Академический Документы

Профессиональный Документы

Культура Документы

14400

Загружено:

AhmedMahmoudАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

14400

Загружено:

AhmedMahmoudАвторское право:

Доступные форматы

SECTION 14400 HYDRAULIC AND ELECTRIC LIFTS/ELEVATORS PART 1 - GENERAL 1.01 RELATED OBLIGATIONS A. B. C.

The general requirements under Division 1 apply to work specified in this Section. Examine all the other Sections of the Specifications for requirements which may affect work of this Section Co-ordinate work with all other trades affecting, or affected by activities of this Section. Co-operate with such other trades to assure the steady progress of all operations under the Contract.

1.02 SCOPE OF WORKS A. The Contractor shall supply, deliver, erect, connect and test all materials and equipment required to provide all the lifts in accordance with the terms and conditions of the Specification, Drawings and Schedules. The Specification detailed below shall apply to all lift installations detailed on the Architectural Drawings and shall be read either singularly or in plural as applicable to provide al the lift installations within the building. The whole of the work and materials supplied shall be in accordance with the relevant British Standard Specification and Codes of Practice and in particular BS 5655. C. The Contractor shall include for all necessary attendance to other trades for the proper coordination of all associated services to be installed and arrange for all conduit, cable and duct routes, positions of switchgear accessories, etc. The Contractor shall obtain all information regarding the precise details of the construction of the shaft and pump room. All work carried out under the Contract shall be to the entire satisfaction of the Architect/Engineer.

B.

D. E.

1.03 SERVICING OF LIFTS AFTER COMPLETION A. The Contractor shall include for providing a comprehensive maintenance on the completed lift installation for a period of 12 calendar months from the date of acceptance by the Architect/Engineer. Maintenance shall be carried out as necessary during the 12 month period and shall include the cleaning, oiling, greasing and adjustments of all parts of the lift and to maintain as far as possible the accuracy of operation as stated in this Specification. During the initial 12 months maintenance period, the Contractor shall make good or replace, at his own expense any part that is found to be defective or show any

B.

C.

Al Qassim University

14400 - 1

Hydraulic and Electric Lifts/Elevators

D. E.

signs of weakness or undue wear in consequence of faulty design, workmanship or material. The lift pump room and pit, floors and walls shall be kept free of oil, grease and rubbish and shall be left in a tidy manner after maintenance. When the lift is not available for use whilst the Contractor is working on it for any reason, the Contractor shall display a suitable notice at each entrance to the lift indicating that it is temporarily out of service. A log book shall be provided by the Contractor to record maintenance visits, inspections, breakdowns, repairs, etc. Failure to complete the log book will constitute a breach of Contract.

F.

1.04 MAINTENANCE AND SERVICING (POST GUARANTEE PERIOD) A. The Contractor shall provide a Schedule indicating the current charge based on a 25 year period per lift for comprehensive maintenance as detailed below. 1. Routine examination of the entire lift equipment, with monthly visits with adjustments as necessary to maintain the performance of the installation as fair wear and tear will permit. The cost of repair or replacement of any component parts of the lift installation due to fair wear and tear. The cost of the servicing to be based on the work being carried out during normal working hours unless stated otherwise, and all possible care shall be taken to ensure that the lift is maintained in proper and safe working order. The service shall include for all necessary call-outs at any time, but if called out during the hours of 8.OOam to 5.OOpm the Contractor may include for premium time.

2. 3.

4.

1.05 MATERIALS AND SAMPLES A. All materials shall be of the best of their particular type and the Contractor shall submit for approval samples of the various items of equipment intended for use in the execution of the work. As an alternative, the Architect/Engineer reserves the rights to be shown all items of equipment offered. The Contractor shall submit samples of any landing or car signal fixtures and finishes detailed in this Specification. All samples will be returned to the Contractor after inspection by the Architect/Engineer.

B. C.

1.06 SHOP DRAWINGS A. The contractor shall prepare assembly and installation drawings. The following drawings shall form the Contractors installation drawings and shall be fully coordinated with the elements related to Lifts. 1. Detailed general arrangement drawings of all equipment supplied and manufactured by the Contractor with structural loads.

Al Qassim University

14400 - 2

Hydraulic and Electric Lifts/Elevators

2. 3. 4. 5. 6.

Detailed Plant room drawings. Any drawings the Contractor intends to use as installation drawings. Detailed plans, sections and elevations showing all required builders work, including size and position of holes, chases and steelwork. Any detail drawings or manufacturers drawings required prior to or found necessary during the manufacturing or erection periods. Wiring diagrams for electrical equipment. Electrical wiring diagrams shall be prepared for all plant requiring electrical connections. Where manufacturers original drawings are used, they shall be specific to the relevant plant and all references to optional features, other machines or a range, etc., shall be deleted. All wiring diagrams shall clearly indicate that wiring which forms part of or is connected to the equipment as delivered and shall include the information necessary to enable the switchgear, site connections and wiring to be completed by the Contractor.

B.

