Академический Документы

Профессиональный Документы

Культура Документы

AHU Fans

Загружено:

mirali74Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AHU Fans

Загружено:

mirali74Авторское право:

Доступные форматы

AHU Fan Section

General discussion / Salient features:

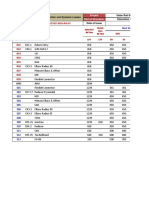

Fans shall be centrifugal double inlet, double width; single inlet single width; or plug direct drive units, manufactured in continuously welded mild steel with stiffeners where necessary with IE3+ permanent magnet motors. Where double inlet fans are used, bearings should be double row ball or roller bearings in cast iron Plummer-block bearing housings. Impellers shall be backward curved with continuously welded high quality steel aerofoil blades. Fans shall be statically and dynamically balanced to BS 5265. Supply air fans shall be arranged so as to minimise suction-side leakage air flows. If two-stage filtering is used, the supply air fan is to be arranged between the first and second filter stage. The fans shall be selected for operation at fan total system input efficiency (to include all motor, drive, and inverter or controller losses) of not less than the efficiencies stated in the table below and the fan discharge velocity shall not exceed 10 metres per second as long as this does not compromise efficiency. The table below shows the typical fan selection based on air flow rates (M3/sec) and the total static pressures. It also shows the system input efficiencies which the fans must meet. 2.5m3/s AHU Configuration 500Pa 2W X 11/2H Fan types: A, B, C Noise 75DB System input efficiency: 63% Fan types: A, B, C Noise 83DB System input efficiency: 65% Fan types: A, C Noise 89DB System input efficiency: 66% Fan types: A, C Noise 92DB System input efficiency: 67% Fan types: A, C Noise 95DB System input efficiency: 66% 5m3/s 21/2W X 2H Fan types: A, C Noise 76DB System input efficiency: 68% Fan types: A, C Noise 84DB System input efficiency: 70% Fan types: A, C Noise 89DB System input efficiency: 70% Fan types: A, C Noise 92DB System input efficiency: 69% Fan types: A, C Noise 95DB System input efficiency: 69% 10m3/s 4W X 3H Fan types: A, C Noise 95DB System input efficiency: 69% Fan types: A, C Noise 86DB System input efficiency: 71% Fan types: A, C Noise 90DB System input efficiency: 72% Fan types: A, C Noise 94DB System input efficiency: 72% Fan types: A, C Noise 97DB System input efficiency: 72% 20m3/s 6W X 4H Fan types: C, A Noise 82DB System input efficiency: 68% Fan types: A, C Noise 90DB System input efficiency: 72% Fan types: A, C Noise 94DB System input efficiency: 72% Fan types: A, C Noise 97DB System input efficiency: 72% Fan types: A, C Noise 100DB System input efficiency: 71%

1000Pa

1500Pa

2000Pa

2500Pa

Fan types: A Double Inlet Backward Curved Aerofoil Blade Direct Drive B Backward Curved Aerofoil Blade Direct Drive Plug Fan C Double Inlet Backward Curved Blade, Belt Drive

Note it should be clear that these are minimum levels are system input efficiencies. This is not the same as total efficiency or static efficiency as have more commonly had been used historically by fan manufacturers.

FanSystem = FanStatic Motor belt-drive Inverter installation

Care should be taken in selecting components that components are optimised for their load: a premium efficiency motor driving a premium efficiency fan does not necessarily equate to a maximum efficiency fan system. Calculations should be based on actual load conditions. There seems to be a direct correlation between fans with high Specific Fan Power (SFP) and Fan Noise (DBA). The table presented above limits the fans to the above criteria. Motor Types Recommended: 1. 2. IE2 Motors (Minimum) IE3 / PMMI /IE4 (Preferred)

Single Inlet Centrifugal fans

Double Inlet Centrifugal Fans

Typical Fan Static Efficiency Curves While selecting centrifugal fans, it should be ensured that the fans are not selected in the stall range resulting in significant pressure pulsations which can damage the fan casing and duct system. The robust nature of the centrifugal fan impeller geometry makes them much more tolerant of inadvertent stall operation. A well designed fan static efficiencies is generally into the high eighties (%).Plug Fans are recommended where total pressures less than 1500 Pa are required as long as target efficiency levels are achieved. We would advocate thrust restraints on inlet/outlet flanges for high pressure fans. The fan arrangement in AHU casing shall ensure even inflow and outflow of air and comply with prEN 130536.3.1 as stated below:

Distance on negative pressure side: - Axial distance from components and walls with a min. 0.5 x impeller diameter - Radial inflow: minimum of 3 x impeller diameter or a diffuser shall be included for double or single inlet fans. For plug fans, minimum of 1 x impeller diameter. This arrangement shall be reviewed along with manufacturers recommendations as indicated.

