Академический Документы

Профессиональный Документы

Культура Документы

Performance Investigation of Chain Saw Lubricants Based On New Sunflower Oil (NSO)

Загружено:

avenclОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Performance Investigation of Chain Saw Lubricants Based On New Sunflower Oil (NSO)

Загружено:

avenclАвторское право:

Доступные форматы

PERFORMANCE INVESTIGATION OF CHAIN SAW LUBRICANTS BASED ON NEW SUNFLOWER OIL (NSO)

PERFORMANCE INVESTIGATION OF CHAIN SAW LUBRICANTS BASED ON NEW SUNFLOWER OIL (NSO)

A. RAC 1,2 A. VENCL 2

1 INTRODUCTION

Vegetable oils and animal fats have been used as lubricants for a very long period of time through the history of mankind. However, since the start of the industrial revolution and introducing of lubricants produced from mineral oil, vegetable oils and animal fats became unattractive and were left by the wayside. Attention on vegetable oils was refocused only during wartime and oil shortage situations. The mineral oils still dominate the market, but the uses of them have become more and more questioned. The growing environmental and health and safety awareness has caused a rapidly growing interest for vegetable oils as base for lubricants. For example, although rapeseed originally began its career as an agricultural crop used for producing lubricants, until the 1970s vegetable oil was not again considered as an environmentally acceptable alternative for lubricant production, and has been effectively sold on the market from the early 1990s [1]. Vegetable oils belong to the group of bio based products. Bio based products are commercial or industrial products (other than food or feed) that are composed in whole, or in significant part, of biological products or renewable agricultural materials or forestry materials [2]. Vegetable oil base lubricants are regarded as environmentally acceptable (EA) lubricants. The lubrication industry uses a variety of terms to address environmental lubricants. A few of these terms, all preceded by the term environmentally are: acceptable, aware, benign, friendly, harmless, safe, sensitive and suitable [3]. Manufacturers and end users agree that for a lubricant to be classified as an EA type it should be biodegradable and nontoxic. Thanks to advancements in biotechnology, lubricants obtained from oilseeds are being used, over the past twenty years, in the sensitivity environment, as a substitution for mineral oils. These vegetable oils are drawing attention also as biodegradable alternatives for synthetic esters because they are less expensive and are available from renewable resources. Vegetable oils are readily biodegradable (72 80 % of tested oils carbon is converted to CO2 in 28 days), while the mineral oils generally exhibit a very slow biodegradation (42 48 %). The synthetic esters exhibit biodegradation rates, varying from relatively low up

1 Serbian Tribology Society, Sestre Janjia 6, 34000 Kragujevac, SRB; arac@mas.bg.ac.yu 2 Tribology Laboratory, Faculty of Mechanical Engineering, University of Belgrade,

Kraljice Marije 16, 11120 Beograd 35, SRB; avencl@mas.bg.ac.yu

TG-Symposium 2008

249

PERFORMANCE INVESTIGATION OF CHAIN SAW LUBRICANTS BASED ON NEW SUNFLOWER OIL (NSO)

to approximately the same level as for vegetable oils (55 84 %) [4]. The prices are variable but the approximate relative costs of base fluids, compared to the refined mineral oil, are: vegetable oils: 1.5 2 and synthetic esters: 4 12 [5, 6]. Both vegetable oil based lubricants (biolubricants) and synthetic ester based lubricants are manufactured in much smaller quantities when compared to mineral oil based lubricants, resulting in higher production costs and thus retail price. Generally, the advantages of using vegetable oils as a base for EA lubricants are: non-toxicity, biodegradability, resource renewability, good lubricity and high viscosity index. However, vegetable oils have some of the following disadvantages: oxidative instability, poor low temperature properties and poor hydrolytic stability. Frost and Sullivan studies of the market in Europe showed that in 1999 some 100,000 tones, or 2 % of the market were biolubricants [7] and that, since 2000, the market for biolubricants has experienced a restricted growth in volumes with an estimated total European volume of 127,000 tonnes in 2006 [6]. Biolubricants market is dominated by independent suppliers and there are around 70 80 independent manufacturers supporting 80 % of the biolubricants market. In this paper laboratory investigations of physical and chemical properties, friction and wear characteristics of the chain saw lubricant, based on domestic New Sunflower Oil (NSO), are presented and compared with standard mineral oil based lubricant used for the same purpose. At the first stage the main issue was to solve the selection of base oil and additives regarding their compatibility, mutual solubility and stability. In the second stage the additive influence on oxidation stability improvements were investigated and finally tribological properties were tested.

