Академический Документы

Профессиональный Документы

Культура Документы

Vaccum System

Загружено:

Safety professionalИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Vaccum System

Загружено:

Safety professionalАвторское право:

Доступные форматы

VACCUM SYSTEM

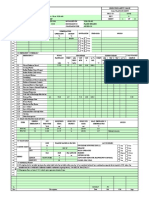

Spray Chamber Non condensable Gas Exhaust Vent

Water Ring Vacuum pump

Air+ Steam+ Hot water+ Cold water

Tyre curing press

Air+ Water vapour

Knock out Drum

Seal water Tank

Dewatering Tank

Pumping Unit

Vacuum is required in tyre curing system for removal of water from the bladder and collapsing the same to enable the tyre to be ejected out. For PCR and TBR plant and OTR area, we have two distinct vacuum systems. Each vacuum system comprises condensing (spray) chamber, knock out drum, water ring vacuum pump, cooling tower etc. as shown in the above block diagram. Air, steam, cold water and hot water will be supplied in certain sequence to the tyre curing machine. The drain from the tyre curing machine will have air and water vapour which will be reaching the condensing (spray) chamber where water will be sprayed to cool the air and condense the water vapour. The condensate from the condensing chamber is taken to the cooling tower with the help of pumps. After getting cooled in the cooling tower this water is pumped into the condensing chamber. Dewatering tank will get the water from spray chamber and knock out drum, based on the level by

the controller operation the air valve within the chamber will get open and gives a motive pressure to water and it is pumped to the cooling tower. The non condensible gases, with water droplets from the condensing chamber are passed on to the knock out drum where the water droplets are eliminated. The non condensible gas is then sucked by the water ring vacuum pump which is controlled by variable frequency drives and PLCs. There needs to be a constant level of water to be maintained within the water ring pump. The water ring vacuum pump develops the vacuum, sucks the non condensable gases and exhaust to the atmosphere. The low pressure water from the water ring pump is collected in a seal water tank and pumped into the cooling tower.

Liquid Ring

Inlet Port

Discharge Port

Inlet Port

Discharge Port

While stopped

While operating

The Liquid ring vacuum pump is a specific form of rotary positive-displacement pump utilizing liquid as a principal element in a gas compression. The compression is performed by a ring of liquid formed as a result of the relative eccentricity between the pumps casing and a rotating multi bladed impeller. The eccentricity results in near complete filling then partial emptying of each rotor chamber during every revolution. The filling and emptying action creates a piston action within each set of rotor of impeller blades. The pumps components are positioned in such a manner as to admit gas when the rotor chamber is emptying the liquid and then to allow the gas to discharge once compression is completed. Sealing areas between the inlet and discharge ports are provided, to close the rotor areas, and to separate the inlet and discharge flows.

Вам также может понравиться

- Construction Working Operation and Maintenance of Liquid Ring Vacuum PumpsДокумент11 страницConstruction Working Operation and Maintenance of Liquid Ring Vacuum PumpsRosy fajriОценок пока нет

- 240-56241288 Fossil Fired Boiler Protection Functions StandardДокумент16 страниц240-56241288 Fossil Fired Boiler Protection Functions StandardiabhuaОценок пока нет

- 240-76992014 Project or Plant Specific Technical Documents and Records Management Work InstructioДокумент23 страницы240-76992014 Project or Plant Specific Technical Documents and Records Management Work InstructioiabhuaОценок пока нет

- 240-56355843 Pressure Measurement Systems Installation StandardДокумент11 страниц240-56355843 Pressure Measurement Systems Installation StandardiabhuaОценок пока нет

- Fractional DestilationДокумент6 страницFractional DestilationCarlos Luis Esquerdo MarcanoОценок пока нет

- 240-55714363 Coal Fired Power Stations Lighting and Small Power Installation StandardДокумент40 страниц240-55714363 Coal Fired Power Stations Lighting and Small Power Installation StandardiabhuaОценок пока нет

