Академический Документы

Профессиональный Документы

Культура Документы

A.1 Job Spec Boiler Package Rev B

Загружено:

prashant937Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A.1 Job Spec Boiler Package Rev B

Загружено:

prashant937Авторское право:

Доступные форматы

Page 1 of 30

HINDUSTAN PETROLEUM CORPORATION LIMITED MUMBAI REFINERY

DOCUMENT NO: 44-LK-5100-712/M.02/0013/A4 TITLE: JOB SPECIFICATION FOR UTILITY BOILER PACKAGE

Rev No. A B

Issue Date 12-Nov-08 02-April-09

Pages 30 30

Rev Description Issued for HPCL comments Revised as per HPCL comments

Prepared By KP KP

Checked By PDB PDB

Approved By SNG SNG

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 2 of 30

TABLE OF CONTENTS

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

GENERAL BASIC DESIGN TECHNICAL REQUIREMENTS BATTERY LIMITS INSPECTION AND TESTING FIELD TEST GUARANTEES PROTECTION AND PAINTING PACKAGING AND IDENTIFICATION SPARE PARTS

3 8 12 25 27 28 28 29 30 30

A.1_Job_spec_Boiler_Package_rev B.doc

Page 3 of 30

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

1.0

1.1

GENERAL

This specification outlines the minimum requirements under which the manufacturer shall design, engineer, manufacture, assemble, erection, commission, test, prove mechanical and performance guarantee, civil works on LSTK basis and supply of One No. of dual fuel (oil and gas) fired, water tube, natural circulation boiler package complete with all accessories mentioned in the specification. CODES AND STANDARDS The latest edition of following codes and standards shall govern unless specified Indian Boiler regulations : IBR Heat exchanger Institute : HEI Pressure vessels : ASME Sec VIII div 1 Centrifugal Fan (FD Fan) : API 673 Centrifugal pumps : API 610 Positive displacement pumps : API 676 for general refinery services Metering pumps : API 675 Code of practice for general : IS 803 Day tanks construction in steel Welded Steel Tanks for Oil : API 650 Storage Code of practice for design : IS 6533 and Construction of steel Chimneys Criteria of earthquake resistant : IS 1893 design of structures Codes of Practice for use of : IS 800 Structural Steel in general Building Construction Structural Steel : IS 2062 Power piping code : ANSI B 31.1 / IBR Acceptance tests for : Hydraulic Institute Standard centrifugal, mixed flow and axial pumps Mechanical Vibration, : ISO 1940 Balancing Quality Requirement Hand operated chain pulley : IS 3832 block Anti-Friction Bearing : AFBMA Manufacturers Association As per emission regulations, of : Air pollution control Central Board for the Prevention & Control of air / water pollution Board India. Noise control : OSHA Standards National fire protection : NFPA codes association Three phase induction motors : IS: 325 Performance testing of Steam : BS 845 Part I & Generation units ASME PTC 4.1-1964 By Indirect Heat loss method (R-1991) Performance test code for : ASME PTC 12.3 Deaerators

1.2 1.2.1

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4 : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : :

Page 4 of 30

AMCA 210 BS 848 Part I ASTM D 888 Method A (Colormetric Indigo Carmine) APHA method Material specification Pipe flanges & fittings ASME section VIII division 1 ASME section IX NFPA-496: 1998 ASHRAE 37 ASHRAE 52.1 ARI 430 AMCA 208 AMCA 204-96 AMCA 2404-99 AMCA 2410-99 IS:655 SMACNA SMACNA IS : 10773 IS 277:1992 IS : 660 IS : 659 IS : 5111 ARI 210 ARI 270 ARI 310 ARI 365 ARI-410 ARI 430 ARI : 520 ARI : 560 IS : 4894 OISD-118 1.2.2

Test code for air moving devices Methods of Testing performance of centrifugal fans Method for testing Oxygen content in liquid Method for testing Carbon Dioxide contents in liquid ASME Sec. II ANSI B 16.5, ANSI B 16.11, ANSI B 36.10 Welding and brazing qualifications Welding and brazing qualifications Standard for purged and pressurized enclosures for electrical equipment Methods of Testing for Rating Unitary AirConditioning and heat Pump Equipment Gravimetric and Dust Spot Procedures for Testing Air-Cleaning Devices used in General Ventilation for Removing Particulate matter Central Station Air Handling Units Field Performance Testing of Fans Balance Quality & Vibration levels for Fans Drive Arrangements for Centrifugal Fans Drive Arrangements for tubular Centrifugal Fans Metal air ducts HVAC Duct Construction Standards HVAC Systems Testing, Adjusting and Balancing Copper tubes for refrigeration purposes Specifications for galvanized steel sheets (Plain & Corrugated) Safety codes for mechanical refrigeration Safety code for air conditioning Code of practice and measurement for testing refrigeration compressors. Standard for Unitary Air Conditioning equipment Standard for application, installation and servicing for Unitary equipment Packaged Terminal Air Conditioners Commercial and Industrial Unitary Air Conditioning Condensing Units Standard for forced circulation air cooling and air heating coils Central Station Air Handling Units Standard for positive displacement refrigeration compressors and condensing units. Performance testing of machine Centrifugal fans Layout for oil and gas installations

Jacobs standards specification and data sheets Jacobs specification and data sheets as attached in RFQ and listed else where shall be referred and followed.

A.1_Job_spec_Boiler_Package_rev B.doc

Page 5 of 30 1.3 1.3.1

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

SCOPE OF SUPPLY Scope of work covers design, engineering, manufacture, assemble, inspection, testing, painting, packing, forwarding, supply, delivery at site, transferring material to erection site, erection, testing, commissioning, proving mechanical and performance guarantees, civil works on LSTK basis of One No of dual fuel (Oil and gas) fired, water tube, natural circulation boiler package and with its all auxiliaries complying to specification, data sheets and other documents attached with the RFQ: and consisting of following as a minimum. Steam drums with internals, water walls, super heaters and economiser with tubes and necessary inlet /outlet/intermediate headers, refractory settings, necessary insulation and cladding, support structures, furnace / convective section / super heater section access doors. Three-element level control arrangement, flow meter cum totaliser and safety valve on main steam header. Main steam stop valve (MSSV) including bypass valve near super heater outlet header, non-return valve in the main steam line etc. Furnace complete with water walls, headers, screens, down comer, risers and furnace bottom including seal plate. All boiler and furnace setting brickwork, all refractory and heat insulation materials, material required for installing refractory and aluminium sheet material for insulation finish. Fuel oil pumps (1W+1S), with necessary indicator/alarm for high/low level and temperature in day tank, piping, OWS in this area. Basket type pre-filters (1W +1S) at upstream of fuel oil pumps, fuel oil pre-heater (dual type: Electrical and steam), basket type after filters (1W +1S) downstream of fuel oil pre heater, fuel oil pumping unit, fuel oil circulating heater, fuel oil return piping. Dual fired burners (Operation with fuel oil /fuel gas with any combination of fuel gas should be possible), burner block, steam injection system, fuel gas pressure regulation system, fuel gas based pilot burner; LPG cylinder and Pilot flame assembly, cooling arrangement for scanner etc. Low NOx (oil /gas) fired burners with necessary modulating controls suitable for turndown ratio, igniters, ignition transformer, flame scanners, air register and scanner cooling system. Fuel gas knockout drum and automatic block and bleed arrangement on fuel gas line to fuel KOD. Mass flow meters on fuel oil supply and return line, flow meter cum totaliser for fuel oil and fuel gas, back pressure control valve to be provided between fuel oil supply and return line. Two Nos. (1W +1S) VFD operated Boiler feed water pumps (API) with drive motor complete with base frame, coupling, connecting flange, suction strainer, non-return valves, minimum flow recirculation valves, insulation and cladding. Two Nos. (1W +1S) Export BFW pumps (API) with min flow recirculation valve. Two Nos. (1W +1S) radial backward curved forced draught fan (FD) & Two Nos. (1W +1S) of Induced draught fan (ID) with VFD operated drive motor, suction silencer & inlet wire mesh filter (Changeable type), coupling, base frame, lubrication system, air flow measurement, insulation and lagging on FD fan, vibration probes, proximitors, RTDs for motor bearings, RTDs for motor windings, RTDs for fan bearing, manual isolation damper at FD fan outlet. Flow indicators for the air from the fans.

