Академический Документы

Профессиональный Документы

Культура Документы

Lecture11b - Basic Gaslift Sec 2 - Hardware

Загружено:

reborn2Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lecture11b - Basic Gaslift Sec 2 - Hardware

Загружено:

reborn2Авторское право:

Доступные форматы

Gas Lift

Production Technology

Lecture 11b - Gas Lift, Section 2 - Hardware

Recommended Texts: Handout and

Artificial A ifi i l Lift Lif Methods, M h d Kermit E. Brown, Volume 2a PennWell Publishing Co, Tulsa, OK, 1980

Akim Kabir Senior Lecturer Department of Petroleum Engineering Curtin University of Technology

Aug 2008

Section 2 - Hardware

Slide 1

Gas Lift

Schematic of Surface System

COMPRESSION STATION GAS LIFTED WELL EXPORT LINE PROCESS GAS/OIL SEPARATOR

WELL LBORE

FLOWLINE

SURFACE FACILITIES NEAR WELLBORE REGION

Section 2 - Hardware

Slide 2

Gas Lift

Gas lift System

FTHP Liftgas bubbling up the well, lightening the fluid column in the well

Produced Fluids + Lift Gas

Low Pressure gas High Pressure Gas

S Separator

CHP Gaslift Compressor

Liquid

Lift gas injected at the deepest mandrel Pwf

Section 2 - Hardware

Slide 3

Gas Lift

Subsurface Gas Lift Equipment

High Pressure Lift Gas Casing Produced Fluids + Lift Gas

Tubing

Unloading valves (Closed after Unloading) Operating Valve (Always open)

Tubing, Casing, Packer, Mandrels and Gas Lift valves Gaslift Valves are housed inside the mandrels and the mandrels is part of the tubing g Upper valves are for unloading Bottom valve is for operation

Casing/Tubin g Annulus

Packer

Reservoir

Perforations

Section 2 - Hardware

Slide 4

Gas Lift

Gas Lift Mandrels

5 1/2 MMRG-4, 1 1/2 POCKET ROUND OU MANDREL DESIGN SG

Orienting Sleeve Tool Discriminator G Latch Lug Polished Seal Bore

CAMCO

ENGINEERING DATA

PART NUMBER SIZE MAX O O.D. D MIN I.D. DRIFT I.D. THREAD TEST PRESSURE INTERNAL TEST PRESSURE EXTERNAL LATCH TYPE KICKOVER TOOL RUNNING TOOL PULLING TOOL MATERIAL TENSILE STRENGTH (EOEC) 05712-000-00001 5 1/2 7 982 7.982 4.756 4.653 17 LB/FT MANN BDS B x P 7740 PSI 6280 PSI RK, RK-1, RKP, RK-SP OM-1, OM-1M, OM-1S RK-1 15079 1 5/8 JDS 15155 410 S.S., , 13 CR 22 HRC MAX 490,000 LBS

Section 2 - Hardware

Slide 5

Gas Lift

Gas Lift Mandrels

CAMCO

A Tubing Retrievable Mandrel A.

B A Side Pocket Mandrel B.

Section 2 - Hardware

Slide 6

Gas Lift

Gas G s lift Valve V ve Features e u es

Bellows protection g Max dome charge Check valve Stem travel Metallurgy Elastomers Max fluid rate

Top Latch

Section 2 - Hardware

Slide 7

Gas Lift

IPO O G/L G/ Valve V ve Components Co po e s

Check valve to hold in nitrogen charge Dome area which holds nitrogen pressure charge Valve bellows. Grows in length with internal pressure. pressure Valve stem with ball tip Valve seat Valve choke Check valve. Seats when fluid velocity is in upward direction.

Section 2 - Hardware

Slide 8

Gas Lift

Gaslift G s V Valve ve Installation s o

A gas lift valve is run and pulled with a special kickover pulling tool

Section 2 - Hardware

Slide 9

Gas Lift

Type ype o of G Gas s Lift V Valves ves

3 basic types of gas lift valves, each available in 1 & 1-1/2 sizes:

Dummy valves l

Orifice valves l

Square edged (DKO-2) Venturi (nova)

Unloading valves l

Injection pressure (casing) operated valve (BK-1) production pressure (fluid) operated valve (BKR-5, RF-1) Throttling/proportional response valve (LM-16R) Combination valve

Section 2 - Hardware

Slide 10

Gas Lift

IPO O Valve V ve

Advantages

Flexible to uncertainty of well data External control rather than well control Re-opening of unloading valves can be avoided

Disadvantages

Requires higher injection pressure Field personnel need to intervene once the well is unloaded and flowing to reduce injection pressure to close the unloading valves If well quit quit, unplanned shutdowns shutdowns, etc. etc operator need to readjust injection gas

