Академический Документы

Профессиональный Документы

Культура Документы

ZG Turn Signal and Hazard Warning Systems 8J - 1

Загружено:

ensmartis0 оценок0% нашли этот документ полезным (0 голосов)

62 просмотров6 страницОригинальное название

EZG_8J

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

62 просмотров6 страницZG Turn Signal and Hazard Warning Systems 8J - 1

Загружено:

ensmartisАвторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

ZG TURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 1

TURN SIGNAL AND HAZARD WARNING SYSTEMS

CONTENTS

page page

GENERAL INFORMATION VEHICLE INFORMATION CENTER . . . . ...... 2

INTRODUCTION . . . . . . . . . . . . . . . . ........ 1 DIAGNOSIS AND TESTING

DESCRIPTION AND OPERATION INTRODUCTION . . . . . . . . . . . . . . . . . . ...... 2

COMBINATION FLASHER . . . . . . . . . . . . . . . . . 1 MULTI-FUNCTION SWITCH . . . . . . . . . . ...... 3

HAZARD WARNING SYSTEM . . . . . . . . . . . . . . 1 TURN SIGNAL AND HAZARD WARNING

TURN SIGNAL INDICATOR LAMP . . . . . . . . . . . 2 SYSTEMS . . . . . . . . . . . . . . . . . . . . . . ...... 3

TURN SIGNAL LAMP . . . . . . . . . . . . . . . . . . . . . 2 REMOVAL AND INSTALLATION

TURN SIGNAL SWITCH AND HAZARD COMBINATION FLASHER . . . . . . . . . . . ...... 4

WARNING SWITCH . . . . . . . . . . . . ........ 2 MULTI-FUNCTION SWITCH . . . . . . . . . . ...... 5

TURN SIGNAL SYSTEM . . . . . . . . . . ........ 1

GENERAL INFORMATION the cam lobes to contact a cancel actuator in the

multi-function switch, the turn signal switch auto-

INTRODUCTION matically returns to the off position.

Following are general descriptions of the major When the turn signal system is activated, the

components in the turn signal and hazard warning selected (right or left) turn signal indicator lamp,

systems. Refer to 8W-52 - Turn Signals in Group 8W front park/turn signal lamp, front side marker lamp,

- Wiring Diagrams for complete circuit descriptions and rear tail/stop/turn signal lamp bulbs will flash.

and diagrams. With the headlamp switch in the Off position, the

front turn signal and front side marker lamps flash

NOTE: This group covers both Left-Hand Drive in unison. With the headlamp switch in the On posi-

(LHD) and Right-Hand Drive (RHD) versions of this tion, the front turn signal and front side marker

model. Whenever required and feasible, the RHD lamps flash alternately.

versions of affected vehicle components have been

constructed as mirror-image of the LHD versions. HAZARD WARNING SYSTEM

While most of the illustrations used in this group The hazard warning system is activated by a

represent only the LHD version, the diagnostic and switch button in the multi-function switch. The but-

service procedures outlined can generally be ton is located on the top of the steering column

applied to either version. Exceptions to this rule between the steering wheel and the instrument

have been clearly identified as LHD or RHD, if a panel. The hazard warning switch button is identi-

special illustration or procedure is required. fied with a double triangle.

The hazard warning system is connected to a non-

switched battery feed so that the system remains

functional, regardless of the ignition switch position.

DESCRIPTION AND OPERATION

Push the switch button in to activate the hazard

warning system, and push in on the button again to

TURN SIGNAL SYSTEM

turn the system off.

With the ignition switch in the On or Accessory

When the hazard warning system is activated, the

position, and the multi-function switch control lever

right and left turn signal indicators, front park/turn

moved up (right turn) or down (left turn), the turn

signal lamps, front side marker lamps, and rear tail/

signal system is activated. The switch has a detent

stop/turn signal lamps will flash.

position in each direction that provides turn signals

with automatic cancellation, and an intermediate

COMBINATION FLASHER

momentary position that provides turn signals only

The combination flasher is a smart relay that func-

until the multi-function switch lever is released.

