Академический Документы

Профессиональный Документы

Культура Документы

Buckling and Wellhead Load After Cementing

Загружено:

scrbdgharaviОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Buckling and Wellhead Load After Cementing

Загружено:

scrbdgharaviАвторское право:

Доступные форматы

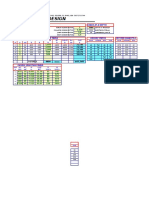

INPUTS Lease Well Name Date Henderson Ranch #2 8/10/2010 13.375 IN. 68.0 #/FT 12.415 IN.

3,200 FT 8,400 FT 9.1 PPG 11.5 PPG 0 12.5 2,450 15.6 750 75 120 185 75 75.0 FT PPG FT PPG FT

Henderson Ranch

-50000

Casing Size Casing Weight Casing ID Casing Setting Depth TD of Next Section Mud Weight Run In Heaviest MW below Overpull When Set Lead Cement Weight Lead Cement Height Tail Cement Weight Tail Cement Height

o o

140.5004 19.4452 1.077326 121.0552

1000

1500

2000

F Surface Temp F @ Casing Point o F @ TD of Heavier MW o F @ TOC (initially) o F @ TOC (final) TOP OF CEMENT EQ CEMENTED HYDROSTATIC AT CASING DEPTH FORCE DUE TO CHANGE IN TEMPERATURE EQ LENGTH CHANGE DUE TO CHANGE IN TEMP BALLOONING FORCE DUE TO HEAVIER MUD WT EQ LENGTH CHANGE DUE TO BALLOONING RUNNING TENSION 3200 0

2500

3000

13.2 PPG 75 0.0 75.0

3500

LBF

0.0 IN. 0 LBF

0.0 IN.

-29445 188155

CEMENTED TENSION 3200 0 0 0

-125921 91679 91679 91679

0 -29444.7 0 188155.3

AXIAL LOAD W/ OVERPULL, TEMP & BALLOONING 0 91679 0 91679 CEMENTED STABILIZING FORCES 3200 -125921 0 0 0 0 WEIGHTED-UP STABILIZING FORCES 0 0 0 0 ADDITIONAL TENSION (OVERPULL) NEEDED LBF Additional Tension to Avoid -91679 Buckling 0

-91679.3

13.375 IN. Casing Tension/Buckling Plot

Henderson Ranch #2

50000 0

500

1000

1500

A 0

-91679

2000

2500

3000

3500

RUNNING TENSION CEMENTED TENSION AXIAL LOAD W/ OVERPULL, T CEMENTED STABILIZING FOR WEIGHTED-UP STABILIZING F Top of Cement

Overpull When Set Additional Tension to Avoid Buckling

-91679

150000

RUNNING TENSION CEMENTED TENSION AXIAL LOAD W/ OVERPULL, TEMP & BALLOONING CEMENTED STABILIZING FORCES WEIGHTED-UP STABILIZING FORCES Top of Cement

Buckling & Wellhead Load After Cementing

CASING PROPERTIES

CASING OD (IN.) CASING ID (IN.) CASING WT./FT CASING LENGTH (FT)

13.375 12.415 68 3200

EXTERNAL END AREA (SQ.IN.) INTERNAL END AREA (SQ.IN.) STEEL END AREA (SQ.IN.) Tensile Strength Casing

140.50 121.06 19.45

Wellhead Loads after Cementing

Buckled?

Yes

-68

INITIAL CONDITIONS (While cement sets)

Wellhead Load (=Tension at surface)

T; Mlbs Mud wt. inside (MWi) Mud wt outside (MWo) Pressure inside (Pi) Pressure outside (Po) Avg cement dens (MWc) Top of cement (TOC) Pickup is +

9.1 9.1 0 0 12.5 0 0

ppg ppg psi psi ppg ft

+wt. of pipe +wt mud inside -wt cement -wt. mud outside + pressure-area + Pickup

+wpf*L/1000 +0.052MWi Ai L/1000 -0.052MWc Ao(L-TOC)/1000 -0.052MWo Ao TOC/1000 + (PiAi - PoAo)/1000 + Pickup

Initial Wellhead Load

218 183 -292 0 0 0

109

Mlb (Slackoff is -)

