Академический Документы

Профессиональный Документы

Культура Документы

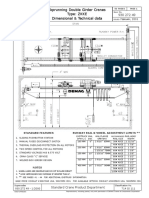

Data Sheet - Overhead Travelling

Загружено:

Sugiarto SaptomoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Data Sheet - Overhead Travelling

Загружено:

Sugiarto SaptomoАвторское право:

Доступные форматы

PTT PUBLIC COMPANY LIMITED ONSHORE COMPRESSOR STATION 4 PROJECT

DATA SHEET FOR ELECTRIC OVERHEAD TRAVELLING (E.O.T.) CRANE

DS-30-0804.02-6000-002

D3 D2 D1

REV.

6-Oct-08 12-Jun-08 2-Apr-09

DATE

Revision Issued for ITB

Issued for ITB Issued for ITB DESCRIPTION

Teerasak Ch. Teerasak Ch. Teerasak Ch.

Sahaporn P. Sahaporn P. PREPARED BY PTT REVIEWED BY PTT

Naret V.

CHECKED BY APPROVED PTT BY PTT

Contract No. Contractor

PTT Project No. 0804.02

Order No. Client Consultant

Engineer

PROJECT NO. PROJECT NAME EQUIPMENT NAME

0804.02 Onshore Compressor Station 4 (OCS 4) Electric Overhead Travelling Crane TAG NO. (Compressor Shetter) DS-30-0804.02-6000-002 2 OF 4 REV NO. 6000-Y-101A/B/C D3

PTT PLUBLIC COMPANY

ELECTRIC OVERHEAD TRAVELLING (E.O.T.) CRANE DATA SHEET

DATE

DATA SHEET NO. PAGE 6000 3

1 SERVICE : Compressor Shelter 2 OWNER : PTT 3 4 Main Hoist 5 Auxiliary Hoist (option) 6 Span and Dimension 7 Crane Girder Type 8 Operating Speed

UNIT QTY.

PLANT LOCATION TYPE OF DUTY Location Temperature Relative Humidity Wind Speed

MAP TA PHUT, RAYONG PROVINCE, THAILAND Occasional SITE CONDITION Map Ta Phut, Rayong Thai land 11 - 45 C 51 - 93 % None Indoor Outdoor Heated Unheat Roof Mon

CHK/APP

CRANE DETAIL 20 tons * See attach sketch Double Speed(m/min) * * * Swivel Yes * * * Yes * * Yes Yes Yes (By Other) CONTROL SYSTEM Full magnetic in NEMA enclosure Yes Yes Yes Yes No No No No (Upper & Lower) Isolator Box : Lighting : (Note 4) Cable Track : Motor Classification : Power Supply : Conductor System : No No No No Fixed No Bridge Girder Drum Wheel Hoist Shafts/Pins Rope Bumper Bearing Brake Auxiliary Anticollision Steel Motor Power(kw) * * * Area Classification

PREPD

DESCRIPTION

9 10 11

Main Hoist : (unload/max. load) Trolley : (unload/max. load) Bridge : (unload/max. load) Safety Catch Bridge Motor Trolley Motor Hoist Motor Vendor to supply rails Type of rail fixings Type & Size of rail Crane Rail Girder Parking Brake End Stop

Class 1 Div 2 MATERIALS (Note 1) CS, box or beam type Bronze Alloy (Note1) CS or Cast Iron CS Winding Wire Rubber Bronze Alloy (Note1) DC Disc Type * *

12 Hook Type

REV NO.

13

14 Motor Type 15

DATE

16 17

CHK/APP

18 Rail Details 19 20 21 22 23

DESCRIPTION

PREPD

24

25 Runway Beam 26 27 Control Type :

ELECTRICAL SYSTEM 380 V / 3Ph / 50 Hz Conductor Festoon Cable Cable Reel Drum Yes Yes Steel No No Stainless Steel

REV NO.