Certain advanced details of builders work such as well sizes, may have already been agreed by the Architect/Engineer, and details included either in schedules or on drawings, but it is the Contractors responsibility to ensure that these details are correct and sufficient for his work.

1.07 STEELWORK AND PAINTING A. B. C. D. E. The Contractor shall supply and fix all guides and necessary steelwork for guide fixings to the structure, landing sills, door tracks and buffers. The Contractor shall include for the supply and fixing of sheet steel fascia panels between the landing sills and headers. These shall have a galvanized finish. The Contractor shall include for supplying and fixing a steel cat ladder in each pit for access. Lifting beams at the top of the lift well will be supplied and fixed as per approved shop drawings. All hoistway steelwork such as guide rails (excluding blades) and fixing brackets, shall receive one coat of an oil based primer and paint before erection and one coat of paint after erection. Steelwork that will be inaccessible after erection shall have the second coat applied before installation. Machinery such as motors, gearboxes and controllers, etc. , shall be primed and cellulosed to an approved color. Any paint work damaged during installation shall be made good on site.

F. G.

1.08 FINAL INSPECTION, TESTING AND COMMISSIONING A. Inspection testing and general commissioning as specified in BS 5655 shall be carried out by the Contractor and be witnessed by the Architect/Engineer. These tests shall be made prior to handing over at the substantial completion stage and any major defects found shall be corrected before the lift is put into service.

Al Qassim University

14400 - 3

Hydraulic and Electric Lifts/Elevators

B. C.

The Contractor shall include for all necessary fees for carrying out these tests together with the provision of all instruments, test weights, etc. The Contractor shall give the Architect/Engineer seven days notice in writing of the date proposed to carry out these tests to enable the Architect/Engineer to be present. A Certificate of Acceptance will be signed by the Architect/Engineer on completion of the installation and these tests. The Contractor shall provide the Architect/Engineer with two typed copies of Certificates of Test of the installation within two weeks of Acceptance. During the tests, a manuscript test certificate shall be available for inspection by the Architect/Engineer. Before the final tests are witnessed by the Architect/Engineer, the Contractor shall conduct such checks and assessments as will satisfy him that when the final tests are conducted they can be carried out with reasonable anticipation that the requirements of the Contract will be met and the final tests can be concluded without interruption and postponement.

D. E.

F.

1.09 RECORD DRAWINGS A. B. C. D. After substantial completion of the Contract, the Contractor shall provide drawings of the work as actually installed. These drawings shall show plans and sections as the Architect/Engineer may consider necessary to show all required information clearly. The drawings shall show clearly the location and size, materials and service installed, together with all cable, conduit and trunking runs including joint boxes. The drawings shall be provided as follows: 1. 2. 3. 4. 5. General arrangement plan of machine room equipment including circuit breakers, isolators, car lighting switch, etc. General arrangement plan of car and hoistway equipment. General arrangement section of hoistway and machine room. General arrangement elevation of the car and landing entrance. Wiring diagram giving full details of all electrical equipment as actually wired and installed. The markings of all terminals on equipment shall be clearly carried out, and these markings shall correspond to the connections on the wiring diagram, which shall also be clearly indicated.

E.

Four dyeline prints of these drawings shall be submitted to the Architect/Engineer for approval before the linen copies are printed and stencils shall be used for all printing on drawings. A spare set of working drawings shall be kept on site in order that all conduit run, positions of equipment, etc., can be checked during the Architect/Engineers routine visits, and an accurate and comprehensive record can be maintained of the installation.

F.

Al Qassim University

14400 - 4

Hydraulic and Electric Lifts/Elevators

G.

The final copies shall consist of one microfilm, one linen print and one negative of each drawing. The final As Fitted drawings shall be submitted to the Architect/Engineer.

PART 2 - PRODUCTS/DESIGN CRITERIA 2.01 ACCEPTABLE MANUFACTURERS A. Products for the use of this Section shall be obtained from the following or equal approved: 1. 2. 3. B. Otis Schindler Evans Lifts Ltd.

LOADING 1. 2. The maximum contract load shall be as indicated in the attached Schedule and load and data plates shall be fitted within the lift car. The load plate shall indicate the maximum loading in Kg and Persons for the lift and shall be manufactured from satin stainless steel with the lettering engraved and filled. Details of the size of all letters etc. shall be submitted to the Architect/Engineer for approval.

3.

2.02 ISOLATION A. The Contractor shall include for all necessary isolation materials, rubber pads, attenuators, etc., to ensure that lifts runs with the minimum of noise and vibration. Having regard to accepted commercial standards, the lift installation shall be free from vibration and with smooth acceleration and retardation, all to the satisfaction of the Architect/Engineer.

2.03 GUIDES A. The guides for the car shall be planed steel tees, erected plumb and securely fixed to the structure by steel brackets. The ends shall be tongued and grooved, forming matched joints and shall be connected by steel fish plates. Fixing brackets shall be provided so that the guides are securely supported along their entire length and that they will not deflect more than 3mm under the normal operation of the lift. The guides shall be of such a length that it is not possible for the car shoes to run off the guides. Guides and their fixings must withstand the application of the safety gear when stopping a fully loaded car. Guides shall be secured to their fastening by through- bolts or by clips of such design that any rotary movement of the clip will not release the guide. Any shims used in the fixing of guides brackets must be of metal and washer type so designed and placed that they cannot fall away from the fixing should they come loose.