tions as both the turn signal system and hazard

When the turn signal switch is in a detent posi-

warning system flasher. The combination flasher is

tion, it is turned off by one of two cancelling cam

designed to handle the current flow requirements of

lobes molded into the hub of the clockspring mecha-

the factory-installed lighting.

nism. When turning the steering wheel causes one of

WINDSHIELD

WINDSHIELDWASHER

WIPER BUT-

TON

TROL

CON- CONTROL

MULTI-FUNCTION

STALK

HAZARD

SWITCH

WARNING BUTTON

8J - 2 TURN SIGNAL AND HAZARD WARNING SYSTEMS ZG

DESCRIPTION AND OPERATION (Continued)

If supplemental lighting is added to the turn signal

lamp circuits, such as when towing a trailer with

lights, the combination flasher will automatically

compensate. This allows the flash rate to remain the

same, regardless of electrical load increases. How-

ever, if a bulb fails in the turn signal lamp circuits,

the flash rate of the remaining bulbs in that circuit

will increase to 120 flashes-per-minute, or higher.

While the combination flasher shares the terminal

orientation (footprint) of a International Standards

Organization (ISO)-type relay, the internal circuitry

is much different. The combination flasher contains

active electronic integrated circuitry elements. Do not

substitute any other relay for the combination

flasher.

Because of the active electronic elements within

the combination flasher, it cannot be tested with con- Fig. 1 Multi-Function Switch

ventional automotive electrical test equipment. If the

combination flasher is believed to be faulty, test the VEHICLE INFORMATION CENTER

turn signal and hazard warning system circuits as Models equipped with an optional Vehicle Informa-

described in this group. Then replace the combina- tion Center (VIC) have a “turn signal on” warning

tion flasher with a known good unit to confirm sys- feature. The VIC module monitors the turn signal

tem operation. circuit from the combination flasher. The VIC module

The combination flasher cannot be repaired and, if will display the message, Turn Signal On, and send a

faulty, it must be replaced. request to the Body Control Module (BCM) on the

Chrysler Collision Detection (CCD) data bus network

TURN SIGNAL SWITCH AND HAZARD WARNING for six chime tones, if a turn signal remains activated

SWITCH for more than approximately one-half mile of driving.

Refer to Group 8E - Instrument Panel Systems for

The turn signal and hazard warning switches are

diagnosis and service of the VIC module. Refer to the

integral to the multi-function switch assembly. The

proper Body Diagnostic Procedures manual for diag-

multi-function switch assembly is secured to the left

nosis and service of the BCM or the CCD data bus.

side of the steering column (Fig. 1). This switch con-

tains circuitry for the following functions:

• Turn signals

TURN SIGNAL LAMP

The exterior lamps in the turn signal and hazard

• Hazard warning

warning circuits include the front park/turn signal,

• Headlamp beam selection

the front side marker, and the rear tail/stop/turn sig-

• Headlamp optical horn

nal. For diagnosis and service of these lamps, refer to

• Windshield wipers

Group 8L - Lamps.

• Windshield washers.

The information contained in this group addresses

only the multi-function switch functions for the turn DIAGNOSIS AND TESTING

signal and hazard warning circuits. For information

relative to the other switch functions, refer to the INTRODUCTION

proper group. However, the multi-function switch When diagnosing the turn signal or hazard warn-

cannot be repaired. If any function of the multi-func- ing circuits, remember that high generator output

tion switch is faulty, or if the switch is damaged, the can burn out bulbs rapidly and repeatedly. If this is a

entire switch assembly must be replaced. problem on the vehicle being diagnosed, refer to

Group 8C - Charging System for further diagnosis of

TURN SIGNAL INDICATOR LAMP a possible generator overcharging condition.

The turn signal indicator lamps are located in the

instrument cluster. They flash with the exterior turn

signal lamps to give the driver a visual indication

that a turn signal or the hazard warning system is

operating. For diagnosis and service of these lamps,

refer to Group 8E - Instrument Panel Systems.

ZG TURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 3

DIAGNOSIS AND TESTING (Continued)

WARNING: ON VEHICLES EQUIPPED WITH AIR- output circuit cavity for the combination flasher in

BAGS, REFER TO GROUP 8M - PASSIVE the junction block. If OK, go to Step 6. If not OK,

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY repair the open circuit to the turn signal fuse as

STEERING WHEEL, STEERING COLUMN, OR required.