2 VEGETABLE CHAIN SAW LUBRICANTS

Vegetable chain saw lubricants (like all the other biolubricants) can be produced from a wide variety of oilseeds with appropriate characteristics and mainly from: rapeseed, soybean and sunflower. Undesirable characteristics of vegetable oils could be improved through the selective plant breeding or genetic modification, but vegetable oils, like mineral oils, can not meet most lubricant requirements without adequate functional additives. Lubricants derived from vegetable sources have been used in many applications, particularly in areas where they can come into contact with water, food or people. Among these applications the chain saw lubricant demands are very often. Good lubricity of the biolubricants provides that the lubricant adheres to the chain better and longer, resulting in lubricant savings. Chain saw lubricants are termed total loss lubricants because the parts they lubricate are exposed to the environment, and the lubricant can be flung off onto the ground, plants or water. That is why the major issues at chain saw lubricants, beside technical performance demands, are biodegradability and nontoxicity. 250

TG-Symposium 2008

PERFORMANCE INVESTIGATION OF CHAIN SAW LUBRICANTS BASED ON NEW SUNFLOWER OIL (NSO)

Generally the two most significant opportunities for all biolubricants are: In applications where there is a high probability of accidental exposure of the lubricants to sensitive environments: high-risk lubricants for example hydraulic equipment in forests and by water; Total loss lubricants where, by the design of the equipment or application the lubricant ends up almost entirely in the environment. Research of the areas and volumes in which biolubricants were used, for 1999, shows that the most significant market, after hydraulic oils, is chain saw oils with over 29 % of share (Table 1). Lubricants marked as biolubricants Hydraulic oils Chain saw lubricants Concrete release agents Metalworking fluids Two-stroke engine oils Greases Gear oils Market volume in 1999 [tons] 51,000 29,000 10,650 4,000 2,000 1,700 1,000

Table 1: European (EU-15) market volumes for biolubricants in 1999 [8]

3 PROPERTIES OF SELECTED VEGETABLE OIL

3.1 Base Oil Characteristics

Selection of vegetable oil was made on the basis of the domestic vegetable oils market analysis and the information and research trends in the world. Some adjustments of the vegetable oils characteristics with the lubricants application demands were also made. It was concluded that only a few domestic vegetable oils could be used as a base for biolubricants. For the further investigation domestic New Sunflower Oil (NSO) was chosen, which physical and chemical characteristics are presented in Table 2. Test methods used for the determination of these characteristics were standard ones. Domestic NSO was produced through the selective plant breeding. The approximate relative cost of this base oil, compared to the refined mineral oil, is: 1.3 1.5.

TG-Symposium 2008

251

PERFORMANCE INVESTIGATION OF CHAIN SAW LUBRICANTS BASED ON NEW SUNFLOWER OIL (NSO)

Characteristic

Density at 15 C [kg/m ] Viscosity [mm /s] at 40 C at 100 C Viscosity index Flesh point [ C] Pour point [ C] Neutralization number [mgKOH/g] Corrosiveness to copper Carbon residue [%] Ash [%] Trace amounts of sediment [%] Moisture and volatile matter content [%] Foaming characteristics [ml] at 24 C at 93 C at 24 after 93 C Iodine value [g/100g] Saponification value [mgKOH/g] Refractive index

