporate a multifunctional LCD displaying, amongst other things, the dew point of the delivered air to enable monitoring of the air quality by the hospitals estates department. Volt free contacts shall be included to enable the dew point alarm signal to be connected to a central medical gas alarm system and/or building management system (BMS). To enable periodic calibration of the dew point sensor element, the hygrometer shall be remotely connected downstream of the dryer via a micro-bore tube. It is not acceptable to install the sensor directly into the medical air supply pipeline.

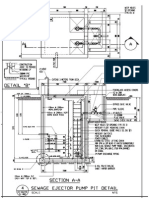

Typical Layout

Compressors

Receivers

Receiver Assembly

Air receivers shall comply with BS EN 286-1, supplied with relevant test certificates. Each air receiver shall be hot dip galvanised inside and out and fitted with a zero loss electronic drain valve. Float type drain valves are not acceptable. The receiver assembly shall be fitted with a pressure safety valve capable of passing the maximum flow output of the compressor at 10% receiver overpressure. The receiver shall be further protected by a safety pressure relief valve and include a pressure gauge.

Dryer

Optional Items

Note Inter connecting pipework (blue illustration) between components to be made on site and provided by the installer. Controller CAN cables are provided as a 10m assembly with each compressor, this can be shortened on site if required.

There shall be the followings options available for enhanced operation of the air plant system: Phase sequence relays that prevent unintentional reverse operation of the compressors OCS electronic water/oil drains for the air plant system EWD zero loss electronic water drains for the dMED dryer including secure mounting to the dryer base VSD compressors and optional harmonics filter for installation close to highly sensitive equipment Synthetic oil for increased compressor life QDT saturation indicators to give clear visual indication of oil carry over to the activated carbon tower Tropical thermostatic sensors for countries with high humidity CO and CO2 monitors including full integration into the ES-Med central controller giving alarm warnings when unacceptable CO and CO2 levels are present Painted hot dipped galvanised vessels

Combined Air Plant Sizing Guide

In HTM02-01, the relative size of receiver capacity and compressor capacity on surgical air or combined medical/surgical air systems changes according to the design flow rate. In order to correctly calculate the receiver capacity and compressor capacity, both the medical and surgical design flow-rates (DFs) are required. It should be noted that for all combined air systems, an additional duplex regulating station (ordered separately) is needed to supply the medical air pipeline. Design Flow (l/min) Surgical Air Compressors <500 500-3500 >3500 Value A FAD (l) 0.33 x DF 0.66 x DF 0.5 x DF

Table 1: Surgical Air Plant Flow Rate Multiplier Value A. Design Flow (l/min) Surgical Air Receivers <500 500-2000 2001-3500 >3500 Table 2: Surgical Air Receiver Multiplier Value B. Value B Receiver water capacity (l) 1 x 200% x DF 2 x 66.6% x DF 2 x 50% x DF 3 x 33.3% x DF

CE Marking

The standard range of BeaconMeds Medical Air plant systems are CE marked under the Medical Devices Directive 93/42/EEC with approval from notified body no. 0088 (Lloyds Register Quality Assurance). Under this directive, the specified products are classified as Class IIa Medical Devices.

BeaconMeds Telford Crescent, Staveley, Derbyshire S43 3PF Tel: +44 (0) 1246 474 242 Fax: +44 (0) 1246 472 982

Company Reg No. 2957933 (English) Company VAT Reg No. 598612590 www.beaconmedaes.com gbn.info@beaconmedaes.com Constructionline Reg No. 75463 CHAS accredited contractor SAFEcontractor Reg No. N00184450

In an effort to continuously improve our products, the right is reserved to change the specification of the items described herein at any time. Please contact us for further information and up to date specifications.