Distance on positive pressure side: - From components: open impellers, min. 1 x impeller diameter - From components: other components, outflow angle min. a = 45 - From walls: Observe manufacturers instructions regarding positive pressure -side distance between open impeller fans and walls in order to minimise dynamic discharge pressure. Specific fan power (SFP)

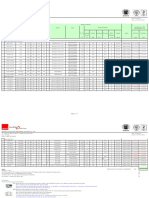

Where: SFP is the specific fan power demand of the air distribution system (W/ (l/s)) Psf is the total fan power of all supply air fans at the design air flow rate, including power losses through switchgear and controls associated with powering and controlling the fans (W). Pef is the total fan power of all exhaust air fans at the design air flow rate, including power losses through switchgear and controls associated with powering and controlling the fans (W). q is the design air flow rate through the system, which should be the greater of either the supply or exhaust air flow (l/s). Note that for an air handling unit, q is the largest supply or extract air flow through the unit. Fan, motor and motor fastenings shall be mounted on horizontal base frame. Fan and motor fastenings for seismically active areas snubbers shall be provided along the base channel to provide three dimensional restraints in case of seismic activity. During normal operation, vibration isolation from building structure shall be provided through base foundation. For seismic active zones, seismic cables shall be used to restraint movement in case of seismic activity in accordance to SEI/ASCE7 standards. For interior height of 1.5 m, sight glass shall be provided with an inside diameter min. 150 mm and light. Motor protection shall be provided for motors upwards of 0.25 kW. Lockable maintenance switch shall be provided near fans. Fans shall be equipotentially bonded. Fan blade imbalance is an important maintenance aspect which is generally not adequately considered during the PPM process, it is recommended that Fan blade imbalance be reviewed on a 6 monthly basis to ensure that the vibration isolation efficiency is not compromised. It is highly recommended that vibration sensors / general purpose accelerometer for the purpose of condition monitoring and protecting fans. Periodic checks on Fan blade imbalance would help in improving AHU fan life by implementing timely remedial measures. Fan Types: Table 1.1 summaries the different types of fans along with their efficiency curves, performance characteristics, application and fan characteristic curves as shown in GPG383 published by The Carbon Trust

Specific fan power (SFP)

Where: SFP is the specific fan power demand of the air distribution system (W/ (l/s)) Psf is the total fan power of all supply air fans at the design air flow rate, including power losses through switchgear and controls associated with powering and controlling the fans (W). Pef is the total fan power of all exhaust air fans at the design air flow rate, including power losses through switchgear and controls associated with powering and controlling the fans (W). q is the design air flow rate through the system, which should be the greater of either the supply or exhaust air flow (l/s). Note that for an air handling unit, q is the largest supply or extract air flow through the unit. As a general rule the Specific fan power contribution for a supply fan is around 80% with an extract fan with around 20%. Selection of SFP class for each fan if unspecified: Maximum Specific Fan Powers in air distribution systems System Type Central Mechanical Ventilation System including heating and cooling ( includes both supply and extract) Central Mechanical Ventilation System including heating only ( includes both supply and extract) All other central mechanical ventilation systems (Supply and extract) Additional Components: Additional return filter for heat recovery HEPA filter Heat Recovery- Thermal Wheel system Heat Recovery- Other systems Humidifier / Dehumidifier (air conditioning systems) 0.1 1.0 0.3 0.3 0.1 SFP (W/(l/s)

1.8 1.6 1.4

Specification: Fans shall be centrifugal double inlet, double width; single inlet single width; or plug direct drive units, manufactured in continuously welded mild steel with stiffeners where necessary with IE3+ permanent magnet motors. Where double inlet fans are used, bearings should be double row ball or roller bearings in cast iron Plummer-block bearing housings. Impellers shall be backward curved with continuously welded high quality steel aerofoil blades. Fans shall be statically and dynamically balanced to BS 5265. Supply air fans shall be arranged so as to minimise suction-side leakage air flows. If two-stage filtering is used, the supply air fan is to be arranged between the first and second filter stage. The fans shall be selected for operation at fan total system input efficiency (to include all motor, drive, and inverter or controller losses) of not less than the efficiencies stated in the table below and the fan discharge velocity shall not exceed 10 metres per second as long as this does not compromise efficiency. The fan arrangement in AHU casing shall ensure even inflow and outflow of air and comply with prEN 13053-6.3.1 as stated below:

Distance on negative pressure side: - Axial distance from components and walls with a min. 0.5 x impeller diameter - Radial inflow: minimum of 3 x impeller diameter, or a diffuser shall be included for double or single inlet fans. For plug fans, minimum of 1 x impeller diameter. This arrangement shall be reviewed along with manufacturers recommendations as indicated. Distance on positive pressure side: - From components: open impellers, min. 1 x impeller diameter - From components: other components, outflow angle min. a = 45 - From walls: Observe manufacturers instructions regarding positive pressure -side distance between open impeller fans and walls in order to minimise dynamic discharge pressure. Fan, motor and motor fastenings shall be mounted on horizontal base frame. Fan and motor fastenings for seismically active areas snubbers shall be provided along the base channel to provide three dimensional restraints in case of seismic activity. During normal operation, vibration isolation from building structure shall be provided through base foundation. For seismic active zones, seismic cables shall be used to restraint movement in case of seismic activity in accordance to SEI/ASCE7 standards. Vibration isolation shall provide a minimum damping of 95%. Spring and damper elements pressureloaded in order to avoid any shear loading (Please refer to Section 4.21 on Vibration Isolation and

Control). The fans shall incorporate vibration sensors / general purpose accelerometer for the purpose of condition monitoring and protecting fans. For interior height of 1.5 m, sight glass shall be provided with an inside diameter min. 150 mm and light. Motor protection shall be provided for motors upwards of 0.25 kW. Lockable maintenance switch shall be provided near fans. Fans shall be equipotentially bonded. Fan shall be fitted with an air flow meter and indicator in order to comply with DIN 1946/4-6.5.13. Precipitation must be prevented in the fan. Size 400 or larger fans with housings shall be fitted with a condensate drain and inspection opening. All fans shall have backward-curved blades with Class IE3 or higher permanent magnet motors. Thrust restraints shall be provided on inlet/outlet flanges for high pressure fans.

Plug Fans are recommended where total pressures less than 1500 Pa are required as long as target efficiency levels are achieved.

Selection of SFP class for each fan if unspecified: Maximum Specific Fan Powers in air distribution systems System Type Central Mechanical Ventilation System including heating and cooling ( includes both supply and extract) Central Mechanical Ventilation System including heating only ( includes both supply and extract) All other central mechanical ventilation systems (Supply and extract) Additional Components: Additional return filter for heat recovery HEPA filter Heat Recovery- Thermal Wheel system Heat Recovery- Other systems Humidifier / Dehumidifier (air conditioning systems) 0.1 1.0 0.3 0.3 0.1 SFP (W/(l/s)

1.8 1.6 1.4

Access doors to hazardous components must not be openable without a tool. Additionally fan section access door(s) shall be fitted with a warning sign. Surface quality for the fan shall include the following: - Impeller protected against corrosion in all cases - Fan housing hot-dip galvanized or painted/coated steel sheet

- Fan motor base frame hot-dip galvanized or painted/coated steel sheet - Mounting rails hot-dip galvanized or painted/coated steel sheet in order to comply with DIN 1946/46.5.10 Fan motor unit of fans with housing shall be removable on units with casing height up to 1.0 m. Sliding surfaces of unit travel rails shall be corrosion and abrasion-resistant, e.g. stainless steel (min 1.4301). Inspection window shall have an inside diameter min. 150 mm and light with smooth surface to comply with DIN 1946/4-6.5.13 Fan motor housings shall have easy access for service and maintenance in order to comply with DIN 1946/4-6.5.10 Sensitive components (e.g. fans on spring isolators) shall be secured to prevent damage in transit and unit labelled accordingly. Unit and components to be cleaned after manufacture, protected from the elements and kept clean in transit, and protected from construction work dust and moisture during any interruptions in assembly. High standard of packaging ex works.