2 3

Test method

ISO 3675 ISO 3104 ISO 2909 ISO 2719 ISO 3016 ISO 6619 ISO 2160 ISO 6615 ISO 6245 ASTM D 2273 ISO 662

Value

917 38.5 8.48 206 255 18 0.35 1a 0.26 0.01 0.0 0.03 0/0 0/0 0/0 97 190 1.465

ISO 6247

ISO 3961 ISO 3657 ISO 5661

Table 2: Physical and chemical characteristics of selected vegetable oil

3.2 Oxidation Stability

One of the very important properties of lubricating oils is their oxidation stability. Oils with low values of oxidation stability will oxidize even more rapidly in the presence of water and at elevated temperatures. When oil oxidizes it will undergo a complex chemical reaction that will produce acid and sludge. Sludge may settle in critical areas of the equipment and interfere with the lubrication and cooling functions of the fluid. The oxidized oil will also corrode the equipment. To improve the oxidation stability of vegetable oil products a research on formulating a proper mixture of base oil with a suitable additive package must be done. For mineral oil formulations small amounts of antioxidants (0.1 0.2 %) are effective. Vegetable oils, however, may require large amounts (1 5 %) of antioxidants to prevent oxidative destruction [5]. Suitable antioxidant was chosen, in the amount of 3 %, and mixed with the base oil. Oxidative stability was investigated for both samples (base oil and base oil with 3 % of antioxidant) according to the ISO 4263 standard. The results of the test are presented in Fig. 1. 252

TG-Symposium 2008

PERFORMANCE INVESTIGATION OF CHAIN SAW LUBRICANTS BASED ON NEW SUNFLOWER OIL (NSO)

4.0

Acid number [mg KOH/g]

3.5 3.0 2.5 2.0 1.5 1.0 0.5 0.0 0 24 48 72

Base oil Base oil with 3 % of antioxidant

Figure 1: Oxidation stability of the tested samples

96

120

144

168

192

216

Time [h]

The results of the test show that oxidation stability of the base oil with additive (178 h) was significantly improved compared with the base oil (30 h), and that this formulation could be used for the further investigation.

4 FRICTION AND WEAR STUDIES

4.1 Physical and Chemical Characteristics of Finished Biolubricant

In order to improve other characteristics of the finished biolubricant (beside oxidation stability) suitable additives as thickeners and PPD were added. Base oil is mixed with these additives to provide the resulting final product with physical, chemical and tribological characteristics required for successful application. This finished biolubricant (ref. as lubricant A) was compared with a product from market a commercial product based on mineral oil (ref. as lubricant B). Physical and chemical characteristics of both tested chain saw lubricants are presented in Table 3.

TG-Symposium 2008

253

PERFORMANCE INVESTIGATION OF CHAIN SAW LUBRICANTS BASED ON NEW SUNFLOWER OIL (NSO)

Characteristic Density at 15 C [kg/m ] Viscosity [mm /s] at 40 C at 100 C Viscosity index Flesh point [C] Pour point [C] Neutralization number [mgKOH/g] Corrosiveness to copper Ash [%] Foaming characteristics [ml] at 24 C at 93 C at 24 after 93 C

2 3

Lubricant A 917 47.6 10.5 218 245 20 0.63 1b 0.035 120/0 120/0 70/0

Lubricant B 881 99.60 11.20 98 248 25 0.47 1a 0.16 0/0 20/0 0/0

Table 3: Physical and chemical characteristics of tested chain saw lubricants

4.2 Test Method and Conditions

Friction and wear tests of both chain saw lubricants were carried out on the blockon-ring tribometer under lubricated sliding conditions, in ambient air at room temperature ( 27 C). Blocks dimensions were: 5.9 mm 12 mm 16 mm. Material of blocks was gray cast iron (220 HB) with the following chemical composition: Fe-C(3.1) - Si(1.9) - Mn(0.9) - S(0.047) - P(0.009) - Cr(0.11) - Ni(0.05), wt.%. Rings having 45.31 mm outer diameter and 10 mm thickness were made of unalloyed steels for hardening and tempering (DIN Ck 60, 46 48 HRC) with the following chemical composition: Fe - C(0.58) - Mn(0.74) - P(0.04) - S(0.038), wt.% and standard heat treatment. Lubrication was provided by revolving of the ring which was dipped into oil container. Surface roughness of blocks and rings was Ra = 0.1 0.3 m. Before and after testing, both the block and ring were degreased and cleaned with benzene. Wear scars on blocks were measured in accordance with ASTM test method G 77 98, with accuracy of 0.05 mm, after each test to calculate the volume loss, while the rings were weighed with accuracy of 10-3 g before and after each test to calculate the mass loss. The values of oil and ambient temperature, friction coefficient, normal and friction force were monitored during the test and through data acquisition system stored in the PC. Tests were carried out at selected test conditions: sliding speed of 1 m/s, sliding distance of 3600 m and normal load of 250 N. For each lubricant, in order to achieve a higher confidence level in evaluating test results, four duplicate runs were performed and the results were averaged. 254