2005629

16/11/11 Page 3 of 7 Issue 1

Example 1 - Small Day Treatment Centre (Upgrade) Flow Rate and Dryer Sizing Medical Air DF = 555 l/min (FAD) (4 Bar) Surgical Air DF = 1138 l/min (FAD) (7 Bar) Combined/total DF = 1693 l/min (FAD) (11 Bar high pressure system) A dryer greater than 1693 l/min outlet flow should be selected (outlet flow is the inlet flow minus purge losses) = dMED25 inlet flow 2025 l/min, outlet flow 1755 l/min Flow Rate and Compressor Sizing From Table 1 surgical air DF is between 500-3500 l/min, so the multiplying factor A = 0.66 Compressor flow rate = Med. DF + (Surg. DF x A) = 555 + (1138 x 0.66) = 555 + 751 = 1306 l/min We also need to add the purge losses to the compressor output. For additional purge consumption use:dMED inlet - dMED outlet = purge losses lpm = 2025 - 1755 = 270 l/min Compressors should be selected with a flow rate greater than 1306 l/min + 270 l/min = 1576 l/min Receiver Sizing From Table 2 surgical air DF is between 500-2000 l/min, so the multiplying factor B = 2 x 2/3 Capacity = (Med. DF x 0.5) + (Surg. DF x B) = (555 x 0.5) + (1138 x 2 x 2/3) = 278 + 1518 = 1796 litres

Example 2 - Large District Hospital Flow Rate and Dryer Sizing Medical Air DF = 4920 l/min (FAD) (4 Bar) Surgical Air DF =2888 l/min (FAD) (11 Bar) Combined/total DF = 7808 l/min (FAD) (11 Bar high pressure system) A dryer greater than 7808 l/min should be selected (outlet flow is the inlet flow minus purge losses) = dMED145 inlet flow 11745 l/min, outlet flow 10092 l/min Flow Rate and Compressor Sizing From Table 1 surgical air DF is between 500-3500 l/min, so the multiplying factor A = 0.66 Plant flow rate = Med. DF + (Surg. DF x Value A) = 4920 + (2888 x 0.66) = 4920 + 1907 = 6827 l/min

We also need to add the purge losses to the compressor output. For additional purge consumption use:dMED inlet - dMED outlet = purge losses lpm = 11745 - 10092 = 1653 l/min Compressors should be selected with a flow rate greater than 6827 l/min + 1653 l/min = 8480 l/min Receiver Sizing From Table 2 surgical air DF is between 2001-3500 l/min, so the multiplying factor B = 2 x 1/2 Capacity = (Med. DF x 0.5) + (Surg. DF x B) = (4920 x 0.5) + (2888 x 2 x 1/2) = 2460 + 2888 = 5348 litres

A combination of receivers with a minimum number of 2 should be selected Selected receiver capacity = 2000 litres (2 x 1000 litre) Plant System Selection Selected plant part number = cAIR-1755-TGA11 If no standard model is available for selection from the standard range a bespoke configuration of dryer, compressors and receivers are available and can be quoted by our sales and sales support teams.

A combination of receivers with a minimum number of 2 should be selected Selected receiver capacity = 6000 litres (3 x 2000 litre) Plant System Selection Selected plant part number = n/a If no standard model is available for selection from the standard range a bespoke configuration of dryer, compressors and receivers are available and can be quoted by our sales and sales support teams.

Receiver Selection Table

Receiver Capacity (litres) Maximim working pressure (bar) Individual Receiver Dimensions (diameter, height, mm) Receiver Weight (kg) Receiver pipe size (mm) Receiver Part Number Accessory Kit Part Number * Drawing Number 250 16 500/1950 80 22 8101 0211 97 Specific to plant tbc 500 16 600/2350 160 22 8101 0212 62 Specific to plant tbc 1000 16 800/2550 304 28 8101 0213 12 Specific to plant tbc 1500 16 1000/2525 445 28 8102 0213 38 Specific to plant tbc 2000 16 1150/2605 557 35 8101 0213 53 Specific to plant tbc

Accessory kit for medical air receiver complete with plant data plate, test certificate, pressure safety valve, zero-loss electronic drain valve (with isolation and bypass valve), pressure gauge (with isolation valve), safety pressure relief valve and inlet and copper outlet union connection pipes (each with isolation valve).