28 Thermal Overload : 29 Control Circuit : 30 Main Contractor :

DATE

31 Limit Switch 32

Operation Station :

CHK/APP

33 34 Operation : 35

Pushbutton station suspended from festooned track system. Pendant Fixed Pendant Sliding Pendant Raise & Lower Pendant Slide, raise & lower pendant (Pendant to be lockable) OTHER REQUIREMENT * * Every 6 months Yes * BS 466, CMAA Class B Project Spec. ES-92.06 Yes Yes * * Min. 10,000 hrs No No No ( No Load) Cab Cab & Pendant

Class 1 Zone 2 IIB T3 APPLICABLE SPECIFICATIONS

PREPD

36 37

SPC-0804.02-30.16 SPC-0804.02-93.06 SPC-0804.02-91.01 SPC-0804.02-99.05 SPC-0804.02-99.03 SPC-0804.02-99-00.05 SPC-0804.02-99.01

Electrical Overhead Travelling Crane Painting Equipment Noise Specification Spare Parts Shop inspection Basic engineering design data Numbering System

DESCRIPTION

38 39 40 41 Total Crane Weight : 42 Test Weight : 43 Service Condition : 44 Walkway Required :

REV NO.

DATE

45 Special Maintenance Facilities : 46 Other Code & Specification : 47 Painting : 48 Other Crane on Gantry : 49 Anticollision System : 50 No. of Wheels: 51 Wheel Loads: (Static/Dynamic) 52 Bearing Life :

PREPD

CHK/APP

DESCRIPTION

53 NOTES 54 1. Vendor to provide materials to avoid sparking. 55 2. Capacity of Overhead Crane shall be heaviest part what will be maintenanced. 56 3. Lighting system including to under ovehead crane shall be provided according to Thai Regulation.

REV

57 4. SWL sign will be applied to the international standard. 58 5. Walk Ways are required for access to all accessaries of Crane what required for Maintenance or repair.

PROJECT NO. PROJECT NAME EQUIPMENT NAME

0804.02 Onshore Compressor Station 4 (OCS 4) Electric Overhead Travelling Crane TAG NO. (Work Shop) DS-30-0804.02-6000-002 3 OF 4 REV NO. 6000-Y-102A/B/C D3

PTT PLUBLIC COMPANY

ELECTRIC OVERHEAD TRAVELLING (E.O.T.) CRANE DATA SHEET

1 SERVICE : Work Shop 2 OWNER : PTT 3 4 Main Hoist 5 Auxiliary Hoist (option) 6 Span and Dimension 7 Crane Girder Type 8 Operating Speed 9 10 11

DATA SHEET NO. PAGE 6000 3

UNIT QTY. CRANE DETAIL (Note 3) tons * See attach sketch Double Speed(m/min) * * * Swivel Yes * * * Yes * * Yes Yes Yes (By Other) CONTROL SYSTEM Full magnetic in NEMA enclosure Yes Yes Yes Yes No No No No No No No No Fixed No

PLANT LOCATION TYPE OF DUTY Location Temperature Relative Humidity Wind Speed

MAP TA PHUT, RAYONG PROVINCE, THAILAND Occasional SITE CONDITION Map Ta Phut, Rayong Thai land 11 - 45 C 51 - 93 % None Indoor Outdoor Heated Unheat Roof Mon

Motor Power(kw) * * * Area Classification

Main Hoist : (unload/max. load) Trolley : (unload/max. load) Bridge : (unload/max. load) Safety Catch Bridge Motor Trolley Motor Hoist Motor Vendor to supply rails Type of rail fixings Type & Size of rail Crane Rail Girder Parking Brake End Stop

Class 1 Div 2 MATERIALS (Note 1)

12 Hook Type 13

Bridge Girder Drum Wheel Hoist Shafts/Pins Rope Bumper Bearing Brake Auxiliary Anticollision

CS, box or beam type Steel Bronze Alloy (Note1) CS or Cast Iron CS Winding Wire Rubber Bronze Alloy (Note1) DC Disc Type * *

14 Motor Type 15 16 17

18 Rail Details 19 20 21 22 23 24

25 Runway Beam 26 27 Control Type : 28 Thermal Overload : 29 Control Circuit : 30 Main Contractor : 31 Limit Switch 32 33 34 Operation : 35 36 37 38 39 40 41 Total Crane Weight : 42 Test Weight : 43 Service Condition : 44 Walkway Required : 45 Special Maintenance Facilities : 46 Other Code & Specification : 47 Painting : 48 Other Crane on Gantry : 49 Anticollision System : 50 No. of Wheels: 51 Wheel Loads: (Static/Dynamic) 52 Bearing Life : 53 NOTES

