Академический Документы

Профессиональный Документы

Культура Документы

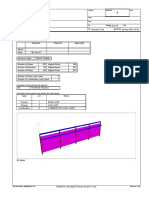

Typical Box Culvert Drawings

Загружено:

lalithniroshaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Typical Box Culvert Drawings

Загружено:

lalithniroshaАвторское право:

Доступные форматы

Humes Pipeline Systems Level 3, Wright Stephenson House, 585 Great South Rd, Penrose, Auckland Private Bag

92817, Penrose, Auckland 1642, New Zealand T: +64 9 580 0800 F: +64 9 580 0801 www.humes.co.nz

STANDARD CONCRETE BOX CULVERTS 100 Year Design Life Materials

Concrete fc = 50 MPa (28 days), Steel fy = 500 MPa, Grade 500E

Design Assumptions

Design Loading to TRANSIT NZ Bridge Manual: HN-HO-72 Load Factors & Combinations, Impact Factor all to TRANSIT NZ Bridge Manual. Serviceability LL factor of 1.35 applied Perpendicular orientation of box culverts relative to centreline of the road General concrete structural design to NZS 3101:Part 1:2006 Earth Pressure - Horizontal, Min/Max at mid wall height to generate max load effects (Ko = 0.55 max, Ko = 0.275 min) All units with fill cover (up to 2000mm) designed for positive projecting embankment conditions at 20 kN/m3. The resultant pressure is factored as an EP. Compressible / Non Compressible base analysis included Deck shear keys provided for fill covers 0-600mm and 300-1000mm, otherwise plain butt joint all slabs Shear reinforcement in the deck slab (VHN >Vc/3), to NZS 3101:2006, 9.3.9 Serviceability check (governed by fatigue stress) to NZS 3101:2006, 2.5.2 (LL factor of 1.35 applied) Lifting to Code of Practice for the safe Handling, Transportation and Erection of Precast Concrete (OSH, Dept of Labour, NZ) Soil Safe Bearing (non factored loads) shall exceed 100 kPa unless specific engineering foundation design is undertaken. Boxes should be placed to a screeded sand layer to ensure uniform support over the base slab Durability Design: (NZS3101:2006, Section 3) 50 MPa GP Concrete Unless otherwise specified all 100 year life standard box culverts are designed for the following exposure classifications All outside surfaces and inside deck, B1 (35 cover to reinforcement) Inside walls and inside base, B2 (40 cover to reinforcement)

Producer Statements, Calculations, Drawings, Site Specific Design

Clarification of requirements (eg. starter bars, inserts, duct holes, etc.) to be agreed at the time of quotation/order If ducts are to be provided it is strongly recommended that they are grouted back after site installation, unless the contract documents specifically provide another agreed means of achieving durability design. Design is associated with the individual precast element only, not with the overall contract/job design (eg. installation, jointing, prestressing, post-tensioning, tie rods, jointing of wingwalls to box culverts, etc).Site specific design is not provided. Calculations / drawings/ standard and non standard details, all intellectual property to Humes, will not be provided Producer Statements will only be made available if mutually agreed at the time of quotation

Manufacturing Standards

Precast Units to NZS 3109:97 Surface Finishes to NZS 3114:87

Formed Surfaces F4 Finish Trowelled Surfaces U2 Finish

07/12/2007

Вам также может понравиться

- Design of Manhole As Per Aashto LRFDДокумент23 страницыDesign of Manhole As Per Aashto LRFDRafique Munde100% (2)

- Construction and Design of Multi Storey Building by Abhimanyu ParidaДокумент38 страницConstruction and Design of Multi Storey Building by Abhimanyu Paridadriverx47100% (19)

- Standard Drawing of Concrete PavementДокумент15 страницStandard Drawing of Concrete PavementBasir AhmadОценок пока нет

- 1 First Fence StaadДокумент8 страниц1 First Fence StaadSiva JaseОценок пока нет

- Apex Masonry Ebook Fence Design Guide CMAA PDFДокумент10 страницApex Masonry Ebook Fence Design Guide CMAA PDFJohnson SambranoОценок пока нет

- Building Estimation in Excel SheetДокумент17 страницBuilding Estimation in Excel SheetGel AhnОценок пока нет

- Celestial Mechanics and Astrodynamics: Theory and Practice: Pini Gurfi L P. Kenneth SeidelmannДокумент553 страницыCelestial Mechanics and Astrodynamics: Theory and Practice: Pini Gurfi L P. Kenneth SeidelmannRAJ PANCHAL100% (2)