BeaconMeds Telford Crescent, Staveley, Derbyshire S43 3PF Tel: +44 (0) 1246 474 242 Fax: +44 (0) 1246 472 982

Company Reg No. 2957933 (English) Company VAT Reg No. 598612590 www.beaconmedaes.com gbn.info@beaconmedaes.com Constructionline Reg No. 75463 CHAS accredited contractor SAFEcontractor Reg No. N00184450

In an effort to continuously improve our products, the right is reserved to change the specification of the items described herein at any time. Please contact us for further information and up to date specifications.

2005629

16/11/11 Page 4 of 7 Issue 1

Compressor Selection Table - Fixed Speed

Model Name Output flow (litres/minute) * 7 bar variant Output flow (litres/minute) * 9.5 bar variant Output flow (litres/minute) * 11.5 bar variant Footprint L x W x H (mm) Compressor weight (kg) Service connection (mm) Noise level/pump (dB[A]) Maximum ambient temperature (0C) Supply voltage (v) Supply frequency (Hz) Nominal motor rating (kW) Full load current per compressor (A) Starting current (A) Cooling air flow per compressor (m3/s) Part Number - 7 bar Part Number - 9.5 bar Part Number - 11.5 bar Drawing Number * Output flow stated at reference conditions 0.8 8153 0345 44 8153 0343 04 8153 0343 12 tbc 0.8 8153 0345 51 8153 0343 20 81530343 38 tbc 1 8153 0345 69 8153 0343 46 8153 0343 53 tbc 1.1 8153 0351 86 8153 0351 94 8153 0352 02 tbc 1.15 8153 0352 10 8153 0352 28 8153 0352 36 tbc 1.2 8153 0352 44 8153 0352 51 8153 0352 69 tbc GA-MED 5 900 702 510 1145 x 710 x 1240 260 22 60 40 380 60 5 GA-MED 7 1308 1032 852 1145 x 710 x 1240 270 22 61 40 380 60 7 GA-MED 11 1842 1494 1320 1145 x 710 x 1240 300 22 62 40 380 60 11 GA-MED 15 2550 2148 1758 1285 x 680 x 922 375 22 72 40 380 60 15 GA-MED 18 3078 2598 2268 1285 x 680 x 922 395 22 73 40 380 60 18 GA-MED 22 3636 3042 2796 1285 x 680 x 922 410 22 74 40 380 60 22

Compressor Selection Table - Variable Speed Drive

Model Name Output flow (litres/minute) 7 bar , 9.5 bar and 11.5 bar variants * Footprint L x W x H (mm) Compressor weight (kg) Service connection (mm) Noise level/pump (dB[A]) Maximum ambient temperature (0C) Supply voltage (v) Supply frequency (Hz) Nominal motor rating (kW) Full load current per compressor (A) Cooling air flow per compressor (m3/s) Part Number Drawing Number * 0.8 8153 0344 45 tbc 0.8 8153 0344 52 tbc 1 8153 0344 60 tbc 1 8153 0344 78 tbc GA-MED VSD 5 924 / 792 / 600 1365 x 710 x 1240 275 22 62 46 380 60 5 GA-MED VSD 7 1230 / 1008 / 828 1365 x 710 x 1240 280 22 64 46 380 60 7 GA-MED VSD 11 1860 / 1446 / 1242 1365 x 1245 x 1325 293 22 66 46 380 60 11 GA-MED VSD 15 2250 / 1854 / 1488 1365 x 1245 x 1325 300 22 69 46 380 60 15

Variable speed drive compressor operate from 4-13 bar at 0-100% speed - start current not applicable for VSD

BeaconMeds Telford Crescent, Staveley, Derbyshire S43 3PF Tel: +44 (0) 1246 474 242 Fax: +44 (0) 1246 472 982

Company Reg No. 2957933 (English) Company VAT Reg No. 598612590 www.beaconmedaes.com gbn.info@beaconmedaes.com Constructionline Reg No. 75463 CHAS accredited contractor SAFEcontractor Reg No. N00184450

In an effort to continuously improve our products, the right is reserved to change the specification of the items described herein at any time. Please contact us for further information and up to date specifications.