All Fans shall include the following data: - Make and year of manufacture - Nominal air flow - Total pressure gain - Nominal and maximum speed - Nominal motor power - Arrow indicating rotation direction on housing The following data to be included in data sheet: - SFPV class - Motor input power PM - Sound pressure level radiated from casing - Duct sound pressure level for intake and outlet, LW (A-rated as total pressure level; unrated in octave band from 125 Hz to 8 kHz) - Maximum fan speed - V-class observed - H-class observed

Вам также может понравиться

- Verbal and Non Verbal Reasoning Learning PackДокумент46 страницVerbal and Non Verbal Reasoning Learning Packmirali74100% (5)

- 100 MW Solar Farm Pre-Feasibility Study For Investment PDFДокумент11 страниц100 MW Solar Farm Pre-Feasibility Study For Investment PDFmirali74Оценок пока нет

- 100 MW Solar Farm Pre-Feasibility Study For Investment PDFДокумент11 страниц100 MW Solar Farm Pre-Feasibility Study For Investment PDFmirali74Оценок пока нет

- TM 9 2835 255 34Документ826 страницTM 9 2835 255 34Derbaz KhalilОценок пока нет

- Second Floor Load CalculationsДокумент1 страницаSecond Floor Load CalculationsSudhir KulkarniОценок пока нет

- York Chiller Log SheetДокумент4 страницыYork Chiller Log SheetEngr Fazal AkbarОценок пока нет

- Duct Design RevДокумент21 страницаDuct Design Revapi-25999517100% (1)

- Duck Work Calculation (Inch)Документ2 страницыDuck Work Calculation (Inch)pratheeshОценок пока нет

- HVAC PresentationДокумент83 страницыHVAC PresentationAnantTyagiОценок пока нет

- CHW Pipe Straight Pressure DropДокумент2 страницыCHW Pipe Straight Pressure DropDesigner ForeverОценок пока нет

- AHU Friction Loss CalculationsДокумент4 страницыAHU Friction Loss CalculationsAdnan AttishОценок пока нет

- Hvac Condensate Calculator: Difference in Specific Humidity gr/ft3Документ4 страницыHvac Condensate Calculator: Difference in Specific Humidity gr/ft3Pradeep SukumaranОценок пока нет

- Chilled Water System Sequence of OperationДокумент3 страницыChilled Water System Sequence of OperationdimasОценок пока нет

- Electrical Loading Estimation WorkstageДокумент15 страницElectrical Loading Estimation WorkstageansonchongОценок пока нет

- Sound Attenuator Selection Path Report: Source Sound Power Level Total Air Flow (M3/sec)Документ1 страницаSound Attenuator Selection Path Report: Source Sound Power Level Total Air Flow (M3/sec)mefaisal75Оценок пока нет

- Sample Calculations of Boiler Pumps and IDДокумент5 страницSample Calculations of Boiler Pumps and IDMasih BelajarОценок пока нет

- Energy Efficient Technologies ECA 04MArch2013Документ41 страницаEnergy Efficient Technologies ECA 04MArch2013Arundeep SinghОценок пока нет

- AHU ChecklistДокумент11 страницAHU Checklistmohammad hamdanОценок пока нет

- 9 571 WaterCooledChillerPlantWithEconomizerVP PDFДокумент10 страниц9 571 WaterCooledChillerPlantWithEconomizerVP PDFFirasОценок пока нет

- VAV PresentationДокумент44 страницыVAV PresentationmitasyahuОценок пока нет

- Vav - 1Документ10 страницVav - 1perezismaelОценок пока нет

- Heat Recovery From Industrial Compressed Air SystemsДокумент4 страницыHeat Recovery From Industrial Compressed Air SystemsmawooaОценок пока нет

- Technical Handbook Air CurtainsДокумент13 страницTechnical Handbook Air Curtainsaca111111Оценок пока нет

- Shop Drawing: Welcome Air-Tech (M) SDN BHDДокумент1 страницаShop Drawing: Welcome Air-Tech (M) SDN BHDKarthi KeyanОценок пока нет

- Proper Engine Room VentilationДокумент2 страницыProper Engine Room VentilationAsok AyyappanОценок пока нет

- Combining DOAS and VRF, Part 2 of 2Документ9 страницCombining DOAS and VRF, Part 2 of 2miniongskyОценок пока нет

- L&T MLCP East Block HVAC Heat Load SUMMARYДокумент3 страницыL&T MLCP East Block HVAC Heat Load SUMMARYSatheesh Kumar NatarajanОценок пока нет