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR (6) Turn the ignition switch to the Off position.

SERVICE. FAILURE TO TAKE THE PROPER PRE- Check for battery voltage at the fused B(+) circuit

CAUTIONS COULD RESULT IN ACCIDENTAL AIR- cavity for the combination flasher in the junction

BAG DEPLOYMENT AND POSSIBLE PERSONAL block. If OK, go to Step 7. If not OK, repair the open

INJURY. circuit to the hazard warning fuse as required.

(7) Disconnect and isolate the battery negative

cable. Check for continuity between the ground cir-

TURN SIGNAL AND HAZARD WARNING SYSTEMS cuit cavity for the combination flasher in the junction

For circuit descriptions and diagrams, refer to block and a good ground. There should be continuity.

8W-52 - Turn Signals in Group 8W - Wiring Dia- If OK, go to Step 8. If not OK, repair the circuit to

grams. ground as required.

(8) Unplug the multi-function switch wire harness

WARNING: ON VEHICLES EQUIPPED WITH AIR- connector as described in this group. Check for con-

BAGS, REFER TO GROUP 8M - PASSIVE tinuity between the combination flasher hazard sig-

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY nal circuit cavities in the junction block and in the

STEERING WHEEL, STEERING COLUMN, OR multi-function switch wire harness connector. There

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR should be continuity. If OK, go to Step 9. If not OK,

SERVICE. FAILURE TO TAKE THE PROPER PRE- repair the open circuit as required.

CAUTIONS COULD RESULT IN ACCIDENTAL AIR- (9) Check for continuity between the combination

BAG DEPLOYMENT AND POSSIBLE PERSONAL flasher turn signal circuit cavities in the junction

INJURY. block and in the multi-function switch wire harness

connector. There should be continuity. If OK, test the

(1) Turn the ignition switch to the On position.

multi-function switch as described in this group. If

Actuate the turn signal lever or the hazard warning

not OK, repair the open circuit as required.

button. Observe the turn signal indicator lamp(s) in

the instrument cluster. If the flash rate is very high,

MULTI-FUNCTION SWITCH

check for a turn signal bulb that is not lit or is very

Perform the diagnosis of the hazard warning

dimly lit. Repair the circuits to that lamp or replace

and/or turn signal systems as described in this group

the faulty bulb, as required. Test the operation of the

before testing the multi-function switch. For circuit

turn signal and hazard warning systems again. If the

descriptions and diagrams, refer to 8W-52 - Turn Sig-

turn signal indicator(s) fail to light, go to Step 2.

nals in Group 8W - Wiring Diagrams.

(2) Turn the ignition switch to the Off position.

Check the turn signal fuse in the junction block WARNING: ON VEHICLES EQUIPPED WITH AIR-

and/or the hazard warning fuse in the Power Distri- BAGS, REFER TO GROUP 8M - PASSIVE

bution Center (PDC). If OK, go to Step 3. If not OK, RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

repair the shorted circuit or component as required STEERING WHEEL, STEERING COLUMN, OR

and replace the faulty fuse(s). INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

(3) Turn the ignition switch to the On position to SERVICE. FAILURE TO TAKE THE PROPER PRE-

check for battery voltage at the turn signal fuse in CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

the junction block; or, leave the ignition switch in the BAG DEPLOYMENT AND POSSIBLE PERSONAL

Off position to check for battery voltage at the haz- INJURY.

ard warning fuse in the PDC. If OK, go to Step 4. If

not OK, repair the open circuit as required. (1) Unplug the multi-function switch wire harness

(4) Turn the ignition switch to the Off position. connector as described in this group.

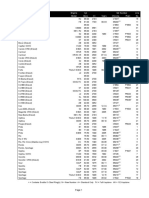

Disconnect and isolate the battery negative cable. (2) Using an ohmmeter, perform the switch conti-

Unplug the combination flasher from the junction nuity checks at the switch terminals as shown in the

block and replace it with a known good unit. Connect Multi-Function Switch Continuity chart (Fig. 2).

the battery negative cable. Test the operation of the (3) If the switch fails any of the continuity checks,

turn signal and hazard warning systems. If OK, dis- replace the faulty switch. If the switch is OK, repair

card the faulty combination flasher. If not OK, the lighting circuits as required.

remove the test flasher and go to Step 5.