2005629

16/11/11 Page 5 of 7 Issue 1

Dryer Selection Table

Model Name Inlet flow at 7 bar (litres/minute) Output flow (litres/minute) at 4 bar line pressure * Inlet flow at 9.5 bar (litres/minute) Output flow (litres/minute) at 7 bar line pressure * Inlet flow at 11.5 bar (litres/minute) Output flow (litres/minute) at 11 bar line pressure * Footprint L x W x H (mm) Dryer weight (kg) Inlet and outlet connections (mm) Supply voltage (v) Supply frequency (Hz) Central control supply - single phase (mm2/Amps) dMED7 420 340 504 424 567 487 1920 x 600 x 1590 255 15 220 60 1.5 (5) 8102 1431 72 0000 0203 58 dMED13 780 632 936 788 1053 905 1920 x 600 x 1590 275 15 220 60 1.5 (5) 8102 1431 80 0000 0203 58 dMED25 1500 1230 1800 1530 2025 1755 1920 x 600 x 1590 325 15 220 60 1.5 (5) 8102 1431 98 0000 0203 71 dMED35 2100 1722 2520 2142 2835 2457 1920 x 600 x 1590 345 15 220 60 1.5 (5) 8102 1432 06 0000 0203 71 dMED50 3000 2430 3600 3030 4050 3480 1920 x 600 x 1870 415 28 220 60 1.5 (5) 8102 1432 14 0000 0203 72 dMED70 4200 3444 5040 4284 5670 4916 1850 x 1250 x 2160 615 28 220 60 1.5 (5) 8102 1432 22 0000 0203 73 dMED80 4800 3936 5760 4896 6480 5616 1850 x 1250 x 2160 700 28 220 60 1.5 (5) 8102 1432 30 0000 0203 73 dMED100 6000 4860 7200 6060 8100 6960 1850 x 1250 x 2160 705 28 220 60 1.5 (5) 8102 1432 48 0000 0203 74 dMED145 8700 7047 10440 8787 11745 10092 1868 x 1250 x 1590 895 28 220 60 1.5 (5) 8102 1432 55 0000 0203 75 tbc 8102 1435 29 0000 0203 75 8102 1434 38 0000 0203 75

Part Number - dryer at 4 bar outlet + QDT hopcolite filter for EurPh

8102 1434 04 0000 0203 73

8102 1433 54 0000 0203 58

8102 1433 62 0000 0203 58

8102 1433 70 0000 0203 71

8102 1433 88 0000 0203 71

8102 1433 96 0000 0203 72

8102 1434 12 0000 0203 73

Part Number - dryer at 7 bar outlet + QDT hopcolite filter for EurPh

8102 1434 46 0000 0203 58

8102 1434 53 0000 0203 58

8102 1434 61 0000 0203 71

8102 1434 79 0000 0203 71

8102 1434 87 0000 0203 72

8102 1434 95 0000 0203 73

8102 1435 03 0000 0203 73

Part Number - dryer at 11 bar outlet + QDT hopcolite filter for EurPh

tbc

tbc

tbc

tbc

tbc

tbc

tbc

Drawing Number

* Output flow stated includes calculated purge lost during the regenration process of between 15-19% depending on model and inlet pressure.