Mud wt inside Mud wt outside Pressure inside Pressure outside

FINAL CONDITIONS 11.5 ppg 9.1 ppg Yes 0 psi 0 psi

2.4 ppg 0 ppg 0 psi 0 psi

-68 Drilling

Changes (final - initial)

dMWi dMWo dPi dPo dTemp

Formulae for dT

dT; Mlbs 0 0 0 0 -177 -177

-68

+ (0.052dMWi)Ai(TOC)/1000 - (0.052dMWo)Ao(TOC)/1000 +2 dPi Ai/1000 -2 dPo Ao/1000 94 -AE(dTemp)/1000 Total dT

Final Wellhead Load

44 F

Buckling of Casing after Cementing INITIAL CONDITIONS (While cement sets)

Initial Effective tension at TOC Mud wt. inside (MWi) Mud wt outside (MWo) Teff;Mlbs

9.1 ppg 9.1 ppg

+pipe below TOC +wt mud inside

+wpf(L-TOC)/1000 +0.052MWi Ai(L-TOC)/1000

218 183

Pressure inside (Pi) Pressure outside (Po) Avg. cement dens (MWc) Top of cement (TOC) Pickup

0 psi 0 psi 12.5 ppg

-wt cement +Pickup

-0.052MWc Ao(L-TOC)/1000 +Pickup

Initial Teff at TOC

-292 0

109

0 ft 0 Mlb (Slackoff is -)

FINAL CONDITIONS

Mud wt inside Mud wt outside Pressure inside Pressure outside Changes (final - initial) dMWi dMWo dPi dPo dTemp

11.5 9.1 0 0 2.4 0 0 0 44

ppg ppg psi psi ppg ppg psi psi F

Formula for dTeff -(1-)(0.052dMWi)Ai(TOC)/1000 +(1-)(0.052dMWo)Ao(TOC)/1000 -(1-2)dPi Ai/1000 +(1-2)dPo Ao/1000 -AE(dTemp)/1000

Total dTeff Final Teff at TOC dTeff;Mlbs

If Teff < 0, assume casing is buckled.

0 0 0 0 -177 -177 -68

Buckled?

Yes

TEMPERATURE CALCULATIONS (For drilling strings )

Static Temperatures

Surface (Ts) Bottom hole (Tb) TVD next hole section

75 F 185 F 8400 ft

y = TOC/TVD k = 0.4+0.306y+0.029y^2-0.125y^3 Init. avg temp: Ts + (Tb-Ts)y/2 Final avg temp; F: Ts+(Tb-Ts)k Must be entered above; F: dTemp

0.00 0.400

75 119 44

(For completion strings )

Surface Injection (Tsi) At perforations (Tp) TVD Perforations E = 30,000,000 psi;

80 F 195 F 9321 ft

Poisson's ratio = 0.3;

y = TOC/TVD For big jobs f = 3 Little jobs f = 2 Final avg temp; F: Tsi+(Tp-Tsi)y/f Must be entered above; F: dTemp Coefficient of thermal expansion = 6.9E-6 / F

0.00 3

80 5

PURPOSE: Computes stresses, loads, and buckling in casing after cementing COMPUTATIONS: 1. Buckling in intermediate and completion casings 2. Wellhead loads in intermediate and completion casings

= FL/EA ;note that we can cancel the length L from each side of the equation, and then cross multiply by E, ar = F/A , however, F/A is stress and we can finally write:

; The thermal stress which develops if a structure or member is completely constrained (not allowed to move a 3713 3800 3900 4000 4100 4200 4300 4400 4500 4600 4700 4800 4900 5000 109 5100 5200 5300 5400 5500 5600 5700 5800 5900 6000 6100 6200 6300 392224 6400 6500 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 0.78626 26.4 0

26.4 1805.881 26.4 3881.606 26.4 5957.331 26.4 8033.056 26.4 10108.78 26.4 12184.51 26.4 14260.23 26.4 16335.96 26.4 18411.68 26.4 20487.41 26.4 22563.13 26.4 24638.86 26.4 26714.58 26.4 28790.31 26.4 30866.03 26.4 32941.76 26.4 35017.48 26.4 37093.21 26.4 39168.93 26.4 41244.66 26.4 43320.38 26.4 45396.11 26.4 47471.84 26.4 49547.56 26.4 51623.29 26.4 53699.01 26.4 55774.74 26.4 57850.46

and then cross multiply by E, arriving at:

nstrained (not allowed to move at all) is the product of the coefficient of linear expansion and the temperature change and

nd the temperature change and Young's modulus for the material.

