Академический Документы

Профессиональный Документы

Культура Документы

Chiller&Cond

Загружено:

varshneyrk@rediffmail.comОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chiller&Cond

Загружено:

varshneyrk@rediffmail.comАвторское право:

Доступные форматы

Chillers & Condensers

RYDLYME dissolves water scale, lime, mud and rust deposits safely, quickly and effectively!

.................................................................................................

the solution to your water scale problems

for Chillers & Condensers

factor (thermal resistance) will increase electrical consumption and decrease efficiency. The increase in electrical energy takes place in the compressor. Scale deposits increase the resistance to heat transfer, and in the condenser higher refrigerant gas temperatures will result. Higher refrigerant gas temperatures mean higher gas pressures, which require greater energy to compress the refrigerant. Therefore, there is an increase in electrical power to operate the compressor. To minimize such potential energy losses requires an ongoing, daily monitoring of KW consumed per ton of refrigerant/air conditioning being generated. The purpose is to recognize inefficient operation and determine where the problem is and fix it. Each day of inefficient operation means excess energy expenditures. Fortunately, RYDLYME dissolves the toughest water formed deposits from virtually any type of water heated, cooled or operated equipment. Please request a Fly Sheet or guide outlining step-by-step instructions on returning your particular equipment back to peak operating efficiencies utilizing our innovative and biodegradable descaler, RYDLYME. Our technical assistance is offered FREE OF CHARGE to afford maximum benefits to you and your company.

RYDLYME is an excellent choice for cleaning water formed deposits from Evaporative Condensers, Shell & Tube Condensers, Absorption Units and Centrifugal Chillers. This descriptive sales brochure should enlighten you to a very helpful tool to add to your toolbox. This tool, called RYDLYME, will help you rid your equipment of scale deposits and have them working at top efficiency in just hours. Lets take a closer look: Whenever there is a deposit of any type on a heat transfer surface, it retards heat transfer. This is referred to as thermal resistance and requires a corresponding increase in energy to overcome it. Major manufacturers of air conditioning equipment generally design condensers and chiller heat exchangers to operate at a maximum thermal resistance or fouling factor" of 0.0005. As a result, with only 0.036 inches (about 1/32) of deposit corresponds to an increase in energy costs of over 30%! This 30% increase in costs relates to a hardness scale (calcium carbonate) deposit. Iron deposits (same thickness) are greater insulators and therefore have lower heat transfer coefficients. The actual heat transfer coefficient of a fouling/deposit (scale, lime, corrosion products, dirt, silt) depends on what it is. Certainly, any fouling/deposit contributing a fouling

Periodic RYDLYME cleaning is necessary for maintaining your equipment at peak operating efficiency and maximum rated output!

Evaporative Condensers

When water scale is deposited on the heat transfer surfaces of an evaporative condenser, the cooling water from the spray heads cannot efficiently condense the refrigerant gas in the coils. As a result, inadequate cooling, overworked machinery, and expensive operation is incurred. To remove these deposits simply turn off the water supply, slowly add the recommended quantity of RYDLYME to the reservoir, turn on the circulating pump of the unit and circulate RYDLYME through the headers and spray nozzles. This will allow the RYDLYME to make contact with the heavy deposits of water scale surrounding the coils and dissolve

these deposits into solution, like sugar in coffee. After just a few hours, drain to normal plant sewer, water flush and return unit back to efficient operation!

www.rydlyme .com

Shell & Tube Condensers

Water scale deposits in the condenser coils cause the compressor to kick out on high head pressure and lowers the cooling capacity of the unit. To remove these insulating water scale, lime, mud, and rust deposits formed on the inside of the shell & tube condensers, simply circulate RYDLYME in through the water supply and out through the water return. Circulate for the prescribed time or until condenser is clean, flush with water, replace zinc or magnesium anodes, and return your equipment back to service, all within one eight hour shift!