14400 - 5 Hydraulic and Electric Lifts/Elevators

B.

C.

D.

Al Qassim University

E. F. G.

If the car enclosure is cantilevered from the side, an additional stabiliser guide rail shall be provided on the opposite side of the car enclosure. The Contractor shall supply any guide gauges or templates that may be required for use during erection. The Contractor shall supply all inserts required for casting into the structure.

2.04 BUFFERS A. B. The lift shall be provided with buffers securely fixed to the pit floor or to the car frame in accordance with approved shop drawings. For passenger carrying lifts having a speed of 1.00m/s or less, the buffers shall be of the spring pattern, manufactured from the best quality square or round section steel in helical formation and be securely bolted or welded to a steel baseplate suitably located under the car and counterweight. Timber, rubber or synthetic buffers are not acceptable.

2.05 TERMINAL STOPPING SWITCHES A. The lift shall be supplied with terminal stopping switches in accordance with the following clauses. 1. The terminal stopping switches in the control circuit shall be of substantial design and shall be of the self resetting type arranged to stop the lift automatically from any speed attained in normal operation within the limits of top and bottom over- travel independently of the buffers. The terminal stopping switches shall be arranged to operate with the lift car as close to the terminal floors as practicable without interfering with the normal operation of the lift.

2.

2.06 ELECTRICAL SUPPLIES AND SHAFT LIGHTING A. B. The supplies to the pump room will terminate in switchgear provided within the pump room. The supplies will be 380/220 volts, 60 Hz, 3-phase, 4- wire, a.c. as required and the Contractor shall supply and install all necessary wiring and enclosures from the switchgear to the lift control panels and from the panels to the various items of equipment. A 220 volt, 60 Hz, single phase, 2-wire, a.c. supply including all cables and conduit will be provided by the Contractor to the pump room and terminated in a consumer unit, to serve the respective lift car light and shaft lighting etc. In addition one adaptable box shall be provided in the pump room to enable the telephone circuit to be continued to the lift car. The Contractor shall extend the alarm and telephone circuits to the respective lift cars by means of PVC cables enclosed in conduit and/or trunking. A 12 volt trickle charger and battery shall be supplied by the Contractor and fitted in the machine room for the lift alarm system.

C.

D. E. F.

Al Qassim University

14400 - 6

Hydraulic and Electric Lifts/Elevators

G.

The Contractor shall allow for the provision of shaft lighting and switches in accordance with BS 5655. The shaft lighting fittings shall be of the fluorescent type OB 3008 manufactured by Thorn or equal and approved. The Contractor shall allow for the provision of electric heating as shown on the mechanical and electrical Tender drawings. The Contractor shall allow for the provision of electrical supplies for the fan coil cooling units located in machine rooms, as shown on the mechanical and electrical Tender drawings.

H. J.

2.07 CONDUIT, TRUNKING AND CABLES A. B. C. D. E. F. C. All cables shall be enclosed in conduit or trunking of approved manufacture. All PVC cables shall be rated at 450/750 volts and shall be in accordance with 85 6231. Inspection elbows and tees shall not be used. All metalwork shall be effectively bonded and earthed. All conduit connections to motors or other such items of removable equipment shall be made with PVC sheathed metallic flexible conduit BS 731 (Kopex). Flexible conduits shall not be more than 1.0mm in length unless the Contractor obtains the written permission of the Architect/Engineer to exceed these limits. The Contractor shall include in his tender for all necessary wiring and enclosures from the main switches to the panels and from the panels to the items of control equipment. All cables, trunking, conduits and fittings shall be installed in accordance with the current I.E.E. Regulations for the Electrical Equipment of Buildings. The Contractor shall allow for trailing cables between the lift car and halfway box. Lighting control alarm and telephone circuits shall be separated. The cables shall be constructed in accordance with BS 6977.

H. J.

2.08 NOTICES, NAMEPLATES AND TOOLS A. The Contractor shall supply and fix the following: 1. A notice on the outside of the lift motor door worded as follows, with characters not less than 13mm high DANCER LIFT MACHINERY. UNAUTHORISED ACCESS PROHIBITED. DOOR TO BE KEPT LOCKED. A framed and glass covered wiring diagram or encapsulated wiring diagrams of at least A3 size with case suitably fixed to the wall. Emergency and operating instructions fixed adjacent to each lifting motor, brake or pump unit. The instructions shall directly relate to the type of gear, pump, etc. Electric shock treatment notice fixed in the motor room.

2. 3.

4.

Al Qassim University

14400 - 7

Hydraulic and Electric Lifts/Elevators

B.

The Contractor shall supply and fix on a wall in the motor room a purpose designed board to which shall be fixed the door release key. Any other tools necessary for emergency use of the lift shall also be fixed to the board. Each individual item shall be suitably labelled on the Tool Board for ease of identification. The labels shall be of Traffolyte material and they shall be pinned or screwed to the board.