- Electropure EDI Engr OEM Manual v3.5.0 (CE)Документ81 страницаElectropure EDI Engr OEM Manual v3.5.0 (CE)Fábio GomesОценок пока нет

- BMS Spec For WL48-50FT18 (English)Документ17 страницBMS Spec For WL48-50FT18 (English)Kennedy MatosОценок пока нет

- Pumps and Cooling TowersДокумент51 страницаPumps and Cooling TowersMikho SaligueОценок пока нет

- Capital Investment Ashok Sahakari Sakhar KarkhanaДокумент59 страницCapital Investment Ashok Sahakari Sakhar Karkhanaakshaykhade9834Оценок пока нет

- Start UpДокумент5 страницStart UpImmanuelОценок пока нет

- Systems Description Lubricating Oil System For LM2000Документ3 страницыSystems Description Lubricating Oil System For LM2000KALPUSHОценок пока нет

- EA in Biscuit MFG With Photo PDFДокумент8 страницEA in Biscuit MFG With Photo PDFSivakumar SelvarajОценок пока нет

- Screw Oil Press/ Oil Expeller: Dr. Hammad KhanДокумент15 страницScrew Oil Press/ Oil Expeller: Dr. Hammad KhanAhmadОценок пока нет

- Carbon Dioxide Scrubber RPДокумент5 страницCarbon Dioxide Scrubber RPpassionОценок пока нет

- Auger Boring ASCE No106-PreviewДокумент18 страницAuger Boring ASCE No106-PreviewMichael AnidisОценок пока нет

- Tropicalisaition of PumpsДокумент3 страницыTropicalisaition of PumpssurawutwijarnОценок пока нет

- Lube Oil System - LinkedInДокумент25 страницLube Oil System - LinkedInbobyОценок пока нет

- Lubrication System Operation (RENR9363) PDFДокумент4 страницыLubrication System Operation (RENR9363) PDFVan Hung DoОценок пока нет

- Broad Xii Non-Electric Chiller: Model Selection & Design ManualДокумент50 страницBroad Xii Non-Electric Chiller: Model Selection & Design ManualUmar MajeedОценок пока нет

- Shantanu DasДокумент10 страницShantanu DasarunkdevassyОценок пока нет

- Diaphragm Pump Seminar ReportДокумент58 страницDiaphragm Pump Seminar ReportMahaManthraОценок пока нет

- Automatic Water Flow ControlДокумент18 страницAutomatic Water Flow ControlssgjmlimОценок пока нет

- Appendix-3.0 Scope of Chiller Maintenance WorksДокумент3 страницыAppendix-3.0 Scope of Chiller Maintenance Worksnoormuddassirkhan100% (1)

- HPAC - Evaluating Deaerator OperationДокумент5 страницHPAC - Evaluating Deaerator Operationghostamir100% (1)

- BoilerДокумент28 страницBoilerHassan Funsho AkandeОценок пока нет

- Service Data Forklift GP40N-GP55NДокумент8 страницService Data Forklift GP40N-GP55Nirsan pratama putra100% (1)

- Operation ManualДокумент83 страницыOperation ManualAn Son100% (1)

- Ultra Filtration SystemДокумент5 страницUltra Filtration SystemAbdul SamadОценок пока нет

- 8.chapter 5 Compressed Air SystemДокумент17 страниц8.chapter 5 Compressed Air SystemAbdullah TalibОценок пока нет

- Compresores Ga 100 PDFДокумент16 страницCompresores Ga 100 PDFFranklin Esteban CárdenasОценок пока нет

- Reciprocating Compressor Cooloing ConsoleДокумент22 страницыReciprocating Compressor Cooloing ConsolerutujaОценок пока нет

- Water Purifier PPT at Bec Doms Bagalkot MbaДокумент11 страницWater Purifier PPT at Bec Doms Bagalkot MbaBabasab Patil (Karrisatte)Оценок пока нет