Notes on plant Design flow in terms of free air delivered after losses at working pressure with the reserve compressor(s) on standby. Tolerance 5%. Component dimensions supplied do not include maintenance access space, and are provided to allow customer to arrange plant components within plant room. Complete installation drawings are available on request. Quote the drawing number required. Duplex systems must be installed with a manifold as the third source of supply for HTM02-01 complaince. Mean sound level in accordance with ISO 2151. Electrical details are provided for guidance only. Site conditions may impose a larger cable size. For exact cable sizing, and fuse / MCB ratings, consult a qualified electrical engineer.

BeaconMeds Telford Crescent, Staveley, Derbyshire S43 3PF Tel: +44 (0) 1246 474 242 Fax: +44 (0) 1246 472 982

Company Reg No. 2957933 (English) Company VAT Reg No. 598612590 www.beaconmedaes.com gbn.info@beaconmedaes.com Constructionline Reg No. 75463 CHAS accredited contractor SAFEcontractor Reg No. N00184450

tbc

8102 1435 11 0000 0203 74

8102 1434 20 0000 0203 74

In an effort to continuously improve our products, the right is reserved to change the specification of the items described herein at any time. Please contact us for further information and up to date specifications.

2005629

16/11/11 Page 6 of 7 Issue 1

Standard Models HTM02-01 Medical Air 4 bar

mAIR-2890-QGA4 mAIR-3445-QGA4 mAIR-3935-QGA4 mAIR-4860-QGA4 mAIR-5620-QGA4 mAIR-7045-PGA4 7045 5 GAMED 18 dMED 145 2 2000 8750 6593 6593 5 GAMED 22 dMED 145 4 2000 tbc cAIR-8750-PGA7 tbc mAIR-1230-TGA4 mAIR-1445-TGA4 mAIR-1720-TGA4 mAIR-1980-TGA4 mAIR-2430-TGA4 2430 3 GAMED 18 dMED 50 2 1000 mAIR-340-TGA4 mAIR-500-TGA4 mAIR-630-TGA4 mAIR-990-TGA4 990 3 GAMED 7 dMED 25 2 250

Model Number

Design flow (litres/minute) Number of compressors Type of compressor Type of dryer Number of receivers Receiver volume (l) (each) Part Number Drawing Number

340 3 GAMED 5 dMED 7 1 250

500 3 GAMED 5 dMED 13 1 250

630 3 GAMED 5 dMED 13 2 250

1230 3 GAMED 11 dMED 25 2 500

1445 3 GAMED 11 dMED 35 2 500

1720 3 GAMED 15 dMED 35 2 500

1980 3 GAMED 15 dMED 50 2 500

2890 4 GAMED 11 dMED 70 2 1000

3445 4 GAMED 15 dMED 70 2 1000

3935 4 GAMED 15 dMED 80 2 1000

4860 4 GAMED 18 dMED 100 2 1500

5620 4 GAMED 22 dMED 145 2 1500

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

HTM02-01 Combined Medical & Surgical Air 7 bar

cAIR-2980-QGA7 cAIR-3500-QGA7 cAIR-4260-QGA7 cAIR-4895-QGA7 cAIR-5950-QGA7 cAIR-8000-PGA7 8000 6000 6000 5 GAMED 18 dMED 145 3 2000 tbc cAIR-1000-TGA7 cAIR-1470-TGA7 cAIR-2130-TGA7 cAIR-425-TGA7 cAIR-790-TGA7

Model Number

Design flow (litres/minute) Required compressor output * Required receiver volume * Number of compressors Type of compressor Type of dryer Number of receivers Receiver volume (l) (each) Part Number Drawing Number

425 282 530 3 GAMED 5 dMED 7 1 1000

790 524 985 3 GAMED 5 dMED 13 1 1000

1000 665 1249 3 GAMED 7 dMED 25 1 1500

1470 1269 1402 3 GAMED 11 dMED 25 2 1000

2130 1776 1962 3 GAMED 15 dMED 35 2 1000

2980 2473 2777 3 GAMED 22 dMED 50 2 1500

3500 2901 3204 4 GAMED 15 dMED 70 2 2000

4260 3556 3213 4 GAMED 15 dMED 70 2 2000

4895 4064 3672 4 GAMED 18 dMED 80 2 2000

5950 4947 4470 4 GAMED 22 dMED 100 3 2000

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

Flow output based on a 50/50 split of medical and surgical air design flow (D.F) For examples on how to calculate the required design flow, compressor flow and receiver volume refer to earlier page, in line with HTM02-01 requirements and tables.