TG-Symposium 2008

PERFORMANCE INVESTIGATION OF CHAIN SAW LUBRICANTS BASED ON NEW SUNFLOWER OIL (NSO)

4.3 Results and Discussion

Friction and wear investigations were just an initial one, with preliminary results and some more experiments have to be done to completely understand tribological behaviour of these chain saw lubricants. An improvement of physical and chemical characteristics of the vegetable base oil is also possible. Obtained average values of the friction and wear testing are presented in Table 4. The results indicate good repeatability of the test. The coefficient of variation (Vr) was calculated as a standard deviation divided by the average value.

Obtained average value

Final dynamic coefficient of friction Block scar volume [mm3] Lubricant temperature rise [C ]

*

Lubricant A

0.053 0.0267 19.1

Lubricant B

0.074 0.0228 21.4

Vr (lub. A) [%]

5.8 12.7 5.7

Vr (lub. B) [%]

5.7 4.2 9.3

Average rings weight losses were not greater than 1 mg

Table 4: Obtained average values from the friction and wear testing* The values of final dynamic coefficient of friction indicate boundary lubrication condition for both lubricants. Lubricant A shows lower value of friction coefficient than lubricant B, but slightly higher wear. Attended values of friction coefficient and oil temperature during the testing were presented in the form of diagram form (Fig. 2). It could be clearly noticed that there are different shapes of friction coefficient curves for two lubricants. Lubricant A, as a biolubricant with good lubricity, shows descending tendency of friction coefficient from the beginning of the test (Fig. 2a). Obtained block wear scar was of very good shape with weakly pronounced jagged scar edges (cross hair was run through a visual average of the jagged edges during measuring) (Fig. 3). Wear test results showed that, for the investigated conditions, lubricant A approves higher wear of both bodies in contact than lubricant B. This could be explained with the fact that tested biolubricant (lubricant A) did not contain antiwear additive. Average rings weight losses did not exceed 1 mg, and ring scar volume was reported as too small to accurately measure. Lubricant temperature was rising during the tests, since it was not controlled, but after initial running-in period it become stabile and had the value of 46.1 C and 48.4 C, for lubricant A and B, respectively (Fig. 3). Consequently the lubricants temperature rose during the testing, was also lower for lubricant A than for lubricant B.

TG-Symposium 2008

255

PERFORMANCE INVESTIGATION OF CHAIN SAW LUBRICANTS BASED ON NEW SUNFLOWER OIL (NSO)

Figure 2: Attended values of friction coefficient and oil temperature for: (a) lubricant A and (b) lubricant B

Figure 3: Example of block wear scar

256

TG-Symposium 2008

PERFORMANCE INVESTIGATION OF CHAIN SAW LUBRICANTS BASED ON NEW SUNFLOWER OIL (NSO)

5 CONCLUSIONS

Application of environmentally acceptable lubricants has increased during the last twenty years, in order to save a sensitive ecosystem, and among them use of biolubricants is becoming evident. Vegetable oils obtained through selective plant breeding, like domestic New Sunflower Oil, could be appropriate base oil for lubricants. The friction and wear results show that properly formulated biolubricant is comparable with mineral base lubricant and it could be an adequate substitution as a lubricant for chain saws.