- RFP BNR C PDFДокумент342 страницыRFP BNR C PDFChanelОценок пока нет

- Ammonia Plant Maint.Документ11 страницAmmonia Plant Maint.mahmadwasiОценок пока нет

- Biogas Processes For Sustainable DevelopmentДокумент246 страницBiogas Processes For Sustainable DevelopmentQuarterbore100% (4)

- DEFO N American ImperialДокумент100 страницDEFO N American ImperialFrancisco Hernandez Hernandez100% (2)

- Handbook Oil Control 01-Co-EngДокумент26 страницHandbook Oil Control 01-Co-EngfebriОценок пока нет

- Water Treatment Operating Procedures-09Документ8 страницWater Treatment Operating Procedures-09Greg MaynardОценок пока нет

- Summer Training ReportДокумент24 страницыSummer Training Reportruman ahmadОценок пока нет

- Understanding and Eliminating Pressure Fluctuations in 2010 Process SafetyДокумент6 страницUnderstanding and Eliminating Pressure Fluctuations in 2010 Process SafetyandriОценок пока нет

- Lift Station Safety and MaintenanceДокумент29 страницLift Station Safety and MaintenanceVinish HARIDAS NAIRОценок пока нет

- Engineering Design - ReportДокумент6 страницEngineering Design - ReportThurya Sathsara Nishakara OwitipanaОценок пока нет

- Distillation Application in PetroleumДокумент46 страницDistillation Application in Petroleumamirthalingam_b671Оценок пока нет

- Hydraulic Actuator SpecificationsДокумент3 страницыHydraulic Actuator SpecificationsRizky RamadhaniОценок пока нет

- DLT 609-1996 300MW Grade Steam Turbine OperationДокумент40 страницDLT 609-1996 300MW Grade Steam Turbine OperationAleksandar MilicОценок пока нет

- Home Werktuigen Domains Werktuigen - NL Public HTML Upload Userfiles File Caterpillar Heftrucks Diesel DP40N-DP55NGPДокумент3 страницыHome Werktuigen Domains Werktuigen - NL Public HTML Upload Userfiles File Caterpillar Heftrucks Diesel DP40N-DP55NGPdonwload bunk100% (1)

- Hycor Hydroscreen Static Screen: Model HSДокумент2 страницыHycor Hydroscreen Static Screen: Model HSMagin Idelfonso TorreblancaОценок пока нет

- BottlingДокумент14 страницBottlingWasiYamanChoudhuryОценок пока нет

- 01 01 03 Alkaline DegreasingДокумент10 страниц01 01 03 Alkaline DegreasingmasoudОценок пока нет

- Smeda Oil Distillaiton UnitДокумент21 страницаSmeda Oil Distillaiton UnitHaseeb A ChaudhryОценок пока нет

- MAV Lube Oil SystemДокумент9 страницMAV Lube Oil SystemMurali Krishna GbОценок пока нет

- Section 22 60 00 - Medical Vacuum and Gas PipingДокумент14 страницSection 22 60 00 - Medical Vacuum and Gas PipingFeroz KhanОценок пока нет

- Yokogawa Rota MassДокумент274 страницыYokogawa Rota MassZikireya79Оценок пока нет

- Anone PlantДокумент2 страницыAnone PlantAbijith100% (1)

- Water Cooled Flooded Vertical Screw ChillersДокумент96 страницWater Cooled Flooded Vertical Screw ChillersaftabОценок пока нет

- The Difference Between API, DIN, IsO, ASME PumpsДокумент1 страницаThe Difference Between API, DIN, IsO, ASME PumpstoicantailieunhatОценок пока нет

- Centrifugal Pump (Various Air Handling Methods)Документ21 страницаCentrifugal Pump (Various Air Handling Methods)karthick_mariner92Оценок пока нет

- Centrifugal Pump (Various Air Handling Methods)Документ31 страницаCentrifugal Pump (Various Air Handling Methods)karthick_mariner92Оценок пока нет

- Day 3 Pumps & Heat ExchangerДокумент48 страницDay 3 Pumps & Heat ExchangerChristian Cañon GenterolaОценок пока нет

