Академический Документы

Профессиональный Документы

Культура Документы

BTS3012 Quick Installation Guide

Загружено:

WANKHAMAАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BTS3012 Quick Installation Guide

Загружено:

WANKHAMAАвторское право:

Доступные форматы

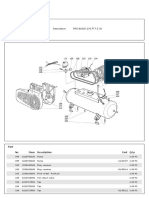

Disassembling the Expansion Bolt D

Installing the Base

Measuring and Adjusting the Levelness of the Insulation Plate

BTS3012 Quick Installation Guide BTS3012

W

Remove the M1260 bolt, spring washer 12, and flat washer 12. M12601212

Use expansion bolts to fix the fixture assembly, insulation plate, and floor together.

Place a level bar on the top plane of the insulation plate in the longitude and latitude directions and use the level bar to measure the levelness of the insulation plate. If the insulation plate is not level, adjust the levelness by adding adjusting pads between the floor and the insulation plate.

Insulation plate Level bar

Fro

Fro

M12x60 bolt M1260

Spring washer 12 12 Flat washer 12 12

Adjusting pad

Before installing a BTS3012 cabinet, prepare the following tools:

D

F 20 F

2F 200 nF 20n F 2nF 2 mA 20 mA 200 mA 10A

Service and Support

POW ER

Fixture assembly

XXX XXX XXX XXX

OH M

200 k 2M 20M hFE

HO LD

200

2k

20k

H

10A

DCV

200 mV 2V 20V 200 V 100 10A 20 0V

D CV

DC A

px

ACA0mA

20K

Hz

200 m

2V

20V

200 V

700 V

!

mA

ACV

!

COM

MA X 10A LIN FU S E

M 200 AX m FUS A ED

!

V

100 MAX 0 700 VDC VAC

Huawei Technologies Co., Ltd. Address: Administration Building, Huawei Technologies Co., Ltd., Bantian, Longgang District, Shenzhen, Peoples Republic of China Email: support@huawei.com Website: http://www.huawei.com Postcode: 518129 518129 http://www.huawei.com 0755-28560000 8008302118 4008302118 0755-28560111 support@huawei.com

Insulation pad

Level bar

Introduction to the BTS3012 cabinet: The BTS3012 cabinet has a modular design. Size: 600 (W) X 450 (D) X 1600 (H) BTS3012: BTS3012 600(W)X450(D)X1600(H)

Ratchet spanner Socket spanner

Phillips screwdriver

Fixing the Cabinet

Using Expansion Bolts to Fix the Cabinet with the Base B Testing the Resistance Between the Cabinet and the Expansion Bolts C

Set a multimeter to the megohm position. Use the multimeter to measure the resistance between the cabinet and the expansion bolts. If the resistance is equal to or greater than five megohms, you can infer that the cabinet is insulated form the earth and that the test is passed. If the resistance is less than five megohms, you can infer that the cabinet is not insulated from the earth. Then you should remove the expansion bolt. Check whether there are damaged or missing insulation pads. 5M ;5M,

Ensuring That the Fixture Grooves on the Cabinet Are in Complete Contact with the Fixture Blocks on the Fixture Assembly A

Determining the Position for Installing the Cabinet

Cabinet Fixture groove

Place the cabinet on the insulation plate. Push the cabinet and ensure that the fixture grooves on the cabinet are in complete contact with the fixture blocks on the fixture assembly.

Determining the Position for Installing the Cabinet

Layout of a Single Cabinet

394

20

B

Unit: mm (mm)

Layout of Multiple Cabinets

Outline of the cabinet

394

Unit: mm (mm)

Insulation plate

Fron

Expansion bolt

t

Fro

Outline of the cabinet

4N- 20 370+1

Hole for M12 expansion bolt M12

420

450

Front of the cabinet

Auxiliary board for marking the outline of the base

Front of the insulation plate

If there is no auxiliary board for marking the outline of the base, you should install the insulation plate properly to ensure that the distance between the front of the insulation plate and the front of the cabinet is 30 mm. 30mm

Hole for M12 expansion bolt M12

4N-20

200 200

3701 420 450

Front of the insulation plate

Fixture assembly

Rear of the cabinet

Rear of the cabinet

Rear of the cabinet

200

800

502 600

Cabinet Installation Base Line

800

502 600

502 600

502 600

200

502 600

200

Cabinet Installation Base Line Front of the cabinet

Interior wall or reference object

Interior wall or reference object

BTS3012BTS312

Outline of the cabinet

394

Layout for a Cabinet Group of the BTS3012 and the BTS312

D

50

Unit: mm (mm)

BTS3012BTS3012

Layout of the BTS3012 and the BTS3012 (Non-Optimized Version) in Side-by-Side Mode

BTS3012

B

Installing the BTS3012 Cabinet on the Concrete Floor with Insufficient Load Capacity

BTS3012

Preparing Supporting U-Steel

Installing the BTS3012 Cabinet on the Bearing Wall

Determining the Position for Installing the U-Steel

Fixing the Supporting U-Steel

Installing and Leveling the Base D

Place the insulation plate on the supporting U-steel and ensure that the holes in the insulation plate align with the holes in the supporting U-steel.

