Академический Документы

Профессиональный Документы

Культура Документы

Welding Cast Iron

Загружено:

Roberto CordovaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Welding Cast Iron

Загружено:

Roberto CordovaАвторское право:

Доступные форматы

Welding of Cast Iron

Welding-cast-iron deals with classes known as Gray, Malleable and Nodular (or Ductile) according to typical appearance of their microstructure, which affects their properties. Cast irons are alloys of iron, carbon and silicon (may have over 2% carbon and 1-3% silicon), and which may include specific amounts of other elements to achieve definite characteristics. Accepted ASTM Specifications on Cast Iron are listed hereafter: ASTM A47/A47M-99(2004) Standard Specification for Ferritic Malleable Iron Castings . ASTM A48/A48M-03 Standard Specification for Gray Iron Castings ASTM A74-06 Standard Specification for Cast Iron Soil Pipe and Fittings

ASTM A126-04 Standard Specification for Gray Iron Castings for Valves, Flanges, and Pipe Fittings . ASTM A159-83(2006) Standard Specification for Automotive Gray Iron Castings ASTM A247-06 Standard Test Method for Evaluating the Microstructure of Graphite in Iron Castings . ASTM A278/A278M-01(2006) Standard Specification for Gray Iron Castings for Pressure-Containing Parts for Temperatures Up to 650 degrees F (350 degrees C). ASTM A319-71(2006) Standard Specification for Gray Iron Castings for Elevated Temperatures for NonPressure Containing Parts ASTM A327-91(2006) Standard Test Methods for Impact Testing of Cast Irons

ASTM A 339 - Discontinued ASTM A395/A395M-99(2004) Standard Specification for Ferritic Ductile Iron Pressure-Retaining Castings for Use at Elevated Temperatures A 396 - Discontinued

ASTM A436-84(2006) Standard Specification for Austenitic Gray Iron Castings AS ASTM A438 - Withdrawn ASTM A439-83(2004) Standard Specification for Austenitic Ductile Iron Castings ASTM A476/A476M-00(2005) Standard Specification for Ductile Iron Castings for Paper Mill Dryer Rolls. ASTM A518/A518M-99(2003) Standard Specification for Corrosion-Resistant High-Silicon Iron Castings . ASTM A532/A532M-93a(2003) Standard Specification for Abrasion-Resistant Cast Irons . ASTM A536-84(2004) Standard Specification for Ductile Iron Castings ASTM A571/A571M-01(2006) Standard Specification for Austenitic Ductile Iron Castings for Pressure-Containing Parts Suitable for Low-Temperature Service ASTM A602-94(2004) Standard Specification for Automotive Malleable Iron Castings ASTM A608/A608M-06 Standard Specification for Centrifugally Cast Iron-Chromium-Nickel High-Alloy Tubing for Pressure Application at High Temperature . ASTM A644-05 Standard Terminology Relating to Iron Castings . ASTM A667/A667M-87(2003) Standard Specification for Centrifugally Cast Dual Metal (Gray and White Cast Iron) Cylinders ASTM A748/A748M-87(2003) Standard Specification for Statically Cast Chilled White Iron-Gray IronDual Metal Rolls for Pressure Vessel Use . ASTM A823-99(2003) Standard Specification for Statically Cast Permanent Mold Gray Iron Castings . ASTM A834-95(2001) Standard Specification for Common Requirements for Iron Castings for General Industrial Use . ASTM A842-85(2004) Standard Specification for Compacted Graphite Iron Castings .

