Академический Документы

Профессиональный Документы

Культура Документы

ZZZZ

Загружено:

HITESHRISHIОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ZZZZ

Загружено:

HITESHRISHIАвторское право:

Доступные форматы

I have posted many battery charger circuits in this site, some are easy to build but less efficient,

while some are too sophisticated involving complex construction steps. The one posted here is possibly the easiset with its concept and also is extremely easy to build. In fact if you had all the required material you would build it within 15 minutes of time. The concept is indeed hugely simple and therefore pretty crude with its going. This means that though this idea is too simple, would require appropriate monitoring of the charging conditions of the battery, so that it does not get over charged or damaged. To make this simplest battery charger circuit quickly, you would require the following bill of materials:

One rectifier diode, 1N5402

An incandescent bulb, having voltage rating equal to the battery which needs to be charged and current rating close to 1/10th of the battery AH.

A transformer having voltage rating equal to twice that of the battery voltage and current twice the charging rate of the battery. That means if the battery is 12V, the transformer should be 24V, and if the AH of the battery is 7.5 then dividing this by 10 gives 750mA which becomes the recommended charging rate of the battery, multiplying this by 2 gives 1.5Amps, so this becomes the required current rating of the transformer.

After you have collected all the above material, you may simply connect the above parameters together with the help of the diagram. The functioning of the circuit may be explained in the following manner: When the power is switched ON, the 1N5402 diode rectifies the 24V DC to produce half wave 24V DC at the output. Though the RMS value of this voltage may appear to be 12V, the peak voltage is still 24V, therefore it cannot be applied directly to the battery. To blunt of this peak value, we introduce a bulb in series with the circuit. The bulb absorbs the high peak values of the voltage and provides a relatively controlled output to the battery, which becomes self regulatory through the glow of the filament intensity of

the bulb (varying resistance). The voltage and current thus automatically becomes adjusted to appropriate charging levels which becomes just suitable for the battery safe charging. The charging of the battery can be witnessed by the gradual dimming of the bulb as the threshold charging voltage of the battery is reached. However once the battery voltage reaches close to 14.5V, the charging must be stopped, irrespective of the bulb glow condition.

Step 1: The circuit and what you need

The circuit is very simple. I used a piece of plywood for a base. I already had a double pole toggle switch. I used a piece of scrap aluminum cabinet angle to mount the switch. Any piece of aluminum or steel could be bent to do the job. I used a 4 Amp. bridge rectifier from Radio Shack. I also got aligator clips already connected to a cord to connect to the auto battery. This was also from Radio Shack. The AC cord and plug came from a neighbor's discarded televison set that was put out on the curb on garbage day. You will need some screws, soldering iron, and a hot glue gun.

Step 2: Mount the transformer and attach the line cord

Use screws to mount the transformer on the plywood base. Solder the ends of the power cord to the primary terminals of the transformer. I used a hot glue gun to cover the solder joints in order to protect against electrical shock. Hot glue is great for this. Be patient and let the first layer of glue harden so you can build the glue up for adequate protection. From the photo you can see the details of the strain relief I made to hold the cord in place.

Step 3: Mount the switch and wire it.

Use the circuit diagram to wire the transformer secondary terminals to the switch. The aluminum angle is held to the base with screws. Label the switch positions for 6 and 12 volts.

Step 4: Wire the rectifier.

Of course you can use individual diodes to make a bridge rectifier. I found it easier to get a rectifier ready to use. I bent the input (AC) leads in one direction and the output (DC) leads in the other direction. This made a convenient base or support for the rectifier. It is a good idea to use a heat sink when soldering diodes to protect them from too much heat. Put a rubber band on the handles of a needle nose plier and clamp the plier jaws on the lead you want to solder. Watch the output polarity so the + terminal on the rectifier connects to the wire for the red aligator clip. I simply glued the bridge rectifier to the plywood with hot glue. Notice the strain relief for the output cord. To use: Select 6 or 12 volts with the switch. Connect the red aligator clip to the red battery terminal and the black to the black. Set the base of the charger someplace safe. Plug in the AC cord. Disconnect the AC cord after 12 or more hours. Then disconnect the aligator clips from the battery. This prevents sparking that could possibly ignite hydrogen gas from the charging. I have also used this charger as a power supply for things like a hot wire cutter. A smoothing capacitor is not necessary because batteries charge better with slightly choppy current.

Вам также может понравиться

- Cs Lab IVSem ECEДокумент86 страницCs Lab IVSem ECEAnonymous G5D0xzq2Оценок пока нет

- Official Rules and Regulations - 2017 Hello Cloud ChallengeДокумент6 страницOfficial Rules and Regulations - 2017 Hello Cloud ChallengeHITESHRISHIОценок пока нет

- Cs Lab IVSem ECEДокумент86 страницCs Lab IVSem ECEAnonymous G5D0xzq2Оценок пока нет

- Implement linear array operationsДокумент113 страницImplement linear array operationsHITESHRISHIОценок пока нет

- Implement linear array operationsДокумент113 страницImplement linear array operationsHITESHRISHIОценок пока нет

- Draft Academic Calendar: For TheДокумент3 страницыDraft Academic Calendar: For TheHITESHRISHIОценок пока нет

- The Transistor Amplifier: Understanding Faults and Improving Circuit DesignДокумент75 страницThe Transistor Amplifier: Understanding Faults and Improving Circuit DesignHITESHRISHIОценок пока нет