C.

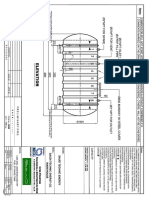

2.09 PUMP UNIT, RAM AND CYLINDER A. B. C. D. The hydraulic pump unit shall be of the immersed type and shall be manufactured by an approved manufacturer. The Contractor shall state the manufacturer and type reference on the Schedule of Materials included. The noise emanating from the pump unit, measured on the A scale at a distance of 1 m from the unit, shall be stated on the Schedule. The Contractor shall include for all hydraulic piping and fixings from the pump room to the lift well, and the system shall incorporate a sound attenuator device (muffler). The Contractor shall provide isolation pads or mountings for the pump unit to minimize the transmission of vibration to the structure.

E.

2.10 SUSPENSION ROPES A. The suspension ropes shall be of traction steel, of best quality manufacture and must comply with BS 329; sizes and number of ropes for car/counterweight and governor as per approved shop drawings. Chain suspension will not be permitted. The ropes shall have a factor of safety of not less than 10 achieved with appropriate combinations of pulley, sheave and drum diameters. The factor of safety shall be based on the ratio of the combined breaking load of the ropes to the static load. Not less than four ropes shall be used for suspending any one lift and they must be of sufficient size that any one rope will carry the total suspended load of the lift. The Contractor shall supply to the Architect/Engineer test certificates for each rope in accordance with BS 329. The Contractor shall include for any necessary rope equalizing gear for the lift.

B. C. D.

E.

2.11 CAR SLING A. The car enclosure shall be carried in a steel frame of robust construction to take the shock of the operation of the safety gear without any permanent deflection of the car frame. The car frame shall be of bolted construction. Each car frame shall be provided with not less than four guide shoes which shall either be phosphor-bronze or cast iron, fitted with renewable self-lubricating liners or rubber or synthetic tyred rollers.

B.

Al Qassim University

14400 - 8

Hydraulic and Electric Lifts/Elevators

2.12 SAFETY GEAR DEVICES A. B. C. The lift car shall be fitted with a safety gear which may be of the instantaneous type for lifts having a speed not exceeding 0.63 m/s. For lifts having a speed of 0.63 - 1.0m/s the safety gear shall be of the instantaneous type with buffered effect. The safety gear shall be fixed to the underside of the lift car frame and be operated by means of a wire rope from the governor located at the top of the hoistway. The safety gear shall be so designed that it will stop and hold the lift with full load in the event of the lift exceeding 115% of the speed in the downward direction. When the safety gear is applied, it shall not cause the car platform to slope more than 1 in 25 to the horizontal and it shall be so arranged that the lift motor control and brake control circuits open immediately. The safety gears, safety ropes, together with the associated stopping distances, shall be in accordance with BS 5655.

D. E.

F.

2.13 GOVERNOR A. B. The lift shall be fitted with a governor to operate the safety gear in the event of overspeed of the lift. The governor shall be located at the top of the hoistway and shall be automatically reset when the car is moved in an upward direction.

2.14 CAR ENCLOSURE AND FINISHES A. The car platform shall be complete with an aluminum sill and shall be mounted on rubber pads forming an isolating cushion between the enclosure and the steel frame to ensure quiet running with minimum vibration to the satisfaction of the Architect/Engineer. The car enclosure shall be of steel construction and shall be totally isolated from the sling. On top of each car a standard 13 amp switched socket outlet shall be fitted complete with plug and 5 amp fuse. The socket outlet shall be wired in 1.0mm PVC insulated cable and then enclosed in trunking and conduit to the distribution board and positioned in the respective lift motor room. An apron shall be provided on the lift car to ensure that nothing can become trapped between the lift car platform and landing while the car is within the landing zone. In addition to fluorescent lighting, a low voltage self- contained emergency light unit shall be supplied and fitted to the car. The emergency light shall be automatically brought into operation on failure of the mains supply and shall operate for a minimum of three hours. The car enclosure finishes shall be generally as follows:

14400 - 9 Hydraulic and Electric Lifts/Elevators

B. C.

D.

E.

F.

Al Qassim University

1.

Dean lift elevators: a. b. Car Panels: Car Door Of steel sheet lined with veneer wood ( teak, maple, cherry ). Of steel sheet, automatic sliding door, telescopic opening, lined with stainless steel (8KT-5 ) Recess for marble 23mm,( Marble by main contractor ). Wood with fluorescent light/spot light. Granite. Panels: stainless steel gold (BKT-5 ) Frame: stainless steel gold (BKT) With card access reader

c. 4. d. e. f. 2.

Floor: Ceiling: Kick plate: Landing Door: Work of lift

Panoramic & lift elevators: a. b. Car Panels: Car Door Laminate glass + stainless steel mirror finish. Of steel sheet, automatic sliding door, telescopic opening, lined with stainless steel (8KT-5 ) Recess for marble 23mm,( Marble by main contractor ). Stainless steel with fluorescent light/ spot light. Granite. Panels: stainless steel gold (BKT-5 ) Frame: stainless steel gold (BKT) access to tubes. Minimum 4 no. tubes and emergency lighting.

c. d. e. f.