1.3.2

1.3.3 1.3.4 1.3.5 1.3.6

1.3.7

1.3.8

1.3.9 1.3.10 1.3.11

1.3.12 1.3.13

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 6 of 30

1.3.14 1.3.15 1.3.16

FD fan suction ducting, air ducting from FD fan to burner/ furnace Flue gas ducting from boiler to ID fan and from ID fan exhaust up to chimney/stack Inlet, expansion joints on ducts. Automatic and emergency operated soot blowers and control equipment for furnace, super-heater, boiler bank and economiser including all integral piping, control valves, pipe hangers and supports and enclosed floor mounting type soot blower control panel. Boiler mountings and fittings as per the relevant IBR act. Pressure reducing station and de-super heater for steam usage within the battery limit. All piping within battery limit including valves and fittings, strainers with necessary supports within the battery limit for steam, feed water, instrument air, drains, vents and blow-down, fuel, air and all other utilities. Temporary piping for start up and commissioning. All necessary instrumentation (inclusive of CO2, O2, SOx, NOx Analysers and flow meter cum totaliser for fuel) and controls with audio/ visual annunciation of alarms and running lights for all the drives on a control panel. All field and panel control wiring including hardware. Common fault annunciation signal on the common DCS. PLC based control panel, VSD panels etc. MCC for all electrical drive motors, UPS, local P. B station and field cablings with trays and supports along with earthing for all equipment within battery limit (refer electrical scope and SLD). Steam generating unit and auxiliary equipment supporting steel structure including superstructure and miscellaneous structural steel platforms, walkways, stairs, handrails, ladders, elevated corrugated metal galvalume roof supported by boiler steel structure to cover adequately the boiler, platforms, main steam stop valve reducing stations and other platforms and stairs. Necessary rainwater down-comer from these roofs up to the ground floor level, access door to furnace/convective section/super heater section. Boiler shall be kept under covered structural steel shed. Shed to be provided by vendor with monorails at required locations. Piping supports, pipe rack, cable rack for electrical and instrumentation cabling and trays, pipe supports and hangers, platform/access & platform within battery limit. Adequate number of access and observation doors for boiler furnace, economiser along with soot blowers, fans and ducts. Blow down flash drum/tank (to generate low pressure steam to be used for deaerator) and RCC pit. Blow down from blow down flash vessel up to B/L., insulation and lagging of tanks, blow down valve for CBD and IBD. HP and LP Chemical dosing system as required complete with mixing cum metering tank, agitators, and metering pumps with piping, valves and accessories. Duplex steel sample coolers suitable for sea water for boiler blow down, steam and feed water.

1.3.17 1.3.18 1.3.19

1.3.20

1.3.21 1.3.22

1.3.23

1.3.24

1.3.25 1.3.26

1.3.27 1.3.28

A.1_Job_spec_Boiler_Package_rev B.doc

Page 7 of 30 1.3.29 1.3.30 1.3.31 1.3.32 1.3.33 1.3.34 1.3.35 1.3.36 1.3.37 1.3.38

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

Deaerator with level control valve, pressure control valve, HV on steam line, online oxygen analyzer at outlet of deaerator, structure platform etc. DENOx facility along with sump for oily waste as described in clause No. 3.8.5 All cold and hot air ducts and necessary expansion joints, dampers, isolators support. All flue gas ducts up to chimney with necessary expansion joints, dampers and supports. A self-supporting carbon steel refractory lined chimney with platforms lightening arrestor strip, aviation lamps. All insulation and cladding for hot air and hot flue gas ducts, hot water and steam piping system within battery limit and other exposed hot surfaces as per attached specification. Flue gas analysis apparatus (gas to be analysed for CO, O2, NOx, SOx). Shelter for same with air conditioning. Provision for sampling points for flue gases. Flushing oil connectivity as per the requirement for congealing services. All necessary safety guards for moving parts, base plates, base frames for pump, blowers, etc. sleeves, anchor bolts, foundation bolts for equipment, structure, shim plates for alignment, nuts and washers. First fill of lubricants for all equipment within battery limit Chemical cleaning of system and Steam blowing. Necessary lifting tools and tackles like monorail, chain pulley block etc, supporting and runway beams for facilitating maintenance work of FD fans, ID Fans, BFW pumps, drive motors, etc. Painting as per specification. Mandatory spare parts as per list specified. Spares for commissioning / start-up of utility boiler package and preparation for shipment, packaging etc. Special tools and tackles crane accessories for erection and commissioning. Erection commissioning of complete package. Pre commissioning, hydro testing etc. Construction of all structural, stairs, platforms, sheds etc. Metallic side sheeting for shade. Carrying out performance guarantee test at site. IBR approval for boiler pressure parts and accessories coming under IBR preview. CCOE approval for tanks. All documentation as specified in the vendor document requirement. Inspection and testing as specified.

1.3.39 1.3.40 1.3.41

1.3.42 1.3.43 1.3.44 1.3.45 1.3.46 1.3.47 1.3.48 1.3.49 1.3.50

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100 1.3.51

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 8 of 30

All statutory approvals from local bodies like IBR, smoke nuisance authority, DGCA approval from civil aviation authority etc. including the liaison and coordination work in this respect. Any change/addition required to be made to meet the requirements and full satisfaction of the statutory authorities shall be carried by vendor free of charge. Vendor shall also provide all assistance for getting PCB approval wherever required. Development of equipment layout for utility boiler package within the space allocated indicated in the conceptual layout attached with the RFQ. For detail electrical scope of work refer the attached document ANNEXURE-1 (Scope of work electrical for utility boiler package) and single line diagram and requirements for HVAC. For detail instrumentation scope of work refer the attached document Standard specification for instrumentation work (Doc No. 44-LK-5100-00/J.02/0017-A4) and various requirements specified in this specification. Air conditioning system for VFD room / control room ; Supply of air conditioning units, supply and return ducts, duct supports, fire dampers, volume control dampers, supply and return grills, acoustic insulation for ducts, compete insulation for supply and return duct, MCC, cabling work, Instrumentation panels, instrumentation cabling. All civil design, detail engineering, construction of RCC foundations, pedestals, trenches, layout, paving requirement and grade slab drawing, supporting structures, good for construction drawings including all documentation, rebar schedules, MTO, construction drawings. Design, engineering, layout, construction of substation building including complete air conditioning package (system) for VFD / control room & fire proofing etc. Packing and forwarding. Mechanical guarantee and performance guarantee. Site performance test and instruments required for same. EXCLUSIONS The following shall be excluded from vendors scope of supply:

1.3.52 1.3.53

1.3.54

1.3.55

1.3.56

1.3.57 1.3.58 1.3.59 1.4

1.4.1 1.4.2 1.4.3

Supply of utilities at one point at the battery limit. Pipe rack up to boiler shed as indicated in conceptual equipment layout for boiler area (Drawing No. 44LK-5100-712-L.01-0204-A1). Fuel oil day tank

2.0

2.1

BASIC DESIGN

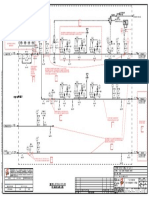

The design of utility boiler package shall meet the requirements specified in : 1. Data sheets. 2. P&IDs. 3. Job specification 4. Applicable codes, standards 5. Standard specifications In case of conflict between the above documents, most stringent shall be followed. However all conflicts shall be referred to the PMC/Owner for clarification and decision of PMC/Owner shall be final and binding on the bidder without any cost or delivery implication

A.1_Job_spec_Boiler_Package_rev B.doc

Page 9 of 30 2.2 2.3 2.4

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

Process data sheet is also attached along with specification. The attached PDS forms a design basis for the utility boiler package. Boiler area classification: Class 1, Division 2, Gas group C/D. Refer attached boiler area classification drawing. The Boiler and auxiliary equipment shall be sized for the following simultaneous conditions as a minimum: - Boiler net capacity of 100 TPH (without internal consumption) and steam pressure of 40 O Kg/cm2 (g) and temperature of 360 C at B/L. - Boiler internal steam requirements such as for deaerator, fuel oil atomization, tracing fuel heating, soot blowers etc. - Export BFW requirement of 50 TPH at specified temperature from deaerator. - Min. ambient temperature for combustion air - No condensate return - Lowest net calorific value among all fuels or combination of fuel gases - Temperature of flue gas min. 15 degrees above sulphur acid dew point in stack Boiler turn down shall be 25% of MCR. Boiler shall be capable of operating with an output of 110% of the MCR rating for a minimum thirty minutes in each of eight hrs shift. Specification of quality of steam shall be as follows: pH = > 8.3 Conductivity at 25 C = <0.2 micro siemens /cm Total silica = <0.02 mg/ lit Total iron = 0.01 mg/ lit max Total Cu = 0.003 mg/ lit max Sodium (Na + K) = 0.01 mg/ lit max The burners shall be dual fired low NOx type. Operation with fuel oil/ fuel gas with any composition of fuel gas shall be possible. For HSFO, LSFO and fuel gas (five cases) specifications refer Basic Engineering design basis (BEDB) Part-II. Deaerator shall be sized for export of 50 TPH BFW, in addition to the requirement for the boiler unit and internal consumption. Deaerator operation shall be able to meet the BFW export requirements even when boilers are out of service. Deaerator and DM water supply system shall be designed for no condensate return case. The feed water shall be mixture of DM water & Condensate return. The analysis is as follows. The condensate max. of 80% of BFW requirement only for Boiler net capacity shall be considered in boiler feed water. Condensate specifications: The pure condensate source shall be from the condensate collection system in DHT, HGU and SRU. The specifications of the condensate are as follows : S No. 1 Parameter Pure condensate source From condensate collection system from DHT, HGU and SRU