ELECTRICAL SYSTEM Power Supply : Conductor System : 380 V / 3Ph / 50 Hz Conductor Festoon Cable Cable Reel Drum (Upper & Lower) Isolator Box : Lighting : (Note 4) Cable Track : Motor Classification : Yes Yes Steel No No Stainless Steel

Operation Station :

Pushbutton station suspended from festooned track system. Pendant Fixed Pendant Sliding Pendant Raise & Lower Pendant Slide, raise & lower pendant (Pendant to be lockable) OTHER REQUIREMENT * * Every 6 months Yes * BS 466, CMAA Class B Project Spec. ES-92.06 Yes Yes * * Min. 10,000 hrs No No No ( No Load) Cab Cab & Pendant

Class 1 Zone 2 IIB T3 APPLICABLE SPECIFICATIONS

SPC-0804.02-30.16 SPC-0804.02-93.06 SPC-0804.02-91.01 SPC-0804.02-99.05 SPC-0804.02-99.03 SPC-0804.02-99-00.05 SPC-0804.02-99.01

Electrical Overhead Travelling Crane Painting Equipment Noise Specification Spare Parts Shop inspection Basic engineering design data Numbering System

54 1. Vendor to provide materials to avoid sparking. 55 2. * To be confirm and specify by contractor. 56 3. Capacity of Overhead Crane shall be heaviest part what will be repaired. 57 4. Lighting system including to under ovehead crane shall be provided according to Thai Regulation. 58 5. SWL sign will be applied to the international standard. 59 6. Walk Ways are required for access to all accessaries of Crane what required for Maintenance or repair.

PROJECT NO. PROJECT NAME EQUIPMENT NAME

0804.02 Onshore Compressor Station 4 (OCS 4) Electric Overhead Travelling Crane TAG NO. DS-30-0804.02-6000-002 4 OF 4 REV NO. 6000-Y-101A/B/C D3

PTT PLUBLIC COMPANY

ELECTRIC OVERHEAD TRAVELLING (E.O.T.) CRANE DATA SHEET

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56

DATA SHEET NO. PAGE

CRANE SKETCH

Note: This drawing for information only, the actual one shall be verified by Contractor.

57

Вам также может понравиться

- General Overhead Crane Maintenance GuideДокумент18 страницGeneral Overhead Crane Maintenance GuidefaisalnadimОценок пока нет

- Gantry Beam DesignДокумент5 страницGantry Beam DesignSanjeev Kumar Pillai100% (9)

- EOT Crane SpecificationДокумент24 страницыEOT Crane SpecificationArvind Sharma100% (1)

- Crane Load D Mag PDFДокумент50 страницCrane Load D Mag PDFrahul ranjanОценок пока нет

- ABUS Jib Cranes Efficiency CentreДокумент12 страницABUS Jib Cranes Efficiency CentreGloria RomicОценок пока нет

- Crane: Technical Specification For EOT Crane Data Sheet 01Документ10 страницCrane: Technical Specification For EOT Crane Data Sheet 01adymenonОценок пока нет

- Eot Crane Datasheet-A1Документ4 страницыEot Crane Datasheet-A1bashok20100% (1)

- Deflection CriteriaДокумент4 страницыDeflection CriteriaaqhammamОценок пока нет

- Technical Specification of CraneДокумент6 страницTechnical Specification of Cranetema satu baja konstruksiОценок пока нет

- Crane Wheel Load PDFДокумент1 страницаCrane Wheel Load PDFShanthakumar PandianОценок пока нет

- Crane Annual PMДокумент4 страницыCrane Annual PMjasonahindsОценок пока нет

- Lifting Sequence Boiler Steel StructureДокумент18 страницLifting Sequence Boiler Steel StructureXwerty BoxОценок пока нет

- Project PPT Pneumatic SystemДокумент25 страницProject PPT Pneumatic SystemPankaj BhangareОценок пока нет

- CRANE LOAD CALCULATION FORMULASДокумент6 страницCRANE LOAD CALCULATION FORMULASMuhammed ShamseerОценок пока нет

