Академический Документы

Профессиональный Документы

Культура Документы

Scada Automation

Загружено:

Radhika PriyadarshiniОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Scada Automation

Загружено:

Radhika PriyadarshiniАвторское право:

Доступные форматы

Definitions of integration and automation: Substation integration and automation can be broken down into five levels, as seen

in Table1.The lowest level is the power system equipment, such as transformers and circuit breakers. The middle three levels are IED implementation, IED integration, and substation automation applications. All electric utilities are implementing IEDs in their substations. The focus today is the integration of the IEDs. Once this is done, the focus will shift to what automation applications should run at the substation level. The highest level is the utility enterprise, and there are multiple functional data paths from the substation to the utility enterprise. The five-layer architecture is shown in Table 1

TABLE.1 Five-Layer Architecture for Substation Integration and Automation Since the substation integration and automation technology is fairly new, there are no industry standard definitions, except for the definition of an IED. The industry standard definition of an IED is given below, as well as definitions for IED integration and substation automation. Intelligent electronic device (IED): Any device incorporating one or more processors with the capability to receive or send data/control from or to an external source (e.g electronic multi function meters, digital relays, controllers). IED integration: Integration of protection, control, and data acquisition functions into a minimal number of platforms to reduce capital and operating costs, reduce panel and control room space, and eliminate redundant equipment and databases. Substation automation: Deployment of substation and feeder operating functions and applications ranging from SCADA (supervisory control and data acquisition) and alarm processing to integrated volt/VAr control in order to optimize the management of capital assets and enhance operation and maintenance efficiencies with minimal human intervention

Interposing Relays: Power station controls often require high power levels and operate in circuits powered from 48-, 125-, or 250-Vdc station batteries or from 120- or 240-Vac station service. Control circuits often must switch 10 or 20 A to effect their action, which imposes constraints on the interposing devices. The interposing between an SA controller or IED and station controls commonly requires the use of large electromechanical relays. Their coils are driven by the SA control system through static or pilot duty relay drivers, and their contacts switch the station control circuits. Interposing relays are often specified with 25-A, 240-Vac contact rating to insure adequate interrupting duty. However, where control circuits allow it, smaller interposing relays are also used, often with only 10- or 3-A contacts,. When controlling dc circuits, the large relays may be required, not

because of the current requirements, but to provide the long contact travel needed to interrupt the arc associated with interrupting an inductive dc circuit. Note that most relays that would be considered for the interposing function do not carry dc interrupting ratings. Magnetic blowout contacts, contacts fitted with small permanent magnets that lengthen the interruption arc to aid in extinguishing it, may also be used to improve interrupting duty. They are polarity sensitive, however, and work only if correctly wired. Correct current flow direction must be observed. Many SA controllers and IEDs require the use of surge suppression to protect their control output contacts. A fast-switching diode can be used across the driven coil to commute the coil-collapse transient when the coil is de-energized. As the magnetic field of the device coil collapses on de energization, the coil voltage polarity reverses, and the collapsing field generates a back EMF in an attempt to sustain the coil current. The diode conducts the back EMF and prevents the buildup of high voltage across the coil. The technique is very effective. It requires the diode to handle the steady-state current of the coil and be able to withstand at least three times the steady-state voltage. Failure of the diode in the shorted mode will disable the device and cause a short circuit of the control driver, although some utilities use a series resistor with the diode to reduce this reliability problem. Other transient suppressors include transorbs and metal oxide varistors (MOV). Transorbs behave like back-to-back zener diodes and clamp the voltage across their terminals to a specified voltage. They are reasonably fast. MOVs are very similar, but the suppression takes place as the voltages across them cause the metal oxide layers to break down, and they are not as fast. Both transorbs and MOVs have energy rating in joules. They must be selected to withstand the energy of the device coil. Many applications of transorbs and MOVs clamp the transients to ground rather than clamping them across the coil. In this configuration, the ground path must be low impedance in order for the suppression to be effective. Intelligent Electronic Devices (IED) for Control: IEDs that have control capability accessible through their communications ports are available. Protective relays, panel meters, re closer controls, and regulators are common devices with control capability. They offer the opportunity to control substation equipment without a traditional interposing relay cluster for the interface, sometimes without even any control-circuit additions. Instead, the control interface is embedded in the IED. When using embedded control interfaces, the SA system designer needs to assess the security and capability of the interface provided. These requirements should not change just because the interface devices are within an IED. External interposing may be required to meet circuit loads or interrupting duty. When equipment with IEDs is controlled over a communications channel, the integrity of the channel and the security of the messaging system become important factors. Not all IEDs have select-before-operate capability common to RTUs and SCADA systems. Their protocols also may not have efficient error detection, which could lead to miss operation. In addition, the requirement to have supervisory control disabled for test and maintenance should not impact the IEDs primary function.