2.5 2.6

2.7 2.8 2.9

2.10 2.11

2.12

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100 2 3 4 2.13

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4 Supply pressure (Normal) Supply temperature Flow rate (Kg/hr) 5 Kg/cm2 G 80 Deg C Max 80% of boiler capacity

Page 10 of 30

DM water specifications: Sr. No. Parameter 1 pH value 2 Turbidity 3 Total hardness as CaCO3 4 Total silica (reactive) as CaCO3 5 Total iron as Fe 6 Conductivity@ 25 Deg C 7 Supply pressure (Min / Normal / max) 8 Design pressure 9 Supply temperature 10 Design temperature Polished condensate specifications:

6.5 to 7.0 < 1 NTU Nil < 0.02 mg/l 0.01 mg/l < 0.2 micromh/cm 6.0 /7.0 /8.0 Kg/cm2 G 11.5 Kg/cm2 G AMB 65 Deg C

2.14

The suspect condensate source shall be from condensate polishing unit. The specifications are as follows: Sr. No. 1 2 3 4 5 6 7 8 9 10 11 12 2.15 Parameter Suspect condensate source Supply pressure (Normal) Supply temperature Flow rate (Kg/hr) TDS Total silica Total iron Copper Organic substance Conductivity@ 20 Deg C Oil content (Hydrocarbon) Total hardness as CaCO3 Oxygen

From condensate polishing unit 5 Kg/cm2 G 40 Deg C (normal), 60 Deg C (Max) Max 80% of boiler capacity < 0.5 mg/l < 0.01 mg/l SiO2 < 0.01 mg/l Fe < 0.003 mg/l Cu Nil as KMnO4 mg/l < 0.2 microS/cm Nil mg/l Nil ppm wt as CaCO3 <0.007 mg/l

The boiler feed water analysis shall be as follows: Sr. No. Parameter 1 pH value 8.8 to 9.5 2 TDS Nil 3 Total copper as Cu 0.003 mg/l (max) 4 Total iron as Fe 0.01 mg/l (max) 5 Silica (reactive) 0.02 mg/l 6 Cation Conductivity@ 25 Deg C 0.2 micromh/cm 7 Hydrazine (residual) 1.0 mg/l (approx.) 8 Morpholine (residual) 2.0 mg/l (approx.) 9 KMnO4 value NA 10 O2 content 0.005 mg/l (max) 11 Oil and grease Nil 12 TSP as PO4 2.0 mg/l (approx.)

A.1_Job_spec_Boiler_Package_rev B.doc

Page 11 of 30

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

2.16 2.16.1 2.16.2

EQUIPMENT QUALIFICATION CRITERIA (EQC): The bidder shall be an established and regular manufacturer of dual fired (oil and gas) fired, water tube, natural circulation boilers. The bidder shall have designed, engineered, manufactured, assembled, supplied, erected, tested and commissioned at least one dual fuel (oil and gas) fired or oil fired or gas fired boilers, generating steam at same or higher pressure & temperature and of capacities equal to at least 65% of the maximum MCR capacity of boiler as specified in the bidding document, during the last seven (7) years, on lump sum turnkey basis (LSTK). The boiler shall have completed minimum 1 year (8000 hrs) of satisfactory continuous operation, as on the bid due date. The period of 7 (seven) years for past experience shall be reckoned from the due date of submission of bid. Bidders shall provide all the relevant documentation, in support of their equipment qualification criteria, along with their bid. Experience record Proforma Boiler package vendor shall complete the Experience Record Proforma as enclosed in the bid document to amply prove that the Equipment offered meet the EQC for technical acceptance failing which the bids are liable for summarily rejection. Package vendor may furnish additional information to justify that the EQC is being met. In addition, manufacturers catalogue and general reference list for all the above equipment shall also be furnished along with the proposal.

2.16.3 2.16.4

2.16.5 2.17

Experience records for Boiler package shall be submitted duly completed along with the offer as per the format attached. TECHNICAL LOADING AND ECONOMIC COMPARISON OF EQUIPMENT VENDORS OFFER Vendor offers shall be loaded for power consumption for the following equipment. The general procedure shall be as follows:

2.17.1 2.17.1.1

Loading on account of equipment energy consumption: Loading (on account of equipment energy consumption) shall be done only for those equipments whose power consumption can be verified in the vendors shops. Loading shall be applied for the following equipments: - Centrifugal Compressors - Centrifugal Pumps - Centrifugal Fans (FD/ID) Only power consumption of driven equipments shall be considered for evaluating energy consumption. Vendors offers shall be loaded by Net Present Value of the cost of excess energy consumption (over the vendor having least energy consumption) over a Five years period starting from one year after delivery. Loading shall be applied on operating units only and not on standby units. Loading shall not be done on equipment, which are for intermittent operation.

2.17.1.2 2.17.1.3

2.17.1.4

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100 2.17.2 2.17.3 2.17.4 2.17.5

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 12 of 30

For economic comparison of equipment vendors offer, Equipment Cost + Cost of Insurance Spares (if specified) + Loading (as defined above) are considered. The values for estimating cost of energy consumption shall be considered as indicated in commercial documents in the enquiry RFQ. The maximum loading to be applied however shall not exceed 10% of the total package cost. The loading for power consumption shall be based on the following simultaneous conditions: - Net Boiler capacity of 100 TPH at specified pressure and temperature conditions at battery limit - Export BFW requirement of 50 TPH - Internal consumption for Boiler auxiliaries - No condensate return - Boiler fuel as typical refinery fuel gas - Normal ambient temperature Vendor shall indicate the individual power consumption for equipment considered for loading (as specified above) for these conditions in the offer clearly. TECHNICAL REQUIREMENTS FEED WATER SYSTEM Feed water system shall consist of Deaerator, BFW pumps, interconnecting piping from Deaerator to BFW pumps suction and from BFW pumps up to the boiler. BFW Export pumps, piping from deaerator to BFW Export pumps and piping from BFW export pumps discharge up to boiler package battery limit in the scope of supply. Boiler net capacity shall be 100 TPH of VHP steam and steam pressure of 40 Kg/cm2 (g) at B/L. Boiler net capacity does not include boiler internal steam requirements such as for deaerator, fuel atomization, soot blower requirement etc. Parallel down flow, spray cum tray type deaerator shall be sized for export of 50 TPH BFW, in addition to the requirement for the boiler unit. Thermal design shall comply with heat exchanger institute standard on `Deaerator Heater Standards or equivalent. Vessel shall be designed for the full vacuum. Deaerators drum size to be based on minimum 30 minutes storage between LAH & LAL. Storage requirement shall be based on capacity of boiler + Export BFW requirement. Normal working level shall be at 0.6 D (diameter of storage tank). Deaerator shall be capable of meeting the turndown requirements of boiler. Deaerators shall be provided with support steel structures, platforms, stairways and located at an elevation to satisfy NPSH requirement of BFW pumps. The elevation of supporting platform shall be accordingly indicated in the bid. The material of the deaerator shall be SA 516. Internals shall be SS. Deaerator shall be spay and tray type. Deaerator and DM water supply system shall be designed for no condensate return case. Deaerator shall be designed for LP steam design conditions. Deaerator shall be provided with level control, pressure control, HV on steam line, online oxygen analyzer at the outlet of deaerator. Control valve on steam, condensate and make up water line shall be sized for with and without condensate return conditions.