Floor: Ceiling: Kick plate: Landing Door:

3.

Passenger lift elevators: a. b. Car Panels: Car Door Of steel sheet lined with stainless steel J5, hairline finish and granite Of steel sheet, automatic sliding door, telescopic opening, lined with stainless steel (J5 ) 7car front wall stainless steel mirror finish. Recess for marble 23mm,( Marble by main contractor ). Stainless steel hairline finish with spot light.

c. d.

Floor: Ceiling:

Al Qassim University

14400 - 10

Hydraulic and Electric Lifts/Elevators

e. f. g. 4.

Handrail Kick plate: Landing Door:

Stainless steel mirror finish. Granite. Panels: stainless steel J5 Frame: stainless steel mirror finish..

Service lift elevators: a. b. Car Panels: Car Door Of steel sheet lined with stainless steel grain cuir( leather finish) Of steel sheet, automatic sliding door, telescopic opening, lined with stainless steel grain cuir( leather finish) &car front wall stainless steel grain cyir ( leather finish). Studded rubber ( Black) Stainless steel hairline finish with spot light & fluorescent light. Stainless steel hair line finish . Stainless steel hair line finish Panels: stainless steel grain cuir( leather finish) Frame: stainless steel mirror finish..

c. d. e. f. g. G.

Floor: Ceiling: BUMPERRAIL Kick plate: Landing Door:

The Contractor shall include in his Tender for the provision of isometric drawings of not less than A2 size of the car enclosure. The drawing shall also show details of skirting, ventilation, frieze, handrail, lighting, etc.

2.15 CAR CONTROL STATION A. Inside the lift car a flush mounted control station shall be fitted, incorporating the following: 1. 2. 3. 4. 5. 6. 7. 8. 9. A bank of push buttons to correspond to the various landing levels served. Alarm push button. Door open push button. A key operated car preference switch arranged so that the lift can be operated by its own car push buttons only, independent of any landing calls. A key operated light switch. A key operated door hold switch. A key switch for the car fan. A car direction indicator. An overload display.

Al Qassim University

14400 - 11

Hydraulic and Electric Lifts/Elevators

10. B.

An intercom unit (car to main lobby).

Car control stations shall be of the same type and finish as any attendant control station, landing call stations or car position indicators - satin stainless steel.

2.16 TELEPHONE STATION A. B. C. A flush mounted telephone cabinet shall be provided in all passenger and goods/passenger/disabled persons lift cars for housing telephone equipment. The travelling cable to carry the telephone circuit shall be provided and installed by the Contractor and shall be an exclusive 4-core flexible cable. The travelling cable associated with the telephone circuit shall be terminated in a separate terminal block from those used for other travelling cables. An adequate separation of the circuits must be maintained at the termination. The Contractor shall also provide wiring between the telephone terminal block and the lift car end of the travelling cable. The telephone wiring (4 conductors) between the lift shaft end of the travelling cable and the telephone terminal block which gives access to the telephone network shall be provided by the Contractor. The terminal block shall be positioned in the pump room. The cable used for connection between the end of the travelling cable and the telephone connection points within the adaptable boxes shall be approved type telephone cable having PVC insulation and sheath and shall be enclosed in steel conduit connected directly to the telephone adaptable box.

D. E.

F.

2.17 CAR POSITION INDICATOR A. Inside the lift car and above the ground floor entrance, the Contractor shall provide a flush mounted digital type car position indicator to indicate the position of the lift car. The indicators shall be finished in satin stainless steel as the car control and landing call stations.

B.

2.18 MAINTENANCE CONTROL A. A maintenance control shall be provided on the top of the car enclosure to operate in the following manner: 1. 2. The lift shall be taken out of automatic control by actuation of an inspection/normal service switch located on the top of car. Operation of UP, DOWN and AUXILIARY control pushes located on the roof of the lift car and arranged such that the lift car will only move when the push is subject to continuous pressure. An emergency Stop/Run switch shall also be provided on the roof of the lift car. A terminal stop switch shall be incorporated in the control to stop the car, when moving in an upward direction , with its roof not less than 1.80m from the top of the well.

14400 - 12 Hydraulic and Electric Lifts/Elevators

3. 4.

Al Qassim University

2.19 CAR AND LANDING DOORS A. B. The car and landing doors shall be automatically power operated and be of the size and type as detailed on the Schedules. The door sills shall be integral with the bottom track and be manufactured from aluminum with non-slip inserts. The bottom tracks of the doors shall be of the self- cleaning type with open ends. All car and landing door tracks, hangers, locks, etc., shall be of approved manufactured. The car and landing doors shall be operated quietly and smoothly by a high performance direct current electric operator unit. During the course of opening and closing, the car and landing doors shall be solidly locked together to ensure simultaneous movement and that they will be smoothly cushioned at both limits of travel. The door operator shall be of approved manufacture and the manufacturer shall be stated on the Schedule. The landing doors shall be constructed of sheet metal panels, and the whole entrance shall be designed to have a certified fire rating of two hours. On the Schedule of Alternatives, the Contractor shall state the reduction in cost for doors having a certified fire rating of one hour. The car doors shall be fitted with an electronic detector device, Should this device touch a person or object while the car door is closing, the device shall cause the car and landing doors to return to the open position. The doors shall remain open until the end of a preset but adjustable time interval and then close automatically. Provision shall be made for the opening of all landing doors by means of an emergency key, which shall be of the triangular type as detailed in BS 5655. All landing doors shall have a satin stainless steel finish.

