Академический Документы

Профессиональный Документы

Культура Документы

Syllabus 4

Загружено:

microsoftkarthiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Syllabus 4

Загружено:

microsoftkarthiАвторское право:

Доступные форматы

Department of Ceramic Engineering

Curriculum of B. Tech (Ceramic Engineering)

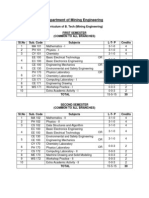

FIRST SEMESTER (COMMON TO ALL BRANCHES) Sl.No 1 2 3 4 5 6 7 8 9 10 Sub. Code MA 101 PH 101 CY 101 EE 100 EC 100 CE 100 CE 130 PH 170 CY 170 CS 171 CE 171 WS 171 Subjects Mathematics - I Physics - I Chemistry Basic Electrical Technology Basic Electronics Engineering Engineering Mechanics Environmental and Safety Engineering Physics Laboratory Chemistry Laboratory Computing Laboratory - I Engineering Drawing Workshop Practice - I Extra Academic Activity - I TOTAL L-T- P 3-1-0 3-1-0 3-1-0 OR OR OR 3-1-0 3-1-0 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 15-5-15 Credits 4 4 4 4 4 2 2 2 2 2 30

SECOND SEMESTER (COMMON TO ALL BRANCHES) Sl.No 1 2 3 4 5 6 7 8 9 10 Sub. Code MA 102 PH 102 CS 102 EC 100 EE 100 CE 130 CE 100 CY 170 PH 170 CS 172 ME 170 WS 172 Subjects Mathematics - II Physics - II Data Structures and Algorithm Basic Electronics Engineering Basic Electrical Technology Environmental and Safety Engineering Engineering Mechanics Chemistry Laboratory Physics Laboratory Computing Laboratory - II Machine Drawing and Solid Modeling Workshop Practice - II Extra Academic Activity - II TOTAL L-T- P 3-1-0 3-1-0 3-1-0 OR OR OR 3-1-0 3-1-0 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 15-5-15 Credits 4 4 4 4 4 2 2 2 2 2 30

THIRD SEMESTER Sl.No 1 2 3 4 5 6 7 8 9 Sub.Code MA 201 CR 211 CR 223 CR 231 MA 270 HS 270 EE 270 EC 270 CR 271 CR 273 Subjects Mathematics III Unit Operations in Ceramic Processing Materials Thermodynamics Properties of Ceramic Raw Materials HS & Open Elective - I Mathematics III Laboratory Language Laboratory Electrical Engineering Laboratory Electronics Laboratory Raw Materials Analysis Laboratory Ceramic Workshop TOTAL L-T- P 3-1-0 3-1-0 3-0-0 3-1-0 3-0-0 0-0-3 0-0-3 0-0-3 0-0-3 Credits 4 4 3 4 3 2 2 2 2 26

OR OR

FOURTH SEMESTER Sl.No 1 2 3 4 5 6 7 8 9 Sub. Code MA 202 CR 212 CR 230 Subjects Mathematics IV Ceramic Processing Science of Ceramic Materials Professional Elective - I HS & Open Elective - II Electronics Laboratory Electrical Engineering Laboratory Language Laboratory Mathematics III Laboratory Drawing of Refractory Lining and Joints Ceramic Fabrication Laboratory TOTAL L-T- P 3-1-0 3-1-0 3-1-0 3-0-0 OR OR 0-0-3 0-0-3 0-0-3 0-0-3 Credits 4 4 4 3/4 3 2 2 2 2 26/27

EC 270 EE 270 HS 270 MA 270 CR 272 CR 274

FIFTH SEMESTER Sl.No 1 2 3 4 5 6 7 8 9 Sub. Code CR 331 CR 341 Subjects Whiteware Technology Physical Ceramics Professional Elective II Professional Elective III HS & Open Elective III High Temperature Processing Laboratory Whiteware Technology Laboratory Ceramic Characterization Laboratory Ceramic Equipment Design Laboratory TOTAL L-T- P 3-0-0 3-1-0 Credits 3 4 3/4 3/4 3 2 2 2 2 24/26

CR 371 CR 373 CR 375 CR 377

3-0-0 0-0-3 0-0-3 0-0-3 0-0-3

SIXTH SEMESTER Sl.No Sub. Code 1 CR 310 2 CR 322 3 4 5 6 CR 370 7 CR 372 8 CR 374 9 CR 376 Subjects Refractories Technology Glass Technology Professional Elective IV Professional Elective V HS & Open Elective - IV Refractories Technology Laboratory Glass Technology Laboratory Ceramic Product Development Laboratory Cement Technology Laboratory TOTAL L-T- P 3-0-0 3-0-0 Credits 3 3 3/4 3/4 3 2 2 2 2 23/25

3-0-0 0-0-3 0-0-3 0-0-3 0-0-3

SEVENTH SEMESTER Sl.No Sub. Code 1 CR 411 2 3 4 5 CR 471 6 CR 491 7 CR 493 8 CR 495 Subjects Advanced Ceramics Professional Elective VI Professional Elective VII HS & Open Elective V Advanced Ceramics Laboratory Research Project I Seminar and Technical Writing - I Short term Industrial/Research Experience TOTAL L-T- P 3-1-0 Credits 4 3/4 3/4 3 2 4 2 2 23/25

3-0-0 0-0-3 0-0-6 0-0-3 0-0-0

EIGHTH SEMESTER Sl. No 1 2 3 4 5 6 7 Sub. Code Subjects Professional Elective VIII Professional Elective IX Professional Elective X HS & Open Elective VI Research Project II Seminar and Technical Writing - II Comprehensive Viva Voce TOTAL L-T- P Credits 3/4 3/4 3/4 3 6 2 2 22/27

CR 492 CR 494 CR 496

3-0-0 0-0-9 0-0-3 0-0-0

LIST OF PROFESSIONAL ELECTIVES

Sl.No Sub. Code 1. CR 226 2. CR 244 3. CR 248 4. CR 325 5. CR 326 6. CR 327 7. CR 330 8. CR 333 9. CR 335 10. CR 336 11. CR 346 12. CR 391 13. CR 392 14. CR 393 15. CR 394 16. CR 395 17. CR 396 18. CR 415 19. CR 416 20. CR 422 21. CR 424 22. CR 426 23. CR 433 24. CR 435 25. CR 441 26. CR 445 27. CR 446 28. BM 222 29. CE 318 30. CH 225 31. CH 331 32. CH 404 33. CS 213 34. CY 531 35. CY 533 36. CY 541 37. CY 551 38. CY 565 39. MA 522 40. ME 250 41. ME 410 42. ME 430 43. MM 256 44. MM 356 45. MM 359 46. PH 351 Subject Pollution & Waste Management in Ceramic Industry Introduction to Engineering Materials Fuels, Furnace and Stoichiometry Computational Materials Science Pyroceramics Interface Science & Sol- Gel Processing Fuel Cell & Batteries Heat Transfer and Fluid Flow Instrumental Characterization Cement Technology Nanoceramics Special Topic in Ceramic Engineering - I Special Topic in Ceramic Engineering - II Special Laboratory in Ceramic Engg - I Special Laboratory in Ceramic Engg - II Engineering Product Development Project - I Engineering Product Development Project - II Bio-ceramics Application of Refractories Ceramic Equipment Design Composite Materials Tribology of Materials Sensor Technology Functional Materials & Devices Electrical and Magnetic Ceramics Application of Phase Diagrams Thin Film and Coating Biomaterials Finite Element Method Chemical Process Calculations Polymer Science & Technology Colloid and Interfacial Engineering Principles of Programming Language Coordination Chemistry Colloids & Surface Chemistry Spectroscopic Methods of Analysis Polymer Chemistry Advanced Solid State Chemistry Operations Research Thermal Engineering Computer Aided Design & Computer Graphics Industrial Management Transport Phenomena Pollution in Metallurgical Industry & its Control Engineering Polymers & Composites Science of Nano materials L-T- P 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-1-0 3-1-0 3-0-0 3-0-0 Credits 3 3 3 3 3 3 3 4 4 3 3 3/4 3/4 2 2 4 4 3 4 3 3 3 3 3 4 4 3 3 4 3 3 3 3 4 4 4 4 4 4 4 3 3 3 3 4 3

0-0-3 0-0-3 0-0-6 0-0-6 3-0-0 3-1-0 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-1-0 3-1-0 3-0-0 3-0-0 3-1-0 3-0-0 3-0-0 3-0-0 3-0-0 3-1-0 3-1-0 3-1-0 3-1-0 3-1-0 3-1-0 3-1-0 3-0-0 3-0-0 3-0-0 3-0-0 3-1-0 3-0-0

DEPARTMENT OF CERAMIC ENGINEERING SUMMARY OF COURSES Sub discipline: CR 211 CR 212 CR 219 CR 310 CR 411 CR 415 CR 416 CR 418 CR 419 Sub discipline: CR 223 CR 226 CR 322 CR 325 CR 326 CR 327 CR 422 CR 424 CR 426 Sub discipline: CR 230 CR 231 CR 330 CR 331 CR 333 CR 335 CR 336 CR 339 CR 433 CR 435 Sub discipline: CR 244 CR 248 CR 249 CR 341 CR 344 CR 346 CR 348 CR 441 Nano & Bio-Ceramics Unit Operations in Ceramic Processing Ceramic Processing Introduction to Ceramics Refractories Technology Advanced Ceramics Bio-ceramics Application of Refractories Nanomaterials Biomaterials for Artificial Implants Glass & Composites Materials Thermodynamics Pollution & Waste Management in Ceramic Industry Glass Technology Computational Materials Science Pyroceramics Interface Science & Sol- Gel Processing Ceramic Equipment Design Composite Materials Tribology of Materials Functional Materials Science of Ceramic Materials Properties of Ceramic Raw Materials Fuel Cell & Batteries Whiteware Technology Heat Transfer and Fluid Flow Instrumental Characterization Cement Technology Ceramics in Electronic Applications Sensor Technology Functional Materials & Devices Magnetic Materials & Thin Films Introduction to Engineering Materials Fuels, Furnace and Stoichiometry Materials Science & Engineering Physical Ceramics Microstructural Design in Ceramics Nanoceramics Introduction to Engineering Ceramics Electrical and Magnetic Ceramics 3-0-0 3-0-0 3-0-0 3-1-0 3-0-0 3-0-0 3-0-0 3-1-0 3 3 3 4 3 3 3 4 3-1-0 3-1-0 3-0-0 3-0-0 3-1-0 3-1-0 3-0-0 3-0-0 3-0-0 3-0-0 4 4 3 3 4 4 3 3 3 3 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3 3 3 3 3 3 3 3 3 3-1-0 3-1-0 3-0-0 3-0-0 3-1-0 3-0-0 3-1-0 3-0-0 3-0-0 4 4 3 3 4 3 4 3 3