Monitoring of Equipment Condition: Many electric utilities have employed equipment condition monitoring (ECM) to maintain electric equipment in top operating condition while minimizing the number of interruptions. With ECM, equipment operating parameters are automatically tracked to detect the emergence of various abnormal operating conditions. This allows substation operations personnel to take timely action when needed to improve reliability and extend equipment life. This approach is applied most frequently to substation transformers and high-voltage electric supply circuit breakers to minimize the maintenance costs of these devices, to improve their availability, and to extend their useful life. Equipment availability and reliability can be improved by reducing the amount of offline maintenance and testing required and by reducing the number of equipment failures. To be truly effective, equipment condition monitoring should be part of an overall condition-based maintenance strategy that has been properly designed and integrated into the regular maintenance program. ECM IEDs are being implemented by many utilities. In most implementations, the communication link to the IED is via a dial-up telephone line. To facilitate integrating these IEDs into the substation architecture, the ECM IEDs must support at least one of todays widely used IED protocols: Modbus, Modbus Plus, or DNP3 (distributed network protocol). In addition, a migration path to UCA 2 MMS is desired. If the ECM IEDs can be integrated into the substation architecture, the operational data will have a path to the SCADA system, and the nonoperational data will have a path to the utilitys data warehouse. In this way, the users and systems throughout the utility that need this information will have access to it. Once the information is brought out of the substation and into the SCADA system and data warehouse, users can share the information in the utility. The private databases that result in islands of automation will go away. Therefore, the goal of every utility is to integrate these ECM IEDs into a standard substation integration architecture so that both operational and nonoperational information from the IEDs can be shared by utility users.

Вам также может понравиться

- 2015 Mtech PSEДокумент29 страниц2015 Mtech PSERadhika PriyadarshiniОценок пока нет

- High Voltage EngineeringДокумент10 страницHigh Voltage EngineeringRadhika PriyadarshiniОценок пока нет

- Scada 1Документ6 страницScada 1Radhika PriyadarshiniОценок пока нет

- Souharda ActДокумент64 страницыSouharda ActRadhika PriyadarshiniОценок пока нет

- 2015 Mtech PSEДокумент29 страниц2015 Mtech PSERadhika PriyadarshiniОценок пока нет

- LshortДокумент171 страницаLshortCXBBAОценок пока нет

- Re Vaca Dodd 2013Документ2 страницыRe Vaca Dodd 2013Radhika PriyadarshiniОценок пока нет

- SylabДокумент36 страницSylabRadhika PriyadarshiniОценок пока нет

- 9-Line Telephone SharerДокумент1 страница9-Line Telephone Sharersiri_vignaneeeОценок пока нет

- Atp Quick GuideДокумент34 страницыAtp Quick Guideingrid_monrreal100% (2)

- CH 2 Power System SecurityДокумент61 страницаCH 2 Power System SecurityRadhika PriyadarshiniОценок пока нет

- Automatic Dual Output DisplayДокумент1 страницаAutomatic Dual Output DisplayRadhika PriyadarshiniОценок пока нет

- Fuzzy Smart3Документ55 страницFuzzy Smart3Radhika PriyadarshiniОценок пока нет

- Practical Inrush Restraint-SetttingДокумент12 страницPractical Inrush Restraint-SetttingtunghtdОценок пока нет

- HVDCДокумент1 страницаHVDCRadhika PriyadarshiniОценок пока нет

- EMTP Ref Model-FinalДокумент61 страницаEMTP Ref Model-FinalRadhika PriyadarshiniОценок пока нет

- Effect of Mag. Inrush CurrentДокумент4 страницыEffect of Mag. Inrush CurrentAbhinesh KumarОценок пока нет

- Energy, Infrastructure & Communcation by Economic SurveyДокумент23 страницыEnergy, Infrastructure & Communcation by Economic SurveyRadhika PriyadarshiniОценок пока нет

- Inrus Effect On TransformersДокумент6 страницInrus Effect On TransformersRadhika PriyadarshiniОценок пока нет

- Regarding Indian Balckout Juli 30-31stДокумент3 страницыRegarding Indian Balckout Juli 30-31stRadhika PriyadarshiniОценок пока нет

- Particle Swarm Optimization For Next Generation Smart Grid Outage AnalysesДокумент6 страницParticle Swarm Optimization For Next Generation Smart Grid Outage AnalysesRadhika PriyadarshiniОценок пока нет

- Micro InverterДокумент4 страницыMicro InverterRadhika PriyadarshiniОценок пока нет

- Energy ParkДокумент5 страницEnergy ParkRadhika PriyadarshiniОценок пока нет

- Chap 5Документ15 страницChap 5sunilkumareceОценок пока нет

- Dynamic Simulations of Electric MachineryДокумент325 страницDynamic Simulations of Electric MachineryJuan PanОценок пока нет