M1240 bolt M1240 Spring washer Flat washer

625

Outline of the cabinet

394 20 4N- 20

Unit: mm (mm)

24

4N- 20

450 420 3701

370 1

Hole for M12 expansion bolt M12 Front of the insulation plate

500

450 370+1 4N- 16

Front of the insulation plate

370+1 420

Prepare supporting U-steel and drill holes for fixing the base on the U-steel. , Unit: mm

450

(mm)

Determine the position for installing the cabinet according to the construction blueprint. Then determine the position for installing the U-steel. After that, mark the size of the hole on the wall based on the cross-sectional area of the U-steel. ,

Bearing wall Unit: mm (mm)

Use the U-steel to bridge the walls and then use concrete to fill the gaps of the holes.

Bearing walls

200

800

502 600 BTS3012

491 1 650 BTS312

Front of the cabinet

Cabinet Installation Base Line

457 1 600 800

200

502 600

Front of the cabinet Cabinet Installation Base Line

Front of the cabinet

2 50

Non-optimized version BTS3012

Interior wall or reference object

BTS3012

Interior wall or reference object

4 39

37 0

Insulation pad M12 nut M12 Hole for fixing the base Holes in the bearing wall Supporting U-steel Hole for fixing the base

Installing the BTS3012 Cabinet on the Concrete Floor with Sufficient Load Capacity

BTS3012

B

Drilling Holes

Settling the Drill Bit

Installing and Leveling the Base

Installing the Expansion Bolt C

Slightly tighten the expansion bolt. Insert the expansion bolt vertically into the hole. Use a claw hammer to strike the expansion bolt into the hole.

M1260 bolt M1260 Spring washer 12 12 Flat washer 12 12 Expansion tube

90

When installing multiple cabinets, prepare supporting U-steel based on the number of cabinets.

The distance between the holes in one bearing wall should be 370 mm. 370mm

Pushing the Cabinet

Place the cabinet on the insulation plate. Push the cabinet and ensure that the fixture grooves on the cabinet are in complete contact with the fixture blocks on the fixture assembly.

37 0

Fixing the Cabinet

Use two bolts to fix the cabinet, base, and U-steel. 2

Testing the Insulation Between the Cabinet and the Expansion Bolts G

Set a multimeter to the megohm position. Use the multimeter to measure the resistance between the cabinet and the expansion bolts. If the resistance is equal to or greater than five megohms, you can infer that the cabinet is insulated from the earth and the test is passed. If the resistance is less than five megohms, you can infer that the cabinet is not insulated from the earth. Check whether there are damaged or missing insulation pads. 5M ;5M,

Using an insulation plate as a template, mark anchor points for the four expansion bolts and for the outer edges of the insulation plate.Then move the insulation plate away and use a chisel to punch a pit. 4

You should punch the pit only after the concrete base gets dry.

Hold the drill stock firmly and keep the drill bit vertical to the floor. Drill holes while using a vacuum cleaner to clean the dust inside the holes. Ensure that the depth of the holes ranges from 52 mm to 60 mm. 52mm-60mm

Cabinet

Fixture groove Insulation plate Fixture block

Bolt

Fro

16

52 mm-60 mm

Guiding slot Guiding rib Nut

Fixture assembly

Rear of the cabinet 2

Rear of the cabinet

Rear of the cabinet 2007Copyright Huawei Technologies Co., Ltd. 2007. All rights reserved.

nt

Fro

nt

600

600

600

20

Fro

nt

nt

nt

Fixture block

nt

Fr

on

Fro

Supporting U-steel Insulation plate

nt

BTS3012

A

Preparing Supporting U-Steel

Installing the BTS3012 Cabinet on the Spandrel Girder

Determining the Position for Installing the Cabinet

3

Outline of the cabinet 600 Unit: mm (mm)

Fixing the Support

A Installing the Expansion Bolt

Slightly tighten the expansion bolt. Insert the expansion bolt vertically into the hole. Use a claw hammer to strike the expansion bolt into the hole.

M1260 bolt M1260 Spring washer 12 12 Flat washer 12 12

B Disassembling the Expansion Bolt

Remove the M1260 bolt, spring washer 12, and flat washer 12. M12601212

C Installing the A600 Support Under the ESD Floor

A600

1

Lead each M12x60 bolt through the spring washer 12, the flat washer 12, and the hole in the support, and then insert the bolt into the nut in the floor. M12601212 Align the hole in the ESD floor with the hole in the support, lead the M12x70 bolt through the flat washer 12 and spring washer 12 in turn, and then insert the bolt into the hole in the floor 1212M1270 Hammer the support slightly to ensure that the ESD floor is in complete contact with the upper surface of the support, and then remove the M12x70 boltt. , M1270 Use a inner hexagon spanner to diagonally fix the height locking bolts and the M12x60 bolts. M12X60

M1270 bolt M1270 Spring washer 12 12 Flat washer 12 12

Prepare supporting U-steel and drill holes for fixing the base on the U-steel and for fixing the U-steel on the floor.

Unit: mm (mm)

Determine the position for installing the cabinet according to the construction blueprint. Then determine the position for installing the U-steel. On the floor, mark the position for installing the U-steel by drawing two parallel lines with spacing of 370 mm. After that, mark installation holes on the floor. , 370mm ,

Hole for fixing the U-steel

ESD floor

Front of the cabinet

502

394

370 4-16

450

Expansion tube Guiding slot Guiding rib Nut

3

Height fixing bolt (side) () Height fixing bolt (middle) ()

Hole for fixing the U-steel

5- 14 Hole for fixing the base 0 120 0 240

0 300

M1260 bolt M1260 Spring washer 12 12 Flat washer 12 12

25

Fixing the Supporting U-Steel C

Install the expansion bolt.