- Di Pipe DrawingsДокумент6 страницDi Pipe DrawingsZatul Akmal ZamilОценок пока нет

- Light Pole FoundationДокумент1 страницаLight Pole FoundationMalik Imran Shakir100% (2)

- Zamil Steel Panel Chart PDFДокумент1 страницаZamil Steel Panel Chart PDFFerdie TolosaОценок пока нет

- Pipe - Culvert Design PDFДокумент1 страницаPipe - Culvert Design PDFDarshan M TОценок пока нет

- Anchor Bolts (Make-Hilti) PDFДокумент4 страницыAnchor Bolts (Make-Hilti) PDFShino UlahannanОценок пока нет

- AUH Muncipality Guideline-2of 2Документ43 страницыAUH Muncipality Guideline-2of 2cbecdmОценок пока нет

- GIFT - Gabion Slope Protection BOQ and Cost EstimateДокумент11 страницGIFT - Gabion Slope Protection BOQ and Cost EstimateshahqazwsxОценок пока нет

- 9m Pole FDN Design 18.2.2015Документ2 страницы9m Pole FDN Design 18.2.2015faizankhan23Оценок пока нет

- Hudson's Precast Concrete Box Culvert Catalogue 2011Документ18 страницHudson's Precast Concrete Box Culvert Catalogue 2011Yoshua Yang100% (1)

- 18M High MastДокумент34 страницы18M High Mastjobees7850Оценок пока нет

- BOQ Box Culvert FinalДокумент19 страницBOQ Box Culvert FinalManoj AhirwarОценок пока нет

- Design Review Checklist Box Culverts Bridge - 201711081516193760Документ20 страницDesign Review Checklist Box Culverts Bridge - 201711081516193760Sumber UnduhОценок пока нет

- 2014 AMC8 SolutionsДокумент8 страниц2014 AMC8 Solutionstony dooОценок пока нет

- Pipe CulvertДокумент5 страницPipe CulvertfazsОценок пока нет

- Circular Precast Concrete ManholesДокумент5 страницCircular Precast Concrete ManholesAnthony Quintua PatinoОценок пока нет

- Aero3110 DBT Group 15Документ22 страницыAero3110 DBT Group 15Atitat RattanachataОценок пока нет

- Plumbing and Fire Fighting Sample BoqДокумент30 страницPlumbing and Fire Fighting Sample BoqNajeeb Ahmad Khan100% (2)

- Design of Reinforced Concrete ManholeДокумент2 страницыDesign of Reinforced Concrete Manholenephembani100% (2)

- PSC Girder Bridge Construction - Construction of A Bridge-Bridge Construction MethodДокумент16 страницPSC Girder Bridge Construction - Construction of A Bridge-Bridge Construction MethodVinay Raj100% (1)

- ASTM Rebar MarkingДокумент1 страницаASTM Rebar Markingကိုနေဝင်းОценок пока нет

- Design Basis Report For Civil and Architectural Engineering PDFДокумент8 страницDesign Basis Report For Civil and Architectural Engineering PDFVijai Prasath100% (1)

- @method Statement For Static Load TestДокумент76 страниц@method Statement For Static Load TestTrương Văn ĐồngОценок пока нет

- Standard Lighting Column FoundationsДокумент2 страницыStandard Lighting Column FoundationsEm MarОценок пока нет

- Iec Sit Sit Sepam CurveДокумент1 страницаIec Sit Sit Sepam Curveyadav_sctОценок пока нет

- DAR Vol 1Документ1 107 страницDAR Vol 1Ramachandra SahuОценок пока нет

- Culvert Design ManualДокумент54 страницыCulvert Design ManualMahmoud Al NoussОценок пока нет

- Box CulvertДокумент2 страницыBox CulvertAnjan Nandan100% (1)

- 2016 BSC Junior (7&8) Paper and AnswersДокумент20 страниц2016 BSC Junior (7&8) Paper and AnswersUmayal Sivanandan100% (1)

- Design of Thrust BlockДокумент5 страницDesign of Thrust BlockDeepak Ramchandani0% (1)

- BOQ Sample For A Civil Work of Mechanical LabДокумент54 страницыBOQ Sample For A Civil Work of Mechanical LabSelvakumar SОценок пока нет

- Culvert Structural DesignДокумент54 страницыCulvert Structural DesigntipsypigОценок пока нет