Вам также может понравиться

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyОт EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyОценок пока нет

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsОт EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsОценок пока нет

- Air Compressors 1170cfm T4Документ2 страницыAir Compressors 1170cfm T4death666darkОценок пока нет

- Strength of Casing and Tubing - PetroWiki PDFДокумент15 страницStrength of Casing and Tubing - PetroWiki PDFLuis David Concha CastilloОценок пока нет

- WebtocДокумент10 страницWebtocriobmОценок пока нет

- Spe 36761 MSДокумент13 страницSpe 36761 MSKarla CotesОценок пока нет

- Flange Design: Welding UnitsДокумент0 страницFlange Design: Welding Unitsabhi1648665Оценок пока нет

- Chapter 2: Casing Design: Calculations of Loads On A CasingДокумент49 страницChapter 2: Casing Design: Calculations of Loads On A Casingkhushbu hasanОценок пока нет

- @@@ Geothermal-WellsДокумент44 страницы@@@ Geothermal-WellsstarykltОценок пока нет

- Ees ExampleДокумент12 страницEes ExamplesbjОценок пока нет

- IADC/SPE 99074 A Re-Examination of Drillpipe/Slip Mechanics: F F D D K K L LДокумент8 страницIADC/SPE 99074 A Re-Examination of Drillpipe/Slip Mechanics: F F D D K K L LJaaTa Da shaanОценок пока нет

- 01 Bolt Tightening ToolДокумент30 страниц01 Bolt Tightening ToolabdulfetahОценок пока нет

- Recommendation For Elimination of Lead Filling in Target FlangesДокумент10 страницRecommendation For Elimination of Lead Filling in Target FlangesYoung Su KoОценок пока нет

- X Over ConnectionДокумент4 страницыX Over ConnectionANSARAKUОценок пока нет

- Davis Lynch Cementing PDFДокумент30 страницDavis Lynch Cementing PDFWilliam0% (1)

- Casing ModuleДокумент12 страницCasing ModuleFarahKhanJamaliОценок пока нет

- Cameron Drilling Products Overview CatalogДокумент587 страницCameron Drilling Products Overview CatalogJayro LeninОценок пока нет

- Casing DesignДокумент12 страницCasing DesignRisTy FrogGiesaa AmaNeeОценок пока нет

- API Casing DesignДокумент2 страницыAPI Casing DesignJohnОценок пока нет

- Casing Data SheetДокумент21 страницаCasing Data SheetAbdul Hameed OmarОценок пока нет

- Planning & Execution of Subsea HPHT WellДокумент14 страницPlanning & Execution of Subsea HPHT WellAliОценок пока нет

- PDFДокумент27 страницPDFEdwin MPОценок пока нет

- Accuracy Prediction For Directional MWDДокумент16 страницAccuracy Prediction For Directional MWDJohnSmithОценок пока нет

- Analysis of An Annular Pressure Buildup Failure During Drill AheadДокумент6 страницAnalysis of An Annular Pressure Buildup Failure During Drill AheadJulian OlarteОценок пока нет

- MACP and Well Control RecordДокумент6 страницMACP and Well Control RecordSudish BhatОценок пока нет

- Tomax AST Tool User ManualДокумент4 страницыTomax AST Tool User ManualChinyere NkereОценок пока нет

- S.C.S.S.V. Leakage RateДокумент1 страницаS.C.S.S.V. Leakage Ratefrancisryan4519Оценок пока нет

- SH Shandong Kerui Petroleum Equipment Co., LTD.: 1, Crown BlockДокумент7 страницSH Shandong Kerui Petroleum Equipment Co., LTD.: 1, Crown BlockCleevh MabialaОценок пока нет

- Swagelok Fittings SpecificationsДокумент3 страницыSwagelok Fittings SpecificationsSam Chong Ks100% (1)

- 1 Stack Component Codes: Halda Etroleum OmpanyДокумент7 страниц1 Stack Component Codes: Halda Etroleum Ompanyislam atifОценок пока нет

- Chapter-3 Fracture Gradient DeterminationsДокумент18 страницChapter-3 Fracture Gradient DeterminationsElisha TalipОценок пока нет

- Master Thesis - Jose Maria MoratallaДокумент80 страницMaster Thesis - Jose Maria MoratallaorlandoОценок пока нет