RYDLYME OUT

RYDLYME IN

Peak operating efficiency is obtained with regular periodic cleanings using RYDLYME

Absorption Units

Water scale, lime, mud, and rust deposits that accumulate on the waterside of absorbers and condensers materially affect the operation and efficiency of any absorption type air conditioning unit. The presence of these mineral deposits, along with lithium bromide or lithium molybdate, can usually be ascertained by the temperature readings of the inlet and outlet water to the absorber and condenser, the skin and gas temperatures, as well as the generator temperatures. When these temperatures fail to stay within an efficient operating range, the accumulated deposits should be removed with RYDLYME. Water formed deposits build up in absorbers and condensers at a rate dependent upon the hardness of the cooling water. The harder the water, the faster the deposits accumulate! Furthermore, a unit that has never been cleaned will require more RYDLYME that a unit receiving periodic or annual cleaning and proper maintenance. The entire cooling water circuit, including absorber, condenser, and piping can be cleaned while the unit is in operation. This attribute is especially important when humidity and temperature control are necessary to keep the plant in efficient operation.

Centrifugal Chillers

The problem most frequently encountered in the operation of centrifugal units is water scale accumulates in the condenser and cooling tower, which causes inefficient operation. The removal of such deposits can very easily be accomplished while the unit is in operation by the addition of RYDLYME to the cooling tower water.

Periodic RYDLYME cleanings will allow your centrifugal chiller to operate at peak efficiency during high demand cycles The dissolved water scale, lime, mud, and rust deposits, including the expended and biodegradable RYDLYME , will be conveniently dissipated by evaporation loss, make-up water and bleed off. Periodic RYDLYME cleaning will maintain peak operating efficiency of your unit and give you maximum rated output. Adding RYDLYME to the cooling tower water gets rid of water scale accumulations in the condenser and cooling tower while the unit is in operation!

www.rydlyme .com

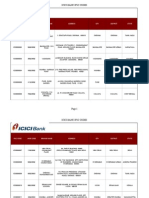

Recommended RYDLYME Quantities

TONNAGE EVAPORATIVE CONDENSERS SHELL & TUBE CONDENSERS CENTRIFUGAL CHILLERS ABSORPTION UNITS CIRCULATING HOURS

10 25 50 75 100 125 150 200 250 400 500 750 1000 2000 3000

4 10 20 30 40 50 60 80 100 160 200 300 400 800 1200

4 10 20 30 40 50 60 80 100 160 200 300 400 800 1200

3 10 15 25 30 40 45 60 75 120 150 225 300 600 900

7 20 35 55 70 90 105 140 175 280 350 525 700 1400 2100

3 4 4 4 5 5 5 5 5 5 6 6 7 7 8

Why Should You Use

scale per gallon!

RYDLYME is EFFECTIVE . . . it dissolves approximately two pounds of RYDLYME is NON-HAZARDOUS . . . it does not fall under any of the seven

federally designated classes of hazardous waste!

RYDLYME is BIODEGRADABLE . . . it has a biochemical oxygen demand of 16

mg/l and can be disposed of through existing plant sewers!

RYDLYME is SAFE . . . it can be held in the open hand without injury! RYDLYME is ECONOMICAL . . . Call us at (800) 451-6291 to learn how an investment in RYDLYME can multiply your efficiency!

P .O. Box 439 Plainfield, Illinois 60544 800-451-6291 FAX 815-436-9418

www.rydlyme.com

......................................................................................................

11/99 Printed in U.S.A. Apex Engineering Products Corporation RYDLYME is registered in the United States Patent and Trademark Office.