CR 445 CR 446 Sub discipline: CR 271 CR 272 CR 273 CR 274 CR 370 CR 371 CR 372 CR 373 CR 374 CR 375 CR 376 CR 377 CR 471 Sub discipline: CR 391 CR 392 CR 393 CR 394 CR 395 CR 396 CR 491 CR 492 CR 493 CR 494 CR 495 CR 496

Application of Phase Diagrams Thin Film and Coatings Laboratory Courses Raw Materials Analysis Laboratory Drawing of Refractory Lining and Joints Ceramic Workshop Ceramic Fabrication Laboratory Refractories Technology Laboratory High Temperature Processing Laboratory Glass Technology Laboratory Whiteware Technology Laboratory Ceramic Product Development Laboratory Ceramic Characterization Laboratory Cement Technology Laboratory Ceramic Equipment Design Laboratory Advanced Ceramics Laboratory Project, Seminar and Special Courses Special Topic in Ceramic Engineering I Special Topic in Ceramic Engineering II Special Laboratory in Ceramic Engg I Special Laboratory in Ceramic Engg II Engineering Product Development Project I Engineering Product Development Project II Research Project I Research Project II Seminar and Technical Writing I Seminar and Technical Writing II Short term Industrial/Research Experience Comprehensive Viva Voce

3-1-0 3-0-0

4 3

0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3

2 2 2 2 2 2 2 2 2 2 2 2 2

0-0-3 0-0-3 0-0-6 0-0-6 0-0-6 0-0-9 0-0-3 0-0-3 0-0-0 0-0-0

3/4 3/4 2 2 4 4 4 6 2 2 2 2

COURSES OFFERED AS OPEN ELECTIVES (Normally not offered to students of Ceramic Engineering) Sl.No. 1. 2. 3. 4. 5. 6. Sub. Code CR 219 CR 249 CR 339 CR 348 CR 418 CR 419 Subject Introduction to Ceramics Materials Science & Engineering Ceramics in Electronic Applications Introduction to Engineering Ceramics Nanomaterials Biomaterials for Artificial Implants L-T- P 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 Credits 3 3 3 3 3 3

DETAILED SYLLABI OF COURSES CR 211 CR 212 CR 219 CR 223 CR 226 CR 230 CR 231 CR 244 CR 248 CR 249 CR 271 CR 272 CR 273 CR 274 CR 310 CR 322 CR 325 CR 326 CR 327 CR 330 CR 331 CR 333 CR 335 CR 336 CR 339 CR 341 CR 344 CR 346 CR 348 CR 370 CR 371 CR 372 CR 373 CR 374 CR 375 CR 376 CR 377 CR 391 CR 392 CR 393 CR 394 CR 395 CR 396 CR 411 CR 415 CR 416 CR 418 Unit Operations in Ceramic Processing Ceramic Processing Introduction to Ceramics Materials Thermodynamics Pollution & Waste Management in Ceramic Industry Science of Ceramic Materials Properties of Ceramic Raw Materials Introduction to Engineering Materials Fuels, Furnace and Stoichiometry Materials Science & Engineering Raw Materials Analysis Laboratory Drawing of Refractory Lining & Joints Ceramic Workshop Ceramic Fabrication Laboratory Refractories Technology Glass Technology Computational Materials Science Pyroceramics Interface Science & Sol- Gel Processing Fuel Cell & Batteries Whiteware Technology Heat Transfer and Fluid Flow Instrumental Characterization Cement Technology Ceramics in Electronic Applications Physical Ceramics Microstructural Design in Ceramics Nanoceramics Introduction to Engineering Ceramics Refractories Technology Laboratory High Temperature Processing Laboratory Glass Technology Laboratory Whiteware Technology Laboratory Ceramic Product Development Laboratory Ceramic Characterization Laboratory Cement Technology Laboratory Ceramic Equipment Design Laboratory Special Topic in Ceramic Engineering - I Special Topic in Ceramic Engineering - II Special Laboratory in Ceramic Engg - I Special Laboratory in Ceramic Engg - II Engineering Product Development Project - I Engineering Product Development Project II Advanced Ceramics Bio-ceramics Application of Refractories Nanomaterials 3-1-0 3-1-0 3-0-0 3-0-0 3-0-0 3-1-0 3-1-0 3-0-0 3-0-0 3-0-0 0-0-3 0-0-3 0-0-3 0-0-3 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-1-0 3-1-0 3-0-0 3-0-0 3-1-0 3-0-0 3-0-0 3-0-0 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 0-0-3 4 4 3 3 3 4 4 3 3 3 2 2 2 2 3 3 3 3 3 3 3 4 4 3 3 4 3 3 3 2 2 2 2 2 2 2 2 3/4 3/4 2 2 4 4 4 3 4 3

0-0-3 0-0-3 0-0-6 0-0-6 3-1-0 3-0-0 3-1-0 3-0-0

CR 419 CR 422 CR 424 CR 426 CR 433 CR 435 CR 441 CR 445 CR 446 CR 471 CR 491 CR 492 CR 493 CR 494 CR 495 CR 496

Biomaterials for Artificial Implants Ceramic Equipment Design Composite Materials Tribology of Materials Sensor Technology Functional Materials & Devices Electrical and Magnetic Ceramics Application of Phase Diagrams Thin Film and Coatings Advanced Ceramics Laboratory Research Project I Research Project II Seminar and Technical Writing - I Seminar and Technical Writing - II Short term Industrial/Research Experience Comprehensive Viva Voce

3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-0-0 3-1-0 3-1-0 3-0-0 0-0-3 0-0-6 0-0-9 0-0-3 0-0-3 0-0-0 0-0-0

3 3 3 3 3 3 4 4 3 2 4 6 2 2 2 2

CR 211

UNIT OPERATIONS IN CERAMIC MATERIALS

4 credits [3-1-0]

Need for communition, different type of communition equipment and theory of size reduction. Milling performance, efficiency and milling performance. Particle size, size reduction and size distribution. Bulk solid transport and mixing. Mixing mechanism and mixedness. Mixing equipment for different type of materials. Consistency, particle mechanics and deformation behaviour of powders, slurries and paste. Particle classification-screening technique, cyclone separators, centrifuge. Filtration and washing process. Plastic forming, extrusion mechanics, control of extrusion defects. Basic concept of drying, costs involved in drying of ceramic, drying mechanisms in particulate systems, characterization of drier operations, drier controls, drying defects and drying shrinkage, advanced drying technologies. Essential Reading: 1. W. L. McCabe, J. C. Smith and P. Harriot, Unit Operations of Chemical Engineering, 7th Ed. McGraw-Hill Professional 2005. 2. J.S. Reed, Introduction to the Principles of Ceramic Processing, 2nd Ed., John Wiley & Sons. 1995. 3. D. A. Brosan and G. C. Robinson, Introduction to Drying of Ceramics: with laboratory exercises, NetLibrary, Incorporated, 2003. Supplementary Reading: 1. A.M. Gaudin, Principles of Mineral Dressing, Tata McGraw-Hill Publishing Company Limited, New Delhi 2003. 2. M. N. Rahaman, Ceramic Processing, CRC Press, 2003 CR 212 CERAMIC PROCESSING 4 credits [3-1-0]

Significance of different ceramic processing operations. Preparation of bodies: Blending of different weight fractions and size ratios, use of binders, types of binders; clay, molecular binder, film forming binders. Plasticizers, Foaming and antifoaming agents, granulation and spray drying. Non-traditional shape forming: Gel casting, Tape casting, Injection moulding, Electro-phoretic deposition, Hot -pressing, Iso-static pressing; porosity, pore structure, drying defects; Diffusion: Mechanism of diffusion in solids, Ficks Laws, Nernst-Einstein equation, Random walk model, Diffusion as a thermally activated process, Diffusion in ceramics, Defects and defect chemistry, Diffusion in Ionic solids; Sintering: Driving force for sintering, solid state and liquid phase sintering, sintering models mechanisms and kinetics. Grain growth and secondary recrystallization. Phase Transformation: Nucleation and Growth, Spinodal decomposition; Mechanism, Thermodynamics and kinetics, Glass formation. Problems of sintering, in homogeneities, Constant sintering, Sintering process variables; Kinetics of Heterogeneous Reactions: Reactions with and between solids, calcination and dehydration reactions, particulate interactions, coarsening, non-isothermal process kinetics. Essential Reading: 1. J.S. Reed, Introduction to the Principles of Ceramic Processing, 2nd Ed., John Wiley & Sons. 1995. 2. M. N. Rahaman, Ceramic Processing and Sintering, 2nd Ed, CRC Press, 2003. Supplementary Reading: 1. D. W. Richerson, Modern Ceramic Engineering: Properties, Processing, and Use in Design, 3rd ed, CRC Press, 2005 2. D. A. Brosan and G. C. Robinson, Introduction to Drying of Ceramics: with laboratory exercises, Net Library, Incorporated, 2003. 3. H. Mehrer, Diffusion in Solids: Fundamentals, Methods, Materials, DiffusionControlled Processes, Springer, 2007.