(5) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

JUNCTION

RIGHT

BLOCK

COWL TRIM

SIDE SCREWS PUSH

VIEW NUT

FROM TERMINAL CASE

8J - 4 TURN SIGNAL AND HAZARD WARNING SYSTEMS ZG

Fig. 2 Multi-Function Switch Continuity

REMOVAL AND INSTALLATION

COMBINATION FLASHER

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access panel by unsnapping it

from the right cowl side trim panel.

(3) Remove the push nut that secures the right

cowl side trim panel to the junction block stud (Fig.

3).

(4) Remove the two screws that secure the right

cowl side trim panel to the right front door opening Fig. 3 Right Cowl Side Trim Panel Remove/Install

trim.

(5) Remove the right cowl side trim panel. (7) Install the combination flasher by aligning the

(6) Unplug the combination flasher from the junc- flasher terminals with the cavities in the junction

tion block. block and pushing the flasher firmly into place.

(8) Connect the battery negative cable.

SWITCH

OUTBOARD

SCREW BEZEL

POD KNEE

SNAP

INBOARD

BLOCKER

CLIP

PODSWITCH

TIONS

LOCA-

BEZEL PANEL

BRACKET

LOWER

NUT

SHROUD

STEERING

NUT

UMNSTEERING

ASSY.

COL-

WHEEL TILT LEVER

MULTI-FUNCTION

SWITCH CONNEC-

TOR

CLOCK

UPPER

TURN

SWITCH

SHROUD

SPRING

SPACER

SIGNAL

LEVER

AND

ZG TURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 5

REMOVAL AND INSTALLATION (Continued)

(9) Test the flasher operation. (8) Remove the knee blocker and steering column

(10) Install the right cowl side trim panel and the cover from the vehicle.

fuse access panel. (9) Remove both the upper and lower shrouds from

the steering column (Fig. 5).

MULTI-FUNCTION SWITCH

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) If the vehicle is so equipped, remove the tilt

steering column lever.

(3) Using a trim stick or another suitable wide

flat-bladed tool, pry gently around the edges of the

instrument panel switch pod bezels and remove both

bezels.

(4) Remove one screw on each side of the steering

column that secures the upper edge of the knee

blocker and steering column cover to the instrument Fig. 5 Steering Column Shrouds Remove/Install-

panel (Fig. 4). Typical

(10) Remove the lower fixed column shroud.

(11) Loosen the steering column upper bracket

nuts. Do not remove the nuts.

(12) Move the upper fixed column shroud to gain

access to the rear of the multi-function switch (Fig.

6).

Fig. 4 Knee Blocker Remove/Install

(5) Remove the one screw that secures the out-

board end of the knee blocker to the instrument

panel.

(6) Remove the four screws that secure the lower

edge of the knee blocker to the lower instrument

panel reinforcement. Fig. 6 Multi-Function Switch Connector -Typical

(7) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the edges of the knee (13) Remove the multi-function switch tamper

blocker away from the instrument panel at the snap proof mounting screws (a Snap On tamper proof torx

clip retainer locations (Fig. 4). bit TTXR20B2 or equivalent is required).

8J - 6 TURN SIGNAL AND HAZARD WARNING SYSTEMS ZG

REMOVAL AND INSTALLATION (Continued)

(14) Gently pull the switch away from the column. • Multi-function switch wire harness connector

Loosen the wire harness connector screw. The screw screw - 2 N·m (17 in. lbs.)

will remain in the wire harness connector. • Multi-function switch retaining screws - 2 N·m

(15) Unplug the wire harness connector from the (17 in. lbs.)

multi-function switch. • Steering column upper bracket nuts - 12 N·m

(16) Reverse the removal procedures to install. (110 in. lbs.).