M1260 bolt M1260 Spring washer 12 12 Flat washer 12 12 Expansion tube Guiding slot Guiding rib Nut M1260 bolt M1260 Spring washer 12 12 Flat washer 12 12 Expansion tube and nut

+24V

+24V

V-

V-

+24V

V+

-48V -48V GND

-48V -48V GND

-48V -48V GND

-48V -48V GND

BTS3012

B

Installing the BTS3012 Cabinet on the ESD Floor

V+

GND

GND

GND

GND

GND

GND

GND

24V

24V

GND

GND

GND

+24V

+24V

+24V

0V

Determining the Position for Installing the BTS3012 Cabinet

Settling the Drill Bit

Using an insulation plate as a template, mark anchor points for the four expansion bolts and for the outer edges of the insulation plate.Then move the insulation plate away and use a chisel to punch a pit. 4

Cabinet 1 1

Cabinet 2 2

Cabinet 1 1

0V

Determining the Installation Direction of the Cabinet A

S1+S1-S2+S2- COM 2

V+

V-

GND

-48V -48V GND

Phoenix

1

Cabinet

COM1

S1+S1-S2+S2-

3 Connect the removed Phoenix terminal to the other end of the cable.

COM1

+24V

-48V -48V GND

COM 2

GND

4 Connect the Phoenix terminal to the S2+S2- port

EAC

on the DSAC of the main cabinet. PhoenixDSACS2+S2- arrester of the extension cabinet. (-48 V cabinet or +24 V cabinet) (-48V+24V)

SYNC

24V

GND

GND

GND

+24V

+24V

EAC

Positioning the Support

E B

Marking the Positions of the Holes for Installing the Supports

SYNC

16

5 Connect the cord end terminal to the alarm port on the power lightning

Determining the Cabinet Connection Mode

Setting the DIP Switches on the Side of the DCSU DCSU

Cabinet Connection Mode

4 1 4 SW7

Placing the Support A

Place the support under the ESD floor. Use bolts to temporarily fix the support with the ESD floor through the connection holes.

Connection holes (outside) ESD floor

C Drilling Holes for Installing the Supports

Remove the supports and then use a percussion drill with a 16 drill bit to drill holes at the anchor points.

1 One mode is the combined cabinets mode.

Based on the holes for installing the supports, mark the position for expansion bolt holes on the ESD floor.

Connect the cable for combined cabinets on the DCSU of the main cabinet to the CC_OUT port instead of the CC_IN port. DCSU CC_INCC_OUT

Step

Set all the bits of the DIP switch SW1 in the extension cabinet to OFF. Set all the bits of the DIP switches SW2-SW5 in the extension cabinet to OFF. SW2~SW5OFF According to the type of the E1 cable, set the DIP switches SW6-SW7. In 75-ohm transmission mode, set all the bits of the DIP switches to ON. In 120-ohm transmission mode, set all the bits of the DIP switches to OFF. E1SW6~SW775ON,120 OFF

ON SW6 OFF 1 SW9 1 4 ON OFF 1 4 SW8 1 4 ON OFF

Combined cabinets SW1OFF

SW10

2 The other mode is the cabinet group mode. Setup is not required.

DCSU

SW14 1

SW5 1 ON 4 4 4 SW2 OFF SW4 1 SW3 1 1 1 1 4 4 4 4

CC_OUT

SW13 SW12

Cabinet group

Set all the bits of the DIP switch SW1 in the cabinet of the extension cabinet group to OFF. SW1OFF According to the type of the E1 cable, set the DIP switches SW6-SW7. In 75-ohm transmission mode, set all the bits of the DIP switches to ON. In 120-ohm transmission mode, set all the bits of the DIP switches to OFF. E1SW6~SW7 75ON,120OFF For the settings of the DIP switch SW8, set the bits (from lower to higher) in extension cabinet group 1 to OFF OFF ON ON respectively and set the bits (from lower to higher) in extension cabinet group 2 to ON OFF OFF ON. SW81OFF OFF ON ON, 2ON OFF OFF ON

90

16

CC_IN

SW11 1 SW1 1 4 4

ON OFF

TO_DTRB

Connection holes (inside)

Holes for installing the supports

TOP2

Initial status

2007Copyright Huawei Technologies Co., Ltd. 2007. All rights reserved.

0V

37 0

25

1200 2400

Front of the cabinet

The distance between the holes for fixing the U-steel should be 370 mm, as shown in the figure above. 370mm

4 1

Installing the BTS3012 Cabinet

For the method of installing the cabinet, refer to the section Installing the BTS3012 Cabinet on the Concrete Floor with Sufficient Load Capacity. BTS3012

Disassemble the expansion bolt.

