Академический Документы

Профессиональный Документы

Культура Документы

Additive 515 m7 PDF

Загружено:

Khubah KhoirurobiqОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Additive 515 m7 PDF

Загружено:

Khubah KhoirurobiqАвторское право:

Доступные форматы

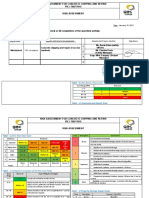

GLYCEROL ESTER OF GUM ROSIN (TENTATIVE)

New tentative specifications prepared at the 71st JECFA (2009 and, published in FAO JECFA Monographs 7 (2009). A group ADI of 0 25 mg/kg bw for glycerol ester of gum rosin and glycerol ester of wood rosin was established at the 71st JECFA (2009). Information is required on batches of commercially available products: representative infrared spectra, with identification of relevant peaks and conditions of analysis. Clean spectra are also required identification of the main resin acids with their relative proportions, obtained with updated chromatographic techniques other data or information useful for distinguishing among the glycerol esters of wood, gum and tall oil rosins

DEFINITION

Glycerol ester of gum rosin is a complex mixture of tri- and diglycerol esters of resin acids from gum rosin, with a residual fraction of monoglycerol esters. It is obtained by the esterification of refined gum rosin under a nitrogen atmosphere with food-grade glycerol, and purified by counter-current steam distillation. Refined gum rosin is obtained by extracting oleoresin gum from living pine trees and refining it through washing, filtration and distillation. It is composed of approximately 90% resin acids and 10% neutrals (non-acidic compounds). The resin-acid fraction is a complex mixture of isomeric diterpenoid monocarboxylic acids having the typical empirical formula C20H30O2, of which the main component is abietic acid. These specifications do not cover substances derived from wood rosin, obtained by the solvent extraction of aged pine stumps, and substances derived from tall oil rosin, a by-product of Kraft (paper) pulp processing. Hard, yellow to pale amber-coloured solid

DESCRIPTION

FUNCTIONAL USES Emulsifier, density adjustment agent for flavouring oils in

beverages

CHARACTERISTICS

IDENTIFICATION Solubility (Vol. 4)

Insoluble in water; soluble in acetone The infrared spectrum of a thin film of the sample (potassium bromide plate) corresponds with the typical infrared spectrum Infrared spectra from commercially available products are requested

Infrared absorption (Vol. 4)

Sulfur test

Negative Weigh 40-50 mg of sample into a test tube and add 1- 2 drops of a 20% (w/v) solution of sodium formate. Place a strip of lead acetate test paper over the mouth of the test tube. Heat the tube until fumes are formed that contact the test paper. Continue heating for 2-5 min. The formation of a black spot of lead sulfide indicates the presence of sulfur-containing compounds. (Detection Limit: 50 mg/kg sulfur).

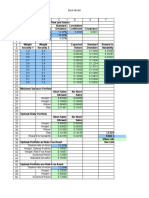

PURITY Specific gravity (Vol. 4) Ring and ball softening point (Vol. 4) Acid value (Vol. 4) Lead (Vol. 4)

d2025: Not less than 0.935 (50% solution in d-limonene) Not less than 82 (see Specific Methods, Glycerol Esters of Rosins) Between 3 and 9 (see Specific Methods, Fats, Oils, and Hydrocarbons) Not more than 1 mg/kg Determine using an AAS/ICP-AES technique appropriate to the specified level. The selection of sample size and method of sample preparation may be based on the principles of the method described in Volume 4 (under General Methods, Metallic Impurities).