Tighten the fasteners as follows:

Вам также может понравиться

- 1989 Ford Truck Shop Manual Volume B Light Duty TruckДокумент564 страницы1989 Ford Truck Shop Manual Volume B Light Duty TruckDins Ziemelis90% (10)

- 2011 Infiniti G37 Coupe Service Repair Manual PDFДокумент20 страниц2011 Infiniti G37 Coupe Service Repair Manual PDFfjjsjekdmmeОценок пока нет

- Transfert Case Getrag 760 PDFДокумент47 страницTransfert Case Getrag 760 PDFLê Văn HoạtОценок пока нет

- Nikon D500: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsОт EverandNikon D500: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsОценок пока нет

- Hino Genuine Truck Parts: and Accessories CatalogueДокумент12 страницHino Genuine Truck Parts: and Accessories CataloguePertamini KTB0% (1)

- Volvo 2007 LCM Design and Function PDFДокумент7 страницVolvo 2007 LCM Design and Function PDFjoel100% (5)

- General Information: Vehicle Identification Number Decoding ChartДокумент10 страницGeneral Information: Vehicle Identification Number Decoding ChartensmartisОценок пока нет

- Sistema ElectricoДокумент22 страницыSistema ElectricoFredy ReyesОценок пока нет

- ADASДокумент3 страницыADASja02306Оценок пока нет

- Furuno Ecdis Trainee Course Manual Version 4.0Документ46 страницFuruno Ecdis Trainee Course Manual Version 4.0Kevin LinnОценок пока нет

- Dynapac Cc4200c Parts ManualДокумент20 страницDynapac Cc4200c Parts Manualmarie100% (43)

- 3300 20 Operation Manual 80178-01 Rev FДокумент24 страницы3300 20 Operation Manual 80178-01 Rev FAhmad Saad Gahwagi100% (1)

- Lamborghini Urus ADWUBB 19.10.22Документ19 страницLamborghini Urus ADWUBB 19.10.22Rosazrom Argentina100% (1)

- OM System "Olympus" OM-1: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsОт EverandOM System "Olympus" OM-1: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsОценок пока нет

- Automotive Engine ElectronicsДокумент4 страницыAutomotive Engine Electronicsmachine tunisieОценок пока нет

- Operating Instructions Operating Instructions: Nano-L SMJ Nano-L SMJ R-16, R-CAN R-16, R-CANДокумент20 страницOperating Instructions Operating Instructions: Nano-L SMJ Nano-L SMJ R-16, R-CAN R-16, R-CANpopo20084455Оценок пока нет

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleОт EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleОценок пока нет

- QT350 Alarm List 200-399Документ31 страницаQT350 Alarm List 200-399Abdul Leon100% (2)

- Vespa Brochure 2011Документ24 страницыVespa Brochure 2011Kristina AndinaОценок пока нет

- IRPrestige21 Users System GuideДокумент78 страницIRPrestige21 Users System GuideSilezio FerreiraОценок пока нет

- Guide to Turn Signal and Hazard Warning SystemsДокумент8 страницGuide to Turn Signal and Hazard Warning SystemsEinar OftebroОценок пока нет

- Jeep XJ 2000 08j Tunr Signal and Hazard Warning SystemsДокумент8 страницJeep XJ 2000 08j Tunr Signal and Hazard Warning SystemsStanislav AnastassovОценок пока нет

- Turn Signals and Hazard Warning FlasherДокумент8 страницTurn Signals and Hazard Warning FlasherChristian MartinezОценок пока нет

- Grand Cherokee WJ 2000Документ14 страницGrand Cherokee WJ 2000العقار امين عيسىОценок пока нет

- Combination Flasher: Installation - CHMSLДокумент3 страницыCombination Flasher: Installation - CHMSLBrian NunesОценок пока нет

- Chrysler Neon - Turn Signal - Hazzard Warning SystemsДокумент6 страницChrysler Neon - Turn Signal - Hazzard Warning SystemseephantomОценок пока нет

- Chrysler Neon - Turn Signal - Hazzard Warning SystemsДокумент6 страницChrysler Neon - Turn Signal - Hazzard Warning SystemseephantomОценок пока нет

- 2009 Citroen c4 Owners ManualДокумент279 страниц2009 Citroen c4 Owners Manualvldjuka2327Оценок пока нет