6 LITERATURE

[1] Mann, S.: Ranking without valuing in the face of major uncertainty The case of the promotion of biodegradable lubricants. Journal of Environmental Management, 85, 1, 2007, 198-203 http://www.usda.gov/biobased Engineer Manual 1110-2-1424: Engineering and Design Lubricants and Hydraulic Fluids, U.S. Army Corps of Engineers, Washington, 1999 Goyan, R. L., Melley, R. E., Wissner, P. A., Ong, W. C.: Biodegradable lubricants. Lubrication Engineering, 54, 7, 1998, 10-17 Lal, K., Carrick, V.: Performance testing of lubricants based on high oleic vegetable oils. Journal of Synthetic Lubrication, 11, 3, 1994, 189-206 Dokos, L.: European Biolubricants Market Where is the Friction?, Frost & Sullivan Market Insight, 16.03.2007, http://www.frost.com Lea, S. W.: European development of lubricants derived from renewable resources. Industrial Lubrication and Tribology, 54, 6, 2002, 268-274 http://www.ienica.net

[2] [3] [4] [5] [6] [7] [8]

TG-Symposium 2008

257

Вам также может понравиться

- Friction and Wear Processes - Thermodynamic ApproachДокумент7 страницFriction and Wear Processes - Thermodynamic ApproachavenclОценок пока нет

- Ecological and Technical Aspects of The Waste Oils Influence On EnvironmentДокумент7 страницEcological and Technical Aspects of The Waste Oils Influence On EnvironmentavenclОценок пока нет

- Influence of Additives and Selective Transfer On Wear Reduction in The Lubricated ContactДокумент10 страницInfluence of Additives and Selective Transfer On Wear Reduction in The Lubricated ContactavenclОценок пока нет

- A Review of The Tribological Properties of PTFE Composites Filled With Glass, Graphite, Carbon or Bronze ReinforcementДокумент6 страницA Review of The Tribological Properties of PTFE Composites Filled With Glass, Graphite, Carbon or Bronze ReinforcementavenclОценок пока нет

- Friction and Wear Properties of Copper-Based Composites Reinforced With Micro - and Nano-Sized Al2O3 ParticlesДокумент8 страницFriction and Wear Properties of Copper-Based Composites Reinforced With Micro - and Nano-Sized Al2O3 ParticlesavenclОценок пока нет

- The Influence of Corrosion On The Microstructure of Thermally Treated ZA27/SiCp CompositesДокумент7 страницThe Influence of Corrosion On The Microstructure of Thermally Treated ZA27/SiCp CompositesavenclОценок пока нет

- Abrasive Wear of Chemical Nickel Coatings With Boron Nitride Nano-ParticlesДокумент7 страницAbrasive Wear of Chemical Nickel Coatings With Boron Nitride Nano-ParticlesavenclОценок пока нет

- Joining of Composite Materials Based On Al-Si Alloys by Using The GMAW ProcessДокумент1 страницаJoining of Composite Materials Based On Al-Si Alloys by Using The GMAW ProcessavenclОценок пока нет

- Mechanical and Wear Behaviour of Titania Plasma-Sprayed CoatingsДокумент7 страницMechanical and Wear Behaviour of Titania Plasma-Sprayed CoatingsavenclОценок пока нет

- The Influence of Strontium Addition On The Tribological Properties of Zn25Al3Si Alloy in Boundary Lubricated ConditionДокумент8 страницThe Influence of Strontium Addition On The Tribological Properties of Zn25Al3Si Alloy in Boundary Lubricated ConditionavenclОценок пока нет

- The Influence of Strontium Addition On The Tribological Properties of Zn25Al1Si Alloy in Boundary Lubricated ConditionДокумент6 страницThe Influence of Strontium Addition On The Tribological Properties of Zn25Al1Si Alloy in Boundary Lubricated ConditionavenclОценок пока нет

- Influence of "Valena" Metal-Plating Additive On The Friction Properties of Ball BearingsДокумент7 страницInfluence of "Valena" Metal-Plating Additive On The Friction Properties of Ball BearingsavenclОценок пока нет

- Characterization and Comparison of The Carbides Morphologies in The Near Surface Region of The Single - and Double Layer Iron-Based Hardfaced CoatingsДокумент6 страницCharacterization and Comparison of The Carbides Morphologies in The Near Surface Region of The Single - and Double Layer Iron-Based Hardfaced CoatingsavenclОценок пока нет

- Abrasive Wear Resistance of The Iron - and WC-based Hardfaced Coatings Evaluated With Scratch Test MethodДокумент5 страницAbrasive Wear Resistance of The Iron - and WC-based Hardfaced Coatings Evaluated With Scratch Test MethodavenclОценок пока нет