Вам также может понравиться

- Wires PDFДокумент5 страницWires PDFvarshneyrk@rediffmail.comОценок пока нет

- 5 Star Hotel Standards Thailand PDFДокумент29 страниц5 Star Hotel Standards Thailand PDFvarshneyrk@rediffmail.com50% (2)

- Vedic MathsДокумент65 страницVedic MathsRagavanОценок пока нет

- Wires PDFДокумент4 страницыWires PDFvarshneyrk@rediffmail.comОценок пока нет

- 4 Consumption of Materials 167-174 PDFДокумент8 страниц4 Consumption of Materials 167-174 PDFSheezan KhanОценок пока нет

- Vastu PDFДокумент43 страницыVastu PDFvarshneyrk@rediffmail.comОценок пока нет

- Wire & Cables PDFДокумент6 страницWire & Cables PDFvarshneyrk@rediffmail.comОценок пока нет

- Wires PDFДокумент3 страницыWires PDFvarshneyrk@rediffmail.comОценок пока нет

- Wires PDFДокумент2 страницыWires PDFvarshneyrk@rediffmail.comОценок пока нет

- Vastu PDFДокумент43 страницыVastu PDFvarshneyrk@rediffmail.comОценок пока нет

- Concrete, Mortar and PlasterДокумент4 страницыConcrete, Mortar and Plasterdox4printОценок пока нет

- Green Habitat - December 2012 PDFДокумент4 страницыGreen Habitat - December 2012 PDFvarshneyrk@rediffmail.comОценок пока нет

- Bronchotab PDF PDFДокумент2 страницыBronchotab PDF PDFvarshneyrk@rediffmail.comОценок пока нет

- The Dhaatri HavanaДокумент6 страницThe Dhaatri Havanavarshneyrk@rediffmail.com100% (1)

- 100 Windows 8 Keyboard ShortcutsДокумент4 страницы100 Windows 8 Keyboard ShortcutsneurraОценок пока нет

- ISLE Newsletter July 2011Документ36 страницISLE Newsletter July 2011varshneyrk@rediffmail.comОценок пока нет

- Your AHU Project TeamДокумент2 страницыYour AHU Project Teamvarshneyrk@rediffmail.comОценок пока нет

- Durga PujaДокумент137 страницDurga Pujavarshneyrk@rediffmail.com100% (1)

- The HavanДокумент8 страницThe Havanvarshneyrk@rediffmail.comОценок пока нет

- The HavanДокумент8 страницThe Havanvarshneyrk@rediffmail.comОценок пока нет

- Gsip Brochure FinalДокумент5 страницGsip Brochure FinalMd IslamОценок пока нет

- Npti CT FanДокумент17 страницNpti CT Fanrashm006ranjanОценок пока нет

- Candle and Home Fragrance Gift Sets with PricesДокумент26 страницCandle and Home Fragrance Gift Sets with Pricesvarshneyrk@rediffmail.comОценок пока нет

- Cooling TowersДокумент19 страницCooling Towersvarshneyrk@rediffmail.comОценок пока нет

- Car Park Systems 2011-08 en E4081 KleinДокумент16 страницCar Park Systems 2011-08 en E4081 Kleinvarshneyrk@rediffmail.comОценок пока нет

- Ifsc-Code of Icici Bank Branches in IndiaДокумент10 725 страницIfsc-Code of Icici Bank Branches in IndiaVenkatachalam KolandhasamyОценок пока нет

- AIRAH Heat Load Fact SheetДокумент3 страницыAIRAH Heat Load Fact Sheetvarshneyrk@rediffmail.comОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Cambridge IGCSE: Chemistry 0620/21Документ16 страницCambridge IGCSE: Chemistry 0620/21Mina AbdouОценок пока нет

- Gujarat Fluorochemicals: IndiaДокумент55 страницGujarat Fluorochemicals: IndiaSathwik PadamОценок пока нет

- Sikaflex®-400 Fire: Product Data SheetДокумент4 страницыSikaflex®-400 Fire: Product Data SheetLA BoiserОценок пока нет

- Diffusion and Osmosis LabДокумент11 страницDiffusion and Osmosis Labapi-255906283Оценок пока нет

- Me 8301 EtdДокумент3 страницыMe 8301 Etdsrinithims78Оценок пока нет

- GD NORM VS8500 - AMS - BB026CA - Eng-Ita 2021-01-05Документ2 страницыGD NORM VS8500 - AMS - BB026CA - Eng-Ita 2021-01-05Trần Thanh ViệnОценок пока нет