3.0 3.1 3.1.1

3.1.2

3.1.3 3.1.4 3.1.5

3.1.6

3.1.7 3.1.8

A.1_Job_spec_Boiler_Package_rev B.doc

Page 13 of 30 3.1.9 3.1.10 3.1.11 3.1.12

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

Steam venting through the deaerator shall not exceed 1% of total steam consumption in deaerator. Sample cooler shall be provided for sampling deaerator water. Sample cooler shall be provided at grade level. Instruments shall suitable for the specified area classification. Deaerator shall be separately supported from ground on steel structure. Platform all around with access staircase shall be provided. Minimum height shall be 10 meter. Platform at Deaerator top also shall be provided with access for maintenance of instruments and valves. Deaerator has to be in operation (to supply BFW to process) even when the boilers is not service. BOILER FEED WATER PUMPS AND BFW EXPORT PUMPS Vendor shall provide 2 Nos. (1W + 1S) of BFW pumps for the boiler unit. The pumps shall be supplied along with drive motors along with VFD, coupling, coupling guard, seals, integral piping, all instruments and controls, etc. The offered pumps shall be as per designed as per API 610 latest edition. Each pump shall be provided with minimum flow auto-recirculation valve mounted on pump discharge flange. BFW pumps shall be capable of pumping when safety valves on the steam drum blow off. BFW pumps shall be provided with reacceleration facility. Also, provision shall be provided to start/stop BFW pumps from DCS. BFW pumps shall have auto-start and auto changeover facility with motor sized for the end of curve operation. Vendor shall provide 2 Nos. (1W + 1S) of BFW Export pumps as per API 610, latest edition. The pump shall be supplied along with drive (along with VFD if required), coupling, coupling guard, seals, integral piping, all instruments and controls, etc. BFW Export pumps shall have min recirculation control valve in its scheme. BFW Export pumps shall have auto-start and auto changeover facility with motor sized for the end of curve operation. Pump metallurgy shall be selected for starting pump in hot conditions or else warm up line shall be provided. Electrical and instrumentation shall be suitable for specified area classification. Monorail for maintenance shall be provided for all pumps. Boiler feed water pumps & Export BFW pumps MOC shall be CI. COMBUSTION SYSTEM Boiler turn down shall be 25% of MCR & boiler shall be capable of operating with an output of 110% of the MCR rating for a minimum thirty minutes in each of eight hrs shift.

3.1.13 3.2 3.2.1

3.2.2 3.2.3 3.2.4 3.2.5

3.2.6

3.2.7

3.2.8 3.2.9 3.2.10 3.2.11 3.3 3.3.1

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100 3.3.2

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 14 of 30

The vendor shall provide Two Nos. (1W +1S) of Forced draft fans (FD) and Two Nos. (1W +1S) Induced draft (ID) fans with inlet silencer and inlet wire mesh filter (changeable type) for boiler capable to supply varying amount of air to match the boiler turndown ratio. Vendor to ensure the safe and stable operation at 30% of rated capacity. Each forced and induced draft fan shall be designed considering 25% margin on pressure and 35% margin on calculated capacity at rated MCR. The combustion air blower shall be provided with drive arrangement, inlet silencer cum filter, ducting between blower and combustion chamber etc. FD and ID fans shall be provided with VFD for regulating air to fuel ratio under turn down operation. FD fan outlet damper shall be shut off type. Dampers shall be motorised or pneumatically operated. The actuators and necessary linkages shall be furnished by the vendor. ID fans shall be provided with Inlet guide vanes For flow measurement, flow transmitters shall be provided for the air from the FD and ID fans. Straight duct length for installation of flow transmitter shall be as per good engineering practice. The radiation loss for the furnace shall be considered as max. 1-2 %. Areas classification for electrical and instrumentation shall be as specified Monorails for all fans motor shall be provided for maintenance. Firing Equipment: Burners shall be dual fired, low NOx type. Operation with fuel oil / fuel gas with any combination of fuel gas shall be possible. The fuel oil specifications and fuel gas specifications are as specified in BEDB Part-II. Burner shall be pressure atomized. Burner shall be suitable for operating continuously on turndown load based on the turndown requirement. Below the maximum turndown the operation shall be ON / OFF type. Burner shall be provided with sight glass for flame inspection. UV scanner per burner shall be provided for detection of flame. Pilot burners shall be gas based. LPG cylinders assembly shall be provided for the start up when fuel gas is not available from refinery. Suitable burner cleaning, holding rack for boiler shall be furnished along with necessary spanners and tools. Facility for cleaning gas spuds shall be provided. The scanner for burner assembly shall have one number ionization rod for each pilot flame and one number UV detector for each main flame. Burner shall be designed for all five cases of fuel gas & fuel oils (HSFO & LSFO). FUEL OIL SYSTEM / FUEL GAS SYSTEM The fuel oil system shall comprise of fuel oil piping from fuel oil day tank (by others) up to burners, two Nos. (1W +1S) of fuel oil pumps, necessary instrumentation and controls, fuel oil pre-heater, fuel oil filters. Vendors scope starts from the nozzles of the fuel oil day

3.3.3 3.3.4 3.3.5 3.3.6 3.3.7

3.3.8

3.3.9 3.3.10 3.3.11 3.4 3.4.1

3.4.2

3.4.3 3.4.4 3.4.5 3.4.6 3.5 3.5.1

A.1_Job_spec_Boiler_Package_rev B.doc

Page 15 of 30

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

tank (by others). 3.5.2 3.5.3 Fuel Oil Day Tank: Existing fuel oil tank shall be used as a day tank for the proposed boiler. Fuel oil will be made available at the nozzles of the existing fuel oil day tank. Boiler vendor has to carry out necessary co-ordination and interface engineering for the same. Vendor to refer process datasheet (PDS) and P&ID of utility boiler. A suitable pumping and heating unit shall be provided for preheating (dual type: Electrical and Steam) fuel oil as required for pumping, atomizing and firing. The unit may be skid mounted consisting of filters, pumps and heaters of specified type. The pumps shall be of positive displacement screw type with relief valve. The pump shall be offered in compliance to the guidelines of API 676. Fuel oil pumps shall be provided with auto-start facility. Pump motor shall be designed for end of curve operation. The heater shall be dual type (electric and steam heated). Heat exchanger shall be designed as per TEMA standards. Fuel oil lines shall be provided with continuously operating re-circulation lines with pressure build up orifice. A suitable pulsation dampener may also be provided to even out any variations in flow rate during pumping Fuel oil supply and return lines shall be provided with mass flow meters. A back pressure control valve shall be provided between fuel oil supply and return line. Basket type prefilters (1W+1S) upstream of fuel oil pumps (designed to remove particles of size up to 10 mesh) & basket type after filters (1W+1S) down stream of fuel oil heaters designed to remove particles of size up to 30 mesh shall be provided by vendor. Fuel oil circulating heater shall be provided. Vendor shall provide the fuel gas knock out drum and automatic block and bleed arrangement on the fuel gas line to fuel KOD inlet and drain lines. Flow meter cum totaliser shall be provided for fuel oil and fuel gas. Fuel oil line from fuel day tank & fuel gas KOD outlet line to be traced. All instrumentation and electrical on gas and fuel circuit shall be Ex (d) TYPE. Boiler vendor to prepare and submit the detailed P &ID for the fuel oil and fuel gas circuit for owner/PMCs review and approval. DRUM INTERNALS Drum internals shall be adequately designed to ensure generation of superheated steam at outlet. The steam drum shall be sized to have minimum 3 minutes hold up at full output between normal water level and low water level in the drum. Drum MOC shall be minimum SA 387 Grade 11 class 1 & 2. HEAT TRANSFER SECTIONS The super heater where included in the scope, shall preferably be with a flat characteristic over the operating range without an attemperator. The economiser along with soot blower inlet and outlet ducting shall be so arranged that it is possible to install soot cleaning. The economiser shall also be arranged for off-load

3.5.4

3.5.5

3.5.6

3.5.7 3.5.8 3.5.9 3.5.10 3.5.11 3.6 3.6.1

3.6.2 3.7 3.7.1 3.7.2

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 16 of 30

water washing. To enable this, means shall be provided for bypassing the economiser on the gas side. The bypass dampers shall be operated from the operating floor level. 3.8 3.8.1 3.8.2 3.8.3 DUCTS, DAMPERS AND THERMAL DENOx FACILITY All air ducts and wind box shall be fabricated from sheet steel not less than 5 mm thick and all gas ducts from min. 6 mm thick plate. Suitable heat conservation insulation shall be provided for the ducts. All dampers shall be as far as possible be operated from operating floor level. Inlet, outlet and by-pass dampers shall be provided for the economiser. Bypass dampers shall have spring-loaded strips or similar to ensure gas tightness. Vendor shall provide ducting for flue gas from boiler to stack with all supports and insulation. DENOx FACILITY Boiler package vendor shall provide Selective non-catalytic reduction (SNCR) process based thermal DENOx facility. The DENOx facility shall consist of sleeves, ammonia injection nozzles, CO analyzer, Ammonia Analyzer, NOx analyser etc. Two Nos. of temperature connections shall be provided, one for measurement of flue gas temperature at up steam of super heater and other one temperature connection between primary and secondary super heater. NOx analyzer shall be provided in the stack for measurement of NOx emissions in flue gas. Adequate maintenance platforms shall be provided at the location of the temperature connections & at the injection nozzle locations. Proper access shall be ensured for the maintenance of the injection nozzles. Vendor has to take a tapping for LP steam for thermal DENOx facility. Vendor has to make a provision for LP steam line. LP steam shall be required as ammonia carrier. Connection with blind flange for CO analyzer to be provided at upstream of the primary super heater. Vendor shall provide the suitable interlinking of boiler P & ID with DENOx system P & ID (i.e. interconnection of fuel/steam flow measuring instruments, analyzers, interlocks etc) Vendor shall take necessary approvals/ clearances required if any, from statutory bodies like IBR for the work in boiler. Adequate space shall be provided on the pipe rack to accommodate approx. 6-8 NB LP steam line, approx. 1 NB ammonia line and if required, approx. 1 NB hydrogen line. CHIMNEY/ STACK Chimney shall be self-supporting type, carbon steel refractory lined up to top. The height of chimney shall comply with the statutory requirements of local authorities and smoke nuisance regulations. However the stack height shall be min. 60m from grade level