BeaconMeds Telford Crescent, Staveley, Derbyshire S43 3PF Tel: +44 (0) 1246 474 242 Fax: +44 (0) 1246 472 982

Company Reg No. 2957933 (English) Company VAT Reg No. 598612590 www.beaconmedaes.com gbn.info@beaconmedaes.com Constructionline Reg No. 75463 CHAS accredited contractor SAFEcontractor Reg No. N00184450

tbc

tbc

In an effort to continuously improve our products, the right is reserved to change the specification of the items described herein at any time. Please contact us for further information and up to date specifications.

2005629

16/11/11 Page 7 of 7 Issue 1

Standard Models HTM2022 EurPh Medical Air 4 bar

mAIR-7045-QGA4 7045 4 GAMED 18 dMED 145 2 2000 8740 5 GAMED 18 dMED 145 3 1500 tbc cAIR-8740-PGA7 tbc mAIR-1230-DGA4 mAIR-1445-DGA4 mAIR-1720-DGA4 mAIR-1980-DGA4 mAIR-2430-DGA4 mAIR-2890-DGA4 mAIR-3445-TGA4 mAIR-3935-TGA4 mAIR-4860-TGA4 mAIR-5620-TGA4 5620 3 GAMED 22 dMED 145 2 1500 7475 4 GAMED 22 dMED 145 2 2000 tbc cAIR-7475-QGA7 tbc mAIR-340-DGA4 mAIR-500-DGA4 mAIR-630-DGA4 mAIR-990-DGA4 990 2 GAMED 7 dMED 25 1 500

Model Number

Design flow (litres/minute) Number of compressors Type of compressor Type of dryer Number of receivers Receiver volume (l) (each) Part Number Drawing Number

340 2 GAMED 5 dMED 7 1 250

500 2 GAMED 5 dMED 13 1 250

630 2 GAMED 5 dMED 13 1 500

1230 2 GAMED 11 dMED 25 1 1000

1445 2 GAMED 11 dMED 35 1 1000

1720 2 GAMED 15 dMED 35 1 1000

1980 2 GAMED 15 dMED 50 1 1000

2430 2 GAMED 18 dMED 50 1 1500

2890 2 GAMED 22 dMED 70 1 1500

3445 3 GAMED 15 dMED 70 1 2000

3935 3 GAMED 15 dMED 80 1 2000

4860 3 GAMED 18 dMED 100 2 1500

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

HTM2022 EurPh Combined Medical & Surgical Air 7 bar

cAIR-6000-QGA7 6000 4 GAMED 18 dMED 100 2 1500 tbc cAIR-1000-DGA7 cAIR-1225-DGA7 cAIR-1530-DGA7 cAIR-1770-DGA7 cAIR-2140-DGA7 cAIR-2475-DGA7 cAIR-3000-TGA7 cAIR-3540-TGA7 cAIR-4280-TGA7 cAIR-4895-TGA7 cAIR-425-DGA7 cAIR-555-DGA7 cAIR-790-DGA7

Model Number

Design flow (litres/minute) Number of compressors Type of compressor Type of dryer Number of receivers Receiver volume (l) (each) Part Number Drawing Number