ASTM A874/A874M-98(2004) Standard Specification for Ferritic Ductile Iron Castings Suitable for Low-Temperature Service . ASTM A888-07a Standard Specification for Hubless Cast Iron Soil Pipe and Fittings for Sanitary and Storm Drain, Waste, and Vent Piping Applications. ASTM A897/A897M-06 Standard Specification for Austempered Ductile Iron Castings. ASTM A942-95(2001) Standard Specification for Centrifugally Cast White Iron/Gray Iron Dual Metal AbrasionResistant Roll Shells. The properties sought for when selecting cast iron are usually economy, good castability even in complex forms, damping of vibrations, resistance to heat checking or heat shock, although strength may not be the primary consideration. Common applications examples are housings, enclosures, machine frames and bases, pipe fittings, clutch plates, brake drums, counterweights etc. Cast iron is much less weldable than low carbon steel because it contains much more carbon and silicon, is brittle and tends to crack. A ductile material should be chosen as filler metal: although specially formulated cast iron electrodes are available, fillers based on nickel or bronze, although more expensive, are sometimes preferred for their increased ductility. One should know before Welding-cast-iron what are material and condition of the job at hand. It is common practice to apply preheating to castings and to provide protected slow cooling, with the purpose of reducing residual stresses and of avoiding cracking. Preheating slows the cooling rate, permitting the formation of less brittle structures. It also permits to the whole casting to contract together with the weld material, reducing residual stresses. Welding-cast-iron for repair may be prohibited in certain highly stressed areas of castings where welding failure is not acceptable. Welding-cast-iron on surfaces to be machined is permitted provided machinability is not impaired. However requirements are set by the user who may or may not allow repairs in specific areas. In any case edge or area preparation for Welding-cast-iron is most important: it should ensure complete removal of defects and provide room for satisfactory filler metal deposition with the minimum penetration allowed. Arc Welding is widely used for Welding-cast-iron. The most popular manual process employed is probably Shielded Metal Arc Welding (SMAW), with proper procedures involving preheat and postheat. One commonly uses nickel based, nickelcopper (Monel) or other bronze electrodes.

Nickel electrodes and Cast iron electrodes and rods are classified in the following: ANSI/AWS A5.11/A5.11M:2005 Specification for Nickel and Nickel Alloy Welding Electrodes for Shielded Metal Arc Welding. ANSI/AWS A5.15-90 (R 2006) Specification for Welding Electrodes and Rods for Cast Iron .

Tip!: it is advisable to follow recommendations as published by established suppliers, for Welding-cast-iron. A few tests should always be conducted before selecting a definite product for a repetitive job, in order to find the best solution for the given application under the prevailing circumstances, including welder's skill. Gas Tungsten Arc Welding can be used for Welding-cast-iron (gray iron). A higher preheat is usually recommended. Filler materials in form of rods but of chemical composition similar to those used for SMAW can be used. Also austenitic stainless streels have been used with direct current, straight polarity (electrode negative). Preheat temperature is usually higher. GTAW does not present any significant advantage vs. other less expensive processes. Gas Metal Arc Welding is better suited to Welding-cast-iron of Ductile and Malleable Iron types than for Gray Iron. It is however used when productivity gains are important. Manual Gas welding or more properly oxyacetylene welding, is performed regularly with success for Welding-cast-iron in small castings. The characteristics of the flame can be controlled to be neutral, carburizing or reducing, as better adapted to the work on hand, but in any case the flame and its surrounding atmosphere can effectively protect the workpiece and the tip of filler metal, if used, from contamination from air. For Welding-cast-iron the Oxyacetylene Process can be used, generally for repair or modifications. One must use appropriate fluxes and suitable filler material like cast iron or bronze, if the difference in color is not objectionable for the application. This process is performed at lower temperatures but with higher heat input than arc welding and is usually slower. It is used with preheat and postheat treatments, and may develop less hard and brittle heat affected zone, which may be an advantage. Oxyacetylene welding is generally applied for Welding-cast-iron Gray and Ductile. It is not recommended for Malleable iron because it is likely to produce a wide heat affected zone of hard and brittle white iron. With proper filler metal, Braze-Welding can be performed instead of Welding-castiron,with the advantage of using lower temperature copper based filler rods (bronzes) and a proper flux. The main objection may be that the weld will stand out because of the different color.