3.8.4 3.8.5 3.8.5.1

3.8.5.2

3.8.5.3 3.8.5.4

3.8.5.5 3.8.5.6 3.8.5.7 3.8.5.8 3.8.5.9

3.9 3.9.1 3.9.2

A.1_Job_spec_Boiler_Package_rev B.doc

Page 17 of 30

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

or calculated based on SOx emission at 110% MCR of the Boiler, maximum height out of this shall be considered. 3.9.3 Design, engineering, fabrication, erection of the stack with all insulation, painting, gas analyser stations, platforms, ladders, lightening arrestor, aviation lamp, junction boxes for aviation lighting, painters trolley etc. shall be provided. Lightning protection as per IS 2309 shall be provided. Two earthing terminals shall be provided at the base of the chimney. For details, refer the Standard specification for steel stacks (Doc No. 44LK-5100-00-V.020211-A4) attached herewith this enquiry documents. Platforms shall be generally having not more than 9 m vertical span. The platforms shall be provided 360 degree all around the stack. Two nos. ladders shall be provided 180 degree apart to the platform up to arch / furnace top level. CHEMICAL DOSING SYSTEM If required, both high pressure and low-pressure chemical dosing systems shall be considered. Chemical dosing systems shall be complete with necessary feed tanks, mechanical agitators, dosing pumps with drives interconnecting piping and all necessary instrumentation. Chemicals supply shall be owners scope. The feed tanks shall be constructed of mild steel plate with inside rubber lining of 5 mm thickness. Each tank shall be provided with calibrated translucent measure pot attached to the tank and shall provide 1-day storage requirement. The dosing pumps (one working & one standby) for each system shall be positive displacement, double diaphragm type, variable stroke with electric motor drive through suitable gear box, stroke control can be adjusted manually as well. Material of construction for all wetted parts shall be SS 304 or rubber lined based on application. All electrical and instrumentation shall be as per area classification specified. Dosing tank shall be suitably provided with platform, stairs for loading chemical and maintenance of agitator. Monorail shall be provided for lifting chemical drums up to platform. BLOW DOWN VESSEL AND DRAINS A blow down flash drum to generate low pressure steam which is to be used for Deaerator & a RCC pit for final disposal of blown down to be provided. Facilities for both intermittent and continuous blow-down shall be included. The blow down vessel shall be adequately sized to take care of maximum blow down quantity. The blow-down drum shall be designed and constructed of boiler quality steel plates as per IBR and shall include adequate vent fitted with an exhaust hood. A blow down flash drum to generate low-pressure steam, which is to be used for deaerator & a RCC pit for final disposal of blow down.

3.9.4 3.9.5 3.9.6

3.10 3.10.1

3.10.2

3.10.3

3.10.4 3.10.5 3.10.6

3.11 3.11.1

3.11.2 3.11.3 3.11.4

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100 3.11.5 3.12 3.12.1

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 18 of 30

Necessary level gauges, safety valves, etc. shall be provided. SOOT BLOWERS Adequate number of motor driven soot blowers shall be provided for proper cleaning of all heating surfaces of boilers, super-heaters, economiser complete with all piping and accessories including valves, controls, control panel and necessary cabling. Pressure reducing station for soot blowers shall be independent of that for atomising steam so as not to affect combustion during soot blowing operation. In zones where gas temperatures are expected to exceed 800oC, retractable type of soot blowers shall be provided. Automatic sequential soot blowing shall be provided through a PLC and MCC along with a local start-stop push button for each soot blower. PLATFORMS, WALKWAYS, STAIRS AND LADDERS Platforms, Galleries and access ladders shall be provided for burner operation, soot blowers, access doors, peep holes, valves requiring manual operation, maintenance, accessibility, etc. so as to facilitate easy operation and maintenance. Platforms to be provided for tank, deareator etc as specified else where. Size of platforms shall be in such a way that the equipment to be attended shall be approachable from all sides. Minimum width of platforms and walkways shall be 1000 mm. Minimum headroom above the top of platform or walkway should be 2200 mm. Members supporting floor panel shall not deflect by more than 1/325 of the span. All stairs shall have a minimum clear width of 750 mm and the slope shall not exceed 45 Deg. with the horizontal. Minimum width of tread of stairs shall be 225 mm and the rise shall not exceed 200 mm. Length of landing should not be less than 900 mm or the clear width of stair, whichever is greater. Maximum number of risers in a flight shall be restricted to 16. Fixed ladders shall be provided to platforms / roofs, which do not require frequent access by the operating personnel. Ladders should preferably of a sloping type with a maximum inclination of 15 Deg. to the vertical. Clear width between strings shall be 450 mm. Minimum thickness of strings shall be 10 mm. Design loads for platforms, stairways, etc. shall be as follows: Access platforms, walkways and staircases, etc. a load of 400 kg/sq.mt. Operating floors and platforms where maintenance work will be carried out; moving load of 200 kg/sq. mt. Plus one point load of 500 kg in an area of 1 mt. Sq. Platform attached to vessels, moving load of 125 kg/sq. mt. Steel staircases shall be 1 m wide and not more than 45 degrees inclination. Staircase landings shall be minimum 900 mm long. Hand railing shall be at 1 m height from the staircase and made of galvanized pipe. Good quality skid proof frills shall be used for steps and toe plates shall be provided on hand railings. Use of cat ladders shall be avoided. Where inevitable, it shall be 450 mm wide and shall have safety cages if the height exceeds 3 meters. Two exits shall be provided for each platform from safety point of view. The boiler unit platform shall be interconnected at lower burner level, drum level and at intermediate level.

3.12.2 3.12.3 3.13 3.13.1

3.13.2

3.13.3

3.13.4

3.13.5

3.13.6

3.13.7 3.13.8

A.1_Job_spec_Boiler_Package_rev B.doc

Page 19 of 30 3.13.9

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

Platforms, walkways, staircases and landings shall be provided for safe operation and maintenance of the boiler and auxiliary equipment and in general conform to an acceptable and proven standard. Arrangement of platforms, walkways and landings shall provide safe access to all openings for inspection and cleaning purposes, permanent and test measuring points, control devices, local instruments, vents and drain valves, soot blowers, safety valves etc. Wherever possible platforms, walkways and staircases shall be supported from unheated structures of boiler or building and shall never be supported from pressure parts or other moving parts of the boiler or other plant. Platforms & walkway panels and stair treads shall be made of structural steel open bar gratings. Cantilever beams are acceptable if the span of the cantilever does not exceed One and Half (1.5) metres. However, even with the above restriction on the span, depending on the loading, requirement of knee bracing or moment bracket should be ascertained & provided. The boiler supporting structure shall be a braced structure with both vertical and horizontal bracing for the transfer of loads effectively. The vertical bracing shall be arranged form top to bottom and shall be continuous to transfer the horizontal loads to the base of the columns. Horizontal bracing shall be arranged at discrete levels to transfer the horizontal loads due to wind, seismic and thermal loads from the boiler, transmitted through the guides, to the columns. Gratings shall be of structural steel with a minimum depth of 30 mm and a minimum width of 300 mm and shall conform to BS:4592 Part I. Top rail, knee rail and vertical post shall be 32 NB (medium) tube conforming to IS:1239. Toe plate shall be 100 mm wide, Handrail shall be galvanised. The complete boiler and the auxiliaries structural steel supports including the roof over the boiler and fuel storage tanks and side cladding from the top to the drum operating floor, all foundation bolts and base plates for the structurals shall be the responsibility of the vendor. The roof of the boiler shall be provided with monitor roof and the side cladding shall be provided with adequate louvers for the proper ventilation of the covered space. Metallic cover sheets shall be used for shade. PIPING, VALVES AND FITTINGS Steam main header shall be designed for 20% excess design up to B/L. Vendor to provide flow meter cum totaliser, pressure transmitter and safety valve on main steam header. Vendor shall provide all interconnecting piping between boiler and boiler flash drum. Vendor shall provide fuel gas KOD outlet line up to boiler battery limit (with tracing) & BFW export line up to boiler battery limit. Vendor shall consider the flushing oil connectivity in the scope of supply. All valves shall be of approved design conforming to IBR and of approved make and those of similar make and type shall be interchangeable. All valves for steam, feed and blow down services shall have cast or forged steel bodies with covers and glands bolted on. All valves shall be fitted with outside screws unless otherwise approved and where extension spindles are fitted, thrust when opening or closing the valve, shall not be taken directly on the valve body. All silencers provided for safety valve outlet/vent valves shall contain noise level to max. 85 dB (A) at 1 M distance.