- PL Turn Signal and Flashers 8J - 1Документ4 страницыPL Turn Signal and Flashers 8J - 1Pelis CloneОценок пока нет

- 93ZJ Secc 8J Turn Signals and Hazard Warning FlashesДокумент4 страницы93ZJ Secc 8J Turn Signals and Hazard Warning Flasheshelgith74Оценок пока нет

- Chrysler Dakota Part14Документ4 страницыChrysler Dakota Part14Sašo Brunšek-BrunoОценок пока нет

- Cableadoa Mitsubichi Lancer OZДокумент24 страницыCableadoa Mitsubichi Lancer OZHector Ernesto Cordero AmaroОценок пока нет

- Chime Buzzer Warning SystemsДокумент4 страницыChime Buzzer Warning SystemsArt DoeОценок пока нет

- 05 X30 User's Manual (MKT-0012)Документ44 страницы05 X30 User's Manual (MKT-0012)VICTOR MANUEL SALAZAR GARCIAОценок пока нет

- Code 3 V-Con Siren ManualДокумент20 страницCode 3 V-Con Siren Manualمحمد العمريОценок пока нет

- Installation Manual for Sailor AP5065 Alarm PanelДокумент24 страницыInstallation Manual for Sailor AP5065 Alarm PanelYOUSSEF ABDELSALAMОценок пока нет

- ZG Chime/Buzzer Warning Systems 8U - 1Документ4 страницыZG Chime/Buzzer Warning Systems 8U - 1ensmartisОценок пока нет

- 861-862-863 User Guide 2016Документ8 страниц861-862-863 User Guide 2016cmlcaldeira10Оценок пока нет

- Gala Coffee 5 IngДокумент68 страницGala Coffee 5 IngalialbassamuccОценок пока нет

- Mirrowstic 3codeДокумент16 страницMirrowstic 3codeJesús EspinosaОценок пока нет

- ZG Power Window Systems 8S - 1Документ8 страницZG Power Window Systems 8S - 1ensmartisОценок пока нет

- ManualДокумент70 страницManualAnonymo -308Оценок пока нет

- Owner's Guide: APS25ZДокумент9 страницOwner's Guide: APS25ZErwin HernandezОценок пока нет

- ZG Horn Systems 8G - 1Документ4 страницыZG Horn Systems 8G - 1ensmartisОценок пока нет

- 08G - Horn SystemsДокумент6 страниц08G - Horn SystemsEinar OftebroОценок пока нет

- XJM60D EN r1.1 29.11.2013Документ6 страницXJM60D EN r1.1 29.11.2013Jennifer Eszter SárközyОценок пока нет

- APS48Z Owners Guide Rev. 0 - 11.13.19Документ8 страницAPS48Z Owners Guide Rev. 0 - 11.13.19Erwin HernandezОценок пока нет

- Smart Wiring System (SWS) : Click On The Applicable Bookmark To Selected The Required Model YearДокумент61 страницаSmart Wiring System (SWS) : Click On The Applicable Bookmark To Selected The Required Model Yearsled novaОценок пока нет

- GO Switch, Seal Fail Relay PDFДокумент2 страницыGO Switch, Seal Fail Relay PDFtotovasiОценок пока нет

- YN-E3-RT ManualДокумент36 страницYN-E3-RT ManualJoseph NaimОценок пока нет

- Electrically Heated Systems: Defogger SystemДокумент10 страницElectrically Heated Systems: Defogger SystemensmartisОценок пока нет

- diagramas etac SWSДокумент546 страницdiagramas etac SWSAlberto AbarcaОценок пока нет

- PLC Generador KiporДокумент32 страницыPLC Generador Kiporjavier aguila rebolledoОценок пока нет

- Chime Warning/Reminder System: Description and Operation Headlamps Left OnДокумент2 страницыChime Warning/Reminder System: Description and Operation Headlamps Left OnRoberto VazquezОценок пока нет

- LXC701 V1.1 enДокумент8 страницLXC701 V1.1 enAnonymous vqsuRy100% (1)