- AHU Operational Control Spreadsheet TrainingДокумент17 страницAHU Operational Control Spreadsheet Trainingniti860Оценок пока нет

- Converting KW Ton To COP or EERДокумент2 страницыConverting KW Ton To COP or EERswsw2011Оценок пока нет

- HPT Optimizing Outside Air With HPTДокумент11 страницHPT Optimizing Outside Air With HPTNGUYEN QUANGОценок пока нет

- Sizing An Exhaust FanДокумент1 страницаSizing An Exhaust Fanomar mohd zainiОценок пока нет

- Plantroom ExhaustДокумент2 страницыPlantroom ExhaustDota NgОценок пока нет

- SAFIDДокумент34 страницыSAFIDsyedahmedsabirОценок пока нет

- Duct DesignДокумент49 страницDuct DesignabianshbaralОценок пока нет

- 1Документ3 страницы1ntt_121987Оценок пока нет

- 01-Pressurization Fan Calculation Sheet - Rev-01Документ4 страницы01-Pressurization Fan Calculation Sheet - Rev-01Hamdy AdelОценок пока нет

- AHUДокумент5 страницAHUksahunkОценок пока нет

- Water-Cooled Series R (TM) RTHD Product ReportДокумент2 страницыWater-Cooled Series R (TM) RTHD Product ReporttrangocvuОценок пока нет

- Dasco 19-26Документ8 страницDasco 19-26Ahmed AzadОценок пока нет

- NY1395 Smoke-Management GeidelДокумент69 страницNY1395 Smoke-Management GeidelTrong Hieu NguyenОценок пока нет

- Energy Conservation in HVACfinalДокумент57 страницEnergy Conservation in HVACfinalAdnan NimachwalaОценок пока нет

- Systemair CatalogueДокумент21 страницаSystemair CataloguePARVEZ AMEENОценок пока нет

- HVAC Chapters 1 5Документ57 страницHVAC Chapters 1 5Mcilwaine Dela CruzОценок пока нет

- Halton Design Guide enДокумент54 страницыHalton Design Guide enimtiyaz94Оценок пока нет

- Comparison of ASHRAE 52.1 and 52.2 PDFДокумент5 страницComparison of ASHRAE 52.1 and 52.2 PDFChi Kit PhoonОценок пока нет

- Heat Wheel: Mohammad Yusuf 13PKB380Документ10 страницHeat Wheel: Mohammad Yusuf 13PKB380Haider Ali100% (1)

- Evergreen Chiller Performance Outputs: Tag Name: 23XRV 350TRДокумент1 страницаEvergreen Chiller Performance Outputs: Tag Name: 23XRV 350TRcalvin.bloodaxe4478Оценок пока нет

- Ahu & Chiller OkДокумент40 страницAhu & Chiller OkAndy DwiОценок пока нет

- ACMV DESIGN: Sample Heat Load Calculation For General Office Meeting RoomДокумент5 страницACMV DESIGN: Sample Heat Load Calculation For General Office Meeting RoomVenkates Adhinarayanan50% (2)

- Ishrae: Submitted To Mrs. Bhavana Mathur Mr. Sunil SharmaДокумент35 страницIshrae: Submitted To Mrs. Bhavana Mathur Mr. Sunil SharmaAnurag JoshiОценок пока нет

- VAV vs. VCDДокумент7 страницVAV vs. VCDomarsosa#747Оценок пока нет

- Aircon Cooling Load EstimationДокумент3 страницыAircon Cooling Load Estimationdokundot80% (5)

- A Theoretical and Practical Guide To The Basics of Designing Air Flow SystemsДокумент3 страницыA Theoretical and Practical Guide To The Basics of Designing Air Flow Systemsmarcoo8Оценок пока нет

- ASHRAE - HVAC-HospitalBook - Room Design PDFДокумент4 страницыASHRAE - HVAC-HospitalBook - Room Design PDFalialavi2Оценок пока нет

- Regulation DD-9.0: Drainage: 9.1 Domestic Drainage 9.2 Water Supply 9.3 Rainwater Drainage 9.4 A/C DrainДокумент10 страницRegulation DD-9.0: Drainage: 9.1 Domestic Drainage 9.2 Water Supply 9.3 Rainwater Drainage 9.4 A/C DrainSarathОценок пока нет