425 2 GAMED 5 dMED 7 1 250

555 2 GAMED 5 dMED 13 1 500

790 2 GAMED 7 dMED 13 1 500

1000 2 GAMED 11 dMED 25 1 500

1225 2 GAMED 11 dMED 25 1 1000

1530 2 GAMED 15 dMED 25 1 1000

1770 2 GAMED 15 dMED 35 1 1000

2140 2 GAMED 18 dMED 35 1 1500

2475 2 GAMED 22 dMED 50 1 1500

3000 3 GAMED 15 dMED 50 1 1500

3540 3 GAMED 15 dMED 70 1 2000

4280 3 GAMED 18 dMED 70 2 1500

4895 3 GAMED 22 dMED 80 2 1500

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

tbc

BeaconMeds Telford Crescent, Staveley, Derbyshire S43 3PF, England Tel: +44 (0) 1246 474 242 Fax: +44 (0) 1246 472 982 www.beaconmedaes.com E-mail: gbn.info@beaconmedaes.com

tbc

tbc

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- AA-036911-001 Insulation Details For Hot Piping PDFДокумент1 страницаAA-036911-001 Insulation Details For Hot Piping PDFzampacaanas100% (2)

- Inspection Test Plan For ElectricalДокумент38 страницInspection Test Plan For Electricalzampacaanas76% (29)

- Bougainvillea GlabraДокумент1 страницаBougainvillea GlabrazampacaanasОценок пока нет

- Fireproofing STD - ARAMCOДокумент1 страницаFireproofing STD - ARAMCOzampacaanasОценок пока нет

- Project Quality Plan RevДокумент81 страницаProject Quality Plan Revzampacaanas89% (9)

- Standard Water Height Level, Setting From Supplier (OASIS)Документ2 страницыStandard Water Height Level, Setting From Supplier (OASIS)zampacaanasОценок пока нет

- Manhole QuotationДокумент6 страницManhole QuotationzampacaanasОценок пока нет

- Quality Requirements For MFCДокумент8 страницQuality Requirements For MFCzampacaanasОценок пока нет

- Xk-0092 - Gsoc SowДокумент31 страницаXk-0092 - Gsoc SowzampacaanasОценок пока нет

- Submersible Pump Detail DrawingДокумент1 страницаSubmersible Pump Detail DrawingzampacaanasОценок пока нет

- 3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2Документ16 страниц3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2zampacaanasОценок пока нет

- Eco-Friendly Domestic Water Filtration Solution: Clean, Healthy and Tasty WaterДокумент2 страницыEco-Friendly Domestic Water Filtration Solution: Clean, Healthy and Tasty WaterzampacaanasОценок пока нет

- Vibration PadДокумент2 страницыVibration PadzampacaanasОценок пока нет

- PHE Method StatementДокумент3 страницыPHE Method Statementzampacaanas0% (1)

- LSQ092H-3 Service ManualДокумент75 страницLSQ092H-3 Service ManualzampacaanasОценок пока нет

- Kone Technical SubmittalДокумент151 страницаKone Technical Submittalzampacaanas73% (11)

- Finance Hiring QuestionnaireДокумент1 страницаFinance Hiring QuestionnairezampacaanasОценок пока нет

- 2008 Consumer Industry Executive SummaryДокумент139 страниц2008 Consumer Industry Executive SummaryzampacaanasОценок пока нет

- Ahu-02 CavДокумент7 страницAhu-02 CavzampacaanasОценок пока нет

- Medaes Agss CatalogДокумент3 страницыMedaes Agss CatalogzampacaanasОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Ahsmrw30dam SD101Документ48 страницAhsmrw30dam SD101ibrahimОценок пока нет

- SSMT Solution ManualДокумент12 страницSSMT Solution ManualPraahas Amin0% (1)

- For Calibration List - OrginalДокумент62 страницыFor Calibration List - Orginaluttam khatriОценок пока нет

- PTX PRM PGL T5 750929eДокумент382 страницыPTX PRM PGL T5 750929eListiyo Imam SantosoОценок пока нет

- Online Assignment - Aritificial LiftДокумент10 страницOnline Assignment - Aritificial LiftfatenamiraОценок пока нет