Add the spring washer 12 and flat washer 12 to the M12x60 bolt. Then lead the bolt through the U-steel. Insert the bolt into the nut in the floor. Use a torque wrench to fix the nuts diagonally and tighten them to 45 Nm. M12601212 , 45N*m

BTS3012

Installing the BTS3012 Cabinet in Side-by-Side Mode

Installing the Cabinets and Cables

Connecting the Cabinets

For the method of installing the cabinet, refer to the section Installing the BTS3012 Cabinet on the Bearing Wall. BTS3012

Connecting the Equipotential Cable

Arrange the two cabinets and ensure that they are flush with and in close contact with each other. Use connecting pieces to connect the cabinets from the top. ,

Connect the OT terminals on both ends of the equipotential cable to the protection grounding bar between the tops of the BTS3012 cabinets OTBTS3012

-48 V cabinet -48V

+24V +24V +24V GND GND GND

+24 V cabinet +24V

+24V +24V +24V GND GND GND

PE ALARM

PE ALARM

Cabinet 2 2

Holes C Drilling

Hold the drill stock firmly and keep the drill bit vertical to the floor. Drill holes while using a vacuum cleaner to clean the dust inside the holes. Ensure that the depth of the holes ranges from 52 mm to 60 mm. 52mm-60mm

BTS3012

Connecting the Lightning Protection Failure Alarm Cable of the BTS3012

Connecting the Lightning Protection Failure Alarm Cables for the Combined Cabinets BTS3012

1 Crimp a connector onto one end of the cable to form a cord end terminal.

Cabinet Direction of the precast slab

Precast slab

Connect the phoenix terminal of the lightning protection failure alarm cable in the main cabinet to the S1+S1- port on the DSAC. phoenix DSACS1+S1-

DSAC

2 Use a flathead screwdriver(width:3mm,thick:0.3mm) to remove the Phoenix terminal of the

cable from the top of the extension cabinet. 3mm0.3mmPhoenix

DSAC

-48 V cabinet -48V

+24V +24V +24V GND GND GND

+24 V cabinet +24V

PE ALARM

BTS3012BTS312

Installing the BTS3012 Cabinet in a Cabinet Group of the BTS3012 and the BTS312

Setting the DIP Switches on the TRB of the BTS312 BTS312TRB

Position of the DIP Switches on the TRB TRB

Installing the Cabinets and Cables

Arranging the BTS3012 and BTS312 Cabinets BTS3012BTS312

Connecting the Equipotential Cable

Settings of the S1 and S3 DIP switches on the TRB TRB S1S3

S5 S6

F_ID3 F_ID2 F_ID1 F_ID0 B_ID2 B_ID1

Settings of the S5 and S6 DIP switches on the TRB TRB S5S6

V+

As shown in the following figure, arrange the BTS3012 and BTS312 cabinets and ensure that they are flush with and in close contact with each other. BTS3012BTS312 BTS3012BTS312

Note: The cabinet in the main cabinet group must be of the BTS3012. BTS3012

1 Connect the OT terminal on one end of the

ON S1

equipotential cable to the protection grounding bar on top of the BTS3012 cabinet. OTBTS3012

+24V

ON

+24V

1 2 3 4 5 6 7 8

V-

S2

BTS312

Bit of the S1 and S3 DIP Switches S1S3 F_ID3 ID6 ON ON ON ON F_ID2 ID5 ON ON OFF OFF F_ID1 ID4 OFF OFF ON ON F_ID0 ID3 ON OFF ON OFF

+24V

GND

+24V +24V +24V GND

BTS312 Cabinet BTS312 If the TRB configured in subrack 0 (lowest) 0() If the TRB configured in other subrack

S5 and S6 S5S6 ON for all bits ON OFF for all bits OFF

ID6 ID5 ID4 ID3 ID7 ID2

ON S3

S4

-48 V cabinet -48V

+24 V cabinet +24V Initial status

Main cabinet in extension cabinet group 1 1 Extension cabinet in extension cabinet group 1 1 Main cabinet in extension cabinet group 2 2 Extension cabinet in extension cabinet group 2 2

GND

GND

-48V -48V GND

-48V -48V GND

24V

GND

GND

2 Connect the OT terminal on the other end of the

cable to the Shell GND terminal on top of the BTS312 cabinet. OTBTS312 Shell GND

0V

GND GND

PE ALARM

Rear SHELLGND Front

BTS3012 BTS312

BTS3012

A

Removing the Protection Covers

Installing the BTS3012 Power Cables

Installing the Power Cables (48 V) B (-48V)

Insert the two wires on the cord end terminal of the power cable into the ports labeled -48V and GND respectively on the left of the wiring terminal block. -48VGND

2 3

Setting the DIP Switches on the DCSU of the BTS3012 BTS3012DCSU

Install the BTS3012 cabinet and set the DIP switches on the DCSU of the BTS3012 by referring to the section Installing the BTS3012 Cabinet in Side-by-Side Mode. BTS3012BTS3012DCSU

Remove the protection covers from the power input wiring terminal block.

Note: To avoid damage to the system, you should correctly connect the power cables by polarity.