Section 2 - Hardware

Slide 11

Gas Lift

PPO O Valve V ve

The commonly Th l used d type t of f gaslift lift valve l i in d dual l completion wells is Production Pressure Operated Gaslift Valve (PPO) Ad Advantage t

Utilizes full injection pressure at operating valve depth Deeper injection depth Little attention by field personnel

Disadvantage

More mandrels/Valves needed than pressure operated design Needs accurate well data. Increase in Water Cut/FTHP can cause the shallower valves to re-open

Section 2 - Hardware

Slide 12

Gas Lift

Unloading Gas Lift Valve Design

Normally required during unloading phase only Open O only l when h tubing t bi and d annulus pressures are high enough to overcome valve setting pressure Valve a ec closes oses a after te t transfer a s e to next station May y be spring p g or nitrogen g charged

Pb Dome

Chevron Packing g Stack Bellows

Stem Tip (Ball) Square Edged Seat

Pc

Pt Chevron Packing Stack

Check Valve

Production Pressure operated gas lift valve

Section 2 - Hardware

Slide 13

Gas Lift

A Pressure Regulator

If Pupstream > Pset, valve opens and maintains Upsteram Pressure = Pset

Diaphragm/ Atmospheric Bellows Spring

Stem Stem Tip Upstream Downstream Port Pressure Regulator

Section 2 - Hardware

Slide 14

Gas Lift

Gas Lift Valve Mechanics (IPO)

Diaphragm/ Atmospheric Bellows Spring

Stem Stem Tip Upstream Downstream Port Pressure Regulator

Upstream /Casing

Downstream / Tubing Spring p g Operated p Gas Lift Valve

Slide 15

Section 2 - Hardware

Gas Lift

Orifice Valves

THERE ARE 2 TYPES OF ORIFICE VALVE: SQUARED EDGED ORIFICE VENTURI (NOVA) Designed for accurate acc rate gas passage prediction. O One-way check h k valve l for f tubing bi integrity. i i

Section 2 - Hardware

Slide 16

Gas Lift

Characteristics of a Square Edge Orifice

200 180

Flow Rate e (MCF/d)

160 140 120 100 80 60 40 20 0 0 100 200 300 400 500 600

Large sub-critical flow regime

The Square-edged q g orifice performance curve

Gas passage dependent on downstream pressure until 40 - 50% pressure lost Poor pressure recovery = large pressure drop & large energy loss

Tubing Pressure

Section 2 - Hardware

Slide 17

Gas Lift

Plot o of o Gas G s Rate e Versus Ve sus Pressure essu e

Gas passage for the square edge orifice

ORIFICE FLOW SUB-CRITICAL FLOW

GAS IN NJECTION N RATE (MM MSCF/D)

PTUBING = 55%

PRESSURE (PSI)

Section 2 - Hardware

PCASING

Slide 18

Gas Lift

Nova Valve Nov V ve

Venturi Valve (orifice type)

Typically an orifice orifice type Gas lift valve always open - allows gas passage whenever correct differential exists Achieved critical flow with Delta P of 100 psi Gas injection controlled by size and differential across replaceable p choke Check valve prevents reverse flow of well fluids from the production conduit

Section 2 - Hardware

Slide 19

Gas Lift

Operating Ope g Principles c p es o of the e Ve Venturi u

THE VENTURI DESIGN ALLOWS THE FOLLOWING :

BETTER PRESSURE & ENERGY RECOVERY LOWER DISCHARGE COEFFICIENT DRASTICALLY REDUCED SUB-CRITICAL FLOW REGIME CRITICAL VELOCITY (VELOCITY OF PRESSURE TRANSMISSION/SONIC VELOCITY) ATTAINED WITHIN 10% PRESSURE DROP REDUCES INFLUENCE OF DOWNSTREAM PRESSURE ON GAS PASSAGE = REDUCED RISK TO PROPAGATING INSTABILITY

Nozzle-Venturi Gas Lift Valve Project P Pressure vs. Flow Fl R Rate t S Summary

4000 3500

1400 psi Upstream

f/d) /d) ow Rate (Mcf/ Flo

3000 2500 2000 1500 1000 500 0 0 200 400 600 800 1000 1200 1400

400 psi Upstream 900 psi Upstream Improved Orifice Valve Conventional Orifice Valve

Downstream Pressure (psi)