- Green Tribology and Quality of LifeДокумент7 страницGreen Tribology and Quality of LifeavenclОценок пока нет

- Testing of The Mechanical Properties For 15mo3 SteelДокумент2 страницыTesting of The Mechanical Properties For 15mo3 SteelavenclОценок пока нет

- MMCs Based On Hypoeutectic Al-Si Alloy: Tribological Properties in Dry Sliding ConditionsДокумент7 страницMMCs Based On Hypoeutectic Al-Si Alloy: Tribological Properties in Dry Sliding ConditionsavenclОценок пока нет

- Multi Spindle GearboxДокумент4 страницыMulti Spindle GearboxAkash Kumar DevОценок пока нет

- Optimization of The Deposition Parameters of Thick Atmospheric Plasma Spray CoatingsДокумент8 страницOptimization of The Deposition Parameters of Thick Atmospheric Plasma Spray CoatingsavenclОценок пока нет

- Tribological Properties of A356 Al-Si Alloy Base Composite Reinforced With Al2O3 Particles (MMC)Документ4 страницыTribological Properties of A356 Al-Si Alloy Base Composite Reinforced With Al2O3 Particles (MMC)avenclОценок пока нет

- Microstructure and Mechanical Properties of The Mo-NiCrBSi Coating Deposited by Atmospheric Plasma SprayingДокумент6 страницMicrostructure and Mechanical Properties of The Mo-NiCrBSi Coating Deposited by Atmospheric Plasma SprayingavenclОценок пока нет

- Tribological Properties of Thixoforming Al-Alloy A356 and Influence of Heat TreatmentДокумент8 страницTribological Properties of Thixoforming Al-Alloy A356 and Influence of Heat TreatmentavenclОценок пока нет

- Influence of The Solid Lubricant Particles Reinforcement On Composites Tribological PropertiesДокумент6 страницInfluence of The Solid Lubricant Particles Reinforcement On Composites Tribological PropertiesavenclОценок пока нет

- Ferrous-Based Coatings For Engine Cylinder Bores Made of Aluminium Alloys: Tribological PropertiesДокумент9 страницFerrous-Based Coatings For Engine Cylinder Bores Made of Aluminium Alloys: Tribological PropertiesavenclОценок пока нет

- Tribological Properties of Thixocasted and Heat Treated Hypoeutectic Al-Si Alloy A356Документ9 страницTribological Properties of Thixocasted and Heat Treated Hypoeutectic Al-Si Alloy A356avenclОценок пока нет

- The Structure and Mechanical Properties of An Aluminium A356 Alloy Base Composite With Al2O3 Particle AdditionsДокумент5 страницThe Structure and Mechanical Properties of An Aluminium A356 Alloy Base Composite With Al2O3 Particle Additionsavencl100% (1)

- Corrosion Behaviour of The As-Cast and Heat-Treated ZA27 AlloyДокумент7 страницCorrosion Behaviour of The As-Cast and Heat-Treated ZA27 AlloyavenclОценок пока нет

- Cylindrical Gears Modeling Using CATIA SoftwareДокумент5 страницCylindrical Gears Modeling Using CATIA Softwareavencl100% (2)

- Tribological Properties of Al-Si Alloy A356 Reinforced With Al2O3 ParticlesДокумент5 страницTribological Properties of Al-Si Alloy A356 Reinforced With Al2O3 ParticlesavenclОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Wivacryl As 50: Styrene Acrylic Paint BinderДокумент7 страницWivacryl As 50: Styrene Acrylic Paint Bindermahesh.nakОценок пока нет

- ME206 Lecture 3 - Key concepts in metal casting flowДокумент28 страницME206 Lecture 3 - Key concepts in metal casting flowHarsh ShahОценок пока нет

- Healthcare WasteДокумент32 страницыHealthcare WasteEddiemtongaОценок пока нет

- Astm A560 A560m - 12Документ3 страницыAstm A560 A560m - 12Leandro Dilkin ConsulОценок пока нет

- Equilibrium and Elasticity: Powerpoint Lectures ForДокумент16 страницEquilibrium and Elasticity: Powerpoint Lectures FordeeparОценок пока нет