- QFPIRA00LG9A6072BДокумент171 страницаQFPIRA00LG9A6072BSameh El-Sabbagh0% (1)

- LPR-N Tester Valve Funcionamiento 1Документ33 страницыLPR-N Tester Valve Funcionamiento 1Александр КинтероОценок пока нет

- Operation Instructions - Multi-Turn - Actuators - SAEx - 07.2-SAEx - 16.2 - SAREx - 07.2-SAREx - 16.2 - Control - HART - enДокумент108 страницOperation Instructions - Multi-Turn - Actuators - SAEx - 07.2-SAEx - 16.2 - SAREx - 07.2-SAREx - 16.2 - Control - HART - enPeter RhoadsОценок пока нет

- 012 +FMC+Technologies+-+Arno+Vissers PDFДокумент21 страница012 +FMC+Technologies+-+Arno+Vissers PDFmalikscribdОценок пока нет

- Custom Pipe Handlers Brochure Feb 27 2013Документ6 страницCustom Pipe Handlers Brochure Feb 27 2013Alejandro Gomez100% (1)

- Model 500 GV CatalogДокумент4 страницыModel 500 GV CatalogYuda100% (1)

- Case Study 3: Managed Pressure DrillingДокумент151 страницаCase Study 3: Managed Pressure DrillingBalkis FatihaОценок пока нет

- Subsea Eng Prog Man 08-09Документ57 страницSubsea Eng Prog Man 08-09Tom LH100% (1)

- API Monogram Mud Gas SeparatorДокумент1 страницаAPI Monogram Mud Gas SeparatorKapwell LimitedОценок пока нет

- 1.8 Casing Design1.9 Burst, Collapse, TensionДокумент19 страниц1.8 Casing Design1.9 Burst, Collapse, TensionMobeen MurtazaОценок пока нет

- Crown Mounted Compensator - CMC 2500-1000-25 PDFДокумент1 страницаCrown Mounted Compensator - CMC 2500-1000-25 PDFMarcos SobreiroОценок пока нет

- Pumptools - BOP CanДокумент1 страницаPumptools - BOP Cancasda73Оценок пока нет

- Texas Oil Tools: Packer Inserts & EnergizersДокумент12 страницTexas Oil Tools: Packer Inserts & Energizersshahrol effendy rodziОценок пока нет

- Stress Analysis of Drillstring Threaded ConnectionДокумент30 страницStress Analysis of Drillstring Threaded ConnectionRyan FenyvesОценок пока нет

- SPE Paper ReferencesДокумент4 страницыSPE Paper ReferencesjamartiОценок пока нет

- Hydril Annular BOP1Документ2 страницыHydril Annular BOP1Abde EsselamОценок пока нет

- WellheadДокумент7 страницWellheadarmin heidariОценок пока нет

- Leak-Off Test Analysis: Well: RigДокумент5 страницLeak-Off Test Analysis: Well: RigstevebeardsleyОценок пока нет

- H4 Connector - Reference OnlyДокумент117 страницH4 Connector - Reference OnlyDanielle Vasconcelos ParraОценок пока нет

- HPHT Production in The GOMДокумент40 страницHPHT Production in The GOMPerlaОценок пока нет

- CDAMnemonicsДокумент18 страницCDAMnemonicsvanthodcОценок пока нет

- Hydraulic Stage Tool: Model 754PD With 854BS Liner Plug SetДокумент6 страницHydraulic Stage Tool: Model 754PD With 854BS Liner Plug SetAli AlakariОценок пока нет

- Shandong Kerui Petrochemical Equipment CO.-business AnalysisДокумент1 страницаShandong Kerui Petrochemical Equipment CO.-business Analysis911targaОценок пока нет

- Autoclave Subsea Ball ValvesДокумент20 страницAutoclave Subsea Ball Valvesvp989Оценок пока нет

- The Deepwater Horizon Oil Spill of 2010: A Disaster UnveiledОт EverandThe Deepwater Horizon Oil Spill of 2010: A Disaster UnveiledОценок пока нет

- Ref 17Документ1 страницаRef 17scrbdgharaviОценок пока нет

- Ref 4Документ1 страницаRef 4scrbdgharaviОценок пока нет

- Reference 18: Schedule 'D' Health, Safety, Environment and SecurityДокумент1 страницаReference 18: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviОценок пока нет