CR 219

INTRODUCTION TO CERAMICS

3 credits [3-0-0]

Introduction, definition and scope of ceramics. Historical perspective, classification, Ceramics and Civilization ; Traditional ceramics: An overview, history, compositions, manufacturing and application of refractories, whitewares and heavy clay wares, glass, cement, ceramic coatings The development of modern ceramic technology, processing of ceramic powders, shape forming operations: pressing, slip casting, isostatic pressing, injection moulding, sheet forming, MLC technology. Firing of ceramics: kiln design and conveyor technology, sintering and densification, hot pressing and hot isostatic pressing. Sol gel processing and monolithic ceramics. Basic glass processing, container glass, fibre glass, speciality glass products, glass- ceramics, glass microspheres, laminated glass, photochrome and photo sensitive glass Modern / high tech ceramics, high tech functions and functional ceramics, structural ceramics, electrical and electronic ceramics, chemical and nuclear ceramics, bio-ceramics, ceramic membranes, artificial gems and ceramics, aerospace and other strategic applications of ceramics, advanced ceramic processing techniques. Energy and pollution controls. Essential Reading: 1. W. D. Kingery, H. K. Bowen and D. R. Uhlmann, Introduction to Ceramics, 2nd Ed. John Wiley & Sons, Singapore, 1991. 2. D. W. Richardson, B. J. Dunbar, The Magic of Ceramics, American Ceramic Society, 2000. Supplementary Reading: 1. J. B. Wachtman Jr., Ceramic Innovations in the 20th Century, American Ceramic Society, 1999. CR 223 MATERIALS THERMODYNAMICS 3 credits [3-0-0]

Introduction, concept of states, systems equilibrium. Equation of states, extensive and intensive properties homogeneous and heterogeneous systems. Internal energy, heat capacity, enthalpy, isothermal, and adiabatic processes; The Second law of thermodynamics, entropy, enthalpy concepts, degree of reversibility and irreversibility, criteria of equilibrium, auxiliary functions, combined statements, Maxwell's relations, transformation formula, Gibbs-Helmoltz equation; Concept of Third law, temperature dependence of entropy, statistical interpretation of entropy, Debye and Einstein concept of heat capacity, relation between Cp and Cv ; Fugacity, activity, equilibrium constant, homogeneous and heterogeneous equilibria. Ellingham-Richardson diagrams and applications; Solution thermodynamics, partial molal quantities, ideal and non-ideal solutions, Henry's law, Gibbs - Duhem equation, regular solution, quasi-chemical approach to solution ; Statistical thermodynamics. Change of standard state. Phase equilibrium and phase rule. Essential Reading: 1. D. R. Gaskell, Introduction to the Thermodynamics of Materials, Taylor & Francis, 2003. 2. J. M. Smith, H. C. V. Ness, and M. M. Abbott, Introduction to Chemical Engineering Thermodynamics, 7th Ed, McGraw-Hill Professional, 2005. Supplementary Reading: 1. A. Ghosh, Textbook of Materials and Metallurgical Thermodynamics, PHI Learning Pvt. Ltd, 2004

CR 226

POLLUTION & WASTE MANAGEMENT IN CERAMIC INDUSTRY

3 credits [3-0-0]

Pollution and waste generation in ceramic and related industries. Kiln and stack emissions, pollution from service units like air compressor, laboratories, gas producers, storage facilities, waste water treatment plant etc; Environmental and health impacts of pollutants and solid wastes. Indian environmental laws and WHOs norms. Pollution reduction measures in ceramic industries: air, sound, solid waste, water. Nature and type of industrial waste useful for ceramic industries. Use of industrial wastes in ceramic industries Utilization of fly ash, rice husk, BF slag in the production of traditional, advanced ceramics. Utilization of red mud and recovery of metals from red mud. Application of zeolite in environment (catalytic effect, water purification). Study of clay water system as an effective absorbent of toxic pollutant; Recycling of industrial waste in ceramic and allied industries. Fluorine contamination in alumina Industry and the disposal and recovery of refractory materials. Application of ceramics for water and air purification. Glass & glass ceramics in nuclear waste management Essential Reading: 1. P. V. Rao, A Text Book of Environmental Engineering, Prentice Hall of India Private Limited, 2002. 2. C. C. Herman (Editor), S. Marra (Editor), D. R. Spearing (Editor), L. Vance (Editor) and J. D. Vienna (Editor), Environmental Issues and Waste Management Technologies XI, Ceramic Transactions, Volume 176. John Wiley & Sons, edition, 2005. Supplementary Reading: 1. S.K. Sundaram, D. R. Spearing, and J. D. Vienna, Environmental Issues and Waste Management Technology in the Ceramic and Nuclear Industries VIII, Ceramic Transactions, Volume 143, The American Ceramic Society, 2002. 2. S. M. Khopkar, Environmental Pollution: Monitoring and Control, New Age International (P) Ltd, 2004.

CR 230

SCIENCE OF CERAMIC MATERIALS

4 credits [3-1-0]

Crystal lattice, crystal class and crystal system. Some Real Structures: Rock Salt, Zinc Blende, Antifluorite, Rutile, Perovskite, Spinels, Wurtzite etc. Crystal imperfections: types and notations, Solid solutions, defects and dislocations. Vitreous state, glasses and structural models; Condensed phase rule and single component system: Silica, Zirconia and Carbon etc. Two component systems and Lever rule. Free energy-composition diagrams, phase stability, solid solutions, Eutectic and Eutectoid, Peritectic reaction, congruently and incongruently melting compound. Some important binary ceramic systems SiO2-Al2O3, MgO-Al2O3, CaO-SiO2, CaO-ZrO2, MgO-SiO2, BaO-TiO2, CaO-Al2O3, CaO-MgO; Ternary System: Representation of composition on triangle, proof of the basis, Temperature, Solid models, Iso-thermal Sections, Base projection method. Ternary systems with binary and ternary Eutectic, Peritectic, congruently and incongruently melting compounds. Some important ternary ceramic systems: CaO-SiO2-Al2O3, MgO-SiO2-Al2O3, CaO-MgO-SiO2. Brief idea on the application of real system binary, ternary and quaternary phase diagrams in the processing and process control of different ceramic materials. Essential Reading: 1. W. D. Kingery, H. K. Bowen and D. R. Uhlmann, Introduction to Ceramics, 2nd Ed. John Wiley & Sons, Singapore, 1991. 2. L.V. Azaroff, Introduction to Solids, Tata McGraw Hill Publishing Co. Ltd, 1977.

3. F. A. Hummel, Introduction to Phase Equilibrium in Ceramic Systems, First Edition, CRC Press, 1984. Supplementary Reading: 1. C. Kittel, Introduction to Solid State Physics, 8th Ed. John Wiley & Sons Pvt. Ltd, 2004. 2. G. Smith, R. S. Roth, T. Negas and L. P. Cook, Phase Diagrams for Ceramists, American Ceramic Society, 1983

CR 231

PROPERTIES OF CERAMIC RAW MATERIALS

4 credits [3-1-0]

Classification of raw materials, beneficiation of raw materials, importance, use and limitations of natural raw materials: Bauxite, Limestone, Chromite, Magnesite, Dolomite, Fluorite, Graphite, Gypsum, Haematite, Kaolinite, Fireclay, Ball clay, Montmorillonite, Magnetite, Nepheline Syenite, Microcline, Feldspars (soda, potash, lime), Pyrophyllite, Quartz, Quartzite, Sillimanite, Kyanite, Andalusite, Talc, Wollastonite, Zircon, Beryl, Mica, Vermicullite, Silica sand etc ; Brief idea on processing of synthetic raw materials: Bayer process, Calcined Alumina, Tabular Alumina, Fused Alumina, Sea-water Magnesia, Zircon and Zirconia, Titania, Magnesio-Aluminate Spinel, Fumed Silica etc. The application areas and limitations of synthetic raw materials; Effect of heat on different raw materials with reference to phase transformation, thermal expansion, melting, decomposition behaviour, compound formation, stabilization. Essential Reading: 1. W. E. Worrall Clays and Ceramic Raw Materials, 2nd edition, Springer, 1986. 2. W. L. McCabe, J. C. Smith and P. Harriot, Unit Operations of Chemical Engineering, 7th Ed. McGraw-Hill Professional 2005. Supplementary Reading: 1. D. Segal, Chemical Synthesis of Advanced Ceramic Materials, Cambridge University Press, 1991. CR 244 INTRODUCTION TO ENGINEERING MATERIALS 3 credits [3-0-0]

Atomic Structure and Bonding. Crystal Structure, crystal class and crystal geometry: Polymorphism; crystal structure analysis, crystalline Imperfections: point defect and line defects. Diffusions in Solids and phase transformations, thermal and athermal transformations. Solid solutions. Solidification: Solidification of metals and single crystals; Brief idea of crystal growth techniques; Mechanical Properties of Metals: Stress and strain, hardness. Strengthening; Recovery and recrystallization; Strength, Fracture toughness, creep and fatigue. Engineering alloys: Fe-C phase diagram; Heat treatment of steel; Classification of steel; Polymeric Materials: Basic structure simple and network molecules; Physical states and transitions; Plasticization; Crystallinity; Polymerization, Degradation and stabilization of polymers, Vulcanization of rubber. Application of polymers, conducting polymers; Composite Materials: Definition; Types of composites, properties and applications; strength and toughness in composites, layered composites, particulate and fibre reinforced composites; Electrical, Magnetic and Optical Properties of Materials: Classification, Electrical and electronic conduction, polarization, dielectric properties, application. BCS theory and Superconducting Materials. Essential Reading: 1. W. F. Smith, Foundations of Materials Science and Engineering, McGraw-Hill Professional, 2003.