Data shown is from actual flow tests

Section 2 - Hardware

Slide 20

Gas Lift

Nova Versus Nov Ve sus Square Squ e Edge dge O Orifice ce

GAS INJEC G CTION RAT TE (MMSCF F/D) CRITICAL FLOW

SUB-CRITICAL FLOW

CRITICAL FLOW

PTUBING = 55%

PTUBING = 90%

PRESSURE ( (PSI) )

PCASING

Section 2 - Hardware

Slide 21

Вам также может понравиться

- Coring Guidelines for Unconsolidated SedimentsДокумент26 страницCoring Guidelines for Unconsolidated Sedimentsreborn2Оценок пока нет

- Lecture12b - Basic Gaslift Sec 5 - Mandrel Spacing DesignДокумент14 страницLecture12b - Basic Gaslift Sec 5 - Mandrel Spacing Designreborn2100% (1)

- Directional DrillingДокумент92 страницыDirectional Drillingreborn2100% (6)

- Coiled Tubing CompletionДокумент9 страницCoiled Tubing Completionreborn2Оценок пока нет

- Lecture11c - Basic Gaslift Sec 3 - Opening and Closing and TRO Pressure CalculationДокумент36 страницLecture11c - Basic Gaslift Sec 3 - Opening and Closing and TRO Pressure Calculationreborn2100% (4)

- Discret IzationДокумент20 страницDiscret Izationreborn2Оценок пока нет

- Beachbody Diet Guide PDFДокумент8 страницBeachbody Diet Guide PDFIbad MohammedОценок пока нет

- Cement PlugsДокумент15 страницCement Plugsreborn2Оценок пока нет

- AADE-13-FTCE-17 - 2-Development of Unique Equipment and Materials With Field Applications To Stop Sever Lost CirculationДокумент11 страницAADE-13-FTCE-17 - 2-Development of Unique Equipment and Materials With Field Applications To Stop Sever Lost Circulationreborn2Оценок пока нет

- DerivationДокумент31 страницаDerivationreborn2100% (1)

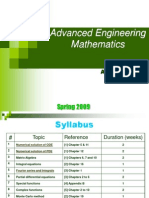

- ADVANCED ENGINEERING MATHEMATICS SYLLABUSДокумент145 страницADVANCED ENGINEERING MATHEMATICS SYLLABUSreborn2100% (2)

- Wireline Pipe Recovery Considerations in Stuck Drill Pipe SituationsДокумент6 страницWireline Pipe Recovery Considerations in Stuck Drill Pipe Situationsreborn2Оценок пока нет

- Mathematical Modelling LectureДокумент10 страницMathematical Modelling Lecturereborn2Оценок пока нет

- Eclipse 100Документ43 страницыEclipse 100zemabderОценок пока нет

- Compositional SimulationДокумент14 страницCompositional Simulationreborn2100% (1)

- Lecture12a - Basic Gaslift Sec 4 - UnloadingДокумент28 страницLecture12a - Basic Gaslift Sec 4 - Unloadingreborn2100% (2)

- Cementing CatalogДокумент18 страницCementing Catalogreborn2Оценок пока нет

- Condensation and AdditionДокумент4 страницыCondensation and Additionapi-3774614Оценок пока нет

- Heinemann - Reservoir Fluids PropertiesДокумент155 страницHeinemann - Reservoir Fluids Propertiesrake1981Оценок пока нет

- Types of CompletionДокумент23 страницыTypes of Completionreborn2Оценок пока нет

- Lecture11a - Basic Gaslift Sec 1 - PrinciplesДокумент35 страницLecture11a - Basic Gaslift Sec 1 - Principlesreborn2100% (3)

- Reaction TypesДокумент10 страницReaction TypesaqibazizkhanОценок пока нет

- Coiled Tubing CompletionДокумент9 страницCoiled Tubing Completionreborn2Оценок пока нет

- Types of CompletionДокумент23 страницыTypes of Completionreborn2Оценок пока нет

- Well Completion PlanningДокумент13 страницWell Completion Planningreborn2100% (1)

- Introduction to Well CompletionsДокумент20 страницIntroduction to Well Completionsreborn2100% (3)

- Capillary Pressure and Rock Wettability Effects On Wireline Formation Tester Measurements PDFДокумент16 страницCapillary Pressure and Rock Wettability Effects On Wireline Formation Tester Measurements PDFreborn2Оценок пока нет

- Basic Well Control PDFДокумент187 страницBasic Well Control PDFkerron_rekhaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- TECA Mechanical Ventilation Checklist 4 2014Документ2 страницыTECA Mechanical Ventilation Checklist 4 2014ridОценок пока нет

- The Projects of Skunk Works - 75 Years of Lockheed Martin's Advanced Development ProgramsДокумент523 страницыThe Projects of Skunk Works - 75 Years of Lockheed Martin's Advanced Development ProgramsAmerigo Zamper86% (7)