- DIXEL Ceh 2 PDFДокумент166 страницDIXEL Ceh 2 PDFMihailОценок пока нет

- PL Instrument Panel and Systems 8E - 1Документ14 страницPL Instrument Panel and Systems 8E - 1Pelis CloneОценок пока нет

- Vehicle Light and Wiper ControlsДокумент14 страницVehicle Light and Wiper ControlsguttinetОценок пока нет

- Ik3 enДокумент7 страницIk3 enEsteban Calixto CrisoloОценок пока нет

- 93ZJ Secc 8D Ignition SystemsДокумент40 страниц93ZJ Secc 8D Ignition Systemshelgith74Оценок пока нет

- SR03 01Mk2 DataSheet Rev4Документ4 страницыSR03 01Mk2 DataSheet Rev4Miroslaw LabudaОценок пока нет

- GLC2200 Graco Grease Autolube Module Timer ControllerДокумент30 страницGLC2200 Graco Grease Autolube Module Timer ControllerRiyan AditiaОценок пока нет

- W211 Rear SAM LightsДокумент1 страницаW211 Rear SAM LightsbinhpaОценок пока нет

- Car Alarm ManualДокумент6 страницCar Alarm ManualTrevor M Cole100% (1)

- 3300/15 Dual Vibration Monitor: Operation ManualДокумент25 страниц3300/15 Dual Vibration Monitor: Operation ManualLinh LyОценок пока нет

- SAILOR AP5065 Alarm Panel: Installation ManualДокумент20 страницSAILOR AP5065 Alarm Panel: Installation ManualVladimirОценок пока нет

- CA 1150 Owner's Guide: Professional SeriesДокумент8 страницCA 1150 Owner's Guide: Professional Seriesjuan HОценок пока нет

- Intelligent Fire Alarm Network: LT-893SEC Rev 0 July 2012Документ44 страницыIntelligent Fire Alarm Network: LT-893SEC Rev 0 July 2012Daniel BustamanteОценок пока нет

- Asco S300G - Manual de UsuarioДокумент40 страницAsco S300G - Manual de UsuarioImplementación OLCОценок пока нет

- Dok 1Документ13 страницDok 1ensmartisОценок пока нет

- Ezg 13Документ12 страницEzg 13ensmartisОценок пока нет

- 08V Overhead Console SystemsДокумент8 страниц08V Overhead Console SystemsDane WallaceОценок пока нет

- General Service InformationДокумент48 страницGeneral Service InformationensmartisОценок пока нет

- ZG Chime/Buzzer Warning Systems 8U - 1Документ4 страницыZG Chime/Buzzer Warning Systems 8U - 1ensmartisОценок пока нет

- Ezg 19Документ32 страницыEzg 19ensmartisОценок пока нет

- Emission Control Systems: On-Board DiagnosticsДокумент28 страницEmission Control Systems: On-Board Diagnosticsensmartis100% (1)

- Ezg 22Документ10 страницEzg 22ensmartisОценок пока нет

- Fuel System: General InformationДокумент108 страницFuel System: General InformationensmartisОценок пока нет

- Ezg 8WLДокумент990 страницEzg 8WLensmartisОценок пока нет

- ZG Exhaust System and Intake Manifold 11 - 1Документ14 страницZG Exhaust System and Intake Manifold 11 - 1ensmartisОценок пока нет

- ZG Power Window Systems 8S - 1Документ8 страницZG Power Window Systems 8S - 1ensmartisОценок пока нет

- Ezg 8TДокумент8 страницEzg 8TensmartisОценок пока нет

- ZG Vehicle Theft/Security Systems 8Q - 1Документ22 страницыZG Vehicle Theft/Security Systems 8Q - 1ensmartisОценок пока нет

- Electrically Heated Systems: Defogger SystemДокумент10 страницElectrically Heated Systems: Defogger SystemensmartisОценок пока нет

- 08R Power Seat SystemsДокумент8 страниц08R Power Seat SystemsDane WallaceОценок пока нет

- Passsive Restraint Systems GuideДокумент12 страницPasssive Restraint Systems GuideDane WallaceОценок пока нет

- 08K Wiper & Washer SystemsДокумент14 страниц08K Wiper & Washer SystemsDane WallaceОценок пока нет