2. V. Raghavan, Materials Science and Engineering, 4th Ed, Prentice-Hall of India Pvt. Ltd, New Delhi, 2004. Supplementary Reading: 1. J. F. Shackelford and M. Meier, Introduction to Materials Science for Engineers, Prentice Hall PTR, 2005. 2. F. Rodrigues, C. Cohen, C. K. Ober and L. A. Archer, Principles of Polymer System, 5th Ed. Taylor & Francis, 2003. CR 248 FUELS, FURNACES AND STOICHIOMETRY 3 credits [3-0-0]

Classification of natural fuels, Brief discussion on alternate and renewable energy sources, winning and washing of coal, classification of coal, proximate and ultimate analysis of coal. Storage of coal and spontaneous ignition. Carbonization and manufacture of coke, caking index and coke quality. Coking process, cokeoven and byproducts; Origin, refining and distillation of crude petroleum, properties of liquid fuel flash point, fire point, cloud point and pour point. Generation of producer gas, water gas, liquidified petroleum gas (LPG), gasifiers and gas analysis; Different types of industrial furnaces; batch and continuous furnaces and kilns, design and operation of different industrial furnaces and kilns, saggers, Fast firing technology, microwave furnaces. Fuel economy and thermal efficiency in the operation of furnaces; Sankey diagram, Regenerators and recuperators. Stack emission, chimney design, combustion calculation and environmental pollution, Measurement of temperature in furnaces- pyrometric cones, rings and bars and temperature controller; Combustion calculations of fuels; Material balance in ceramic processes. Batch and recipe calculation for refractories, glass, whitewares and cement. Energy Balance and flame temperature calculations. Combined material and energy balances. Essential Reading: 1. R. M. Felder and R.W. Rousseau, Elementary Principles of Chemical Processes, Third Edition, Wiley., 2004. 2. S. Sarkar, Fuels and Combustion, Orient Longman, Mumbai, 2nd Ed, 1990. 3. G. B. Remmy Jr., Firing of Ceramics, World Scientific, 1994. Supplementary Reading: 1. W. Trinks and M. H. Macwhinney, A. Shannon, R. J. Reed and J. R. Garvey, Industrial Furnaces, 6th Ed., Wiley-Interscience, 2003. 2. R. A. Eppler and D. R. Eppler, Glazes and Ceramic Coatings, American Ceramic Society, 2000. 3. D. R. Dinger, Particle Calculations for Ceramists, Dinger Ceramic Consulting Services, Clemson, US, 2001 CR 249 MATERIALS SCIENCE AND ENGINEERING 3 credits [3-0-0]

Introduction to materials science and engineering, Bonding and structure of materials, Crystal Structure and Crystal Geometry: Space lattice; Unit cells; Crystal systems; Bravis lattices; Miller indices; Volume, planar and linear density unit cell calculations; Polymorphism; Crystal structure analysis, Crystalline Imperfections, defect chemistry, diffusions in Solids; Phase equilibrium and transformation, Solidification: Solidification of metals and single crystals; Solid solutions Physical properties of materials, Mechanical properties of materials, Electrical and semi conducting properties of materials, Dielectric and Magnetic properties of materials, Optical and thermal behaviour of materials, piezolectric and electro optic behaviour of materials, Superconducting materials, electrochemical

properties etc ; Engineering materials: alloys and inter metallics, ceramic materials, glasses, polymers and composites etc. Essential Reading: 1. W. F. Smith, Foundations of Materials Science and Engineering, McGraw-Hill Professional, 2003. 2. V. Raghavan, Materials Science and Engineering, 4th Ed, Prentice-Hall of India Pvt. Ltd, New Delhi, 2004. Supplementary Reading: 1. L. H. V. Vlack, Elements of Materials Science and Engineering, 6th Edition, Prentice Hall, 1989 2. J. F. Shackelford and M. Meier, Introduction to Materials Science for Engineers, Prentice Hall PTR, 2005.

CR 271

RAW MATERIALS ANALYSIS LABORATORY

2 credits [0-0-3]

1. Determination of Ca+2 and Mg+2 in water by EDTA method. 2. Chemical analysis of limestone/dolomite. 3. Complete analysis of Portland cement. 4. Chemical analysis clay/magnesite/bauxite following Na2CO3/NaOH fusion. 5. Determination of silica in quartz by HF treatment. 6. Determination of very low-alkali content by flame photometer. 7. Quantitative chemical analysis of Alumino-Silicate brick. 8. Chemical analysis of ordinary soda-lime-silicate glass. 9. Quantitative chemical analysis of tri-axial porcelain body. 10. Determination of chemical analysis of glaze frit. 11. Preparation of Precipitated Silica and determination of its moisture absorption capacity.

CR 272

DRAWING OF REFRACTORY LINING & JOINTS

2 credits [0-0-3]

1. Study and drawing of different refractory bricks of standard shape. 2. Study and drawing of non-standard shapes of refractory bricks. 3. Drawing of brick wall and brick joints. 4. Drawing of different parts of rotary kiln. 5. Drawing of converter. 6. Drawing of ladle. 7. Drawing of Blast Furnace Trough Lining 8. Drawing of slide plates refractories. 9. Drawing of sub entry nozzle. 10. Drawing of monoblock stopper. 11. Chimney calculation and drawing of chimney.

CR 273

CERAMIC WORKSHOP

2 credits [0-0-3]

1. Sieve analysis and particle size distribution of milled product. 2. Verification of Rittingers Crushing Law and determination of crushing efficiency of a Jaw Crusher. 3. Validation of Bonds Law and determination of crushing efficiency of a Roller Crusher. 4. Determination of angle of nip and maximum feed size for a Roll Crusher.

5. Determination of critical speed and crushing rate of a Ball Mill. 6. Study of Filter Press and preparation of filter cake. 7. Determination of filtration rate of ceramic slurry. 8. Study and operation of de-airing Pug Mill and preparation of extruded body. 9. Operation of Counter Current Mixer and determination of mix consistency. 10. Study and operation of Hydraulic Press and determination of bulk density. CR 274 CERAMIC FABRICATION LABORATORY 2 credits [0-0-3]

1. Determination of particle size and particle size distribution by Andreasen Pipette and Centrifuge. 2. Determination of specific surface area of ceramic powder 3. Determination of intra-particle porosity of ceramic powder 4. Effect of additives on the rheology of oxide ceramic slurries. 5. Preparation of slurry for slip casting of oxide ceramics and study of casting process. 6. Determination of zeta potential and iso-electric point of ceramic slurry 7. Study of compaction behaviour of powder during dry pressing 8. Setting of plaster and determination of temperature rise and expansion of plaster during setting. 9. Study of water to plaster ratio on physical properties of mould. 10. Shaping of plaster of paris block. CR 310 REFRACTORIES TECHNOLOGY 3 credits [3-0-0]

Classification of refractories, properties of refractories, packing of solid particles monosized particles, bimodal mixtures of spheres, bimodal mixture of non spherical particles, ternary and multiple mixtures, continuous particle size distribution, particle interaction during dry compaction; Shaped Refractories: Alumino-silicate, high alumina, magnesia, silica, doloma, carbonaceous, Refractories; raw materials, processing, process quality control, Detailed analysis of phase diagrams with respect to the raw materials controlling the firing temperature and schedule; properties, microstructure applications; Composite refractories: alumina-carbon, magnesia-carbon, Spinel, alumina-silicon carbidecarbon, zirconia-carbon; Unshaped refractories; castables, gunning mass, ramming mixes, shotcreting mass, compositions/classifications, additives, manufacturing process, quality control, properties and applications; Properties and tests: Specification of different kinds of bricks, fusion point in relation to equilibrium diagram, PCE Test, HMOR, torsional creep properties and tests, Re-heat shrinkage, Spalling resistance, slag resistance ; Reaction between refractories and glasses, heat transmission, behaviour of refractories in different environments, corrosion and failure of refractories, detailed analysis and interpretation of the refractories behaviour with respect of microstructure. Essential Reading: 1. J. H. Chesters, Refractories- Production and Properties, The Iron and Steel Institute, London, 1973. 2. C. A. Schacht, Refractories Handbook, CRC Press, 2004. 3. S. Banerjee, Monolithic Refractories: A Comprehensive Handbook, Wiley-American Ceramic Society, 1998. Supplementary Reading: 1. P. P. Budnikov, The Technology of Ceramics and Refractories, Translated by Scripta Technica, Edward Arnold, The MIT Press, 4th Ed, 2003. 2. C. A. Schacht, Refractory Linings: Thermo-mechanical Design and Applications, CRC Press, 1995.

CR 322

GLASS TECHNOLOGY

3 credits [3-0-0]

Concept of the glassy state. The enthalpy temperature diagram. Glass transition temperature Fundamentals of Glass Formation: Structural and Kinetic Approaches. Nucleation and crystal growth. TTT diagram. Structural models of silicate and non silicate glasses, bridging and non-bridging oxygen, batch calculation, mixing and handling, viscosity, low and high temperature viscosity, temperature and compositional dependence of viscosity, glass transition temperature; thermal expansion and density; Glass composition and manufacturing process. Crystallization of glass devitrification; glass-batch formulation. Mixing and handling of glass batch. Glass melting process, refining of glass. Decolourisation of glass. Reactions leading to glass formation. Fabrication process: Feeders, Colburn process, PPG process, Float process. Hollow ware and fibre glass; Quality control of glass, defects in glass: Stones, Seeds, Cords and Blisters, redox equilibrium and chemical durability of glass, toughening and strengthening of glass; Optical properties of glass, optical glass, coloured glass including photochromic and electrochromic glass, solarization and photosensitive glasses, coating of glass. Non conventional glass making: Vapour quenching method, sol gel; General idea about glass-ceramic preparation. Essential Reading: 1. A. Paul, Chemistry of Glasses, 2nd Ed., Springer, 1990. 2. J. E. Shelby, Introduction to Glass Science and Technology, The Royal Society of Chemistry, 2005. Supplementary Reading: 1. P. W. McMillan, Glass Ceramics, 2nd Ed., Academic Press, NY, 1979. 2. A. K. Varshneya, Fundamentals of Inorganic Glass, Academic press, 1994. 3. H. Bachs and D. Krause, Low Thermal Expansion Glass Ceramics, Springer, 2005.