- DATA SHEET FOR OVERHEAD CRANEДокумент2 страницыDATA SHEET FOR OVERHEAD CRANENurcahyo Djati WОценок пока нет

- Catalog CRANEДокумент37 страницCatalog CRANEhipreyashОценок пока нет

- Designing of Cranes With StandardsДокумент95 страницDesigning of Cranes With Standardsank_mehraОценок пока нет

- Design Calculation LiftingДокумент2 страницыDesign Calculation LiftingAbu Al Sayyid100% (1)

- Gantry Crane ManualДокумент6 страницGantry Crane ManualPrateek KashyapОценок пока нет

- Specialist Services: Force Resolution CalculationДокумент5 страницSpecialist Services: Force Resolution CalculationNaresh KumarОценок пока нет

- 01 Top Running Double Girder Crane DataДокумент8 страниц01 Top Running Double Girder Crane Dataevelyn_inocenci6140Оценок пока нет

- Crane Load CombinationsДокумент12 страницCrane Load CombinationsSusi UmarohОценок пока нет

- 600AJ Boom FlyerДокумент2 страницы600AJ Boom FlyerAhmad BilalОценок пока нет

- Kito Crane: End Carriage, Geared Motor, Peripheral EquipmentДокумент40 страницKito Crane: End Carriage, Geared Motor, Peripheral EquipmentVenu GopalОценок пока нет

- Eurobloc VT 9 10 11 12 GBДокумент6 страницEurobloc VT 9 10 11 12 GBToni RenedoОценок пока нет

- Multiconductor TechnicalДокумент24 страницыMulticonductor TechnicalJuan Felipe Vieira GaviriaОценок пока нет

- Design Lifting Beam (80 MT)Документ10 страницDesign Lifting Beam (80 MT)hardeep SinghОценок пока нет

- Vertical bladder tank proportioning systemsДокумент1 страницаVertical bladder tank proportioning systemsmuthuvelaaОценок пока нет

- Pveng: Pressure Vessel Engineering LTDДокумент5 страницPveng: Pressure Vessel Engineering LTDBruno TrujilloОценок пока нет

- Chain BlockДокумент1 страницаChain BlockvarunpassiОценок пока нет

- Jib CranesДокумент26 страницJib CranesMiroslav Vasilev100% (1)

- Types of Overhead CraneДокумент16 страницTypes of Overhead CraneKharis MahfudzОценок пока нет

- EOT CraneДокумент5 страницEOT CraneNaveen NagisettiОценок пока нет

- Crane load calculationsДокумент4 страницыCrane load calculationsToc Hu KwuОценок пока нет

- Crane Beam DesignДокумент13 страницCrane Beam DesignMarcelo DelgadoОценок пока нет

- Lift & Tail CalcsДокумент3 страницыLift & Tail Calcsnazeer_mohdОценок пока нет

- Is 6938Документ13 страницIs 6938Dhanashri Patil100% (1)

- Double Girder Overhead Crane Product ManualДокумент12 страницDouble Girder Overhead Crane Product ManualAdityo RahmanОценок пока нет

- Chain Block & Puller Inspection ChecklistДокумент1 страницаChain Block & Puller Inspection Checklistibrahim100% (1)

- EN 12079-1:2006 (E) Forklift Pocket DimensionsДокумент3 страницыEN 12079-1:2006 (E) Forklift Pocket Dimensionsdsn_sarmaОценок пока нет

- Technical Specification For 35-5T EOT Crane Nalco 27012021-2021-02-09-03-53-40Документ208 страницTechnical Specification For 35-5T EOT Crane Nalco 27012021-2021-02-09-03-53-40Avinash GuptaОценок пока нет

- Structural PresentationДокумент23 страницыStructural PresentationAravindanОценок пока нет

- Analyzing stresses on new lifting lugДокумент4 страницыAnalyzing stresses on new lifting lugdharwinОценок пока нет

- AA - SPEC - 114005 - Flooring, Stairs, Ladders & HandrailsДокумент45 страницAA - SPEC - 114005 - Flooring, Stairs, Ladders & HandrailsJakesОценок пока нет

- Design Report - Gantry Crane 20ton8.53mspanДокумент34 страницыDesign Report - Gantry Crane 20ton8.53mspanAdeeb Shahzada100% (1)