- Stem Paper Airplane Challenge Time FortakeoffДокумент92 страницыStem Paper Airplane Challenge Time FortakeoffYEO YIT JUAN MoeОценок пока нет

- MFR Nara - t8 - Faa - Dion Richard - 9-22-03 - 01151Документ2 страницыMFR Nara - t8 - Faa - Dion Richard - 9-22-03 - 011519/11 Document ArchiveОценок пока нет

- Baw106 Omdb-Egll (20 Jul 2155 Utc)Документ30 страницBaw106 Omdb-Egll (20 Jul 2155 Utc)cpa744Оценок пока нет

- Long Range Technical Training Manual A330 GE CF6 - T1/T1+T2, CMQ T1/T1+T2 Debriefing SchematicsДокумент23 страницыLong Range Technical Training Manual A330 GE CF6 - T1/T1+T2, CMQ T1/T1+T2 Debriefing SchematicsAlexis Dumontroty100% (1)

- Epm Manual Prima PRO Sentinel PROДокумент203 страницыEpm Manual Prima PRO Sentinel PROGloria HamiltonОценок пока нет

- Durham Fluent Tutorial GuideДокумент6 страницDurham Fluent Tutorial GuidenavidelecОценок пока нет

- Design and Fabrication of Small Scale Trainer AircraftДокумент24 страницыDesign and Fabrication of Small Scale Trainer AircraftTarik Hassan ElsonniОценок пока нет

- The Epic Story of The Fastest Ride in History Though The Heart of The Grand Canyon: THE EMERALD MILE by Kevin FedarkoДокумент33 страницыThe Epic Story of The Fastest Ride in History Though The Heart of The Grand Canyon: THE EMERALD MILE by Kevin FedarkoSimon and SchusterОценок пока нет

- Cirrus: SR22 / SR22T WM Temporary Revision 31-60-02 Indicating/Recording SystemДокумент3 страницыCirrus: SR22 / SR22T WM Temporary Revision 31-60-02 Indicating/Recording Systemmidun0% (1)

- Occupant Load CalculatorДокумент2 страницыOccupant Load CalculatorDaryl Gomez TimatimОценок пока нет

- 27 Flight ControlsДокумент6 страниц27 Flight ControlsAhmed Abdoul ZaherОценок пока нет

- NASA: 71283main 03-051Документ2 страницыNASA: 71283main 03-051NASAdocumentsОценок пока нет

- 07a82104 HelicopterengineeringДокумент7 страниц07a82104 Helicopterengineeringanand1540Оценок пока нет

- The Martian Andy WeirДокумент5 страницThe Martian Andy WeirPuke 2Оценок пока нет

- 6 Turbo-Expander Case History - EmersonДокумент11 страниц6 Turbo-Expander Case History - EmersonxinghustОценок пока нет

- TutorialДокумент69 страницTutorialManoj MahendrakarОценок пока нет

- Mil Mi-8 Startup Manual and ChecklistДокумент13 страницMil Mi-8 Startup Manual and ChecklistOscar Alfonso100% (2)

- Project Pulse Jet EngineДокумент18 страницProject Pulse Jet EngineJoel Kevin SaldanhaОценок пока нет

- IHP Pneumatic SymbolsДокумент4 страницыIHP Pneumatic SymbolsBIPIN SHARMAОценок пока нет

- LETO (Torrejon) : General InfoДокумент39 страницLETO (Torrejon) : General InfoMiguel Angel MartinОценок пока нет

- Robot: Past Present and FutureДокумент22 страницыRobot: Past Present and FutureHareesha N GОценок пока нет

- Level III - Ata 51 StructureДокумент244 страницыLevel III - Ata 51 Structurewagdi100% (1)

- LM - 4663 PDFДокумент13 страницLM - 4663 PDFDaniel Arcia JiménezОценок пока нет

- 737ng Acms CodesДокумент13 страниц737ng Acms CodesSamitha Ruwan Kumara100% (2)

- Sharma - R Bird Aviation, Vereeniging Airport. 1936 Z3834920Документ3 страницыSharma - R Bird Aviation, Vereeniging Airport. 1936 Z3834920Raveena SharmaОценок пока нет

- MRC A 10 Warthog PDFДокумент24 страницыMRC A 10 Warthog PDFRonny FitriadiОценок пока нет

- Electronic Installations and Service-Parts Manual PDFДокумент745 страницElectronic Installations and Service-Parts Manual PDFmastrangelo2973100% (3)

- Types of Stress On ShipsДокумент4 страницыTypes of Stress On Shipssumedhb21Оценок пока нет