Unsuitable processes... Welding-cast-iron is not suitable by Friction Welding, a solid state process with lower than melting temperature, because cast iron contains graphite which interferes with heating and because the material is not forgeable, which is a pre-condition for the process. Also Resistance Welding Process is not applicable to Welding-cast-iron. Repairing a crack in Cast Iron The following Section summarizes the information needed to repair, by Welding-castiron, a crack found in a Cast Iron body. It is the result of recurring requests on the part of our readers who asked for detailed answers to their problems. We deal primarily with Gray Cast Iron which represents the largest majority of general purpose castings. Other types of cast iron include Nodular (or Ductile), and Malleable Cast Iron, which were developed to provide more elaborated mechanical properties, suitable for specific purposes. Preparation It is understood that for Welding-cast-iron a cracked item it should be stripped of any accessories and parts assembled to it, and freed of any external loads. Assuming that the crack is limited in size, and the part is not broken in two or more separate pieces, one needs to drill a small stop hole (about 3 mm or 1/8") at each end of the crack and its branches. To find the end one should grind the area with sandpaper and look with a magnifying glass. Then the crack has to be cleaned by mechanical means like milling or hand grinding with a proper grinding wheel,to provide a V shape channel, with an opening of 60 degrees reaching the bottom of the crack, usually leaving a thin "land" to be completely melted during Welding-cast-iron. In thin sections, backing may be required to get a full penetration root pass. Thicker walls may need special shape channels. Completes the preparation a thorough cleaning of the area, especially if the casting is soaked with oil, grease, paintor other contaminants. A burnout should be done in a furnace for 15 minutes at 480 0C (900 0F), followed by energetic brushing to remove residues. Preheating Reasons for preheating for Welding-cast-iron were already pointed out in this page. Preheating should be performed in a furnace at 200 to 300 0C (400 to 600 0F) for at least an hour. For a small casting torch heating may be acceptable. Welding

Shielded Metal Arc Welding (SMAW or stick) with covered electrodes is the most applied process. Filler metal available ranges from electrodes for cast iron (designated ECI) to Nickel containing electrodes (ENi-CI, ENiFe-CI [preferred for general purposes], ENiCu-A, ENiCu-B) and other types, including bronzes. The selection should be based essentially on experience, preferring the most economic material that permits welding without producing other cracks. For one occasional repair it is suggested that the Nickel electrodes be used, although more expensive, because they are more ductile and as such capable of absorbing larger stresses without cracking. The technique should concentrate in melting the minimum of base metal, by introducing the least amount of heat, with the smallest electrode at the least current, with thin weld beads. The weld is built up with additional beads (after slag removal) until finished, without cooling down. Post heating The welded part should then be allowed to cool down slowly under covering of insulating material or, preferably, be stress relieved immediately in a furnace at 600 to 650 0C (1100 to 1200 0F) for one hour and then furnace cooled. Other processes Oxyacetylene Welding is also possible, with the same preparation, but then, with proper filler metal, Braze-Welding can be performed instead, as per above reference.

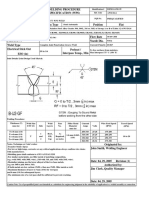

Filler Metal Selection for Cast Iron

Different filler metals electrodes and rods are available for welding and for braze-welding Cast Iron. The selection as usual should be based on the material allowing for the least possible total cost of the application (Material + preparation + welding + finishing) that meets acceptable requirements of integrity and minimum properties. Here we propose a few guidelines for selection. However also the adopted procedure has a determining importance in the success of the operation. Maybe that a certain filler producing cracks if welded without adequate preheating or with too high heat input, will provide acceptable results with different parameters. For Shielded Metal Arc Welding, the following should be considered: Cast Iron Electrodes (ECI) must be used on preheated parts. Their use is usually limited to repairing small flaws. Steel Electrodes (ESt) are made of low carbon wire, with special covering designed to permit low amperage welding. Due to unavoidable dilution of carbon from cast iron, they develop a hard structure unless preheated to a high temperature or post weld annealed. Covered Nickel base electrodes are classified in the following: Pure Nickel (ENi-CI), NickelIron (ENiFe-CI) with 55% Ni and Nickel-Copper (ENiCu). Due to the important presence of nickel in their composition they are relatively expensive. If phosphorus is high, nickel