C. D.

E.

F.

G. H.

2.20 LANDING DOOR LOCKS A. Each set of landing doors shall be fitted with electromechanical locks to ensure that it is impossible to open the landing doors unless the lift is stationary at the particular landing and that the lift cannot move or be kept in motion unless all the landing doors are properly locked, except when the car is levelling on slow speed from a position 250mm above or below landing level. The locks shall be provided with release mechanisms so that the doors can be opened by an authorised person in an emergency. The locks shall be of approved manufacture.

B. C.

2.21 ARCHITRAVES A. The Lift Contractor shall include for supplying and fitting landing door entrance trims as necessary to maintain the fire integrity of the landing doors. These shall have a satin stainless steel finish.

Al Qassim University

14400 - 13

Hydraulic and Electric Lifts/Elevators

2.22 LANDING CALL STATIONS A. B. C. Each call push unit shall consist of a double button unit at intermediate floors with a single button unit at terminal floors. The call station shall be arranged for flush mounting within the front hoistway wall and shall have an overlapping satin stainless steel face plate. The call stations shall incorporate an illuminating feature to indicate that a call has been registered. Illumination incorporating tungsten lamps will not be acceptable.

2.23 HALL LANTERNS A. B. C. D. Illuminating hall direction arrows (lanterns) shall be supplied and fitted above each landing entrance. These shall not incorporate tungsten lamps. At the ground floor main lobby, they shall be incorporated with the car position indicator unit. The unit shall incorporate an audible signal to announce the arrival of the lift. The finish of the units shall be satin stainless steel.

2.24 CONTROLLER A. B. C. D. E. F. G. The controller shall incorporate electro-mechanical components and all safety circuits shall be failsafe in the event of a failure in the micro-processor circuitry. Overloads shall be provided which will cut off the control supply and motor if the car is overloaded for a predetermined time or if single phasing occurs. The control panel shall incorporate on site diagnostic facilities without the aid of any special tools or devices. A reverse phase device shall be included. The controller shall be enclosed in a sheet steel cubicle finished cellulose to an approved Color. All terminals, contactors, etc., shall be labelled or numbered in an obvious and permanent manner to aid identification. Hinged doors shall be fitted at the front of the cubicle, which shall also be complete with additional access panels and louvred vents as required. Lift of f panels shall not be acceptable. The functions of all components in the control panel shall be clearly indicated on a diagram, together with a key to abbreviations or symbols used, which shall be attached to the inside of the control cubicle door.

H.

2.25 CONTROL SYSTEM A. The control system shall be as stated on the Tender Drawings but it must also comply with the following clause.

Al Qassim University

14400 - 14

Hydraulic and Electric Lifts/Elevators

1. The cars shall park with doors closed with one lift at the ground floor and the other at its last stop. 2.26 FLOOR SELECTORS A. The lift shall be fitted with automatic floor selection equipment operated by inductor switches on the cars, so arranged and designed to ensure that the specified levelling accuracy is maintained. The selection equipment shall be incorporated within the controller and be electrically operated by means of impulses from the car inductor switches. The relays, inductor and rotary switches of the selector shall be fitted with silver to silver contacts. The conductor switches shall be enclosed in dust-tight metal cases. The inductor switches shall be fixed to the top of the car in accessible positions and the operating steel vanes fixed to the guides. All steel vanes shall be painted bright yellow. If it is the Contractors standard practice to use other methods of floor selection than that described below, for example: 1. 2. A tape head device. Selector in the motor room operated by a steel tape attached to the car. then full details and a description of the method included in the tender shall be submitted to the Architect/Engineer.

B. C.

D. E. F.

2.27 AUTOMATIC CAR LEVELLING A. The lift car shall be provided with a levelling device that will automatically bring the lift car to the landings within a tolerance specified below, according to the type of machine. The levelling device shall, within its zone, be entirely automatic and independent of the operating panel. The device shall compensate for any over-travel, undertravel, or rope stretch. For hydraulic lifts, the tolerance shall be 6mm under conditions of full contract load through to empty car. The tolerances shall not be exceeded for any landing in either direction of travel.

B.

C. D.

2.28 EMERGENCY ALARM CONTROLS A. B. The lift car shall be fitted with an alarm push incorporated in the car control station. The supply for the emergency alarm system shall be obtained from a 12 volt trickle charged battery, located in the machine room, incorporating automatic voltage regulation.