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Muscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeДокумент4 страницыMuscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeCarlo FilipponeОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Astm B633Документ5 страницAstm B633nisha_khan100% (1)

- Reverse Osmosis Desalination: Our Global Expertise To Address Water ScarcityДокумент16 страницReverse Osmosis Desalination: Our Global Expertise To Address Water Scarcitynice guyОценок пока нет

- Standerdised Tools of EducationДокумент25 страницStanderdised Tools of Educationeskays30100% (11)

- Root Pouch Info Brochure 10Документ20 страницRoot Pouch Info Brochure 10Khubah KhoirurobiqОценок пока нет

- Kecamatan Ngemplak Kecamatan Ngaglik Peta Administrasi Kecamatan DepokДокумент1 страницаKecamatan Ngemplak Kecamatan Ngaglik Peta Administrasi Kecamatan DepokKhubah KhoirurobiqОценок пока нет

- Patented May 30, 1967: Be Determined. IДокумент4 страницыPatented May 30, 1967: Be Determined. IKhubah KhoirurobiqОценок пока нет

- Multiple Sequence Alignment Tools: Tutorials and Comparative AnalysisДокумент19 страницMultiple Sequence Alignment Tools: Tutorials and Comparative AnalysisKhubah KhoirurobiqОценок пока нет

- Ancon Tension Systems March 2008Документ16 страницAncon Tension Systems March 2008Slinky BillОценок пока нет

- 8 Categories of Lipids: FunctionsДокумент3 страницы8 Categories of Lipids: FunctionsCaryl Alvarado SilangОценок пока нет

- Brochure - ILLUCO Dermatoscope IDS-1100Документ2 страницыBrochure - ILLUCO Dermatoscope IDS-1100Ibnu MajahОценок пока нет

- Nodular Goiter Concept MapДокумент5 страницNodular Goiter Concept MapAllene PaderangaОценок пока нет

- BKM 10e Ch07 Two Security ModelДокумент2 страницыBKM 10e Ch07 Two Security ModelJoe IammarinoОценок пока нет

- Team SportsДокумент143 страницыTeam SportsYashОценок пока нет

- Acuson P10Документ2 страницыAcuson P10anon-259218Оценок пока нет

- Ra Concrete Chipping 7514Документ5 страницRa Concrete Chipping 7514Charles DoriaОценок пока нет

- RMP ContractДокумент181 страницаRMP ContractHillary AmistosoОценок пока нет

- Literary Portraiture & Modern Spain: Dr. Rebecca M. Bender (Документ6 страницLiterary Portraiture & Modern Spain: Dr. Rebecca M. Bender (Pedro PorbénОценок пока нет

- Case Report 3 MukokelДокумент3 страницыCase Report 3 MukokelWidychii GadiestchhetyaОценок пока нет

- Unit Weight of Soil in Quezon CityДокумент2 страницыUnit Weight of Soil in Quezon CityClarence Noel CorpuzОценок пока нет

- Jurnal SOL MeningiomaДокумент6 страницJurnal SOL MeningiomaConnie SianiparОценок пока нет

- Hamraki Rag April 2010 IssueДокумент20 страницHamraki Rag April 2010 IssueHamraki RagОценок пока нет

- English PoemДокумент4 страницыEnglish Poemapi-276985258Оценок пока нет

- Formulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersДокумент5 страницFormulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersIndradewiОценок пока нет

- L04-課文單片填空 (題目) (Day of the Dead)Документ3 страницыL04-課文單片填空 (題目) (Day of the Dead)1020239korrnellОценок пока нет

- Intentions and Results ASFA and Incarcerated ParentsДокумент10 страницIntentions and Results ASFA and Incarcerated Parentsaflee123Оценок пока нет

- Variance AnalysisДокумент22 страницыVariance AnalysisFrederick GbliОценок пока нет

- Mdp36 The EndДокумент42 страницыMdp36 The Endnanog36Оценок пока нет

- Biology 1st Term PaperДокумент2 страницыBiology 1st Term PapershrirahulambadkarОценок пока нет

- Chapter One - FiveДокумент118 страницChapter One - FivePrecious AnthonyОценок пока нет

- CP 1Документ22 страницыCP 1api-3757791100% (1)

- The Impact Behaviour of Composite MaterialsДокумент6 страницThe Impact Behaviour of Composite MaterialsVíctor Fer100% (1)

- Missoula County Fairgrounds Phase 2Документ10 страницMissoula County Fairgrounds Phase 2Olivia IversonОценок пока нет