electrode welding is more susceptible to cracking than nickel-iron which are also less expensive. Copper base electrodes are either alloyed with tin (ECuSn-A, ECuSn-C) or with aluminum (ECuAl-A2). Their color match is poor and melt at lower temperature (providing effectively a sort of braze-welding) than cast iron. Deposits do not harden by carbon pick-up, yield to shrinkage stresses and are machinable. Copper-aluminum welds are stronger than coppertin, and can be used for hardfacing on cast iron. Popular specifications are as follows: AWS A5.11 - NICKEL AND NICKEL ALLOY WELDING ELECTRODES FOR SHIELDED METAL ARC WELDING, SPECIFICATION FOR AWS A5.11/A5.11M - SPECIFICATION FOR NICKEL AND NICKEL ALLOY WELDING ELECTRODES FOR SHIELDED METAL ARC WELDING Cast iron electrodes and rods are given in: AWS A5.15 - SPECIFICATION FOR WELDING ELECTRODES AND RODS FOR CAST IRON Specifications represent experience of different groups, and a wide agreement reached among them. Specifications are therefore a frame of reference, not a rigid constraint unless called for in a binding document. When looking for a proper filler metal electrode for welding Cast Iron, one should remember that manufacturers experiment even out of Specification limits. Therefore they may come up with non conventional solutions which may be exactly appropriate for a particular problem. Their claims may be overly optimistic, but they cannot be dismissed without trying. Readers are urged to try new products not yet standardized if their problem looks them difficult. First ask (describe your problem) then try (with somewhat different procedures), finally decide.

Welding of Ductile Cast iron

Ductile Iron, although less ductile than wrought steel, is however much more ductile than other types of Cast Iron. This quality, very important for certain applications, is achieved by careful additions of manganese and tiny amounts of magnesium or cerium in the melt. The result, upon solidification and cooling of the castings, is that it produces graphite agglomerations of spherical shape, called nodules, instead of the common graphite flakes present in gray iron. Each nodule is surrounded by a zone of ferrite (carbon-free iron) with the balance of the metal matrix usually in the form of ferrite or pearlite.

Graphite, an essential constituent, is the stable form of pure carbon in cast iron. Graphite flakes act like cracks in the gray cast iron matrix and as such contribute to the damping properties of that material. Graphite spheroids, on the contrary, act as crack arresters, giving to the ductile irons remarkably improved mechanical properties. Nodular or ductile irons are available with pearlite, ferrite or pearlite-ferrite matrixes which offer a good combination of strength and toughness, greater ductility, excellent wear resistance and fatigue strength properties. The mechanical properties of ductile iron as determined by tensile test, beam test, ring bending test, and bursting test, including modulus of elasticity, tensile elongation and impact strength are many times those of gray cast iron. Welding is commonly used on cast items to salvage castings by removing defects, to repair worn or damaged parts, or to fabricate parts from two or more separate components. Successful application of Welding-ductile-iron requires understanding of the base metal metallurgy of ductile iron, of the welding influence of fusion processes on microstructure and on the effects of heat treatment. Furthermore the absence of welding defects must be assured, the deployment of sufficient mechanical properties must be achieved and the machinability of the welded portions must not be impaired. Fusion welding of cast irons starts with intricate base metal phase morphology, involves melting or transformation of the phases present and the re-solidification of this melt. Three distinct regions are formed by Welding-ductile-iron, namely the fusion zone, the partially melted zone, and the heat affected zone (HAZ). Unless cared for properly, the welds are prone to cracking in all the three regions. Within the fusion zone, the molten casting and the deposited filler metal can mix freely affecting the dilution extent. Some of the carbon will enter into the weld pool to the effect that mechanical properties may suffer when dilution by the casting is excessive. As with any base material, the success of Welding-ductile-iron depends on suitable equipment, correct procedures, skilled and qualified welders, and effective quality control procedures. When Welding-ductile-iron one should remember that the fusion zone will not resolidify as ductile iron because the graphite will precipitate as vermicular or quasi-nodular. That is why ductility and impact resistance will be drastically reduced, and some carbides are likely to form, particularly in the pearlitic grade. Furthermore the Heat Affected Zone will produce martensite, hard and brittle, especially in the pearlitic grade, that must be heat treated as explained down this page to restore some