- TYcul LAYOUT 5 PDFДокумент1 страницаTYcul LAYOUT 5 PDFkanishkaОценок пока нет

- Box Culvert, VUP & Minor BridgeДокумент22 страницыBox Culvert, VUP & Minor BridgeĐărsĥąna RanasingheОценок пока нет

- Hollow Core Planks Application and Design GuideДокумент46 страницHollow Core Planks Application and Design Guidemixi1978100% (1)

- Bathroom FittingsДокумент4 страницыBathroom Fittingsdox4printОценок пока нет

- 1 PDFДокумент22 страницы1 PDFNeeraj Sharma0% (1)

- BD 8200Документ19 страницBD 8200JosephChongОценок пока нет

- 783 Hume Pipe LayingДокумент83 страницы783 Hume Pipe LayingAmit Ghorpade100% (2)

- Civil Work BoqДокумент8 страницCivil Work Boqous_biju0% (1)

- Foundation Design of Lamp PostДокумент1 страницаFoundation Design of Lamp PostMayank Agrawal100% (1)

- Box Culvert Methodology - R0Документ20 страницBox Culvert Methodology - R0Lalit Pratap Singh TomarОценок пока нет

- Construction and Design of MultistoreyДокумент37 страницConstruction and Design of MultistoreyFawadОценок пока нет

- Cantilever Masonry Manual Nov 03Документ27 страницCantilever Masonry Manual Nov 03Dwi SulistyoОценок пока нет

- v2 TD S P 1002 1 F Shape Parapet 1 22m High Type A B General Layout and SectionsДокумент1 страницаv2 TD S P 1002 1 F Shape Parapet 1 22m High Type A B General Layout and SectionsSudathipTangwongchaiОценок пока нет

- PROKON Structural Analysis and DesignДокумент9 страницPROKON Structural Analysis and Designmanhal alnoaimy100% (1)

- U-Shape Drain (T-6) PU Series: FUJI Precast Concrete SolutionДокумент3 страницыU-Shape Drain (T-6) PU Series: FUJI Precast Concrete SolutiongautamОценок пока нет

- Septic Tank DrawingДокумент3 страницыSeptic Tank DrawingPaldipSinghОценок пока нет

- Design of Box CulvertДокумент11 страницDesign of Box Culvertjs kalyana ramaОценок пока нет

- West Bengal Schedule Rates of Building Works 2015Документ399 страницWest Bengal Schedule Rates of Building Works 2015Arunashish Mazumdar75% (8)

- Method Statement For Providing Pipe Sleeve Opening On R.C. BeamДокумент1 страницаMethod Statement For Providing Pipe Sleeve Opening On R.C. Beamhiyumiwks100% (1)

- Standard Drawings - Kerb and Wheel Stopper DetailsДокумент1 страницаStandard Drawings - Kerb and Wheel Stopper DetailsprmraoОценок пока нет

- List of Drawings of Part 2 - Roads: Drawing Title DWGДокумент74 страницыList of Drawings of Part 2 - Roads: Drawing Title DWGFenner Electromechanical100% (1)

- Estimate Electrical Guwahati UniversityДокумент19 страницEstimate Electrical Guwahati UniversityTandon Abhilash BorthakurОценок пока нет

- PileДокумент5 страницPileSuman NakarmiОценок пока нет

- 14) Structure Guideline August 2017Документ40 страниц14) Structure Guideline August 2017lwin_oo2435Оценок пока нет

- BOQ Boundary WallДокумент3 страницыBOQ Boundary WallAshwani Goel50% (2)

- CE414 Module 1Документ48 страницCE414 Module 1MOHD AMILОценок пока нет

- Appendix 2 Concrete OverlaysДокумент29 страницAppendix 2 Concrete Overlaysproteor_srlОценок пока нет

- Iesl Guideline Structure For Engineering Consultancy Fees 10012013Документ11 страницIesl Guideline Structure For Engineering Consultancy Fees 10012013lalithniroshaОценок пока нет

- 2Документ15 страниц2lalithniroshaОценок пока нет

- Metric Bolt StrengthДокумент8 страницMetric Bolt StrengthlalithniroshaОценок пока нет

- Tariff Calculator: Input The Rate of Levy Into The Relevant Cages in Green. (Input 0% When The Rate Is Free or Ex.)Документ3 страницыTariff Calculator: Input The Rate of Levy Into The Relevant Cages in Green. (Input 0% When The Rate Is Free or Ex.)lalithniroshaОценок пока нет

- Milan, Missouri: Elmwood Reservoir Forcasting With 1988 Climatic DataДокумент9 страницMilan, Missouri: Elmwood Reservoir Forcasting With 1988 Climatic DatalalithniroshaОценок пока нет