- Video Training Courses in Offshore Structures DesignДокумент102 страницыVideo Training Courses in Offshore Structures Designscrbdgharavi100% (2)

- Reference 19: Schedule 'D' Health, Safety, Environment and SecurityДокумент1 страницаReference 19: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviОценок пока нет

- Reference 15: Schedule 'D' Health, Safety, Environment and SecurityДокумент1 страницаReference 15: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviОценок пока нет

- Reference 14: Schedule 'D' Health, Safety, Environment and SecurityДокумент1 страницаReference 14: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviОценок пока нет

- Reference 6: Schedule 'D' Health, Safety, Environment and SecurityДокумент1 страницаReference 6: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviОценок пока нет

- Reference 16: Schedule 'D' Health, Safety, Environment and SecurityДокумент1 страницаReference 16: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviОценок пока нет

- Reference 2: Schedule 'D' Health, Safety, Environment and SecurityДокумент1 страницаReference 2: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviОценок пока нет

- HSE Management - Guidelines For Working Together in A Contract EnvironmentДокумент72 страницыHSE Management - Guidelines For Working Together in A Contract EnvironmentscrbdgharaviОценок пока нет

- U.S. Government Pipeline Safety Regulation: by J C CaldwellДокумент6 страницU.S. Government Pipeline Safety Regulation: by J C CaldwellscrbdgharaviОценок пока нет

- 0973r04 OKIOC Marine ManualДокумент79 страниц0973r04 OKIOC Marine ManualscrbdgharaviОценок пока нет

- An Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferДокумент8 страницAn Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferscrbdgharaviОценок пока нет

- Pre On-Line Inspection Pigging: by C KershawДокумент6 страницPre On-Line Inspection Pigging: by C KershawscrbdgharaviОценок пока нет

- Reference 3: Schedule 'D' Health, Safety, Environment and SecurityДокумент1 страницаReference 3: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviОценок пока нет

- Internal Cleaning and Coating of In-Place Pipelines: by C KleinДокумент4 страницыInternal Cleaning and Coating of In-Place Pipelines: by C KleinscrbdgharaviОценок пока нет

- Solutions To Unpiggable' Pipelines: by Allen A PenningtonДокумент6 страницSolutions To Unpiggable' Pipelines: by Allen A PenningtonscrbdgharaviОценок пока нет

- Pigging Multi-Diameter Lines and Other Specialist TechniquesДокумент6 страницPigging Multi-Diameter Lines and Other Specialist TechniquesscrbdgharaviОценок пока нет

- A Comparison of CP Survey Techniques and Intelligent Pig InspectionДокумент6 страницA Comparison of CP Survey Techniques and Intelligent Pig InspectionscrbdgharaviОценок пока нет

- Cleaning and Geometry Inspection Prior To Corrosion InspectionДокумент4 страницыCleaning and Geometry Inspection Prior To Corrosion InspectionscrbdgharaviОценок пока нет

- New Developments in The Inspection of Gas Distribution MainsДокумент6 страницNew Developments in The Inspection of Gas Distribution MainsscrbdgharaviОценок пока нет

- Mud MixДокумент2 страницыMud MixscrbdgharaviОценок пока нет

- Engineering Technical ServicesДокумент11 страницEngineering Technical ServicesscrbdgharaviОценок пока нет

- Horizontal Turn: 161277483.xls - Ms - Office Mitchell Engineering ProgramsДокумент1 страницаHorizontal Turn: 161277483.xls - Ms - Office Mitchell Engineering ProgramsscrbdgharaviОценок пока нет

- Hor PlanДокумент1 страницаHor PlanscrbdgharaviОценок пока нет

- 4.1 Genetic Counselling 222Документ12 страниц4.1 Genetic Counselling 222Sahar JoshОценок пока нет

- WaveДокумент1 страницаWavejimbieОценок пока нет

- Sindhudurg Kokan All Tourism Spot Information WWW - Marathimann.inДокумент54 страницыSindhudurg Kokan All Tourism Spot Information WWW - Marathimann.inMarathi Mann92% (12)

- Ila 0306Документ11 страницIla 0306Hong ChenОценок пока нет

- Isolasi Dan Karakterisasi Runutan Senyawa Metabolit Sekunder Fraksi Etil Asetat Dari Umbi Binahong Cord F L A Steen S)Документ12 страницIsolasi Dan Karakterisasi Runutan Senyawa Metabolit Sekunder Fraksi Etil Asetat Dari Umbi Binahong Cord F L A Steen S)Fajar ManikОценок пока нет