3.13.10

3.13.11 3.13.12 3.13.13

3.13.14 3.14 3.14.1 3.14.2 3.14.3 3.14.4 3.14.5 3.14.6

3.14.7

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 20 of 30

3.14.8 3.14.9

The battery limit terminal flanges shall be as per ANSI B 16.5. The valves shall be to relevant BS/ API standards and approved by IBR for those coming under IBR preview. Vendor shall develop and submit the complete equipment layout for boiler package area within space allocated. The same shall be submitted to PMC/Owner for review and approval. All valves which are not accessible shall be motorized. All motorized valves shall be by vendor. The following valves shall be motorised as a minimum: a) Main steam stop valve b) Main steam stop valve bypass (line bypass of size NB 50) with inching type. c) Start up Vent isolation valve with inching facility d) Soot blower steam line main valve (upstream of control station) and drain valve, if soot blower is required. e) Upstream isolation valves in the Boiler Feed water control stations and motorised gate valve for the feed control station 100% inlet isolation, inlet isolation bypass, 30 % inlet isolation. f) Both continuous and intermittent Blow down valves with inching type. g) All super heaters drain and vent valves. The first isolation valve will be a motorized valve. The motorized valves open / close time shall be suitable for the application. All valve shall be with position indicator. The boiler feed water piping downstream of the Boiler feed water pumps and up to the feed check and stop valve shall be designed for the cold shut off pressure of the boiler feed water pumps. Stress analysis for lines having operating temp above 65 degree C and line size greater than 3 shall be carried out. Report shall be submitted for same. Hanger type / spring type guide type support shall be provided based on stress analysis report. Lines at B/l shall be provided with anchor supports however same shall taken care as a part of detail engineering. INSULATION For insulation requirements, refer the Standard specification for hot insulation (Doc No. 44LK-5100-00-V.02-0003-A4). INSTRUMENTATION The control system for boiler and auxiliaries shall be through electronic instrumentation system in the control room of the plant. Burner start-up panels shall be mounted on the firing floor of the boiler. Burner management system shall be through electronic instrumentation and control system and floor- mounted. Alarm and trips for the upset parameters and safety requirements of the equipment shall be through electronic instrumentation system. Parallel information on DCS system (provided by Owner) shall be made available by vendor. The vendor shall furnish list of all critical parameters to be connected to the plant DCS/PLC.

3.14.10

3.14.11 3.14.12

3.14.13 3.14.14 3.14.15 3.15 3.15.1 3.16 3.16.1 3.16.2

3.16.3

A.1_Job_spec_Boiler_Package_rev B.doc

Page 21 of 30 3.16.4

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

Data logging and reporting facility for the following minimum parameters shall be made available in the DCS system (or main control room) Steam flow rate Steam pressure Steam temperature Common fault alarm Burner Management System and combustion control shall be provided with lead-lag features for air and fuel so that at any moment of time boiler does not have fuel rich condition. The combustion control shall operate the steam-generating unit within the limit of the equipment being controlled and within the specified turn down. The combustion o control shall maintain the boiler steam pressure within + 2%, temperature + 5 C the excess air in the furnace within + 5% and the draft in the furnace within +1.2 mm (0.05) of water of the predetermined draft value provided the rate of load change on the boiler is not more than 20% of the boiler capacity in any one (1) minute. Feed water control shall be through 3-element drum level control with two out of three logic and shall be located on operating platform. On very low drum level two out of three rotary logic shall be used for tripping the boiler. All control valves shall be provided with isolation and bypass valve. Steam temperature control shall be provided to maintain the super heater outlet o temperature of steam at + 5 C throughout the entire control range of turndown. For instrumentation technical requirements, refer the attached documents for instrumentation. Al trips shall be provided with 2oo3 logic. No switches are acceptable. Only transmitters shall be provided. Vendor to provide the following instruments as a minimum requirement. The following list is indicative only and vendor shall supply all the field sensors, transmitters, final control elements that are required for smooth, safe and automatic operation of the boiler unit and the other auxiliaries. 3 element drum level control with 100% redundancy, 2 out of 3 logic - Drum level differential pressure transmitter - Digital drum water level indicator in the boiler floor - Main steam flow transmitter 2 Nos. - Feed water flow transmitter 2 Nos. - Flow nozzle for steam flow - Control valve for feed water 2 Nos. (In which 1 No. 100% & 1 No. 30%) - I/P converter for feed control valve 2 Nos. - Orifice plate for water flow 1 No. - Drum pressure transmitter-1 No. - Drum level low low, high high alarm and tripping shall be generated from Owners DCS. - Main steam temperature low high, high high alarm and tripping shall be generated from Owners DCS. Combustion control - O2 analyser 1 No. - Combustion air flow element (Venturi at FD inlet) Each 1 No. - FD fan air damper actuator - power cylinder Each 1 - I/P converter for FD fan actuator Each 1

3.16.5

3.16.6

3.16.7 3.16.8 3.16.9 3.16.10

3.16.10.1

3.16.10.2

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100 3.16.10.3

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 22 of 30

Furnace draft control - Furnace pressure transmitter 6 Nos. - ID fan damper cylinder Each 1 - I/P converter for ID fan power cylinder Each 1 - Inlet/Outlet damper open/close limit switches Each 1 Steam temperature control. Desuperheater - Thermocouple - Inter stage Steam - I/p converter for spray water control valve 1 No. - Spray water Control valve 1 No. - Temperature Transmitter 3 Nos. - Main steam temperature element (Duplex) - 2 Nos. - Attemperator outlet steam temperature element( Duplex)1 No - Spray water flow transmitter 1 No. - Orifice for spray water flow 1 No. - Main steam temperature digital indicator (at operating floor)-1No. Continuous blow down tank level control - Level Transmitter 1 No - Level control valve 1 No - I/P for control valve 1 No Soot Blower pressure control with control panel - I/P converter - Control valve - Soot Blower sequence operation - Pressure Transmitter Deareator - Deaerator level transmitter (2 out of 3 logic) - I/p converter - Level Control valve - Deaerator overflow control level switch - On/ Off control with solenoid valve in deaerator to feed water storage tank line. - Pressure transmitter 2 Nos - temperature transmitter 2 Nos. Pressure gauges - Drum pressure 1 No - Drum pressure ( at operating floor) 1 No - Auxiliary steam pressure - 2 Nos. - Attemperator Spray water line pressure 1 No. - HP dosing pump discharge pressure Each 1 No. - LP dosing pump discharge pressure Each 1 No. - FW before Control Valve 1 No. - CBD tank pressure - Feed water pressure before Feed Control Station 1 No. - Feed water pressure before economiser 1 No. - Feed water pressure before economiser (at operating floor)-1 No. - Feed water pressure after Economiser- 1 No. - Main steam pressure -1 No. - Main steam pressure (at operating floor) -1 No. - Soot blower pressure (if required) - On each fuel line 2 Nos. each. - Feed water export line 2 Nos. - Cooling water lines supply and return.

3.16.10.4

3.16.10.5

3.16.10.6

3.16.10.7

3.16.10.8

A.1_Job_spec_Boiler_Package_rev B.doc

Page 23 of 30 3.16.10.9

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

Temperature gauges - Steam temperature SH1 outlet -1 No - FG temperature after economiser -1 No. - FG after air heater temperature-1 No. - FD air after air heater temperature-1 No. - Steam temperature at PSH inlet -1 No - Feed water Temperature after Economiser-1 No - Feed water Temperature at Economiser inlet-1 No - Main steam temperature-1 No - Secondary SH inlet temperature -1 No - on each fuel line 2 Nos. - BFW export line 2 Nos. - Cooling water supply and return line across each user.