Al Qassim University

14400 - 15

Hydraulic and Electric Lifts/Elevators

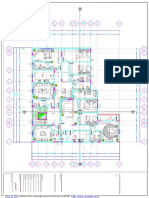

2.29 PANORAMIC ELEVATOR A. 1. MAIN BUILDING B1 Elevator Type P1-P2-P3-P4 - Nos. of Elevator: - Type of Elevators: - Load/Capacity: - No. of Persons: - Drive: - Control System: - Speed: - Number of Stops: - Door Arrangement: - Floor Designation: - Travel Distance: - Electrical Power Supply: - Machine Room Location: 4, Passengers Elevator 800 kg 10 Geared traction, with variable voltage variable frequency motor (VVVF), solid-state power converters Simplex Collective Selective 1.0 mps 2 In Line at Ground Floor, First Floor and Second Floor. Ground Floor, First Floor and Second Floor. 4.80 m 220/127V, 60 Hz, 3 Phases Roof.

- Hoistway (Shaft) Dimension: As indicated on Drawings - Pit Depth: - Overhead: - Elevator Car Type: - Car Dimensions: - Car Wall: cherry). - Car Ceiling: - Car Floor: - Car Enclosures: As indicated on Drawings As indicated on Drawings Steel and Glass As indicated on Drawings steel sheet lined with veneer wood (teak, maple, Wood with fluorescent light. Recess for marble 23mm (Marble by main contractor) Electric Fan Handrails in two sides Granite Kick plate Emergency Exit (Top of Car)

14400 - 16 Hydraulic and Electric Lifts/Elevators

Al Qassim University

- Car Door Type:

Steel sheet, automatic sliding door, telescopic opening, lined with stainless steel (8KT-5 ) Provided with Proximity Card Reader System As indicated on Drawings Infrared Door Detector Closing Force Limiter Steel plates Type IL (LED)

- Door Dimensions: - Door Safety Device: - Sill:

- Indicators and Direction Arrows:

- Landing Indicator Finishing: Steel plates - Main Floor: - Remaining Floors: - Landing Doors: Position Indicator - Arrows + Gong Direction Arrows & Gong Panels: stainless steel gold (BKT-5 ) Frame: stainless steel gold (BKT) access to tubes. Minimum 4 no. tubes and emergency lighting. As indicated on Drawings Emergency Unlocking by Key Phase Protection Device Automatic Return at Main Floor Intercom 3 Stations. Micropush Satin finish stainless steel Position Indicator (LED) Direction Arrows (LED) Alarm Button Emergency Car Light Door Open and Close Buttons Telephone Compartment Reservation Key switch Lamp and Buzzer for Overload Proximity Card Reader access control System Micropush Satin finish stainless steel On/Off Key switch.

- Clear Opening: - Safety Features: - Additional Features:

- Car Board: - Car Board Finish: - Car Board Equipment:

- Landing Board: - Landing Board Finishing: - Main Floor:

Al Qassim University

14400 - 17

Hydraulic and Electric Lifts/Elevators

2.30 2.

DEAN ELEVATOR SPECIFICATIONS Elevator Type ET : TYPE PS (TYPICAL SERVICE ELEVATORS) - Nos. of Elevator: 2 - Type of Elevators: - Load/Capacity: - No. of Persons: - Drive: - Control System: - Speed: - Number of Stops: - Door Arrangement: - Floor Designation: - Travel Distance: - Electrical Power Supply: - Machine Room Location: Service /Passengers Elevator 1600 kg 21 Geared traction, with variable voltage variable frequency motor (VVVF), solid-state power converters Simplex Collective Selective 1.0 mps. 2 In Line at Ground Floor, First Floor, Second and Floor Third Floor. Ground Floor, First Floor, Second Floor and Third Floor. 4.80 m 220/127V, 60 Hz, 3 Phase Roof.

- Hoistway (Shaft) Dimension: As indicated on Drawings - Pit Depth: - Overhead: - Elevator Car Type: - Car Dimensions: - Car Wall: - Car Ceiling: - Car Floor: - Car Enclosures: As indicated on Drawings None Steel As indicated on Drawings Steel sheet lined with stainless steel grain cuir( leather finish) Stainless steel hairline finish with spot light & fluorescent light. Studded rubber ( Black) Electric Fan Bumper rail Stainless steel hair line finish Kick plate Stainless steel hair line finish

14400 - 18 Hydraulic and Electric Lifts/Elevators

Al Qassim University

Emergency Exit (Top of Car) - Car Door Type: Steel sheet, automatic sliding door, telescopic opening, lined with stainless steel grain cuir( leather finish) &car front wall stainless steel grain cyir ( leather finish As indicated on Drawings Infrared Door Detector Closing Force Limiter Steel plates Type IL (LED)

- Door Dimensions: - Door Safety Device: - Sill:

- Indicators and Direction Arrows:

- Landing Indicator Finishing: Steel plates - Main Floor: - Remaining Floors: - Landing Doors: - Clear Opening: - Safety Features: - Additional Features: Position Indicator - Arrows + Gong Direction Arrows & Gong Panels: stainless steel grain cuir( leather finish) Frame: stainless steel mirror finish... As indicated on Drawings Emergency Unlocking by Key Phase Protection Device Automatic Return at Main Floor Intercom 3 Stations. Micropush Satin finish stainless steel Position Indicator (LED) Direction Arrows (LED) Alarm Button Emergency Car Light Door Open and Close Buttons Telephone Compartment Reservation Key switch Lamp and Buzzer for Overload Proximity Card Reader access control System Micropush Satin finish stainless steel On/Off Key switch.