ductility. Ductile iron is more susceptible to welding stresses, and more likely to crack while welding or during cooling. Therefore, highly stressed ductile iron castings or portions thereof should never be welded. It is recommended not to perform welds if their section is more than 20% of the metal thickness. Standard Welding-ductile-iron Procedure Preheating should be done preferably in a temperature-controlled furnace at 290 0C (550 0F) by raising gradually the heat from room temperature to avoid temperature gradients and internal stresses. Holding at temperature should last for at least one hour per inch (25 mm) of thickness but not more than six (6) hours. The effect of preheating is to reduce the cooling rate after Welding-ductile-iron. This will effectively avoid or reduce the formation of martensite, the hard phase prone to cracking under stress. The interpass temperature should be preferably 320 0C (600 0F) but in any case not more than 370 0C (700 0F). The shielded metal arc welding process (SMAW) is commonly used for Welding-ductileiron. Direct Current with positive electrode, (reverse polarity DCRP) is required for the electrodes recommended. The voltage and amperage settings should be based on recommendations of the electrode manufacturer. Nickel containing electrodes are preferred because nickel does not form carbides and has low carbon solubility. Therefore carbon is rejected as graphite from the melt upon cooling. Shrinkage stresses and cracking are reduced. AWS ENiFe-CI and ENiFe-CI-A have about the same content (50%) of nickel and iron. Their strength, higher than that of high nickel electrodes, is suitable for Welding-ductileiron even for thick sections. Upon dilution with the base metal, the composition of the weld metal approaches 30% Ni and 70% Fe which has the lowest thermal expansion of all nickel-iron alloys, contributing to the reduction of shrinkage stresses. For Welding-ductile-iron of the high strength grades the nickel-iron-manganese electrodes, designated ENiFeMn-CI, can be used. These are suitable also for wear resistance applications and for surfacing or buildup of worn out parts. To avoid absorption of humidity, the electrodes must be stored in a warm, dry oven after the cans are opened. The weld bead should be of stringer type. If previous weld deposit is present, the arc should be struck on existing beads. Careful attention should be applied to remove slag from the weld deposit between each pass by chipping, peening and wire brushing.

Post Weld Heat Treatment (PWHT). To restore the ductility of welded joints in ductile irons, to levels near those of the original casting, heating to 480 0C (900 0F) and slow air cooling are sufficient for moderate stress relief and softening. Treatments designed to dissolve any carbides that have formed in the welded region provide greater properties improvements. A treatment which transforms to ferrite the structure of the heat affected zone matrix would be suitable for a ductile iron with a ferritic matrix. For obtaining ferrite and pearlite on cooling from austenite, as required for a stronger ductile iron with a matrix containing pearlite, the following treatment could be used, to transform any martensite, produced after cooling from Welding-ductile-iron, back to austenite. Heat to 900 0C (1650 0F) at less than 55 0C (100 0F) per hour and hold for 25 minutes per centimeter (or one hour per inch) of thickness. Furnace cool to 260 0C (500 0F), again at the same hourly rate, then cool to room temperature in still air. If a softer ferrite matrix is needed, it can be achieved as follows: Heat to 840-900 0C (1550-1650 0F), at less than 55 0C (100 0F) per hour and hold at this temperature for 25 minutes per centimeter (or one hour per inch) of thickness. Furnace cool to 675 0C (1240 0F) (at less than 55 0C (100 0F) per hour) and hold for 5-6 hours, then furnace cool to 2600C (500 0F) (at less than 55 0C (100 0F) per hour) before cooling to room temperature in still air. Alternatively, to perform tempering of the normalized structure obtained above, when the temperature of the casting is below 320 0C (600 0F), it may be placed into a tempering furnace, held at 320 0C (600 0F) for 25 minutes per centimeter (or one hour per inch) of thickness for six hours maximum, and heated slowly to 650 0C (1200 0F). Hold at that temperature for 25 minutes per centimeter (or one hour per inch) of thickness for six (6) hours maximum and cool in still air. The reasons why the heating and cooling rates are restricted is to minimize the development of thermal stresses in the castings. The necessary skills for Welding-ductile-iron must be developed by dedicating sufficient training and exercise toward building the necessary expertise and by performing inspection and tests on welded castings.