3.6.10.10

Draught transmitters

- FG at chimney inlet 1 No - FD fan discharge 1 No - FD air after air heater 1 No - FG after boiler bank 1 No. - FG after economiser 1 No - FG after air heater 1 No - FG at furnace outlet 1 No - FG at super heater 1 outlet 1 No - FG at super heater 2 outlet 1 No

3.6.10.11

Temperature Elements (Duplex) and Transmitters - Feed water temperature after Economiser (RTD) -1 No - Feed water temperature before Economiser (RTD) -1 No - FD air after air heater (RTD) -1 No - FG after Economiser (RTD) -1 No - FG after boiler bank (K Type T/C) -1 No + Transmitter - Steam temperature after DSH (K Type T/C) -1 No + Transmitter - Furnace temperature (R / S Type T/C) -4 No + Transmitter - FD fan discharge -1 No. - Flue gas at Economiser inlet -1 No (R/S type T/C) + Transmitter - Flue gas temperature at SSH outlet -1 No + Transmitter - Fuel line one each on line - BFW export line 2 Nos. LevelTransmitters -HP/LP dosing tank level -1 No (Transmitter) - HP/LP dosing tank level low 1 No. Level gauges - Drum level 2 Nos. - IBD tank 1 No - CBD tank - 1 No - HP/LP dosing tank 1 No. Vibration Measurement Monitors with control panel - For FD & ID fan in the drive end. - Boiler feed pump Start up vent control - I/P for start up vent control valve 1 No

3.6.10.12

3.6.10.13

3.6.10.14

3.6.10.15

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 24 of 30

- Position transmitter for control valve 1No 3.6.10.16 3.6.10.17 BMS for Start up Oil Firing system with PLC based control system shall be provided. Stack Gas Analyzers with Panel in field - Particulate emission - SOx

- NOx

- O2 3.6.10.18 3.17 3.17.1 3.17.2 3.17.3 SWAS with control panel ELECTRICAL Refer technical specification for electrical equipments in utility boiler package (Doc No. 44 LK-5100-712/E.02/0038) attached herewith this specification. For the scope of work electrical, refer Annexure-1 Electrical scope of work (Doc No. 44 LK-5100-712/E.02/0038) attached herewith this specification. The MCC and PLC based control panel for the burner management system and other control panels, local start-up panels, VSD panels etc. shall be supplied by vendor. MCC panels and control panels shall be kept in the substation building located in the Boiler area as indicted in the conceptual layout. This building shall be designed and engineered and constructed by the Boiler vendor. Air conditioning required for the control room, switchgear room and VSD panel room in substation building shall be provided by vendor. All design engineering, supply, erection, commissioning, performance guarantee of the HVAC system including MCC, controls, cablings, distribution boxes etc shall be by vendor. The HVAC system shall be designed as per the engineering design basis attached with the enquiry. Vendor shall provide air cooled condensers for VFD room, control room & switchgear room. Fire dampers shall be provided for isolation in each area. CIVIL Vendor to refer the document No. 44LK- 5100-712/C.02/ 1154/A4 for Scope of work for civil, structural and architectural. Topographical survey drawing for boiler area is attached herewith this specification. The finished floor level for boiler area shall be 18.4 m. Vendor to refer the Engineering design basis-general civil, Engineering design basisarchitectural attached herewith this specification. Vendor to refer the various standard specifications & standard drawings attached herewith this specification. Vendor shall provide air conditioning system for VFD / control room/ Switchgear room in the substation building. The complete design, engineering, manufacture, supply, erection, commissioning, performance guarantee for the air conditioning system shall be in the vendor scope of work. Vendor shall provide the heat load calculations for the proposed air conditioning system. A/C equipment layout and ducting layout shall be submitted by vendor for consultants / Owners review and approval.

3.17.4

3.18 3.18.1 3.18.2 3.18.3 3.18.4 3.19

A.1_Job_spec_Boiler_Package_rev B.doc

Page 25 of 30 3.19.1 3.19.2 3.19.3 3.19.4

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

Lighting load 20 watts per m2 shall be considered for heat load calculation, this shall be in addition to the load furnished above. Vendor shall consider 20% margin on heat load calculations while selecting machine/units. Noise level inside control room shall be less than 60 dBA. . Duct sizing: Vendor shall size all ducts as per SMACNA. Vendor to provide supply and return air duct system in all areas. Vendor to provide damper to isolate AHUs. Vendor to provide fire damper in each system. Velocity of air inside the main supply ducts shall not exceed 1500 fpm and in return ducts it shall not exceed 1000 fpm. All supply and return shall be provided with VCD as a minimum.

3.19.5 3.19.6 3.19.7

Type of refrigerant shall be non CFC type. A/C Machine shall be suitable for continuous operation of 24 hours per day and 365 days. Vendor shall provide Chemical Filter unit for Fresh Air for Control Room along with Fresh Air Supply Fan. There shall be a separate Chemical Filter for each Air Handling Unit. For VFD room fresh air shall be considered through filter. Chemical Filters are designed for ISA class G1 outlet conditions. Chemical filter shall be selected for the chemical life of minimum one year. Fire dampers (CBRI certified) shall be provided for isolation of area as per OISD. Heater shall be provided for dehumidification and winter condition. Vendor to supply manometers, temp and humidity measurement at least 3 location in each room for air conditioned area, All electrical work related to HVAC package shall be done by vendor. This include MCC, all cabling, cabling support trays specified and meet generally as per electrical work outlined else where. All instrumentation required for safe and continuous operation for HVAC system shall be in vendor scope. Fire alarm signal shall be made available for tripping of units / operation of fire damper. Vendor shall submit the complete instrumentation and control philosophy for the air conditioning system. NOISE Noise level of all equipment shall be restricted to 85 dB (A) at 1 M distance BATTERY LIMITS Following utilities shall be made available on pipe rack at approx. elevation of 5m from FGL at one point at vendors battery limit. All further distribution / routing etc. shall be by vendor. All battery limit lines shall be terminated with flanged connections by vendor. All lines shall be terminated with isolation valves and blinds by vendor. Package vendor to indicate the utility requirements for boilers at package B/L for normal operation and start-up (both continuous and intermittent with rate & operating conditions i.e. pressure, temperature) Service Vendors Scope of work Owners Scope of work

3.19.8 3.19.9 3.19.10 3.19.11

3.19.12

3.20 3.20.1 4.0 4.1

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100 1 2 3 4 5 DM water

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4 From one point at battery limit From one point at battery limit From one point at battery limit and Up to one point at battery limit From fuel oil day tank nozzle From one point at battery limit Up to outlet of stack and up to one point at battery limit for analysers From one point at vendor battery limit From one point at vendor battery limit From one point at vendor battery limit From one point at vendor battery limit Up to one point at Battery limit with isolation vales. Drains for line containing oil and without oil shall be separated. Funnel to be provided at end point. From one point at battery limit To atmosphere at safe location From inlet of dosing tank

Page 26 of 30 Up to one point at battery limit Up to one point at battery limit Up to one point at battery limit From one point at battery limit Up to fuel oil day tank nozzle

Condensate Polished condensate Main Steam export BFW Fuel Oil

6 7

Fuel gas Flue gas

Up to one point at battery limit From one point at battery limit upto analyser inlet in analyser shed. Up to one point at vendor battery limit Up to one point at vendor battery limit Up to one point at vendor battery limit Up to one point at vendor battery limit From one point at battery limit.

Plant Air

9 10 11 12

Instrument air Cooling water supply / return Sea cooling water supply / return Drains

13 14 15

N2 gas Safety valve exhaust and vent HP and LP dosing chemicals

Up to one point at battery limit At the inlet of dosing tank

4.2

Electrical 1 Power cabling 2 Emergency power

Refer SLD and specification attached Not applicable

Refer SLD and specification attached

A.1_Job_spec_Boiler_Package_rev B.doc

Page 27 of 30 4.3 Instrumentation 1 Cabling

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

From field instruments to LCP, junction box, PLC control panel

From LCP, JB, PLC control panel to plant DCS/PLC

4.4 4.4.1 4.4.2 4.4.3 4.4.4 5.0 5.1

OWNERS SCOPE OF WORK Supply of utilities at one point. Control Cabling from LCP to plant PLC/DCS. Pipe rack design, engineering and construction up to battery limit (Boiler shed) Fuel oil day tank. INSPECTION AND TESTING Equipment shall be subjected to stage-wise expediting, inspection and testing by Owner/PMC. Vendor shall submit quality assurance plans (QAP) before commencement of fabrication. Approved QAP shall form the basis of equipment inspection. Fittings, valves, instruments, other accessories like filter etc., shall be duly tested and manufacturers test certificates shall be furnished. Material Test Certificates shall be submitted for all pressure parts. All the pressure vessels shall be hydrostatically tested and inspected as per applicable codes and standards. Any other tests as per data sheets, standards, and codes shall also be performed. Vendor shall be responsible for obtaining approvals from the Chief Inspector of Boilers at shop as well as at site for all boiler components falling under the purview of the Statutory Authorities (IBR). The original certificates of approval shall be passed onto the Owner. The Owner / PMC shall be kept informed of all negotiations between the vendor and Statutory Authorities. All other approvals from civil aviation, pollution control boards, CCOE, local authorities shall be obtained by vendor. Hydraulic and performance tests in accordance with design codes shall be carried out. Valves and boiler mountings shall undergo hydraulic pressure and functional tests. Firebrick material shall be subject to tests as per manufacturers standard, vendor shall submit test certificates for all the tests performed by him in his shop. Hydraulic testing All pressure parts of the boiler, super-heaters, economisers, air pre heater, deaerator with their associated pipe-work and fittings shall be hydraulically tested in accordance with Indian Boiler Regulations and to the approval of the Owner and IBR Inspectorate. Running Test: Boiler The boiler casing tightness shall be tested by pressurizing the boiler to 1.5 times the furnace design pressure and holding it for minimum 10 minutes. Loss in pressure should not be more than 125 mm with a smoke bomb or equivalent test method. Performance test of each boiler after successful completion of reliability test run shall be