CR 325

COMPUTATIONAL MATERIALS SCIENCE

3 credits [3-0-0]

Description of atomic interactions; Basics of the density functional theory, approximations in terms of pair potentials; embedded atom method and tight-binding. Material behaviour and computational model in nano-, micro-, meso- and macro-scales in the content of real materials-related problems (mechanical and thermodynamic properties, Phase transformation microstructure evolution during processing; Linear Elasticity Theory for Crystal Plasticity, Dislocation Statics and dynamics, Finite Element and Difference Methods at the MesoMacroscale, Polycrystal Elasticity and Plasticity Models; introduction to computational modeling; molecular statistics; Molecular Dynamics: models of interatomic potentials, Equations of Motion for Atomic Systems:Application of Molecular Dynamics in Materials Science: Simulation of Brittle Fracture, Simulation of Interaction of Dislocations with Grain Boundaries; Monte Carlo Simulation and Integration and lattice dynamics, Interpretation of modeling in terms of structures using radial distribution function, Fundamentals of the Algorithm, Spin Monte Carlo methods,Thermo dynamic and statistical analyses, Simulation of Surface Segregation, Phase Transition, Thin Film Deposition Application of computing and statistical fundamentals to solve Material Science and Engineering problems Essential Reading: 1. D. Raabe, Computational Materials Science: The Simulation of Materials Microstructure and Properties, Wiley-VCH, 1998.

2. M. Meyer and V. Pontikis, Computer Simulation in Materials Science: Inter-atomic Potentials, Simulation, Techniques and Applications , Kluwer Academic Publishers, 1991. Supplementary Reading: 1. K. Ohno, K. Esfarjani and Y. Kawazoe, Computational Material Science: from ab initio to Monte Carlo methods, Springer, 1999. 2. J. R. Hill, L. Subramanian and A. Maiti, Molecular Modeling Techniques in Material Science, CRC Press, 2005. CR 326 PYROCERAMICS 3 credits [3-0-0]

Glass and glass ceramics, Thermodynamics of phase separation, Crystallization of glass: Homogeneous and heterogeneous nucleation, Rate of crystal growth, Growth and nucleation, metastable phases and phase separation; ceramization process, composition of low expansion glass ceramics, structure, composition and properties of High Quartz and Keatite- type alumino- silicates, decoration, composition of ceramic colours, production of glass ceramic cook top panels, glass ceramics for other house hold applications, glass ceramics for optical precision applications technology of large casting, thin walled cylinders and light weight mirrors, special characteristics of optical glass ceramics- dimensional stability, radiation stability and chemical durability. Surface strengthening of glass ceramics thermal strengthening and chemical strengthening, refractory glass ceramics, microstructure and crystallization of binary (Mullite) and ternary (Mullite, Hexacelsian, Celsian-Rutile) glass ceramics; Fabrication and properties of Glass ceramics. Application of Glass ceramicscooking systems, reflective optics, laser gyroscopes. Essential Reading: 1. M. H. Lewis, Glass & Glass Ceramics, Chapman & Hall, London, 1989. 2. H. Bachs and D. Krause, Low Thermal Expansion Glass Ceramics, Springer, 2005. Supplementary Reading: 1. A. Paul, Chemistry of Glasses, Chapman and Hall, 2nd Ed., 1990. 2. P. W. McMillan, Glass Ceramics, Academic Press, 2nd Ed., NY, 1979. CR 327 INTERFACE SCIENCE & SOL-GEL PROCESSING 3 credits [3-0-0]

Thermodynamics of surface. Adsorption Isotherm. Physical aspects of interfaces, Grain boundary, Contact angle, Dihedral angle and Grain shape prediction, Concept of wetting. Structure of surface and interface; Colloids, Sols and gels, Types of colloids; attractive surface forces, stabilization of colloids, Electrostatic stabilization, charge development on the particle surface in aqueous medium, origin of electrical double layer, Iso-electric points and zeta potential, , Effect of electrolytes on double layer. Ion exchange capacity and exchange equilibrium, adsorption of polymers and steric stabilization, electrosteric stabilization, structure of consolidated colloids, rheology of consolidated colloids, Flocculation and deflocculation phenomena, kinetics of flocculation ; Wetting agents, Plasticizers, Foaming and antifoaming agents, Lubricants; Types of gel, sol-gel processing of aqueous silicates, metal alkoxides, hydrolysis and condensation, effect of pH on gelation, aging, drying and gel densification. Sol- gel preparation technique, single and multi-component gel, use of double alkoxides, applications of sol-gel processing Essential Reading: 1. D. Myers, Surfaces, Interfaces and Colloids: Principles and Applications, 2nd Edition, Wiley-VCH; 1999.

2. J. Reed, Introduction to the Principles of Ceramic Processing, 2nd Ed., John Wiley & Sons, 1995. Supplementary Reading: 1. M. N. Rahaman, Ceramic Processing, CRC Press, Taylor & Francis Group, FL, 2007. 2. R. J. Pugh and L. Bergstrom, Surface and Colloid Chemistry in Advanced Ceramics Processing , CRC, 1994

CR 330

FUEL CELLS AND BATTERIES

3 credits [3-0-0]

Introduction; History, thermodynamics and electrochemical kinetics, fuel cell components and their impact on performance ; Fuel cell systems: Proton exchange membrane fuel cell; Direct methanol fuel cells; Molten carbonate fuel cells; Polymer electrolyte fuel cells; solid oxide fuel cells; Fundaments of electrical and ionic conductivity, fast ionic conductors, defect chemistry, Electrolyte, material system, synthesis, properties, fabrication, applications ; Anode, material system, synthesis, properties, fabrication, applications. Cathode, material system, synthesis, properties, fabrication, applications interconnects material system, synthesis, properties, fabrication, applications Special materials, material system, synthesis, properties, fabrication, applications. Stack design and fabrication techniques. Electorde polarization fundamentals, polarization kinetics. Testing and characterization of fuel cells and its components. Fuel processing and reforming of fuel; Batteries: general terms and characteristics, battery parameters, Fundamental aspects of battery system. Battery component, electrolyte, catode, anode, material system, synthesis, properties, fabrication, applications. Stack design and fabrication techniques. Testing and characterization of batteries and its components. Essential Reading: 1. P. G. Bruce, Solid State Electrochemistry, Cambridge University Press, 1997. 2. G. Hoogers, Fuel Cell Technology Handbook, CRC Press, 2003. Supplementary Reading: 1. H. A. Kiehne, Battery Technology Handbook, CRC Press, 2003. 2. J. S. Newman and K. E. Thomas-Alyea, Electrochemical Systems, Wiley-IEEE, 2004. 3. C. Julien and G. A. Nazri, Solid State Batteries: materials design and optimization, Springer, 1994. CR 331 WHITEWARE TECHNOLOGY 3 credits [3-0-0]

Raw materials, processing, properties, batch composition and the effect on the properties of whiteware bodies, effect of particle size distribution of kaolinite on plasticity and workability of clay. Rheology and properties of clay - water system, mechanism of plasticity, additives/binders, plasticizers, flocculants and deflocculants and slip properties; Classification of whiteware bodies, batch formulation Tri-axial bodies - porcelain, stoneware, earthenware, hotel ware, majolica, terra-cotta, bone china, parian-art ware, insulator, tiles, sanitary ware etc. Body preparation including the unit operations and fabrication processes. Application of granular mechanics to slip casting. Influence of particle size distribution on properties of fired whiteware bodies. Mould materials, mould and mould design; Fundamentals of drying and shrinkage. Firing of whiteware bodies, microstructure evolution during firing of whiteware bodies. Time, temperature and atmosphere effects on firing of whitewares, special firing techniques, Glaze structure, formulation, raw materials, batch calculation, preparation, slip rheology, application. colours, decoration firing. Testing of white ware bodies.

Essential Reading: 1. W. Ryan and C. Radford, Whitewares: Production, Properties and Quality Control, Pergamon Press, Oxford, 1987. 2. W. M. Carty, C. W. Sinton, Science of Whitewares II, American Ceramic Society, 1999. 3. F. H. Norton, Fine Ceramics: Technology and Application, McGraw Hill, NY, 1970. Supplementary Reading: 1. R. A. Eppler and M. Obstler, Understanding Glazes, The American Ceramic Society, 2005. 2. V. E. Henkes, George Y. Onoda, W. M. Carty, Science of Whitewares, The American Ceramic Society, 1996

CR 333

HEAT TRANSFER AND FLUID FLOW

4 credits [3-1-0]

Steady state and unsteady state conduction. Heat flow through composite walls, cylinders and spheres, Thermal resistances in series for ceramic materials. Convective heat transfer: Free and forced convection, application of dimensional analysis to convection problems. Radiation Heat Transfer black and grey bodies, Stefan-Boltzmans law, Kirchoffs law. Radiation through furnace openings. Combined effect of conduction, convention and radiation, overall heat transfer coefficient. Heat transfer through fluidized bed. Computation of heat loss from furnaces and kilns- sankey diagram. Heat transfer concept and selection of refractories. Fluid properties, density, viscosity, surface tension, compressibility. Classification of fluids: Newtonian and non-Newtonian fluids. Equation of continuity for compressible and incompressible fluid flow. Flow measurements: Venturimeter, Orifices, Pitot tube and Rotameter. Significance of Reynolds, Nussles and Prandlts Numbers; Eulers numbers, Archimedes number ; Pressure drop in flow and pressure drop calculation in various cases, Flow through bends, Straight and bend pipes, Packed beds. Essential Reading: 1. W. L. McCabe, J. C. Smith and P. Harriot, Unit Operations of Chemical Engineering, McGraw Hill professional, 2005. 2. D. Q. Kern, Process Heat Transfer, McGraw Hill International Auckland Bogota, 1986. Supplementary Reading: 1. R. H. Perry, D. W. Green and J. O. Maloney, Chemical Engineers Handbook; McGraw-Hill, 1999.