- CI 03 Highway SignalДокумент1 страницаCI 03 Highway SignalPrem PrakashОценок пока нет

- Nano MotorДокумент2 страницыNano MotorRadhika PriyadarshiniОценок пока нет

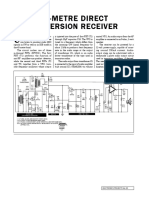

- 40-Meter Direct Conversion Receiver PDFДокумент1 страница40-Meter Direct Conversion Receiver PDFShrivlsi RamОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- 1049 Datasheet PDFДокумент1 страница1049 Datasheet PDFPalash choudharyОценок пока нет

- Atomic Structure PDFДокумент4 страницыAtomic Structure PDFAlexia LudlowОценок пока нет

- Thyristor Controlled Battery Charger / Rectifier Rda/Rdat Series User ManualДокумент44 страницыThyristor Controlled Battery Charger / Rectifier Rda/Rdat Series User Manualamhtet67% (3)

- The Phasor Transform and Impedance: 1. ObjectiveДокумент4 страницыThe Phasor Transform and Impedance: 1. ObjectivejbusowiczОценок пока нет

- Resonac SLD MaintenanceДокумент1 страницаResonac SLD MaintenanceArman KhanОценок пока нет

- EEE430 STUDENT KIT - PO3 CEEE222 - Single Phase Transformer Parameters and Load TestДокумент10 страницEEE430 STUDENT KIT - PO3 CEEE222 - Single Phase Transformer Parameters and Load Testamardarwish321Оценок пока нет

- TMST110Документ3 страницыTMST110Sara ArroyaveОценок пока нет

- Optical Illusion ApparatusДокумент1 страницаOptical Illusion ApparatusSatish PatelОценок пока нет

- SV660P Hardware Guide enДокумент156 страницSV660P Hardware Guide enkerim gümüşОценок пока нет

- Arc Rersistance TestДокумент18 страницArc Rersistance TestMMFAWZYОценок пока нет

- Elias - PX - BDA - 1 - 1Документ36 страницElias - PX - BDA - 1 - 1soundman11Оценок пока нет

- Equivalent Circuit of Transformer Referred To PrimaryДокумент5 страницEquivalent Circuit of Transformer Referred To PrimaryGideon Moyo100% (1)

- Electrical Load EstimationДокумент8 страницElectrical Load EstimationWidhi ImranovichОценок пока нет

- 06 Contactors1Документ44 страницы06 Contactors1Yash TavseОценок пока нет

- R1283K001CДокумент26 страницR1283K001CdinhdtdОценок пока нет

- TCSC 501 MS EeДокумент27 страницTCSC 501 MS EeNouman Alam SiddiquiОценок пока нет

- Dealer / Office QuotationДокумент12 страницDealer / Office QuotationBilel Ben SlamaОценок пока нет

- PVTRIN Training Course: Troubleshooting GuideДокумент20 страницPVTRIN Training Course: Troubleshooting GuideBeni Saputra100% (1)

- ElectrochemistryДокумент63 страницыElectrochemistryVivek SehgalОценок пока нет

- Dbss - HSDD - Startup Routine: Field Component ManualДокумент25 страницDbss - HSDD - Startup Routine: Field Component ManualМихаил100% (1)

- Solar12-100: Solra Series Vrla BatteryДокумент2 страницыSolar12-100: Solra Series Vrla BatteryMarcoОценок пока нет

- AC CircuitsДокумент15 страницAC CircuitsAlbert Tuazon92% (38)

- Lab2 ModifiedДокумент12 страницLab2 ModifiedIfeAdekoyaОценок пока нет

- Arduino AC-DC Voltmeter PDFДокумент6 страницArduino AC-DC Voltmeter PDFyb3hgf2222Оценок пока нет

- American Wire Gauge 1Документ3 страницыAmerican Wire Gauge 1sungjoo75Оценок пока нет

- Panasonic Sa Ak230 PDFДокумент94 страницыPanasonic Sa Ak230 PDFCOL. CCEEОценок пока нет

- S60SC4M Mxqwqqs PDFДокумент11 страницS60SC4M Mxqwqqs PDFBaharak BaghiОценок пока нет

- Lec 11Документ4 страницыLec 11Abdullah AloglaОценок пока нет

- Sample Question PDFДокумент1 175 страницSample Question PDFsignalcontrolspjОценок пока нет

- A Paul Kemble Web Page - Mission Cyrus 1 Integrated Amplifier2 PDFДокумент3 страницыA Paul Kemble Web Page - Mission Cyrus 1 Integrated Amplifier2 PDFZafer ÖzerОценок пока нет