5.2 5.3

5.4

5.5

5.6 5.6.1

5.7 5.7.1

5.7.2

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 28 of 30

conducted as per ASME PTC 4.1 (losses method) and the following guaranteed parameters shall be demonstrated. a) Thermal efficiency of boiler. b) Flue gas composition c) Steam generation capacity d) Steam temperature control range e) Turndown range of boiler f) Steam Quality: Conductivity at 25 C, Total silica, Total iron, Total Cu, Sodium (Na + K) as specified in Clause No. 2 Basic Design. g) Auxiliary steam consumption at 100%, 50% & 25% load. h) Auxiliary power consumption at 100%, 50% & 25% load. 5.7.3 5.7.4 All necessary equipment, instruments, etc. required for the performance testing shall be provided by the Vendor and shall be calibrated before the conductance of the test. Procedure for performance testing of boiler shall be furnished by the Vendor (to be approved by the Owner/PMC) before conductance of the performance test for Owners/ PMC review and approval. Deaerator testing The materials used shall be of tested quality. Vendor shall submit material test certificates and hydro-test certificates. Performance testing of the De-aerator at site shall be conducted as per ASME PTC 12.3 to establish the following guarantee parameters. Deaerated water flow at MCR. A) Turndown range. B) Oxygen content in the entire turndown range Forced Draft Fans / Induced Draft fans Performance test on FD fans shall be carried out at manufacturers works in accordance with BS 848 and / or AMCA 210. The tolerance on power consumption, speed input and air delivery shall be in accordance with BS 848 Class A. Performance test for boiler feed water pumps & BFW Export pumps shall be carried out at manufacturers works. The inspection and testing of BFW pump shall include material test certificates, hydro test reports, ND test reports, balancing test report and performance test report FIELD TEST The boiler package shall be subjected to field trial run for 48 hours of continuous uninterrupted operation. During the field trials safe and satisfactory operation of the boiler unit shall be established. This run shall be carried out during total plant reliability run. Other tests for Boiler and auxiliaries shall be carried out as indicated in the attached indicative test plans and other documents in the RFQ. GUARANTEES Mechanical:

5.8 5.8.1 5.8.2 5.8.3

5.9 5.9.1 5.9.2 5.10 5.10.1

6.0 6.1

7.0 7.1

A.1_Job_spec_Boiler_Package_rev B.doc

Page 29 of 30

Job Specification for Utility Boiler Package Doc.No: 44-LK-5100-712-M.02-0013-A4

HPCL, Mumbai DHT Project 44LK-5100

Vendor shall stand guarantee against defective materials and workmanship for the period specified in commercial terms and conditions. 7.2 Performance: The equipment shall be guaranteed for satisfactory performance at all operating conditions on the data sheet and performance curve. Field checks on performance, when made by the Owner, shall be made within the agreed time of initial operation The offered boiler shall be capable of operating at 110% of the MCR rating for a period of minimum 30 minutes in each 8 hrs shift. The boiler package vendor shall guarantee the followings operating conditions for all the cases of fuels (fuel oil, fuel gases or any combination of fuels): a) Rated capacity & efficiency of boiler (min. 90%) b) Steam pressure, steam temperature and quality of steam. c) Turndown ratio d) Boiler Blow-down (quantity, frequency, composition and temperature) e) No leakage of flue gases from furnace. f) Steam consumption for auxiliaries. g) Power consumption for auxiliaries. h) Fuel consumption for full load, 50% load, 25% load based on calorific value i) Composition of flue gases at the chimney/stack (limited to permissible levels) j) Utility consumption. The above guarantees shall be stated clearly in bid and are to be demonstrated by tests. The thermal efficiency given for MCR is to be guaranteed and the test result is to be within +2% of the figures specified. All instruments shall be calibrated and no further instrument tolerance shall be applied. The thermal efficiency is to be based on the gross calorific value of the fuel in the `as fired condition and a curve is to be submitted which will enable the guarantee to be adjusted if calorific value of test fuel, as established by sampling, differs from that on which the guarantee is based. The curve shall be submitted at tender stage for the variation of G.C.V. Overall efficiency of boiler unit shall be determined as per ASME PTC-4 code indirect method with following conditions: - Net Boiler capacity of 100 TPH at specified pressure and temperature conditions at battery limit - Export BFW requirement of 50 TPH at specified temperature, even when the boilers are out of service. - Min. ambient temperature for combustion air - No condensate return - Boiler fuel as typical refinery fuel gas - Normal ambient temperature Should the unit supplied fail to achieve the specified performance under the given conditions, vendor shall carryout all modifications or replacements to the unit as necessary to meet the required performance within the mutually agreed time period. The test shall be again carried out to prove the performance. The unit shall be in commercial operation at least for specified duration (min. 72 hrs.) before the performance tests are carried out to prove the performance guarantee. PROTECTION AND PAINTING

7.3 7.4

7.5

7.6

7.7

7.8

7.9

8.0

A.1_Job_spec_Boiler_Package_rev B.doc

HPCL, Mumbai DHT Project 44LK-5100 8.1 9.0 9.1

Job Specification for Utility boiler package Doc.No: 44-LK-5100-712/M.02/0013/A4

Page 30 of 30

Painting of the equipment shall be as per attached specification. PACKAGING AND IDENTIFICATION All packaging shall be done in such a manner as to reduce the volume. The equipment shall be dismantled into major components suitable for shipment and shall be properly packed to provide adequate protection during shipment. All assemblies shall be properly match marked for site erection. Attachments, spare parts of the equipment and small items shall be packed separately in wooden-cases. Each item shall be appropriately tagged with identification of main equipment, its denomination and reference number of the respective assembly drawing. Detailed packing list in waterproof envelope shall be inserted in package together with equipment. Each equipment shall have an identification plate giving salient equipment data, make, year of manufacture, equipment number, name of manufacturer etc. SPARE PARTS As a minimum operational/maintenance spares as defined under mandatory spare part list in the enquiry document and commissioning spares as recommended by the manufacturer shall be included in the basic price. Recommended list of spare parts with recommended quantities and itemised prices for two years of operation of the equipment shall be submitted. Proper coding and referencing of spare parts shall be done so that later identification with appropriate equipment will be facilitated. Recommended spare and their quantities shall take into account related factors of equipment reliability, effect of equipment down time upon production or safety, cost of parts, and availability of vendors service facilities around proposed location of equipment. Set of special tools and tackles if required for erection, field assembly and maintenance of each component of the utility boiler package should be supplied and included in basic price.

9.2

9.3 9.4

10.0 10.1

10.2

10.3

10.4

A.1_Job_spec_Boiler_Package_rev B.doc

Вам также может понравиться

- Standard Norsok Standard R 001 For Mechanical EqptДокумент152 страницыStandard Norsok Standard R 001 For Mechanical Eqptaravindhcam100% (2)

- 5 Axis Generic PostДокумент68 страниц5 Axis Generic Postwidya90% (10)

- SP3D-Isometric Practice LabsДокумент141 страницаSP3D-Isometric Practice LabsLucafuck93% (15)

- Air Cooled COndenser PDFДокумент7 страницAir Cooled COndenser PDFRajAnandОценок пока нет

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedДокумент12 страницSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoОценок пока нет

- N2 Purging Demand Calculation Shutdown - Flare SystemДокумент54 страницыN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridОценок пока нет

- 1231 de 00 DC PCJ 001 01Документ33 страницы1231 de 00 DC PCJ 001 01Hamid MansouriОценок пока нет