- ORC Working Fluids Comparison ECOS PresentationДокумент16 страницORC Working Fluids Comparison ECOS Presentationoverlord5555Оценок пока нет

- AHU Design BasicsДокумент29 страницAHU Design BasicsHari Babu Dharmavarapu100% (2)

- System Duct Pressure Loss CalculationДокумент6 страницSystem Duct Pressure Loss Calculationthanh_79Оценок пока нет

- Selection Sheet - 30XA452 Screw ChillerДокумент1 страницаSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478Оценок пока нет

- Fan and BlowerДокумент58 страницFan and BlowerKAZI SIAMUL ISLAM100% (1)

- Fan BlowerДокумент20 страницFan BlowerShariq AliОценок пока нет

- Cooling Fan CalculationsДокумент13 страницCooling Fan CalculationsF. A AhmedОценок пока нет

- Basic Fan SelectionДокумент4 страницыBasic Fan Selectioncem_kamalОценок пока нет

- CLCH PRC008 enДокумент352 страницыCLCH PRC008 enOscar Andrés PavónОценок пока нет

- Swimming Pool Ventilation DesignДокумент49 страницSwimming Pool Ventilation Designmirali74Оценок пока нет

- Legionella Bacteria ChecklistДокумент21 страницаLegionella Bacteria Checklistmirali74Оценок пока нет

- Lot 108 Auction ContractДокумент11 страницLot 108 Auction Contractmirali74Оценок пока нет

- Lot 108 Drainage & WaterДокумент18 страницLot 108 Drainage & Watermirali74Оценок пока нет

- Heat Stress at WorkplaceДокумент4 страницыHeat Stress at Workplacemirali74Оценок пока нет

- Modified Cable Sizing Strategies - Egemin - Publication 2014 JanuaryДокумент54 страницыModified Cable Sizing Strategies - Egemin - Publication 2014 Januarymirali74Оценок пока нет

- Exponentials and Logarithms: The Exponential FunctionДокумент2 страницыExponentials and Logarithms: The Exponential Functionmirali74Оценок пока нет

- 05-IZMIT-COW-PRE-DD-GEN-0010 - 1.0 - IABSE Denmark Mini-Seminar 2013.pptx (Read-Only) PDFДокумент37 страниц05-IZMIT-COW-PRE-DD-GEN-0010 - 1.0 - IABSE Denmark Mini-Seminar 2013.pptx (Read-Only) PDFmirali74Оценок пока нет

- The Product and Quotient RulesДокумент1 страницаThe Product and Quotient Rulesmirali74Оценок пока нет

- FunctionsДокумент3 страницыFunctionsmirali74Оценок пока нет

- RestitutionДокумент1 страницаRestitutionmirali74Оценок пока нет

- Non-Verbal Reasoning Rotating 3d ShapesДокумент4 страницыNon-Verbal Reasoning Rotating 3d Shapesmirali74100% (1)

- Non-Verbal Reasoning Cubes Practice 0Документ4 страницыNon-Verbal Reasoning Cubes Practice 0mirali74100% (2)

- Decision Mathematics 1: MEI Structured Mathematics Module Summary SheetsДокумент7 страницDecision Mathematics 1: MEI Structured Mathematics Module Summary Sheetsmirali74Оценок пока нет

- ASSIGNMENT Transformations Work SheetДокумент6 страницASSIGNMENT Transformations Work Sheetmirali74Оценок пока нет

- MEI Structured Mathematics Module Summary Sheets: C3, Methods For Advanced MathematicsДокумент10 страницMEI Structured Mathematics Module Summary Sheets: C3, Methods For Advanced Mathematicsmirali74Оценок пока нет

- Non-Verbal Reasoning Cubes and Nets An Introduction 0Документ6 страницNon-Verbal Reasoning Cubes and Nets An Introduction 0mirali74Оценок пока нет

- Cooling Unit SpecДокумент4 страницыCooling Unit Specmirali74Оценок пока нет

- Beach Enclave Swimming Pool - OutdoorДокумент1 страницаBeach Enclave Swimming Pool - Outdoormirali74Оценок пока нет

- SDLT 6Документ74 страницыSDLT 6mirali74Оценок пока нет

- Book 1 CompletoДокумент69 страницBook 1 CompletoRaissaCurtyОценок пока нет

- Mission Control Center Familiarization ManualДокумент159 страницMission Control Center Familiarization ManualBob AndrepontОценок пока нет