Вам также может понравиться

- Powermatic 58480438-Millrite-Mvn-Manual PDFДокумент54 страницыPowermatic 58480438-Millrite-Mvn-Manual PDFJason Willis75% (4)

- ASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelДокумент2 страницыASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelBernice JohnsonОценок пока нет

- JIS SectionДокумент2 страницыJIS SectionthakrarhitsОценок пока нет

- A834Документ4 страницыA834mithileshОценок пока нет

- Steel Bars, Alloys, For NitridingДокумент2 страницыSteel Bars, Alloys, For Nitridingruben carcamoОценок пока нет

- Deposition RateДокумент4 страницыDeposition Rateahmed100% (1)

- Guide Cast Iron WeldingДокумент8 страницGuide Cast Iron WeldingAgustine SetiawanОценок пока нет

- Correlation of Hardness Values To Tensile Strength: Semih Genculu, P.EДокумент9 страницCorrelation of Hardness Values To Tensile Strength: Semih Genculu, P.ERakesh DasОценок пока нет

- Electrodes ConsumablesДокумент2 страницыElectrodes Consumablesranjith_007100% (2)

- Astm A31 (1995)Документ4 страницыAstm A31 (1995)gsb2100% (1)

- A299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFДокумент2 страницыA299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFGagan SinghОценок пока нет

- Welding of Cast IronДокумент12 страницWelding of Cast IronwalitedisonОценок пока нет

- - 50 Đề Thi Học Sinh Gioi Lớp 12Документ217 страниц- 50 Đề Thi Học Sinh Gioi Lớp 12Nguyễn Thanh ThảoОценок пока нет

- A1084-15a Standard Test Method For Detecting Detrimental Phases in Lean Duplex Austenitic - Ferritic Stainless SteelsДокумент18 страницA1084-15a Standard Test Method For Detecting Detrimental Phases in Lean Duplex Austenitic - Ferritic Stainless Steelstjt4779Оценок пока нет

- Functional Capacity Evaluation: Occupational Therapy's Role inДокумент2 страницыFunctional Capacity Evaluation: Occupational Therapy's Role inramesh babu100% (1)

- AISI 410 Martensitic Stainless Steel: Gloria Material Technology CorpДокумент1 страницаAISI 410 Martensitic Stainless Steel: Gloria Material Technology CorppvdangОценок пока нет

- ASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFДокумент7 страницASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFJA KОценок пока нет

- Astm A536 PDFДокумент6 страницAstm A536 PDFmatias aliagaОценок пока нет

- High Strength Microalloyed Linepipe Half A CenturyДокумент26 страницHigh Strength Microalloyed Linepipe Half A Centurym_seyedОценок пока нет

- Asme Section II A Sa-276Документ10 страницAsme Section II A Sa-276Anonymous GhPzn1xОценок пока нет

- 13 Ed Gulski PraesentationДокумент45 страниц13 Ed Gulski Praesentationcarlos vidalОценок пока нет

- HIC Resistance SteelДокумент180 страницHIC Resistance SteelArash Ilbagi100% (1)

- High Perf Metals Brochure v1Документ5 страницHigh Perf Metals Brochure v1arianaseriОценок пока нет

- Asme Sa-812 Specification For Steel Sheet, High-Strength, Low-Alloy, Hot-Rolled, For Welded Layered Pressure VesselsДокумент3 страницыAsme Sa-812 Specification For Steel Sheet, High-Strength, Low-Alloy, Hot-Rolled, For Welded Layered Pressure Vesselslucecita1902Оценок пока нет

- Hot Rolled Round Steel Bars PDFДокумент20 страницHot Rolled Round Steel Bars PDFwalitedison100% (1)

- Equivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronДокумент2 страницыEquivalent Grades of Gray Iron, Ductile Iron, SG Iron, Nodular Graphite IronBao Duy Nguyen100% (3)

- Evolution Practice Test 2 With AnswersДокумент10 страницEvolution Practice Test 2 With AnswersSuhani SinhaОценок пока нет

- Heat Resitant Steel Castings MaterialsДокумент2 страницыHeat Resitant Steel Castings MaterialssusisaravananОценок пока нет

- Current Advances in Mechanical Design & Production IV: Proceedings of the Fourth Cairo University MDP Conference, Cairo, 27-29 December 1988От EverandCurrent Advances in Mechanical Design & Production IV: Proceedings of the Fourth Cairo University MDP Conference, Cairo, 27-29 December 1988Y. H. KabilОценок пока нет