- MBH Metals CatalogueДокумент56 страницMBH Metals CataloguetaichiОценок пока нет

- Adsorption, Corrosion Inhibition Mechanism, and Computational Studies of Aza Indica For Mild SteelДокумент16 страницAdsorption, Corrosion Inhibition Mechanism, and Computational Studies of Aza Indica For Mild Steeldanish.hakeem251Оценок пока нет

- Ingredients and Formulation of Laundry DetergentДокумент34 страницыIngredients and Formulation of Laundry DetergentMuhammad Usman Hameed80% (5)

- 2018 Gen Ed Reviewer: Chemistry: Welcome To LET Exam Questions and Answers!!!Документ28 страниц2018 Gen Ed Reviewer: Chemistry: Welcome To LET Exam Questions and Answers!!!Christine Grace IlanОценок пока нет

- The Group 1a and Group 2a Elements PDFДокумент36 страницThe Group 1a and Group 2a Elements PDFEZ RioОценок пока нет

- Filters and Beam Restrictors in RadiologyДокумент19 страницFilters and Beam Restrictors in RadiologyPratap singhОценок пока нет

- 2020-Microbial Nanotechnology For Bioremediation of Industrial WastewaterДокумент8 страниц2020-Microbial Nanotechnology For Bioremediation of Industrial WastewaterAmin ZamaniОценок пока нет

- Excellent Extended Essay (Chemistry)Документ38 страницExcellent Extended Essay (Chemistry)Aqeel JariwallaОценок пока нет

- New Way of Hydroquinone and Catechol Synthesis Using NitrousДокумент10 страницNew Way of Hydroquinone and Catechol Synthesis Using NitrousCintia Andrade MoóОценок пока нет

- Problemset4 3Документ1 страницаProblemset4 3Gregory Eleazar D. AngelesОценок пока нет

- Mineralogi Part.2 3Документ10 страницMineralogi Part.2 3Roges tomara mahesa100% (2)

- Maneurop NTZ Low Temp - Refrigeration CompressorsДокумент32 страницыManeurop NTZ Low Temp - Refrigeration CompressorsMacSparesОценок пока нет

- Milk, An Excerpt From American Farmstead CheeseДокумент14 страницMilk, An Excerpt From American Farmstead CheeseChelsea Green PublishingОценок пока нет

- Lecture 1Документ22 страницыLecture 1Devakan BalaganeshОценок пока нет

- VERSAMUL - Product BulletinДокумент2 страницыVERSAMUL - Product BulletinIgorCencičОценок пока нет

- Polymist F5A: PolytetrafluoroethyleneДокумент3 страницыPolymist F5A: PolytetrafluoroethyleneRobert MorrisОценок пока нет

- SemiconductorsДокумент37 страницSemiconductorsANSHU RAJОценок пока нет

- VLSI Epitaxy and Thin Film DepositionДокумент20 страницVLSI Epitaxy and Thin Film DepositionRubel RiadОценок пока нет

- MSE Admission and Degree RequirementsДокумент6 страницMSE Admission and Degree Requirementsdeathbuddy_87Оценок пока нет

- HUGPS209Документ13 страницHUGPS209Aditya KavuluriОценок пока нет

- High-Performance Concrete Characteristics and PropertiesДокумент16 страницHigh-Performance Concrete Characteristics and PropertiesChukwuma OgbonnaОценок пока нет

- Sweeper & Vacuum TruckДокумент8 страницSweeper & Vacuum TruckAfryanto BuliОценок пока нет

- Dokumen - Tips Raphex 2001 Cloud Object Storage Store Retrieve Data s3 2012-04-30raphexДокумент40 страницDokumen - Tips Raphex 2001 Cloud Object Storage Store Retrieve Data s3 2012-04-30raphexRuan MouraОценок пока нет

- MSE Strength and PropertiesДокумент20 страницMSE Strength and PropertiesEdrian A. MañalongОценок пока нет