GND

-48V -48V GND

Settings of the S1 DIP switch on the CMB CMB S1

S1

1 2 3 4

Settings of the S2 DIP switch on the CMB CMB S2

4 ON OFF ON OFF BTS312 Main cabinet in the extension cabinet group Extension cabinet in the extension cabinet group 1 ON OFF BTS312 Main cabinet in the extension cabinet group Extension cabinet in the extension cabinet group 1 OFF OFF Bit of the S2 DIP Switch S2 2 3 OFF OFF ON OFF 4 ON OFF

Settings of the S4 DIP switch on the CMB CMB S4

BTS312 Main cabinet in the extension cabinet group Extension cabinet in the extension cabinet group 1 ON OFF Bit of the S4 DIP Switch S4 2 3 ON OFF ON OFF 4 ON OFF

Wiring terminal block for power input cable

-48V -48V GND

DC power distribution device

GND

Setting the DIP Switches on the CMB of the BTS312 BTS312CMB

V+

V-

Setting the DIP Switches on the CMB of the BTS312 BTS312CMB

EMI filter EMI

ON

BTS312 Main cabinet in extension cabinet group 1 1 Extension cabinet in extension cabinet group 1 1 Main cabinet in extension cabinet group 2 2 Extension cabinet in extension cabinet group 2 2

1 ON ON ON ON

Bits of the S1 DIP Switch S1 2 3 ON ON OFF OFF OFF OFF ON ON

S3

1 2 3 4

ON ON

S5

1 2 3 4

S4

1 2 3 4

ON

Settings of the S3 DIP switch on the CMB CMB S3

Bit of the S3 DIP Switch S3 2 3 ON OFF ON OFF 4 ON OFF

Settings of the S5 DIP switch on the CMB CMB S5

Product Model BTS312 1 ON Bit of the S5 DIP Switch S5 2 3 ON ON 4 OFF

Installing the Power Cables (+24 V) C (+24V)

Fixing the Power Cables D

S2

1 2 3 4

ON

Initial status

Insert the cord end terminals of the power cables into the ports labeled +24V and GND respectively on the left of the wiring terminal block. +24VGND

Connect the OT terminals of the power cables to the corresponding wiring posts on the power distribution frame. OT

Note: To avoid damage to the system, you should correctly connect the power cables by polarity.

Wiring terminal block for power input cable

GND

Position of the DIP Switches on the TDU TDU

DC power distribution device

+24V

+24V

Setting the DIP Switches on the TDU of the BTS312 BTS312TDU

+24V

OT terminal OT

GND

GND

24V

+24V +24V +24V GND GND GND

Terminal bolt

Settings of the DIP switches on the TDU TDU

BTS312 Main cabinet in the extension cabinet group Extension cabinet in the extension cabinet group

ON

Flat washer

PE ALARM

1 OFF OFF

Bit of the DIP Switch 2 OFF OFF EMI filter EMI

0V

Spring washer DC lightning arrester Nut

S1

Initial status 5 6 2007Copyright Huawei Technologies Co., Ltd. 2007. All rights reserved.

(If the RF RX cables and RF TX cables are installed on site, skip this section)

(

Installing the Internal RF Signal Cables in the BTS3012 Cabinet A BTS3012 Pushing the Module into the Corresponding Slot Slightly

the RF Signal Cables Between a Type-A Cabinet Installing the RF Signal Cables Between Type-A Cabinets B C Installing and a Type-B Cabinet AA AB

Tightening the Screws

Tighten the screws on the cables by using a socket spanner .

The type-A cabinet is a cabinet with an optical cable hole on the right of the cabinet top. A

Optical cable holes

The type-B cabinet is a cabinet without an optical cable hole on the right of the cabinet top. B

Optical cable hole

Before installing the module, wear ESD gloves.Then use both bands to install the module because it is heavy.

Use an inner hexagon spanner to tighten the M6 hexagon socket head cap screws on the panel of the module. For the method of installing other modules, refer to the method of installing this module. Tighten the DDPU by using a cross screwdriver 5mm Tighten the DTRU by using a phillips screwdriver width5.6mmthick0.6mm DDPU5mmDTRU5.6mm0.6mm)

Take the typical configuration of S4/4/4 as an example. When the DDPU is configured, set the transmit mode to PBT and the receive mode to receive diversity. DDPUS4/4/4 PBT,

DDPU

RXA1 RXA2 RXA3 RXA4 RXB1 RXB2 TX A

Take the typical configuration of S4/4/4 as an example. When the DFCU is configured, set the transmit mode to transmit independency and the receive mode to receive diversity. DFCUS4/4/4 ,