CR335

INSTRUMENTAL CHARACTERIZATION

4 credits [3-1-0]

Differential Thermal Analysis (DTA), Thermogrvimetric Analysis (TGA), Differential Scanning Calorimetry (DSC). Factors affecting the phase transformations - particle size, packing, heating rate, buoyancy effect. Thermal Conductivity, Dilatometry basic principles, instrumentations and case study in ceramic applications. Study of sintering kinetics by dilatometry; Particle Size Analysis, Surface area and porosity basic principle, data analysis; Spectroscopic method: UV-Visible, IR, FTIR and Raman Basic principle, instrumentation and analysis of data; X-Ray Methods: x-ray generation, diffraction, Bragg law, Diffraction under ideal and non-ideal conditions, Scattering and structure factor. Principles of x-ray Diffractometer (XRD), x-ray data file and its analysis, indexing of crystal type. Chemical analysis by x-ray fluorescence (XRF) Wave length and energy dispersive

XR; Optical microscopy - light optics, microscope components, possibilities and limitations. Scanning Electron Microscopy - Optics and performance of a SEM, Image interpretation, crystallographic information in a SEM, analytical microscopy. Transmission Electron microscopy - construction and operation of a TEM, electron diffraction, Image interpretation. Techniques of sample preparation for TEM and SEM methods. Electron Beam Microprobe Analysis. Essential Reading: 1. R. F. Speyer, Thermal Analysis of Materials, CRC Press, 1994. 2. B. D. Cullity, Elements of X-ray Diffraction, Addison Wesley Publishing Company; 2nd edition 1978. 3. P.J. Goodhew, J. Humphreys and R. Beanland, Electron Microscopy and Analysis, Third Edition, Taylor & Francis, 2001. Supplementary Reading: 1. H. P. Klug and L. E. Alexander, X-ray Diffraction procedures for Polycrystalline and Amorphous Materials, 2nd Edition, John Wiley, 1974. 2. D. A. Skoog, F. J. Holler and T. A. Nieman, Principles of Instrumental Analysis, 5th Ed., Hartcourt College Publishers, 1998.

CR 336

CEMENT TECHNOLOGY

3 credits [3-0-0]

Introduction to hydraulic materials. Classification of Cement, Chemistry of hydrated and anhydrous cement compound. Manufacturing of Portland cement; Dry, Semi-dry, wet and semi-wet process, Cement grinding, Testing of cement, Cement compounds and their phase relations, Cementing qualities of cement phases, The burning of Portland cement, Constitution of Portland cement, Phase equilibrium conditions of clinker crystallization, Calcia-Alumina-Silica system, Clinker constitution and cooling process, refractories used in the rotary kiln, Role of free magnesia and free lime in the clinker, hydration of cementing phases and Portland cement, theories and mechanism of cement setting and hardening, Action of acid water and sulphate waters on Portland cement, Steam-curing of Portland cement. Special Cement and cement additives, Blast Furnace slag- and high alumina cement. Concrete: Types, Method of production and Properties of concrete, Alkali-aggregate reaction, Electrical and fire resistance of cement and concrete. Pollution control in cement industries. Essential Reading: 1. P. Hewlett, Lea's Chemistry of Cement and Concrete, Fourth Edition, Butterworth Heinemann; Fourth edition, 2004. 2. H. F. W. Taylor, Chemistry of Cement, Thomas Telford, 1997. Supplementary Reading: 1. E. M. Gartner and M. Uchikawa, Cement Technology, The American Ceramic Society, 1994. 2. K.E. Peray, Cement Manufacturer's Handbook, Chemical Publishing Company, 1979

CR 339

CERAMICS IN ELECTRONIC APPLICATIONS

3 credits [3-0-0]

Introduction, elementary solid state science, electrical conduction, defect and defect chemistry, charge displacement process. Ceramic conductors: high temperature heating elements and electrodes, ohmic resistors, varistors, thermistors PTC, NTC, fuel cells and batteries, sensors, materials system, powder synthesis, processing, properties, devices and application. Fundamentals of superconductivity, theories of superconductors, materials system, synthesis, processing, properties and application; Dielectric and insulators,

fundamentals of capacitors, classification of dielectric matrials, materials system, low permittivity, medium permittivity and high permittivity, Powder synthesis, processing, properties, fabrication and application. Capacitor designs, processing; Fundamentals of piezoelectricity, materials system, synthesis, processing, properties, devices and application. Fundamentals of pyroelectricity, materials system, synthesis, processing, properties, devices and application. Electro-optic fundamentals, materials system, synthesis, processing, properties, devices and application; Fundamentals of magnetism, Magnetics ceramics basic concepts, model ferrites: spinel ferrites, hexaferrites, garnets, properties influencing magnetic behavior, soft ferrites, hard ferrites, microwave ferrites, Preparation of ferrites, rawmaterials, mixing calcinations and milling, sintering, post sintered processing, applications. Essential Reading: 1. R. C. Buchanan, Ceramic Materials for Electronics: processing, properties and applications, Marcel Dekker, NY, 1986. 2. L. M. Levinson, Electronic Ceramics: properties, device and applications, CRC Press, 1987. Supplementary Reading: 1. A. J. Moulson and J. M. Herbert, Electroceramics: Materials, Properties and Applications, Springer, 1990. 2. B. Jaffe, W. R. Cook, H. Jaffe and H. L. C. Jaffe, Piezoelectric Ceramics, R.A.N Publishers, 1990. CR 341 PHYSICAL CERAMICS 4 credits [3-1-0]

Mechanical Properties: Concept of strength and its relation with fundamental parameters, plastic deformation, viscous flow, creep, Fracture of materials; Thermal Properties: Thermal expansion, thermal shock, annealing and chemical strengthening, specific heat and heat capacity, thermal conduction process; Electrical Properties: Electrical, electronic and ionic conduction phenomena in crystals, Fast ionic conductors, glasses and non-stoichiometric compounds. PTCR, NTCR, Varistors, thermisters etc; Dielectric Properties: Dielectric loss of crystals and glasses, dielectric strength, piezoelectric and ferroelectric ceramics; Magnetic Properties: Concept of magnetic phenomena in solids. Structure and magnetic properties of spinel ferrites, rare-earth garnets, ortho-ferrites and hexagonal ferrites with special reference to their microstructure; Optical Properties: Refractive index and dispersion, reflectance, opacity and translucency, absorption and colour from modern concepts in crystalline and vitreous ceramic systems. Essential Reading: 1. W. D. Kingery, H. K. Bowen and D. R. Uhlmann, Introduction to Ceramics, 2nd Ed., John Wiley & Sons Pte Ltd., Singapore,1991. 2. Y. M. Chiang, D. Birnie III and W. D. Kingery, Physical Ceramics: Principles for Ceramic Science and Engineering, Wiley, 1996. Supplementary Reading: 1. M. Barsoum, Fundamentals of Ceramics, CRC Press, 2002. 2. L. V. Azaroff, Introduction to Solids, Tata McGraw Hill, 1977.

CR 344

MICROSTRUCTURAL DESIGN IN CERAMICS

3 credits [3-0-0]

Characteristic of microstructure; Quantitative analysis; Properties and factors affected by microstructure; microstructural aspects of sintering and grain growth, microstructural variables; Mechanical, thermal, optical properties and the effect of microstructure; High temperature degradation; Wear behaviour; Techniques for characterizing ceramic microstructure. Resolution and its implications for routine microscopy, Optical microscopy, scanning electron microscopy, stereoscopy and stereology. Preparation of ceramic samples for microscopy. Fine powders and granulates; microstructural characterization of green bodies- sample preparation for SEM and TEM study; Dense fired ceramics, porous ceramics, microstructural maps of sintered body, polished surface and fractured surface microstructure, common pore structure in ceramic bodies, pore morphology and properties, quantitative estimation of different phases and grain size; study and interpretation of wetting behaviour, grain boundary film, crystalline interface boundaries, crystalline interphase boundaries, dislocations in the sintered body by SEM and TEM; microstructure of different types sintered ceramic bodies: Triaxial whiteware bodies, refractories, clay products, glass, glazes and enamels, glass ceramics, advanced and special ceramics. Essential Reading: 1. W. E. Lee and W. M. Rainforth, Ceramic Microstructures: Property Control by Processing, First Edition, Springer, 1994. Supplementary Reading: 1. W. D. Kingery, H. K. Bowen and D. R. Uhlmann, Introduction to Ceramics, 2nd Ed., John Wiley & Sons Pte Ltd., Singapore,1991.

CR 346

NANOCERAMICS

3 credits [3-0-0]

Introduction to nanotechnology: Formation of nanomaterials by size reduction: Amorphisation of metals by milling, molten drop impingement and limitations of milling for ceramic materials. Gas phase processes for nanomaterial synthesis: Nanosized clusters of elementary particles and ceramic materials. Condensed phase processes for nanomaterial synthesis; Manufacture of nanostructured materials (densification, nanocomposites). Determination of structure and chemical, mechanical, magnetic, electrical and optical physical properties of nanomaterials. Methods for determination of particle size, porosity, specific surface, chemical and supramolecular structures at the nanometric level. Proximal microscopies (AFM and STM), nanolithography and nanofabrication; technological applications of nanomaterials- super-plasticity, plastic flow processing of ceramics; ultrapure and biocompatible ceramics; gas sensors; transparent ceramic coatings, diamond-like coatings, the fullerenes and carbon nanotubes, nano magnets for sensors and high density data storage, spin-tronic devices, nanotechnology for biological system & bio-sensor applications. Essential Reading: 1. M. Wilson, K. Kannangara, G. Smith and M. Simmons, Nanotechnology: Basic Science and Emerging Technologies, CRC Press, 2002. 2. R. Freer, Nanoceramics: A British Ceramic Proceedings. British Ceramic Society, 1993. 3. A. S. Edelstein, R. C. Cammarata, Nanomaterials: synthesis, properties and applications, CRC Press, 1998 Supplementary Reading: 1. M. A. Ratner and D. Ratner, Nanotechnology: A Gentle Introduction to the Next Big

Idea, Prentice Hall PTR, 2003. 2. G. Cao, Nanostructures and Nanomaterials: Synthesis, Properties and Applications, Imperial College Press, 2004. 3. H. G Rubahn, Basics of Nanotechnology, 3rd Edition, Wiley, 2008