- Service Manual - DM0412SДокумент11 страницService Manual - DM0412SStefan Jovanovic100% (1)

- Astm A192 Asme Sa192Документ4 страницыAstm A192 Asme Sa192Mingo EvaОценок пока нет

- Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesДокумент11 страницHot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesNilton Santillan OrtegaОценок пока нет

- Asme Section II A Sa-193 Sa-193mДокумент18 страницAsme Section II A Sa-193 Sa-193mAnonymous GhPzn1xОценок пока нет

- Umali v. Estanislao (1992, 209 SCRA 446)Документ12 страницUmali v. Estanislao (1992, 209 SCRA 446)KTОценок пока нет

- Asme Section II A Sa-354Документ8 страницAsme Section II A Sa-354Anonymous GhPzn1xОценок пока нет

- ARI 700 StandardДокумент19 страницARI 700 StandardMarcos Antonio MoraesОценок пока нет

- Astm A449 1978Документ7 страницAstm A449 1978rensieoviОценок пока нет

- Astm A216Документ3 страницыAstm A216Ruth Sarai YañezОценок пока нет

- MATERIAL GRADE COMPARISON TABLE For Web PDFДокумент9 страницMATERIAL GRADE COMPARISON TABLE For Web PDFsucihaОценок пока нет

- ALuminium MIG Welding of All Series With Filler MetalsДокумент37 страницALuminium MIG Welding of All Series With Filler MetalsSuresh G KumarОценок пока нет

- GB3077-1999 English VersionДокумент20 страницGB3077-1999 English VersionHermanto SupuОценок пока нет

- Sa 276Документ12 страницSa 276edisson_barreraОценок пока нет

- A434Документ3 страницыA434alirioОценок пока нет

- Asme Section II A Sa-302 Sa-302mДокумент4 страницыAsme Section II A Sa-302 Sa-302mAnonymous GhPzn1xОценок пока нет

- Incoloy 800Документ2 страницыIncoloy 800shashi_uit100% (1)

- ASTM A297 (HN) SpecificationДокумент5 страницASTM A297 (HN) SpecificationGuglielmo CancelliОценок пока нет

- D10.4 R1986PVДокумент7 страницD10.4 R1986PVGabriela AxinteОценок пока нет

- A723A723M-18a 1.05 PDFДокумент5 страницA723A723M-18a 1.05 PDFist93993Оценок пока нет

- A597 Standard Specification For Cast Tool Steel1Документ2 страницыA597 Standard Specification For Cast Tool Steel1tsliaОценок пока нет

- Age-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsДокумент4 страницыAge-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsGustavo SuarezОценок пока нет

- Thermanit MTS 3 - GTAWДокумент1 страницаThermanit MTS 3 - GTAWdnageshm4n244Оценок пока нет

- QU AL ITY: Material Data SheetДокумент5 страницQU AL ITY: Material Data SheetAlex007Оценок пока нет

- About En19Документ1 страницаAbout En19ramanamurtytv7176Оценок пока нет

- A 789 - A 789MДокумент4 страницыA 789 - A 789MJGD123Оценок пока нет

- Index PHP PDFДокумент9 страницIndex PHP PDFEloise CamposОценок пока нет

- Welding Rod For c5 & f5 - Er 80s-b6Документ1 страницаWelding Rod For c5 & f5 - Er 80s-b6SatyamEngОценок пока нет

- Disclosure To Promote The Right To InformationДокумент13 страницDisclosure To Promote The Right To InformationTennis Mathew100% (1)

- The Welding Metallurgy of HASTELLOY Alloys C-4, C-22, and C-276Документ2 страницыThe Welding Metallurgy of HASTELLOY Alloys C-4, C-22, and C-276Ivan GarzonОценок пока нет

- Gmaw Complete Aws d1.6Документ1 страницаGmaw Complete Aws d1.6Silvia CardenasОценок пока нет

- Domex 100 XF Data SheetДокумент2 страницыDomex 100 XF Data Sheetzubblwump5063Оценок пока нет