TX/RX-ANT TX/RX-ANT RXD-ANT TX/RX-ANT RXD-ANT RXD-ANT

Optical cable hole

RUN ALM VSWRA VSWRB

RUN ALM VSWRA VSWRB

RUN ALM VSWRA VSWRB

RUN ALM VSWRA VSWRB

RUN ALM VSWRA VSWRB

RUN ALM VSWRA VSWRB

RUN ALM VSWRA VSWRB

RUN ALM VSWRA VSWRB

DDPU

RXA1 RXA2 RXA3 RXA4 RXB1 RXB2 TX A

DDPU

RXA1 RXA2 RXA3 RXA4 RXB1 RXB2 TX A

COM

COM

COM

COM

COM

COM

COM

COM

POWER TXA RXA1 RXA2 RXA3

RXA3

POWER TXA RXA1 RXA2 RXA3

POWER TXA RXA1 RXA2 RXA3

POWER TXA RXA1 RXA2 RXA3

POWER TXA RXA1

POWER TXA RXA1 RXA2 RXA3

POWER TXA RXA1 RXA2 RXA3

POWER TXA RXA1 RXA2 RXA3

TX2

TX2

TX2

Cable holder

DAFU0 DAFU1 DAFU2 DAFU3

TXB

RXA3

TXB

RXA3

RXB1 RXB2 RXB3 RXB4

RXB1 RXB2 RXB3 RXB4 RXB2 RXB3 RXB4

TXB

RXA3

TXB

RXB2 RXB3 RXB4

Cable holder

DAFU2 DAFU3 DAFU4 DAFU5

DAFU0 DAFU1 DAFU2 DAFU3

RXA2 RXA3

RXA3

TXB

RXA3

TXB

RXA3

TXB

RXA3

TXB

RXB1 RXB2 RXB3 RXB4

RXB1 RXB2 RXB3 RXB4 RXB2 RXB3 RXB4 RXB2 RXB3 RXB4

DAFU4

DAFU5

DAFU0

DAFU1

DAFU4

DAFU5

DAFU0

DAFU1

DAFU2

DAFU3

DAFU4

DAFU5

TX B

TX B

TX B

RXB3 RXB4

RXB3 RXB4

RXB3 RXB4

RUN ALM VSWRA VSWRB

DDPU

DTRU DTRU DTRU DTRU DTRU DTRU

TX1 TCOM

TX1 TCOM TX2

RUN ACT ALM RF_M RUN ACT ALM RF_M

TX1 TCOM TX2

RUN ACT ALM RF_M

TX1 TCOM TX2

RUN ACT ALM RF_M

TX1 TCOM TX2

RUN ACT ALM RF_M

TX1

DTRU DTRU DTRU DTRU DTRU DTRU

TCOM

TX1 TX1 TX1 TX1 TX1 TX1

DDPU

RUN ALM VSWRA VSWRB

TX2

COM

TX2

TCOM TCOM TCOM TCOM TCOM TCOM

RUN ACT ALM

POWER

RF_M

TX2

TX2

TX2

TX2

TX2

TX2

TXA

RS

RS

RS

RS

RS

RS

RUN ACT ALM RF_M

RUN ACT ALM RF_M

RUN ACT ALM RF_M

RUN ACT ALM RF_M

RUN ACT ALM RF_M

RUN ACT ALM RF_M

COM

RXA1 RXA2

RXA3

POWER

RXA4

RS

RS

RS

RS

RS

RS

RXM2

TXB

RXM2

RXM2

RXM2

RXM2

RXM2

TXA

RXB1

Type-A cabinet A

Type-A cabinet A

Type-B cabinet B

Type-A cabinet A

RXA1 RXA2

RXB2

RXM2

RXM2

RXM2

RXM2

RXM2

RXM2

RXB3 RXB4

RXA3

RUN ALM VSWRA VSWRB

DDPU

RWR

RWR

RWR

RWR

RWR

RWR

RXA4

RWR

RWR

RWR

RWR

RWR

RWR

TXB

RXB1

RXB2

RXB3 RXB4

COM

POWER

1

Loosening the Screws A

Connecting the Power Cables to the Lightning Protection Filtering Box on Top of the Cabinet

Insert the cord end terminal of the -48V DC power cable (blue) into the port labeled -48V. -48V DC-48V Insert the cord end terminal of the GND cable (black) into the port labeled GND. GND

-48 V cabinet -48V

Connecting the Power Cables to the Sidepower Sidepower

OUTPUT VOLTA GE OUTPUT CURRENT

Pushing the Board into the Subrack

Fixing the Board C

Turn the ejector levers outwards.

Connect the OT terminal of the -48 V DC power cable (blue) to the negative output copper bar of the Sidepower. -48V DCOTSidepower Connect the OT terminal of the GND cable (black) to the positive output copper bar of the Sidepower. GNDOTSidepower

Output positive copper bar

RTN

Push the board into the subrack.

V-

Load1

Load2

AUX12

AUX34

GND

-48V -48V GND

-48V -48V GND

GND

Output negative MCB

V+

SPD BOX SPD11D There is a fault When any LED is off Lightning Protection Indicator

Wiring terminal block for power input cable

Check that the small hooks on the two handles clasp the upper and lower rectangular holes on the subrack.

Connecting the Alarm Cable to the DSAC DSAC

DSAC COM 2

Connecting the Alarm Cable to the Sidepower Sidepower

Connect the power cable between the BTS3012 Busbar and the DTRU subrack to the PWR port on the DTRU. BTS3012 BusbarDTRUDTRUPWR

POWER

D D P U

POWER

D D P U

D F C U /

D F C B

DC-IN-48V

Connect the power cable between the BTS3012 Busbar and the DAFU subrack to the POWER port on the DDPU or to the DC-IN-48V port on the DFCU/DFCB. BTS3012 BusbarDAFUDDPU POWERDFCU/DFCBDC-IN-48V

POWER

D D P U

POWER

D D P U

D F C U /

D F C B

DC-IN-48V

P6.1

P6.2

P6.3

P6 P6

Fan

PWR D T R U D T R U

P17

POWER P17

P17

COM1

Keep the dustproof cap removed from the power cable for future use.