- Single Girder EOT Cranes (SG-EOT)Документ5 страницSingle Girder EOT Cranes (SG-EOT)Nikhil PoriyaОценок пока нет

- Part 14 - Crane & HoistsДокумент11 страницPart 14 - Crane & HoistsrickymmaОценок пока нет

- Crane GirderДокумент15 страницCrane GirderRalf Snell100% (1)

- Dimensional ToleranceДокумент1 страницаDimensional ToleranceNguyen Anh TuanОценок пока нет

- Crane AssessmentДокумент8 страницCrane AssessmentPernando SagaОценок пока нет

- Crane Solutions and ModelsДокумент24 страницыCrane Solutions and ModelsAmandeep NandaОценок пока нет

- Crane Guide 2 E5 PДокумент6 страницCrane Guide 2 E5 PsergiooiОценок пока нет

- EOT CraneДокумент23 страницыEOT CraneSantiago Cuichán Velasco100% (1)

- Gantry Girder LoadingДокумент6 страницGantry Girder Loadingajith chandranОценок пока нет

- Spreader Bar3 - L.9 M-CertificationДокумент10 страницSpreader Bar3 - L.9 M-CertificationsiagiandobahОценок пока нет

- Lift Analysis: R L T LДокумент27 страницLift Analysis: R L T Lgarateta100% (5)

- TBA 3 POMPA - 4-04-13 Rev.1Документ14 страницTBA 3 POMPA - 4-04-13 Rev.1Pratama Trendy LeoОценок пока нет

- Khan Cranes PresentationДокумент28 страницKhan Cranes PresentationMili Marius100% (1)

- P Power S Bhar Sector Rat Hea R Proje Avy Elec Ect Eng Noida India Ctrical Ineeriin A Ls LTD NG Mana Agemen NTДокумент41 страницаP Power S Bhar Sector Rat Hea R Proje Avy Elec Ect Eng Noida India Ctrical Ineeriin A Ls LTD NG Mana Agemen NThuynhthanhtamga1981Оценок пока нет

- Marine Electrical Practice: Marine Engineering SeriesОт EverandMarine Electrical Practice: Marine Engineering SeriesРейтинг: 4 из 5 звезд4/5 (8)

- AHA Scientific Statement on Self-Care for Cardiovascular Disease and Stroke Prevention and ManagementДокумент27 страницAHA Scientific Statement on Self-Care for Cardiovascular Disease and Stroke Prevention and ManagementSugiarto SaptomoОценок пока нет

- Cir 0000000000000757Документ458 страницCir 0000000000000757Nona Suci rahayuОценок пока нет

- SikaGrout-215 2011-11 - 1 PDFДокумент4 страницыSikaGrout-215 2011-11 - 1 PDFFaiz RahmatОценок пока нет

- Allowable Load On Single PileДокумент16 страницAllowable Load On Single PileSugiarto SaptomoОценок пока нет

- Field Estimates Pile Capacity PDFДокумент4 страницыField Estimates Pile Capacity PDFAniculaesi MirceaОценок пока нет

- PT Inter World Steel MillsДокумент20 страницPT Inter World Steel Millssugiarto budiОценок пока нет

- Hiley's Piles GeneralДокумент34 страницыHiley's Piles GeneralPERUNDINGAZRAОценок пока нет

- 316L SA 240 Ferguson MetalДокумент1 страница316L SA 240 Ferguson MetalSugiarto SaptomoОценок пока нет

- 2 - Retaining Wall Ashton Lawler PDFДокумент87 страниц2 - Retaining Wall Ashton Lawler PDFtaz_taz3100% (1)

- Demag Crane BrochureДокумент20 страницDemag Crane BrochureSugiarto SaptomoОценок пока нет

- Manual Training FMS 101Документ86 страницManual Training FMS 101Sugiarto SaptomoОценок пока нет

- Design of Structures and Foundations For Vibrating Machines PDFДокумент39 страницDesign of Structures and Foundations For Vibrating Machines PDFsaputrafrandy_958992Оценок пока нет

- Stainless Steel 316l (SA240)Документ2 страницыStainless Steel 316l (SA240)Sugiarto SaptomoОценок пока нет