CR 348

INTRODUCTION TO ENGINEERING CERAMICS

3 credits [3-0-0]

Definition of engineering ceramic materials. Engineering ceramics generally considered in the ceramics family- natural ceramics, polycrystalline ceramics fabricated by sintering, glass, glass-ceramics, single crystals of different ceramics and artificial gems. Engineering with ceramics: high temperature applications, ceramics in metal processing, glass production, industrial processes, ceramics in heat engines, wear and corrosion resistant applicationsceramics in seals, valves, pumps, bearings, thread guides, ceramics in paper making, ceramics as cutting tool inserts, super hard abrasives; Electrical applications of ceramicsdielectric ceramics, semiconductors, conducting ceramics, ceramic superconductors. Magnetic ceramics, opotical and opto-electronic applications of ceramics. Ceramic composites- particulate, whiskers, fibre reinforced ceramics. Medical applications of ceramics, ceramics in efficient use of energy and pollution control. Design with ceramics, design considerations- reliability requirement, fabrication limitation and cost consideration. Design approaches empirical, deterministic and probabilistic design, Weibull statistics and failure analysis. Advantages and limitations of probabilistic design, linear elastic fracture mechanics approach and combined approach Essential Reading: 1. J. B. Wachtman Jr., Treatise on Materials Science & Technology, Structural Ceramics Vol- 29, Academic Press Inc., New York, 1989. 2. D. W. Richerson, Modern Ceramic Engineering: Properties, Processing, and Use in Design, 3rd ed, CRC Press, 2005 Supplementary Reading: 1. S. Hampshire, Non-Oxide Technical and Engineering Ceramics, Elsevier Applied Science, London, 1986. 2. W. E. Lee and W. M. Rainforth, Ceramic Microstructures: Property Control by Processing, First Edition, Springer, 1994. CR 370 REFRACTORIES TECHNOLOGY LABORATORY 2 credits [0-0-3]

1. Determination of packing density of one component system of various particle sizes. 2. Determination of packing density of two component system having various size ratios. 3. Recipe calculation and recipe making for refractory mix. 4. Study of compaction response behaviour of refractory mix. 5. Shaping of refractory brick by dry pressing/hand moulding method. 6. Determination of porosity and density of the prepared refractory brick. 7. Determination of crashing strength of refractory bricks. 8. Study of thermal shock resistance and PLCR of refractory brick. 9. Determination of MOR and HMOR of refractory brick. 10. Vibrocasting of supplied castable and study of cured property. 11. Effect of casting parameter on the properties of cast refractories. 12. Study of strength development of castable with temperature.

CR 371

HIGH TEMPERATURE PROCESSING LABORATORY

2 credits [0-0-3]

1. 2. 3. 4. 5. 6.

Calibration of thermocouple and determination of temperature profile of the furnaces. Effect of process parameters on the response behaviour of PID controller. Calibration of PID temperature Controller. Study of isothermal sintering behaviour of ceramic materials. Study of non-isothermal sintering behaviour of ceramic materials. Study of decomposition kinetics of a material from its isothermal weight loss behaviour. 7. Study of phase transformation kinetics from differential thermal analysis. 8. Study of the heating rate on constant rate heating densification behaviour. 9. Study of binder burnt out behaviour by TGA. 10. Study of recystallization behaviour of materials. CR 372 GLASS TECHNOLOGY LABORATORY 2 credits [0-0-3]

1. Batch calculation and preparation of soda-lime-silicate glasses 2. Fabrication of plate glass and annealing. 3. Determination of glass transition temperature of the processed glass 4. Effect of refining agents during preparation of glasses. 5. Fabrication of hollow glass ware by blowing techniques 6. Study of chemical durability of glasses using Flame Photometer. 7. Batch calculation and fabrication of different coloured glasses. 8. Determination of refractive index and colour concentration of glass. 9. Determination of density of glass by non-destructive methods. 10. Detection of strain in glass and annealing schedule. 11. Determination of CTE of commercial glasses. 12. Study of Littleton softening point of glass.

CR 373

WHITEWARE TECHNOLOGY LABORATORY

2 credits [0-0-3]

1. Design and drawing of model and mould. 2. Shaping of a pre-designed plaster model. 3. Fabrication of pre-designed slip casting mould. 4. Fabrication of model using Jigger and Jolly 5. Determination of plasticity and Plasticity Index. 6. Determination of drying sensitivity of a green body. 7. Study of drying curve and critical moisture content of a green body. 8. Determination of vitrification range of a whiteware body. 9. Determination of deffloculant demand curve of slip. 10. Study of slip casting behaviour. 11. Study of glaze-body fit by dilatometer 12. Determination of flow limit of glaze 13. Finishing, drying and glazing of cast wares. 14. Crazing resistance of glazed article.

CR 374

CERAMIC PRODUCT DEVELOPMENT LABORATORY

2 credits [0-0-3]

This is a project based laboratory where the students are required to develop a specific ceramic product having a given range of different properties. On the basis of the supplied

end properties and the possible application area, the student will choose the raw material and the powder processing route, the green shape fabrication method. The developed green ceramic product needs to be sintered for evaluation of product property. The statistical analysis of the evaluated properties should be carried out to judge the product reliability. CR 375 1. 2. 3. 4. CERAMIC CHARACTERIZATION LABORATORY 2 credits [0-0-3]

Study of thermal decomposition behaviour of dolomite / limestone/ magnesite. Study of phase transition in quartz by DTA. Weight loss behaviour of dolomite, magnesite and limestone by TGA. Study of thermal expansion behaviour and determination of thermal expansion coefficient of ceramic product. 5. Determination of thermal hysteresis of zirconia by dilatometric method. 6. Study and operation of x-ray diffractometer. 7. Indexing of cubic crystal system and determination of its lattice parameter. 8. Determination of lattice parameter of tetragonal crystals. 9. Determination of crystallite size from x-ray line broadening. 10. Study of data acquisition and processing for obtaining an x-ray profile. 11. Phase identification using software. 12. Determination of a calibration curve for quantitative estimation of two-phases in a mixture. CR 376 CEMENT TECHNOLOGY LABORATORY 2 credits [0-0-3]

1. Preparation of Portland cement in the laboratory 2. Determination of consistency of cement. 3. Study of initial and final setting of cement by Vicat apparatus. 4. Determination of soundness of cement Le Chatelier method. 5. Making and curing of cement mortar. 6. Compressive strength of cement mortar fine with ageing time. 7. Determination of surface area of cement by Blain Air Permeability apparatus. 8. Determination of fineness modulus and grain size distribution of fine aggregate. 9. Effect of casting process parameters on the properties of cement mortar. 10. Quantitative chemical analysis of cement. 11. Effect of admixture on cement mortar 12. Study of the durability of cement mortar CR 377 1. 2. 3. 4. 5. 6. CERAMIC EQUIPMENT DESIGN LABORATORY 2 credits [0-0-3]

Design of tunnel kiln brick lining Design of rotary kiln brick lining Design of electrically heated laboratory furnace Design of spray drier/spray pyrolyzer heating chamber Design of L-D converter lining Design of Ladle lining ADVANCED CERAMICS 4 credits [3-1-0]

CR 411

Introduction and classification fracture, toughness, statistical structure, phases, types of importance and application.

of Structural Ceramics, Brief review of Griffith theory of nature of strength Alumina and alumina ceramics Crystal alumina, properties and its relation to microstructure, Zirconia Ceramics Crystal structure and polymorphic

modifications, Transformation Toughening; different system in zirconia, application. Composites: strengthening and toughening mechanisms, composite fabrication. Composites of some oxides and nonoxides. Classification of non-oxide ceramics, silicon carbide, silicon nitride Sialon, Tungsten Carbide, Boron Carbide, Boron Nitride, Carbon and Graphite, phase diagrams, processing, sintering and properties. Abrasives; natural and synthetic; properties, applications and performances; Semiconductor, electronic, ionic conductors and fast ion conductors; defects in fluoride type and perovskite oxides; conduction process and transference number; electronic conduction in oxides; semiconductor - metal transition; Ionic conduction in oxides; fast ion conductors; resistors and varistors, ceramic capacitors, piezoelectric and electro-optic ceramics, Super conductivity: basic principles; materials; synthesis and applications; Magnetic Ceramics: Introduction; types of magnetism: magnetic anisotropy; magnetostriction; domains and magnetization processes; magnetic Materials: soft and hard; synthesis; characterization and applications, ferro-electricity in capacitor technology, recent developments in this area. Essential Reading: 1. J. B. Wachtman Jr., Structural Ceramics, Treatise on Materials Science & Technology Vo l- 29, Academic Press, New York, 1989. 2. W. E. Lee and W. M. Rainforth, Ceramic Microstructures: Property Control by Processing, Springer, 1994. 3. R. C. Buchanan, Ceramic Materials for Electronics: Processing, properties and applications, Marcel Dekker, 1986. Supplementary Reading: 1. E. Dorre and H. Hubner, Alumina: Processing, Properties and Applications, SpringerVerlag, Berlin Heidelberg, 1984. 2. A. J. Moulson and J. M. Herbert, Electroceramics: Materials, Properties and Applications, Springer, 1990.