- Random Variables and Discrete Probability DistributionsДокумент37 страницRandom Variables and Discrete Probability DistributionswadihaahmadОценок пока нет

- International Metrology - The Work of The BIPM and The OIMLДокумент4 страницыInternational Metrology - The Work of The BIPM and The OIMLsigit.kurniadiОценок пока нет

- Nemo Outdoor Brochure Oct 2014Документ2 страницыNemo Outdoor Brochure Oct 2014treejumboОценок пока нет

- What Caused The Fall of Ancient EgyptДокумент13 страницWhat Caused The Fall of Ancient EgyptEugenio ZarauzОценок пока нет

- Environmental Sustainability in The Food-Energy-Water-Health NexusДокумент10 страницEnvironmental Sustainability in The Food-Energy-Water-Health NexusPutri Alya KrisnamurtiОценок пока нет

- Difference Between Plasma and SerumДокумент4 страницыDifference Between Plasma and SerumQuraishi SahbОценок пока нет

- Mock ExamДокумент7 страницMock ExamJoannaОценок пока нет

- Tjo 35 2 139Документ11 страницTjo 35 2 139Manuel CastilloОценок пока нет

- ValdorДокумент1 страницаValdorprojectkmoОценок пока нет

- SLK20R - Data SheetДокумент2 страницыSLK20R - Data SheetAhmed MijwilОценок пока нет

- Table-A: Summary of Materials / Products Specification and QA/QC Test RequirementsДокумент42 страницыTable-A: Summary of Materials / Products Specification and QA/QC Test RequirementsVictor VargheseОценок пока нет

- Experiment 4 Determination of Total Hardness As PPM Calcium CarbonateДокумент26 страницExperiment 4 Determination of Total Hardness As PPM Calcium CarbonateJordanОценок пока нет

- Autumn The Bear Girl: by JojilieДокумент9 страницAutumn The Bear Girl: by JojilieBrenda Acuña100% (1)

- A.kishore Journal PaperДокумент34 страницыA.kishore Journal PaperA KishoreОценок пока нет

- RM50HG 12SДокумент3 страницыRM50HG 12SAbu Bakr M. SaeedОценок пока нет

- FumojagaДокумент3 страницыFumojagaFlaudemir Silva de SouzaОценок пока нет

- Haynes 230 Alloy: Principal FeaturesДокумент28 страницHaynes 230 Alloy: Principal FeaturesMatheus DominguesОценок пока нет

- BV-Rules For The Classification of Steel Ships - Part B-Hull and StabilityДокумент112 страницBV-Rules For The Classification of Steel Ships - Part B-Hull and Stabilitytruong271230% (1)

- Yvl2 7eДокумент9 страницYvl2 7ekazmi81Оценок пока нет

- Xdeed3qtt - 1 - Concepts in The Care of at Risk and Sick Adult ClientsДокумент14 страницXdeed3qtt - 1 - Concepts in The Care of at Risk and Sick Adult ClientsCamille GuintoОценок пока нет

- Estimate LEL and FlashДокумент2 страницыEstimate LEL and Flashnirmal_subudhiОценок пока нет

- Krezo 2016 Field Investigation and Parametric Study of Greenhouse GasДокумент14 страницKrezo 2016 Field Investigation and Parametric Study of Greenhouse GasAbhiram shuklaОценок пока нет

- Node2vec: Scalable Feature Learning For Networks: Aditya Grover Et Al. Presented By: Saim Mehmood Ahmadreza JeddiДокумент30 страницNode2vec: Scalable Feature Learning For Networks: Aditya Grover Et Al. Presented By: Saim Mehmood Ahmadreza Jeddisiraj mohammedОценок пока нет

- Christmas Goes PantoДокумент3 страницыChristmas Goes PantoAna SolОценок пока нет

- Increase and Decrease WBC CountДокумент2 страницыIncrease and Decrease WBC CountLecture NotesОценок пока нет

- Veterinary Ophthalmology: An International Journal of Clinical and Investigative OphthalmologyДокумент3 страницыVeterinary Ophthalmology: An International Journal of Clinical and Investigative OphthalmologyBlanca A SerranoОценок пока нет

- Rear Axle Service Manual Daf LF DemoДокумент12 страницRear Axle Service Manual Daf LF DemoValera Chuhmanov ChuhmanovОценок пока нет