D C C U POWER

D T R U

P13

D C C U

D T R U

D T R U

D T R U

P13

S1+S1-S2+S2-

P13

Fan

PWR

P13

COM 2

Before installation, check that the connection of the power cable between the BTS3012 Busbar and the common subrack and the connection of the power cable between the BTS3012 Busbar and the fan subrack are correct. Busbar

D T R U P12 PWR

D T R U P11

D T R U P10

D T R U P9

D T R U P8

D T R U P7

P7 P8 P9 P10 P11 P12

D T R U

D T R U

D T R U

D T R U

D T R U

D T R U

SYNC

EAC

S1+S1-S2+S2-

Insert the DB26 male connector on one end of the alarm cable into the EAC port on the DSAC on top of the BTS3012 cabinet. DB26 BTS3012DSACEAC

Insert the DB9 male connector on the other end of the alarm cable into the DB9 female connector on the alarm board of the Sidepower. DB9SidepowerDB9

Buzzer on Buzzer off

Installing the Power Cable Between the BTS3012 Busbar and the DTRU Subrack BTS3012 BusbarDTRU

Installing the Power Cable Between the BTS3012 Busbar and the DAFU Subrack BTS3012 BusbarDAFU

COM1

Connecting the Alarm Cable to the DSAC DSAC

DSAC

Connecting the Alarm Cable to the EMU EMU

PWR

Insert the DB9 male connector on one end of the alarm cable into the COM1 or COM2 port on the DSAC on top of the BTS3012 cabinet. DB9 BTS3012DSACCOM1COM2

Insert the DB9 male connector on the other end of the alarm cable into the RS458 port on the EMU. DB9EMURS458

RE4- RE4+ RE3- RE3+ RE2- RE2+ RE1- RE1+

GND Water12VW 24VW Humi 24VH Temp 24VT

GND2 ANA2 12V2 24V2 GND3 ANA1 12V1 24V1

RS232

PWR2- PWR2+ PWR1- PWR1+

EAC

P17

RS485

NC NC NC NC RE6- RE6+ RE5- RE5+ Gate 12VD Smoke 24VS GND OPTI 24VI 12VI S12- S12+ S11- S11+ S10- S10+ S9S9+ GND4 ANA4 12V4 24V4 GND3 ANA3 12V3 24V3 S8S8+ S7S7+ S6S6+ S5S5+ S4S4+ S3S3+ S2S2+ S1S1+

EMU

S16- S16+ S15- S15+ S14- S14+ S13- S13+

SYNC

S32- S32+ S31- S31+ S30- S30+ S29- S29+

S28- S28+ S27- S27+ S26- S26+ S25- S35+

S24- S24+ S23- S23+ S22- S22+ S21- S21+

S20- S20+ S19- S19+ S18- S18+ S17- S17+

2007Copyright Huawei Technologies Co., Ltd. 2007. All rights reserved.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Lecture 6 Cellular ConceptДокумент28 страницLecture 6 Cellular ConceptThinushan GayarangaОценок пока нет

- Function Var Arg OutДокумент12 страницFunction Var Arg OutWANKHAMAОценок пока нет

- 04NCNetwork Protocol Configuragftion Guide)Документ82 страницы04NCNetwork Protocol Configuragftion Guide)WANKHAMAОценок пока нет

- 03LLC (Link Layer Protocol Configuration Guide)Документ89 страниц03LLC (Link Layer Protocol Configuration Guide)WANKHAMAОценок пока нет

- 3 Day ASSEfT32 Training Course 20020831 B 1 (1) .0Документ148 страниц3 Day ASSEfT32 Training Course 20020831 B 1 (1) .0WANKHAMAОценок пока нет

- Gprs WPДокумент19 страницGprs WPapi-3701758Оценок пока нет

- Chapter 09 Access Control List and Address TranslationДокумент22 страницыChapter 09 Access Control List and Address TranslationWANKHAMAОценок пока нет

- Quidway S Series Network ProductДокумент31 страницаQuidway S Series Network ProductWANKHAMAОценок пока нет

- Call Drop RadioДокумент1 страницаCall Drop RadioaguzizОценок пока нет

- Chapter 05 Router Basis and ConfigurationsДокумент45 страницChapter 05 Router Basis and ConfigurationsWANKHAMAОценок пока нет

- Chapter 03 Common Interface and CableV2.0Документ23 страницыChapter 03 Common Interface and CableV2.0WANKHAMAОценок пока нет

- Training Object: Principles and Various Parts of VOIPДокумент41 страницаTraining Object: Principles and Various Parts of VOIPWANKHAMAОценок пока нет

- 2G KPI Anapysis Problem and SolutionsДокумент50 страниц2G KPI Anapysis Problem and Solutionselahe19100% (5)

- Chapter 07 WAN Princinpal and ConfigrationV2.0Документ55 страницChapter 07 WAN Princinpal and ConfigrationV2.0WANKHAMAОценок пока нет

- SAT12 Trobule ShoottingДокумент21 страницаSAT12 Trobule ShoottingWANKHAMAОценок пока нет

- Chapter 10 DDR and ISDNДокумент37 страницChapter 10 DDR and ISDNWANKHAMAОценок пока нет

- SAT08 MulticastДокумент44 страницыSAT08 MulticastWANKHAMAОценок пока нет

- SAT07 STPДокумент40 страницSAT07 STPWANKHAMAОценок пока нет

- Chapter 12 HSRP V2.0Документ18 страницChapter 12 HSRP V2.0WANKHAMAОценок пока нет

- Training Object: Principles and Various Parts of VOIPДокумент41 страницаTraining Object: Principles and Various Parts of VOIPWANKHAMAОценок пока нет