- RECAP Lecture 7: FA of EVEN EVEN, FA Corresponding To Finite Languages (Using Both Methods), Transition GraphsДокумент23 страницыRECAP Lecture 7: FA of EVEN EVEN, FA Corresponding To Finite Languages (Using Both Methods), Transition GraphsMuhammad EahteshamОценок пока нет

- CH 13 ArqДокумент6 страницCH 13 Arqneha.senthilaОценок пока нет

- ECON2100 CO Abdool W21Документ5 страницECON2100 CO Abdool W21Imran AbdoolОценок пока нет

- Pitch PDFДокумент12 страницPitch PDFJessa Mae AnonuevoОценок пока нет

- Introduction To Biostatistics KMPK 2023Документ46 страницIntroduction To Biostatistics KMPK 2023ciciОценок пока нет

- Reflection (The We Entrepreneur)Документ2 страницыReflection (The We Entrepreneur)Marklein DumangengОценок пока нет

- BattleRope Ebook FinalДокумент38 страницBattleRope Ebook FinalAnthony Dinicolantonio100% (1)

- BS Assignment Brief - Strategic Planning AssignmentДокумент8 страницBS Assignment Brief - Strategic Planning AssignmentParker Writing ServicesОценок пока нет

- Chemistry Chapter SummariesДокумент23 страницыChemistry Chapter SummariesHayley AndersonОценок пока нет

- Parallels of Stoicism and KalamДокумент95 страницParallels of Stoicism and KalamLDaggersonОценок пока нет

- Story of Their Lives: Lived Experiences of Parents of Children With Special Needs Amidst The PandemicДокумент15 страницStory of Their Lives: Lived Experiences of Parents of Children With Special Needs Amidst The PandemicPsychology and Education: A Multidisciplinary JournalОценок пока нет

- Cheat SheetДокумент2 страницыCheat SheetFrancis TanОценок пока нет

- MODULE 13 Ethics Through Thick and ThinДокумент7 страницMODULE 13 Ethics Through Thick and ThinCristobal M. CantorОценок пока нет

- NursesExperiencesofGriefFollowing28 8 2017thepublishedДокумент14 страницNursesExperiencesofGriefFollowing28 8 2017thepublishedkathleen PerezОценок пока нет

- Form Aplikasi CCAI GTP 2011Документ5 страницForm Aplikasi CCAI GTP 2011Tomo SiagianОценок пока нет

- NCLEX 20QUESTIONS 20safety 20and 20infection 20controlДокумент8 страницNCLEX 20QUESTIONS 20safety 20and 20infection 20controlCassey MillanОценок пока нет

- May Be From Interval (1,100) .The Program Output May Be One of The Following (Scalene, Isosceles, Equilateral, Not A Triangle) - Perform BVAДокумент3 страницыMay Be From Interval (1,100) .The Program Output May Be One of The Following (Scalene, Isosceles, Equilateral, Not A Triangle) - Perform BVAsourabh_sanwalrajputОценок пока нет

- Canine HyperlipidaemiaДокумент11 страницCanine Hyperlipidaemiaheidy acostaОценок пока нет

- Proff Ethi PDFДокумент12 страницProff Ethi PDFgeethammani100% (1)

- 1574 PDFДокумент1 страница1574 PDFAnonymous APW3d6gfd100% (1)

- Visual Impairments in Young Children: Fundamentals of and Strategies For Enhancing DevelopmentДокумент13 страницVisual Impairments in Young Children: Fundamentals of and Strategies For Enhancing Developmentfadil ahmadiОценок пока нет

- Reaction PaperДокумент4 страницыReaction PaperCeñidoza Ian AlbertОценок пока нет

- Chapter 23 AP World History NotesДокумент6 страницChapter 23 AP World History NotesWesley KoerberОценок пока нет

- CBSE Class11 Maths Notes 13 Limits and DerivativesДокумент7 страницCBSE Class11 Maths Notes 13 Limits and DerivativesRoy0% (1)

- Mejia V Reyes - DumaguingДокумент1 страницаMejia V Reyes - DumaguingRonalyn GaculaОценок пока нет