- 08E Instrument Panel SystemsДокумент70 страниц08E Instrument Panel SystemsDane WallaceОценок пока нет

- 08H Vehicle Speed Control SystemДокумент12 страниц08H Vehicle Speed Control SystemDane WallaceОценок пока нет

- ZG Charging System 8C - 1Документ10 страницZG Charging System 8C - 1ensmartisОценок пока нет

- ZG Horn Systems 8G - 1Документ4 страницыZG Horn Systems 8G - 1ensmartisОценок пока нет

- 08D Ignition SystemДокумент24 страницы08D Ignition SystemDane WallaceОценок пока нет

- ZG Cooling System 7 - 1Документ72 страницыZG Cooling System 7 - 1ensmartisОценок пока нет

- ZG Audio Systems 8F - 1Документ18 страницZG Audio Systems 8F - 1ensmartisОценок пока нет

- ZG Starting Systems 8B - 1Документ14 страницZG Starting Systems 8B - 1ensmartisОценок пока нет

- ZG Battery 8A - 1Документ18 страницZG Battery 8A - 1ensmartisОценок пока нет

- Uvoz Vozila 2010-2020Документ13 страницUvoz Vozila 2010-2020Sarajevo ZidОценок пока нет

- Mercedes Nut Replacement DetailsДокумент3 страницыMercedes Nut Replacement DetailsAlexander NguОценок пока нет

- Reasons Why Tesla Belongs To FutureДокумент8 страницReasons Why Tesla Belongs To FutureRishit GulatiОценок пока нет

- AP RACING Fitment Template CP9660-372Документ1 страницаAP RACING Fitment Template CP9660-372Kyriakos AnagnostouОценок пока нет

- Kopi-O: Seating ProductsДокумент8 страницKopi-O: Seating Productsishanj1991Оценок пока нет

- GTO Radio InstallДокумент8 страницGTO Radio InstallAnthony_Blacksna_646Оценок пока нет

- Lista de Precios Highfil CombustibleДокумент1 страницаLista de Precios Highfil Combustibleleonar eduardo montoya pinedaОценок пока нет

- New 308 Price Spec GuideДокумент14 страницNew 308 Price Spec Guidenexy bОценок пока нет

- Catalogo Fuel Pumps Air Flow 17122009135336Документ88 страницCatalogo Fuel Pumps Air Flow 17122009135336evailson2Оценок пока нет

- Micro Merlin With HandbrakeДокумент1 страницаMicro Merlin With HandbrakeCarlos GutiérrezОценок пока нет

- F-Pace: Enter Swipe To InteractДокумент49 страницF-Pace: Enter Swipe To InteractB.C.DОценок пока нет

- Engine Cyl Set Number Line Application Model Bore CC Years Chrome Plain NoДокумент3 страницыEngine Cyl Set Number Line Application Model Bore CC Years Chrome Plain Nomarran almarranyОценок пока нет

- 2023 CorollaДокумент8 страниц2023 Corollawilamer wilamОценок пока нет

- Catálogo de Repuestos Originales Suzuki Ignis 2000 - 2005Документ270 страницCatálogo de Repuestos Originales Suzuki Ignis 2000 - 2005Gabriel Avilez GonzalezОценок пока нет

- Ecat TATA - PDF DIFF POSTДокумент2 страницыEcat TATA - PDF DIFF POSTSTEFANOОценок пока нет

- 2018 TSC MowerPartsДокумент32 страницы2018 TSC MowerPartsName HereОценок пока нет

- Specifications - 10029140Документ2 страницыSpecifications - 10029140BeymarGeronimoОценок пока нет

- Manual Central Facility Top - Unificado - Rev3Документ2 страницыManual Central Facility Top - Unificado - Rev3OSVALDO MALGESINIОценок пока нет

- BMW-3Series F30-Flyer RFДокумент6 страницBMW-3Series F30-Flyer RFNizar TumaisuriОценок пока нет

- BT Reflex (B Series)Документ4 страницыBT Reflex (B Series)Yumiko ChungОценок пока нет

- Honda Accord Shop ManualДокумент1 711 страницHonda Accord Shop ManualDiego Hernan Piñeiro100% (1)