- NAHB Second EditionДокумент25 страницNAHB Second EditionSafety professionalОценок пока нет

- Fire Race PassДокумент1 страницаFire Race PassSafety professionalОценок пока нет

- FRC Team Safety Manual PDFДокумент22 страницыFRC Team Safety Manual PDFSafety professionalОценок пока нет

- Goals!: How To Get Everything You Want Faster Than You Ever Thought Possible!Документ11 страницGoals!: How To Get Everything You Want Faster Than You Ever Thought Possible!Safety professionalОценок пока нет

- Contractor Personnel and Safety Statistics Monthly Summary - Form S2052Документ1 страницаContractor Personnel and Safety Statistics Monthly Summary - Form S2052Safety professionalОценок пока нет

- W Hhwsop1 02Документ6 страницW Hhwsop1 02Safety professionalОценок пока нет

- Instructions 1. Instructions: Sponsored Links Commission CalculatorДокумент6 страницInstructions 1. Instructions: Sponsored Links Commission CalculatorSafety professionalОценок пока нет

- Chapter 10Документ14 страницChapter 10Rajesh MohananОценок пока нет

- BoilersДокумент5 страницBoilersSafety professionalОценок пока нет

- MSDS - NeoTabДокумент7 страницMSDS - NeoTabSafety professionalОценок пока нет

- PSV Calculation Sheet APIДокумент10 страницPSV Calculation Sheet APIionutlaur86100% (2)

- Principles of Hydrostatic PressureДокумент48 страницPrinciples of Hydrostatic PressureJongson Dantes Rodriguez100% (1)

- Gas CalculationsДокумент3 страницыGas CalculationsaizatОценок пока нет

- Gases Under Pressure: Gases Under Pressure Are Gases Which Are Contained in A Receptacle at A Pressure of 200Документ11 страницGases Under Pressure: Gases Under Pressure Are Gases Which Are Contained in A Receptacle at A Pressure of 200manusia biasaОценок пока нет

- Cyclones ExerciseДокумент4 страницыCyclones ExerciseValeria cОценок пока нет

- General Chemistry I - Q2 M7.1 Ionic & Covalent BondsДокумент22 страницыGeneral Chemistry I - Q2 M7.1 Ionic & Covalent BondseliОценок пока нет

- PsychrometricsДокумент32 страницыPsychrometricskdsahooОценок пока нет

- Chapter 3 - Flow of Compressible FluidsДокумент38 страницChapter 3 - Flow of Compressible FluidsFatin FatehaОценок пока нет

- Expt 2 Measuring Density and SGДокумент12 страницExpt 2 Measuring Density and SGmariel dolojanОценок пока нет

- AIRCON - Powerpoint PresentationДокумент64 страницыAIRCON - Powerpoint PresentationAnonymous zMXgZVEОценок пока нет

- PYL 703 2015 Lect 01 PDFДокумент8 страницPYL 703 2015 Lect 01 PDFShashankGahlautОценок пока нет

- Air Products - Air Separation Plants PosterДокумент1 страницаAir Products - Air Separation Plants PosterVictor PomboОценок пока нет

- 4.0 - Kinetic Theory - MCQSДокумент21 страница4.0 - Kinetic Theory - MCQSMarshell JonesОценок пока нет

- Advance Semiconductor DevicesДокумент1 страницаAdvance Semiconductor DevicesMuhammad Atiq Ur Rehman 22-FET/PHDEE/S19Оценок пока нет

- Presentation of Internship ProjectДокумент34 страницыPresentation of Internship ProjectReinaldo Ongky Billy AnandoОценок пока нет

- Liquid CrystalsДокумент15 страницLiquid CrystalsReddyvari VenugopalОценок пока нет

- Chapter 10 Refrigeration SystemДокумент95 страницChapter 10 Refrigeration SystemMinh Hiếu CaoОценок пока нет