- A 1031 - 04 Qtewmze - PDFДокумент4 страницыA 1031 - 04 Qtewmze - PDFqueno1Оценок пока нет

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFДокумент12 страниц253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulОценок пока нет

- Uni 663 Grade Fe55 1 Tubes PDFДокумент1 страницаUni 663 Grade Fe55 1 Tubes PDFMitul MehtaОценок пока нет

- 1 7335Документ5 страниц1 7335stamatsОценок пока нет

- Aerospace Material SpecificationДокумент6 страницAerospace Material SpecificationadiОценок пока нет

- Soldadura de Hierro ColadoДокумент10 страницSoldadura de Hierro ColadoclnОценок пока нет

- ProjectДокумент34 страницыProjectSTAR PRINTINGОценок пока нет

- Final Plant Diversity Lab ReportДокумент6 страницFinal Plant Diversity Lab Reportapi-508660724Оценок пока нет

- Evolution of Fluidized Bed TechnologyДокумент17 страницEvolution of Fluidized Bed Technologyika yuliyani murtiharjonoОценок пока нет

- A Guide To LU3 PDFДокумент54 страницыA Guide To LU3 PDFMigs MedinaОценок пока нет

- RA ELECTRONICSTECH CEBU Apr2019 PDFДокумент12 страницRA ELECTRONICSTECH CEBU Apr2019 PDFPhilBoardResultsОценок пока нет

- Strep Throat FactsДокумент2 страницыStrep Throat FactsFactPaloozaОценок пока нет

- Operator's Manual: SE Series Slab ScissorsДокумент52 страницыOperator's Manual: SE Series Slab ScissorsthuanОценок пока нет

- CA02 ParchamentoJVMДокумент6 страницCA02 ParchamentoJVMJohnrey ParchamentoОценок пока нет

- Tool 10 Template Working Papers Cover SheetДокумент4 страницыTool 10 Template Working Papers Cover Sheet14. Đỗ Kiến Minh 6/5Оценок пока нет

- Performance Management and Strategic Planning:: Organization's Strategic PlanДокумент7 страницPerformance Management and Strategic Planning:: Organization's Strategic PlanSara AbidОценок пока нет

- Raffles Hotel Jakarta Pricelist 2020Документ2 страницыRaffles Hotel Jakarta Pricelist 2020kielachela aaОценок пока нет

- Network Access Control Quiz3 PDFДокумент2 страницыNetwork Access Control Quiz3 PDFDaljeet SinghОценок пока нет

- Cdd161304-Manual Craftsman LT 1500Документ40 страницCdd161304-Manual Craftsman LT 1500franklin antonio RodriguezОценок пока нет

- Diagnostic Test 12Документ3 страницыDiagnostic Test 12Honorato BugayongОценок пока нет

- Gpat Reference NotesДокумент9 страницGpat Reference NotesPreethi KiranОценок пока нет

- Learners ' Health and Safety Practices and Their Academic PerformanceДокумент10 страницLearners ' Health and Safety Practices and Their Academic PerformanceHira SaddozaiОценок пока нет

- The Man Booker PrizeДокумент2 страницыThe Man Booker PrizeChu Hòa Bình100% (1)

- Water Quantity Estimation PDFДокумент3 страницыWater Quantity Estimation PDFOladunni AfolabiОценок пока нет

- Task 2: Health Services Survey: School Community 1. What Are The Health Services Provided?Документ1 страницаTask 2: Health Services Survey: School Community 1. What Are The Health Services Provided?Bernadeth BaiganОценок пока нет

- EC Type-Examination Certificate: Reg.-No.: 01/205/5192.02/18Документ11 страницEC Type-Examination Certificate: Reg.-No.: 01/205/5192.02/18Orlando Ortiz VillegasОценок пока нет

- Diablo LED Wall LightДокумент2 страницыDiablo LED Wall LightSohit SachdevaОценок пока нет

- Achievement Test Science 4 Regular ClassДокумент9 страницAchievement Test Science 4 Regular ClassJassim MagallanesОценок пока нет

- Lecture 8: Separation DesignДокумент45 страницLecture 8: Separation DesignRavi Kiran MОценок пока нет