- ESTIMATE of The EXPENSE Necessary To Be Incurred For Improvements To Bandarawela - Uvahighlands - Ettampitiya Road (0.0-0.5 KM)Документ18 страницESTIMATE of The EXPENSE Necessary To Be Incurred For Improvements To Bandarawela - Uvahighlands - Ettampitiya Road (0.0-0.5 KM)lalithniroshaОценок пока нет

- Science and TechnologyДокумент18 страницScience and Technologysharon emailОценок пока нет

- Practical Wet Test Acid Radical-1Документ5 страницPractical Wet Test Acid Radical-1psyxs4tsv9Оценок пока нет

- MATH 1211 Tutorial IX-Volume IntegralsДокумент2 страницыMATH 1211 Tutorial IX-Volume IntegralsKeshav GopaulОценок пока нет

- Chapter 2Документ28 страницChapter 2nurul najwaОценок пока нет

- Lab 4 - Kirchhoffs LawsДокумент4 страницыLab 4 - Kirchhoffs LawsAnuradha ItwaruОценок пока нет

- Test Certificate: Reference No.Документ3 страницыTest Certificate: Reference No.Maninder ChaudharyОценок пока нет

- Experiment 6 Conservation of EnergyДокумент5 страницExperiment 6 Conservation of EnergyHarold ParenasОценок пока нет

- Moisture Buffering Capacity of Hygroscopic Building Materials: Experimental Facilities and Energy ImpactДокумент13 страницMoisture Buffering Capacity of Hygroscopic Building Materials: Experimental Facilities and Energy ImpactBayang SilamОценок пока нет

- Gravitator: "How I Control Gravitation" British Patent # 300,311Документ17 страницGravitator: "How I Control Gravitation" British Patent # 300,311Brian BennОценок пока нет

- Applied Linerar Algebra FinalДокумент193 страницыApplied Linerar Algebra FinalAslesh ChoudharyОценок пока нет

- Physics 101 - HW34Документ1 страницаPhysics 101 - HW34Tim JonesОценок пока нет

- CRF - Charing MethodДокумент13 страницCRF - Charing MethodAshwary Sheel Wali Research Scholar, Dept of Mech Engg., IIT (BHU)Оценок пока нет

- JCT College of Engineering and Technology: Pichanur, Coimbatore.641105Документ2 страницыJCT College of Engineering and Technology: Pichanur, Coimbatore.641105arumugamОценок пока нет

- Astm E1 14 2020Документ15 страницAstm E1 14 2020gvegar62_392488973Оценок пока нет

- Optimization of The Wood Drying ProcessДокумент10 страницOptimization of The Wood Drying ProcessBambang AriantaraОценок пока нет

- Sem NotesДокумент39 страницSem NotesN NandiniОценок пока нет

- Introduction To Design OptimizationДокумент16 страницIntroduction To Design OptimizationPeter JammyОценок пока нет

- Physics Project - MotionДокумент15 страницPhysics Project - MotionHirak I like this BasuОценок пока нет

- GS-200 Operation Manual 10 VerДокумент466 страницGS-200 Operation Manual 10 VersunhuynhОценок пока нет

- Precalculus Module Conic SectionsДокумент35 страницPrecalculus Module Conic SectionsDekkle YeoОценок пока нет

- Effective Mass of An Oscillating Spring: Eduardo E. Rodríguez, Gabriel A. GesnouinДокумент4 страницыEffective Mass of An Oscillating Spring: Eduardo E. Rodríguez, Gabriel A. GesnouinEudomar HenriquezОценок пока нет

- 13-Cash Flow at Risk Valuation of Mining Project Using Monte Carlo Simulations With Stochastic Processes Calibrated On Historical DataДокумент38 страниц13-Cash Flow at Risk Valuation of Mining Project Using Monte Carlo Simulations With Stochastic Processes Calibrated On Historical DataFranhel alexandra GarciaОценок пока нет

- Principles of Continuous Flow Centrifugation: Technical Application NoteДокумент18 страницPrinciples of Continuous Flow Centrifugation: Technical Application NoteDiksha SurekaОценок пока нет

- MEMO Test1 2019 SEM1 Electrical Engineering IIIДокумент3 страницыMEMO Test1 2019 SEM1 Electrical Engineering IIImjaji khulehОценок пока нет

- Cramer RaoДокумент11 страницCramer Raoshahilshah1919Оценок пока нет