- ME436: Heat Transfer: 1 Flow Over A Flat PlateДокумент3 страницыME436: Heat Transfer: 1 Flow Over A Flat Platerewqrewq5Оценок пока нет

- FORMATEMANUAL A5 Crystallization TemperatureДокумент20 страницFORMATEMANUAL A5 Crystallization TemperaturejcОценок пока нет

- Materials Science and Engineering Properties 1st Edition Charles Gilmore Solutions ManualДокумент36 страницMaterials Science and Engineering Properties 1st Edition Charles Gilmore Solutions Manualsugarstearoneymw4l9100% (23)

- ConversationДокумент2 страницыConversationHiggilty PiggiltyОценок пока нет

- Ralph L. Webb, Nae-Hyun Kim - Principles of Enhanced Heat Transfer-CRC Press (2005)Документ816 страницRalph L. Webb, Nae-Hyun Kim - Principles of Enhanced Heat Transfer-CRC Press (2005)arif aktaş100% (1)

- Chemistry Study Guide Chapter 15,16,18 2022 (Omit 18.3)Документ3 страницыChemistry Study Guide Chapter 15,16,18 2022 (Omit 18.3)JocelynОценок пока нет

- Refrigeration Manual System Design P-4 Ae104Документ102 страницыRefrigeration Manual System Design P-4 Ae104Milton UrrozОценок пока нет

- Super Critical CO2 As Green SolventДокумент11 страницSuper Critical CO2 As Green SolventAnushka ChakrabortyОценок пока нет

- Lewis SymbolДокумент20 страницLewis SymbolVivian May J. GuibalaОценок пока нет

- Ce 129: Hydraulics: Chapter 1: Properties of FluidsДокумент4 страницыCe 129: Hydraulics: Chapter 1: Properties of FluidsLimuel Carlo SabileОценок пока нет

- Problem Set #1 Fluid PropertiesДокумент6 страницProblem Set #1 Fluid PropertiesEdgar Henri NicolasОценок пока нет

- Wet Leg Vs Dry LegДокумент2 страницыWet Leg Vs Dry LegGCОценок пока нет

- Water Dewpoint DepressionДокумент2 страницыWater Dewpoint DepressiondndudcОценок пока нет

- Bulk Material Handling: Practical Guidance for Mechanical EngineersОт EverandBulk Material Handling: Practical Guidance for Mechanical EngineersРейтинг: 5 из 5 звезд5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОт EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОценок пока нет

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionОт EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- The Laws of Thermodynamics: A Very Short IntroductionОт EverandThe Laws of Thermodynamics: A Very Short IntroductionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideОт Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideРейтинг: 3.5 из 5 звезд3.5/5 (7)

- Basic Digital Signal Processing: Butterworths Basic SeriesОт EverandBasic Digital Signal Processing: Butterworths Basic SeriesРейтинг: 5 из 5 звезд5/5 (1)

- Mechanical Vibrations and Condition MonitoringОт EverandMechanical Vibrations and Condition MonitoringРейтинг: 5 из 5 звезд5/5 (1)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)От EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Рейтинг: 4 из 5 звезд4/5 (12)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionОт EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionРейтинг: 3 из 5 звезд3/5 (1)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionОт EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionОценок пока нет

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CОт EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CОценок пока нет

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseОт EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (51)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsОт EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongОценок пока нет

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItОт EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItРейтинг: 4 из 5 звезд4/5 (25)

- Safety Theory and Control Technology of High-Speed Train OperationОт EverandSafety Theory and Control Technology of High-Speed Train OperationРейтинг: 5 из 5 звезд5/5 (2)

- Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataОт EverandLaminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataОценок пока нет

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- The Galactic Federation: Discovering the Unknown Can Be Stranger Than FictionОт EverandThe Galactic Federation: Discovering the Unknown Can Be Stranger Than FictionОценок пока нет

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsОт EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsРейтинг: 4 из 5 звезд4/5 (9)

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeОт EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeРейтинг: 4 из 5 звезд4/5 (9)