- A Study of The Effect of Magnetite Additions To Shell Molds On THДокумент106 страницA Study of The Effect of Magnetite Additions To Shell Molds On THneel gajОценок пока нет

- Lec 6 Module 1Документ18 страницLec 6 Module 1vedant chavanОценок пока нет

- Revised PT Program April-May 2021 30% Discount Metal TestingДокумент2 страницыRevised PT Program April-May 2021 30% Discount Metal TestingSaravanan PОценок пока нет

- Lab 4-Measurement of Plastic Viscosity of Different Mud Samples by Viscometer.Документ20 страницLab 4-Measurement of Plastic Viscosity of Different Mud Samples by Viscometer.Sunny BbaОценок пока нет

- Bronze Castings For Bridges and TurntablesДокумент4 страницыBronze Castings For Bridges and TurntablesmatiullahОценок пока нет

- MIDC UNITSДокумент16 страницMIDC UNITSSatej SatyanОценок пока нет

- Masterlife Ci 220 v5Документ2 страницыMasterlife Ci 220 v5Tech BoyОценок пока нет

- Expanded Silicone Rubber Sponge - Grades SIL10, SIL16, SIL24 & SIL33Документ3 страницыExpanded Silicone Rubber Sponge - Grades SIL10, SIL16, SIL24 & SIL33ari wiliamОценок пока нет

- Physico-chemical characteristics of corrosion scales in old iron pipesДокумент9 страницPhysico-chemical characteristics of corrosion scales in old iron pipesGustavo Alejandro GonzalezОценок пока нет

- Coal combustion calculationsДокумент3 страницыCoal combustion calculationsShane PatulotОценок пока нет

- Mechanical SealДокумент64 страницыMechanical SealKhoh Kai ShengОценок пока нет

- Notes:: 6"-12" PIPE Flowline Removable AnchorДокумент1 страницаNotes:: 6"-12" PIPE Flowline Removable Anchornarutothunderjet216Оценок пока нет

- NONWOVEN - Vinay Kumar MidhaДокумент11 страницNONWOVEN - Vinay Kumar Midhaglobal-marketin8184Оценок пока нет

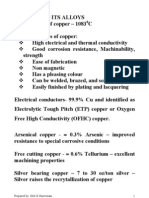

- Copper and It's AlloysДокумент5 страницCopper and It's AlloysReza MortazaviОценок пока нет

- Lesker FeedthroughsДокумент39 страницLesker FeedthroughspericoОценок пока нет

- Tabele Saturacije PDFДокумент20 страницTabele Saturacije PDFTrkulja GoranОценок пока нет

- Microencapsulation in Textiles Provides Health and Performance BenefitsДокумент2 страницыMicroencapsulation in Textiles Provides Health and Performance BenefitsAswathy UnnikrishnanОценок пока нет

- ZOLLERN-Broschuere ZGF Legierungen ENGДокумент16 страницZOLLERN-Broschuere ZGF Legierungen ENGPablo PadillaОценок пока нет

- BIS0418 C1L2P1 Technical Guide Bending Rolling Shearing Punching WEB SIN...Документ6 страницBIS0418 C1L2P1 Technical Guide Bending Rolling Shearing Punching WEB SIN...MarcoОценок пока нет

- Honel A SeriesДокумент6 страницHonel A SeriesAustin WilsonОценок пока нет

- Dowsil 335 Butyl Sealant: Primary Sealant For Insulating GlassДокумент2 страницыDowsil 335 Butyl Sealant: Primary Sealant For Insulating GlassKhurshed Alam IndiaОценок пока нет

- Building TechnologyДокумент3 страницыBuilding TechnologyClaro III TabuzoОценок пока нет

- Analysis and Design of Steel I-Girder Bridge Using CSI-Bridge SoftwareДокумент300 страницAnalysis and Design of Steel I-Girder Bridge Using CSI-Bridge SoftwareChinmay TejaswiОценок пока нет

- 2019 Y5 Work Book 1 (Practical 3) SolutionsДокумент9 страниц2019 Y5 Work Book 1 (Practical 3) SolutionsChenluyingОценок пока нет