- SAT10 Ethernet SecurityДокумент52 страницыSAT10 Ethernet SecurityWANKHAMAОценок пока нет

- SAT12 Trobule ShoottingДокумент21 страницаSAT12 Trobule ShoottingWANKHAMAОценок пока нет

- Chapter 07 WAN Princinpal and ConfigrationV2.0Документ55 страницChapter 07 WAN Princinpal and ConfigrationV2.0WANKHAMAОценок пока нет

- SAT08 MulticastДокумент44 страницыSAT08 MulticastWANKHAMAОценок пока нет

- SAT07 STPДокумент40 страницSAT07 STPWANKHAMAОценок пока нет

- SAT08 MulticastДокумент44 страницыSAT08 MulticastWANKHAMAОценок пока нет

- Training Purpose: Types of Ethernet (Standard, Fast, Kilomega)Документ31 страницаTraining Purpose: Types of Ethernet (Standard, Fast, Kilomega)WANKHAMAОценок пока нет

- SAT06 Vlan RoutingДокумент20 страницSAT06 Vlan RoutingWANKHAMAОценок пока нет

- Training Objectives: Understand VLAN Generation BackgroundДокумент24 страницыTraining Objectives: Understand VLAN Generation BackgroundWANKHAMAОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Introduction To Computer HardwareДокумент39 страницIntroduction To Computer HardwareBusiness BusinessОценок пока нет

- Zxevo User Manual Revc EngДокумент19 страницZxevo User Manual Revc EngConrad RussoОценок пока нет

- Electrical Wiring and SafetyДокумент25 страницElectrical Wiring and SafetyCharo Nudo PongasiОценок пока нет

- Date GP No. Name Agency: Safety Ppes Item Issue RegisterДокумент12 страницDate GP No. Name Agency: Safety Ppes Item Issue RegisterDeepak MallikОценок пока нет

- NEMA VE - 2 QUIZ With AnswersДокумент12 страницNEMA VE - 2 QUIZ With AnswersAbdul RaheemОценок пока нет

- E-11 StandardABYCДокумент3 страницыE-11 StandardABYCEdgar MartínОценок пока нет

- HMD (Hotmetaldetector) 3000 BROCHUREДокумент8 страницHMD (Hotmetaldetector) 3000 BROCHUREminhtrieu999Оценок пока нет

- RSS SectionДокумент8 страницRSS SectionMarcos BarrosОценок пока нет

- Renault Trafic Fault Codes ListДокумент2 страницыRenault Trafic Fault Codes Listcandido vargas gutierrez100% (1)

- WEEE Calculation Tool ManualДокумент39 страницWEEE Calculation Tool ManualcanaconaОценок пока нет

- Working Principle of Earth Leakage Circuit Breaker ELCB and Residual Current Device RCDДокумент6 страницWorking Principle of Earth Leakage Circuit Breaker ELCB and Residual Current Device RCDMouna NjОценок пока нет

- ABAC, b6000 - 270 - ft7.5 - After - April - 2008Документ4 страницыABAC, b6000 - 270 - ft7.5 - After - April - 2008ramsey222Оценок пока нет

- Lorentz Ps2-Speed-Controller Manual en PDFДокумент1 страницаLorentz Ps2-Speed-Controller Manual en PDFLuis RolaОценок пока нет

- Notifier Device Compatibility DocumentДокумент21 страницаNotifier Device Compatibility DocumentleunamsayanОценок пока нет

- TT3020Документ75 страницTT3020Romeish KelaartОценок пока нет

- Fuel PumpДокумент32 страницыFuel PumpAndres Colina Carico100% (1)

- SR102AMДокумент4 страницыSR102AMMarcello ScalioniОценок пока нет

- Anti Knife JacketДокумент1 страницаAnti Knife JacketfsfdgdfОценок пока нет

- Sample Compliance SheetДокумент4 страницыSample Compliance SheetsulaymanОценок пока нет

- Bosch Routers CatalogДокумент34 страницыBosch Routers CatalogertwuyОценок пока нет

- VRF SpecДокумент9 страницVRF Specmannu11Оценок пока нет

- Vol02 Tab01Документ128 страницVol02 Tab01jonathanОценок пока нет

- All Chibitronics TemplatesДокумент5 страницAll Chibitronics Templatesapi-299738243Оценок пока нет

- Wireless Antenna Installation GuideДокумент24 страницыWireless Antenna Installation GuideAher256Оценок пока нет

- 45 Harmony Xb4 Xb5 Xb7 Push ButtonsДокумент217 страниц45 Harmony Xb4 Xb5 Xb7 Push ButtonsAntonioОценок пока нет

- 3sb5 Datasheet NewДокумент32 страницы3sb5 Datasheet NewArun KumarОценок пока нет

- Specification For Line Materials and EquipmentДокумент40 страницSpecification For Line Materials and EquipmentDipankar Das100% (2)

- Inserting Tools For Screwdrivers D3320 enДокумент20 страницInserting Tools For Screwdrivers D3320 enDaveRadaОценок пока нет

- Installation Manual EM-103: I. Accessory Parts II. Installation ProceduresДокумент2 страницыInstallation Manual EM-103: I. Accessory Parts II. Installation ProceduresАндрей КрупкинОценок пока нет

- BM14G DatasheetДокумент4 страницыBM14G DatasheetJona DanielОценок пока нет