CR 415

BIOCERAMICS

3 credits [3-0-0]

Introduction to biomaterials, bio-ceramics as implant in human body, Physics of bone and structure of tooth, Cortical bone versus Trabecular bone structure. Different type of biomaterials: Metal and alloys, Ceramics, Polymers and composites ; Bio-glass and A/W Glass ceramics, Hydroxyapatite, Bioactivity and bone bonding, porous hydroxyapatite and study of bio-compatibility; Composite implant materials: mechanics of improvement of properties by incorporating different elements. Composite theory of fiber reinforcement. Polymers filled with osteogenic fillers. Host tissue reactions; Properties of biomaterials: Bulk properties mechanical, biological and chemical properties; Surface properties Surface roughness and surface characterization. Testing of biomaterials/Implants: In vitro testing (Mechanical testing): tensile, compression, wears, fatigue, corrosion studies and fracture toughness. In-vivo testing (animals): biological performance of implants. Ex-vivo testing: in vitro testing simulating the in vivo conditions. Standards and specifications of implant materials, recent developments in this area. Essential Reading: 1. L. L. Hench and J. R. Jones, Biomaterials, Artificial Organs and Tissue Engineering, Taylor & Francis 2007 1. J. F. Shackelford, Advanced Ceramics (vol.1) Bioceramics, Gordon and Breach Science Publishers, New York, 1999. Supplementary Reading:

1. A. Wereszczak, M. Mizuno and E. L. Curzio, Advances in Bioceramics and Biocomposites II, John Wiley & Sons, 2007.

CR 416

APPLICATION OF REFRACTORIES

4 credits [3-1-0]

Review of metallurgical processes ; Identification of different refractory linings for primary and secondary steel making operations, Hot repairing Materials, Repairing techniques; Future trends in utilization of refractories towards efficient lining for steel making ; Coke oven refractories, Blast furnace refractories, trough refractories, taphole clay, refractories for cooling and heat saving in blast furnaces, Refractories for steel making, Ladle refractories, Continuous casting refractories: Materials, Production, Properties, Applications and Future trends; Use of non-oxide ceramic materials in ferrous and non-ferrous industries. Refractories in cement industries. Refractories in glass industries. Direct bonded magchrome aggregates and refractories for Aluminium, Copper, Zinc and Petrochemical Industries. Standardization, testing including non destructive testing. New generation slide gate refractories with improved performance, Plant trial performance of non shaped and advanced refractories developed using surface chemistry, thermo-mechanical considerations for refractory linings, refractories for the refineries and circulating fluid beds, plasma processing of refractory aggregates, coating techniques for improving the oxidation resistance of graphite. Recent developments in the application of refractories, recent developments in this area. Essential Reading: 1. J. H. Chesters, Refractories- Production and Properties, The Iron and Steel Institute, London, 1973. 2. R. Amavis, Refractories for the Steel Industry, Elsevier Applied Science, Springer, 1990. Supplementary Reading: 1. S. C. Caniglia and G. L. Barna, Handbook of Industrial Refractories Technology: Principles,Types, Properties and Applications, William Andrews Inc, 1992. 2. S. Banerjee, The Changing Refractories Industry: New Technologies, Materials and Markets, Business Communication Co, 1999. CR 418 NANOMATERIALS 3 credits [3-0-0]

Introduction to Nanostructured materials, Low-dimensional structures: Nano clusters & Nano crystals, superparamagnetic materials, nanomagnetic composite materials, Magnetic nanostructured materials, Nanoscale magnetism of fine particles of transition metals, alloys and oxides, Survey of materials and scaling with respect to different types of nanomaterialsmetals, ceramics, semiconductors, polymers, structural materials and functional materials; Rate- controlling mechanisms and diffusion. Nucleation-classical nucleation theory, clusters and nucleation rates; characterization of nanostructured materials, different synthesis techniques; Ultrafine powders and communition. Nanocomposites, Thin films and Coatings. Sol-gel processing of different types of materials and their consolidation. Monoliths, films, membranes ; Gas phase synthesis, photolithography; Nanotechnology and MEMS, nano magnets for sensors and high density data storage, carbon nanotube, spin-tronic devices, nanotechnology for biological system & bio-sensor applications, recent developments in this area. Essential Reading:

1. C. N. R. Rao, A. Mller and A. K. Cheetham, The Chemistry of Nanomaterials: Volume 1, Synthesis, Properties and Applications; Wiley-VCH, 2006. 2. C. N. R. Rao, A. Mller and A. K. Cheetham, The Chemistry of Nanomaterials: Volume 2, Synthesis, Properties and Applications, Wiley-VCH, 2006. Supplementary Reading: 1. G. Cao, Nanostructures and Nanomaterials: Synthesis, Properties and Applications, Imperial College Press, 2004. 2. R. Booker and E. Boysen, Nanotechnology: The fun and easy way to explore the science of matters smallest particles, Wiley Publishing Inc.2005 CR 419 BIOMATERIALS FOR ARTIFICIAL IMPLANTS 3 credits [3-0-0]

Bio-compatability-definition and issues, introduction to biological environments, function and degradation of materials in vivo- swelling and leaching, corrosion and dissolution, reactions of biological molecules with bio-material surfaces, mechanics of materials- deformation and failure, friction and wear. Biological effects of implants- inflammatory process, adaptation, allergic foreign- body response; Surface chemistry of materials- surface energy, contact angle, critical surface tension, electrokinetic theory; Biomaterials, types- metals, polymershydrogels, polymer degradation, resorbable polymers, sutures, drug delivery, dialysis membranes. Ceramics, - dense ceramics, porous ceramics, bio-active ceramics, resorable ceramics, composites - structure and properties; processing of bio-materials. Coated Hydroxyapatite need for coating, type of coating Plasma sprayed coating, bio-mimetic coating. Characterization of biomaterials; in-vitro and in-vivo testing, Polymeric biomaterials naturally occurring polymeric biomaterials, synthetic non bio-degradable and bio degradable polymers, polymer matrix composite biomaterials; Application of bio-materialsdental implants, orthopaedic implants, soft tissue application, Tissue engineeringbiomaterials for tissue engineering, recent developments in this area. Essential Reading: 1. S. V Bhat, Biomaterials, Kluwer Academic Publishers, 2002. 2. J. B. Park and J. D. Bronzino, Biomaterials: Principles and Applications, CRC Press, 2002. Supplementary Reading: 1. D. L. Wise, D.J. Trantolo, D. E. Altobelli, M. J. Yaszemski and J. D. Gresser, Human Biomaterials Applications, Humana Press, 1996. CR 422 CERAMIC EQUIPMENT DESIGN 3 credits [3-0-0]

Design of Ball Mill, Design of Laboratory Furnace, Design of cement rotary kiln, Design of tunnel kiln for refractory industry, Design of tunnel driers, Design of humidity control drier, Design of LD converter lining, Design of Electric Arc Furnace lining, Design of Ladle lining, Design of Spray Drier. Essential Reading: 1. S. M. Walas, Chemical Process Equipment: Selection and Design, Butterworths Heinemann, Butterworths, 1988. Supplementary Reading: 1. H.J. Sandler, and E.T. Luckiewicz, Practical Process Engineering: A Working Approach to Plant Design, McGraw Hill Book Company, 1987. 2. V. C. Davis, Calculation in Furnace Technology, Pergamon Press ltd, 1970.

CR 424

COMPOSITE MATERIALS

3 credits [3-0-0]

Composites- Definition, Classification and Importance, design of composite materials, the concept of load transfer, Glass, ceramic and carbon fibres, silicon carbide, alumina and alumino-silicate fibres. Common ceramic matrix material and their properties, interfaces in composites, interaction at the interface. Types of reinforcement: continuous fibre, short fibre, whisker ; Ceramic Matrix composites: fibre packing arrangement, fabrication, properties, interface reaction, toughness ; specific examples - Alumina -silicon carbide, Mullite- Zirconia, polymer-PZT composites, metal composites, layered composites- composite processing, densification and application ; properties of composites: Density, Mechanical properties, mechanism of load transfer from matrix to fibre, elastic deformation of laminates, variation of lamina properties with orientation, tensile and compressive strength and failure mechanism of long and short fibre composites, toughness of composites and sub-critical crack growth, thermal behaviour of composites debonding, fibre pull out, delamination fracture. Application of composites. Recent advances in composite technology, recent developments in this area. Essential Reading: 1. G. F. Carter and D. F. Paul, Materials Science and Engineering, ASM International, 1991. 2. J. F. Shackelford and M. Meier, Introduction to Materials Science for Engineers, Prentice Hall PTR, 2005. Supplementary Reading: 1. F. L. Matthews and R. D. Rawlings, Composite Materials: Engineering and Science, Woodhead Publishing, 1999. 2. K. K. Chawla, Composite Materials: Science and Engineering, Springer, 2001. CR 426 TRIBOLOGY OF MATERIALS 3 credits [3-0-0]

Introduction: Different types of materials and applications, surface characterization (Physico chemical characteristics of surface layers) Surface visualization, Geometry of non conforming surfaces (analysis and measurement of surface roughness), Surface and subsurface stress distributions and Hertzian contact ; Contact between solid surfaces; Adhesion Friction; Testing, Frictional behavior (Solid solid contact, liquid mediated contact), Friction mechanism of metals, ceramics and polymers, solid lubricants. Thermal properties of sliding surfaces; Classification of wear and wear testing, role of humidity; the various modes of wear: adhesive, delamination, fretting, abrasive, erosive, corrosive, oxidizing (mild and severe), melt and the wear-mechanism maps, types of particle present in wear debris; Surface Engineering Methods to reduce wear, Electrolytic, Spraying, Hardfacing, Chemical Vapour Deposition (CVD), Plasma Vapour Deposition (PVD), Mechanical methods, Surface melting and Thermo chemical treatments ; Lubrication: Solid lubricants, Liquid lubricants, Fluid film lubrication, Introduction to Elasto-Dynamic (ED) and ElastoHydro Dynamic (EHD) Lubrication, Mixed and Boundary lubrication, micro and nano tribology, solution of tribological problems, recent developments in this area. Essential Reading: 1. B. Bhushan, Principles and Applications of Tribology, Willey IEEE, 1999. 2. M. Hutchings, Tribology: Friction and Wear of Engineering Materials, Edward Arnold, 1992. ( Original from the University of Michigan Digitized 6 Dec 2007) Supplementary Reading: 1. K. C. Ludema, Friction, Wear, Lubrication: A Textbook in Tribology, CRC Press, 1996.

2. R. D. Arnell, P. Davies, J. Halling, and T. Whomes, Tribology Principles and Design Applications, MacMillan, 1991( Original from the University of Michigan Digitized 6 Dec 2007)

CR 433

SENSOR TECHNOLOGY

3 credits [3-0-0]