- TypeДокумент14 страницTypeHITESHRISHIОценок пока нет

- Ict C++Документ14 страницIct C++HITESHRISHI100% (2)

- 294Документ30 страниц294Arun ChungappallyОценок пока нет

- XyzДокумент6 страницXyzHITESHRISHIОценок пока нет

- This Is To Certify That Student of Has Done The Project Work On Under My Supervision and Guidance With My Full Satisfaction in The Stipulated Time PeriodДокумент1 страницаThis Is To Certify That Student of Has Done The Project Work On Under My Supervision and Guidance With My Full Satisfaction in The Stipulated Time PeriodHITESHRISHIОценок пока нет

- Project Supporting ContentДокумент14 страницProject Supporting ContentHITESHRISHIОценок пока нет

- Project Supporting ContentДокумент14 страницProject Supporting ContentHITESHRISHIОценок пока нет

- 47ce43646e452project XiiДокумент15 страниц47ce43646e452project XiimannuОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- PPA Status List 066-067 18 OCTДокумент8 страницPPA Status List 066-067 18 OCTPradeepОценок пока нет

- Ecm C18 PDFДокумент9 страницEcm C18 PDFomarОценок пока нет

- 12HRL140 HRL Series: ModelДокумент2 страницы12HRL140 HRL Series: ModelJesusОценок пока нет

- SMPS Design TutorialДокумент18 страницSMPS Design TutorialRuve Baba100% (6)

- Instruction Manual For Modular Calibration System MCS100Документ84 страницыInstruction Manual For Modular Calibration System MCS100Mo AsarОценок пока нет

- 615 Series General Presentation - 756700 - ENgДокумент75 страниц615 Series General Presentation - 756700 - ENgmarcondesmague1Оценок пока нет

- New 3-Level Topology For Efficient Solar Applications: Power ConvertersДокумент3 страницыNew 3-Level Topology For Efficient Solar Applications: Power ConvertersfgokcegozОценок пока нет

- Zelio Analog RMCA61BDДокумент2 страницыZelio Analog RMCA61BDZorantdjОценок пока нет

- RTU Training DIGSI Training DIGSI001 5Документ97 страницRTU Training DIGSI Training DIGSI001 5Ratheesh KumarОценок пока нет

- Pe 26 Ee17Документ23 страницыPe 26 Ee17Syed AfzalОценок пока нет

- Report For A Power Supply With A Rated Output of 9.9V /1aДокумент8 страницReport For A Power Supply With A Rated Output of 9.9V /1aSend noobsОценок пока нет

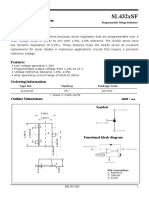

- SL432xSF: DescriptionДокумент5 страницSL432xSF: Descriptionserrano.flia.coОценок пока нет

- What Is The Turns Ratio For A Resistance Welding Transformer - How-To Resistance WeldДокумент4 страницыWhat Is The Turns Ratio For A Resistance Welding Transformer - How-To Resistance Weldmohamed lamine elbiskriОценок пока нет

- Communications Site Installation: CSII/R56 Installer Version Competency RequirementsДокумент6 страницCommunications Site Installation: CSII/R56 Installer Version Competency Requirementswiyah1610Оценок пока нет

- Chapter 3-Lossy CapacitorsДокумент24 страницыChapter 3-Lossy Capacitorsmarceloassilva7992Оценок пока нет

- Aircraft Electrical Systems GuideДокумент16 страницAircraft Electrical Systems GuideEvan TubaleОценок пока нет

- P R O F I L E Steel Salem PDFДокумент7 страницP R O F I L E Steel Salem PDFmusham90% (1)

- QuestionnaireДокумент3 страницыQuestionnairepushp8363Оценок пока нет

- DGI300 Manual 4.1Документ154 страницыDGI300 Manual 4.1Caraiane Catalin100% (2)

- Kries-Energietechnik Catalogue 8 2017 EДокумент88 страницKries-Energietechnik Catalogue 8 2017 EANTONIO SOLISОценок пока нет

- Dong Fang HistoryДокумент55 страницDong Fang Historyramnadh803181Оценок пока нет

- Slow-Front OvervoltagesДокумент30 страницSlow-Front Overvoltagessorry2qazОценок пока нет

- Annexure-II Nalco Spec.Документ1 страницаAnnexure-II Nalco Spec.techbhazОценок пока нет

- 330DДокумент2 страницы330DAlex Consuegra MedinaОценок пока нет

- Fluke Type 73 Digital MultimeterДокумент7 страницFluke Type 73 Digital MultimeterAbiyot AderieОценок пока нет

- Xux0Aksam12: Product Data SheetДокумент2 страницыXux0Aksam12: Product Data SheetGenesis SolanoОценок пока нет

- High Volteage EngineeringДокумент5 страницHigh Volteage EngineeringSenthil NathanОценок пока нет

- Field Test On DC Series MotorДокумент6 страницField Test On DC Series MotorsanjuОценок пока нет

- Miele Coffee Maker Cva - 4070 - EncaДокумент6 страницMiele Coffee Maker Cva - 4070 - EncaJim LawlerОценок пока нет

- Centre-Break Disconnectors GuideДокумент2 страницыCentre-Break Disconnectors Guidechock channel 19Оценок пока нет