- Service Quality and Passengers Satisfaction of Southern Railways by ServQual ModelДокумент4 страницыService Quality and Passengers Satisfaction of Southern Railways by ServQual ModelSamy Pulla da NaanОценок пока нет

- Can You Find What Is The Type of Motor Used For These Applications?Документ17 страницCan You Find What Is The Type of Motor Used For These Applications?nandhakumarme0% (1)

- Gulfstream ParkДокумент19 страницGulfstream Parkreinaldo yoveraОценок пока нет

- Factory Acceptance Test Check SheetДокумент4 страницыFactory Acceptance Test Check SheetThai Hai LyОценок пока нет

- Elizabeth Line Timetable May 2023Документ51 страницаElizabeth Line Timetable May 2023senenregistroОценок пока нет

- Transportation 1Документ228 страницTransportation 1Hasan Hüseyin ÇakırОценок пока нет

- Green Building Consultants in QatarДокумент25 страницGreen Building Consultants in QatarConserveОценок пока нет

- Gmrt2045 Iss 2Документ25 страницGmrt2045 Iss 2bijendrakumar1991Оценок пока нет

- MSC in Transportation EngineeringДокумент8 страницMSC in Transportation EngineeringKrishna Prasad PheluОценок пока нет

- High Speed Railways - PITДокумент57 страницHigh Speed Railways - PITIndian Railways Knowledge Portal100% (1)

- Work Method of Sandwich Panel Halim StationДокумент84 страницыWork Method of Sandwich Panel Halim Stationirvan udin utomoОценок пока нет

- Last SheetДокумент51 страницаLast SheetPratik GuptaОценок пока нет

- Technical SpecificationsДокумент16 страницTechnical SpecificationsYacoub CheikhОценок пока нет

- ADC Section 4 - Commuter Facilities Design RequirementsДокумент127 страницADC Section 4 - Commuter Facilities Design Requirementsusernaga84Оценок пока нет

- Inggris BeritaДокумент1 страницаInggris BeritaKimino UdinОценок пока нет

- RST Travel Tips For EuropeДокумент96 страницRST Travel Tips For EuropeÁdámHegyiОценок пока нет

- E (O) III Order 10 - 08 - 21Документ4 страницыE (O) III Order 10 - 08 - 21Ajit ChauhanОценок пока нет

- Section 1 - General Provisions: B D S - A 2000Документ3 страницыSection 1 - General Provisions: B D S - A 2000Anonymous I8dXeoОценок пока нет

- Adipur Mundra Port LineДокумент23 страницыAdipur Mundra Port LineSaurabh SumanОценок пока нет

- 2019 03 AS-7517-2014 Wheelsets PreviewДокумент19 страниц2019 03 AS-7517-2014 Wheelsets PreviewAriful Hassan KallolОценок пока нет

- Perth CAT Timetable 203 20230702Документ2 страницыPerth CAT Timetable 203 20230702Nadine SilvaОценок пока нет

- Exercises 1 para ImprimirДокумент8 страницExercises 1 para ImprimirL Anabella Mendoza DvОценок пока нет

- A Project Management Bench Mark: Delhi MetroДокумент26 страницA Project Management Bench Mark: Delhi Metrodineshsoni29685Оценок пока нет

- EzekyanДокумент203 страницыEzekyanAnahit GhazaryanОценок пока нет

- Rly. BD - LetterДокумент3 страницыRly. BD - LetterImma JacoОценок пока нет

- Stanley Cobotics BrochureДокумент12 страницStanley Cobotics BrochureEberthsonОценок пока нет

- Y y Y Y Y: Design of Machinery Robert L. NortonДокумент1 страницаY y Y Y Y: Design of Machinery Robert L. NortonFernando Pauli PradoОценок пока нет

- Executive Summary Toward Universal Mobility For Web ShareДокумент20 страницExecutive Summary Toward Universal Mobility For Web ShareAnonymous 8v54VwOGtОценок пока нет

- Sustainable Transportation: An Direction StrategyДокумент58 страницSustainable Transportation: An Direction StrategymfaizaОценок пока нет

- MSRTC - Online Reservation SystemДокумент1 страницаMSRTC - Online Reservation Systemgetgaurav100% (1)