- Characteristics of Logic Gates: A. ObjectivesДокумент10 страницCharacteristics of Logic Gates: A. ObjectivesManish KumarОценок пока нет

- NEF 50006 BSI WidescreenДокумент13 страницNEF 50006 BSI Widescreenmiguelq_scribdОценок пока нет

- BS en 00480-6-2005 PDFДокумент8 страницBS en 00480-6-2005 PDFShan Sandaruwan AbeywardeneОценок пока нет

- CS300.1 CS60.4 CS60.2: The Official Brand of Live MusicДокумент8 страницCS300.1 CS60.4 CS60.2: The Official Brand of Live MusicLuis RodriguezОценок пока нет

- Fee ChallanДокумент1 страницаFee ChallanMuhammad UsmanОценок пока нет

- SPC & MSA PresentationДокумент84 страницыSPC & MSA PresentationRaajha Munibathiran100% (3)

- Um0244 01 GBДокумент84 страницыUm0244 01 GBnetharafernando1Оценок пока нет

- Society and Culture With Family PlanningДокумент7 страницSociety and Culture With Family PlanningHope Earl Ropia BoronganОценок пока нет

- O21350 CMMKKДокумент2 страницыO21350 CMMKKwade.hynesoutlook.comОценок пока нет

- Swaroop (1) ResumeДокумент4 страницыSwaroop (1) ResumeKrishna SwarupОценок пока нет

- Digital Booklet - Oh My My (Deluxe) PDFДокумент8 страницDigital Booklet - Oh My My (Deluxe) PDFMehmet Akif DelibaşОценок пока нет

- CS506 - Web Design and Development (Handouts) PDFДокумент471 страницаCS506 - Web Design and Development (Handouts) PDFSyed Shahzad100% (2)

- BRIDGES - PPT 404 SEMДокумент204 страницыBRIDGES - PPT 404 SEMlokendraОценок пока нет

- Pursuit ManualДокумент26 страницPursuit Manualhunter9903Оценок пока нет

- Spherical Pillow Block Manual (MN3085, 2018)Документ13 страницSpherical Pillow Block Manual (MN3085, 2018)Dillon BuyeОценок пока нет

- Coal JourneyДокумент2 страницыCoal JourneyasnandyОценок пока нет

- Self-Regulated Learning - Where We Are TodayДокумент13 страницSelf-Regulated Learning - Where We Are Todayvzzvnumb100% (1)

- Uniclass 2015 Ss - Systems Table v1.22: April 2021Документ3 страницыUniclass 2015 Ss - Systems Table v1.22: April 2021Nagabhushana HОценок пока нет

- TPCN Monthly List of Subcontractors 06-2017Документ3 страницыTPCN Monthly List of Subcontractors 06-2017Teddy WilsonОценок пока нет

- HIV Sero-Status and Risk Factors of Sero-Positivity of HIV Exposed Children Below Two Years of Age at Mityana General Hospital in Mityana District, UgandaДокумент14 страницHIV Sero-Status and Risk Factors of Sero-Positivity of HIV Exposed Children Below Two Years of Age at Mityana General Hospital in Mityana District, UgandaKIU PUBLICATION AND EXTENSIONОценок пока нет

- Domus Ventilation Guide 2019Документ96 страницDomus Ventilation Guide 2019Regie CayasОценок пока нет

- Traffic Management During Construction, RSA - 240608Документ104 страницыTraffic Management During Construction, RSA - 240608mrasdan100% (2)

- Regulatory Compliance and Generator ControlДокумент59 страницRegulatory Compliance and Generator ControlsulemankhalidОценок пока нет

- Know The Escalation Matrix To ReportДокумент1 страницаKnow The Escalation Matrix To ReportHemal GandhiОценок пока нет

- Analysis and Design of Bridge Substructures PDFДокумент195 страницAnalysis and Design of Bridge Substructures PDFsuheilbugs100% (1)