- Car Board: - Car Board Finish: - Car Board Equipment:

- Landing Board: - Landing Board Finishing: - Main Floor:

Al Qassim University

14400 - 19

Hydraulic and Electric Lifts/Elevators

PART 3 - EXECUTION 3.01 All work shall be done strictly in accordance with manufacturers instructions and to approved shop drawings. PART 4 - MEASUREMENT 4.01 LIFTS A. B. Lifts shall be enumerated. Doors, and door surrounds, shall be described with the item of lifts.

4.02 SUNDRIES A. Sundries shall be included with the lift item, including: 1. 2. 3. 4. 5. Supports, which shall include fixings, anchors, insulating blocks and antivibration devices. Identification, which shall include plates, discs, labels, charts and color coding. Testing and commissioning which shall include operating completed installations and providing fuel and power. Tools and spares, which shall include loose keys, and consumable stores. Documents, which shall include drawings, operating instructions and maintenance manuals.

4.03 INCIDENTAL WORK A. Work incidental to lift installations shall be described with the item of lifts, including the following: 1. 2. 3. 4. 5. Co-ordination with other engineering installations. Cutting and forming holes, mortices, chases or the like, and making good finishes. Building in or cutting and pinning brackets or the like, and making good finishes. Removing protective coating and wrapping. Cleaning and polishing exposed surfaces.

PART 5 - PAYMENT 5.01 PAYMENT A. The work shall be measured and payment shall be made in accordance with the requirements stated in Bill No. 1 Preliminaries and General Requirements. END OF SECTION

14400 - 20 Hydraulic and Electric Lifts/Elevators

Al Qassim University

Вам также может понравиться

- 1706 - BF HOTEL - Specs - Architectural - Part 1Документ236 страниц1706 - BF HOTEL - Specs - Architectural - Part 1AhmedMahmoudОценок пока нет

- Brochure TanksДокумент2 страницыBrochure TanksAhmedMahmoudОценок пока нет

- 1706 - BF HOTEL - Specs - StructuralДокумент152 страницы1706 - BF HOTEL - Specs - StructuralAhmedMahmoudОценок пока нет

- 1706 - BF HOTEL - Specs - Contract DocumentsДокумент85 страниц1706 - BF HOTEL - Specs - Contract DocumentsAhmedMahmoudОценок пока нет

- SECTION 01040 Coordination: Coordination 01040 - 1 Al Qassim UniversityДокумент2 страницыSECTION 01040 Coordination: Coordination 01040 - 1 Al Qassim UniversityAhmedMahmoudОценок пока нет

- Precast Concrete Frames GuideДокумент58 страницPrecast Concrete Frames GuideHari Amudhan Ilanchezhian100% (9)

- Construction of Large Transfer Plates in Hong Kong High-Rise BuildingsДокумент56 страницConstruction of Large Transfer Plates in Hong Kong High-Rise BuildingsAhmed NabilОценок пока нет

- Fuel TankДокумент2 страницыFuel TankAhmedMahmoudОценок пока нет

- Project documentation with revisions and design detailsДокумент1 страницаProject documentation with revisions and design detailsAhmedMahmoudОценок пока нет

- 26Документ4 страницы26AhmedMahmoudОценок пока нет

- 3 KSN AnchorsДокумент24 страницы3 KSN AnchorsAhmedMahmoudОценок пока нет

- 01005Документ6 страниц01005AhmedMahmoudОценок пока нет

- Ancon CXL Coupler Brochure International Version 2015Документ10 страницAncon CXL Coupler Brochure International Version 2015AhmedMahmoudОценок пока нет

- Allpile Manual PDFДокумент102 страницыAllpile Manual PDFAhmedMahmoudОценок пока нет

- HRC500INFOДокумент2 страницыHRC500INFOAhmedMahmoudОценок пока нет

- Chapter 5 WallsДокумент19 страницChapter 5 Wallsdashne134Оценок пока нет

- Solid SlabsДокумент3 страницыSolid SlabsAhmedMahmoudОценок пока нет

- Index Volume 1ggДокумент3 страницыIndex Volume 1ggAhmedMahmoudОценок пока нет

- Check Punching Of Raft Foundation For Column LoadsДокумент2 страницыCheck Punching Of Raft Foundation For Column LoadsAhmedMahmoudОценок пока нет

- Qa ConsultingjkljДокумент8 страницQa ConsultingjkljAhmedMahmoud100% (1)

- 00001Документ12 страниц00001AhmedMahmoudОценок пока нет

- Check Punching Of Raft Foundation For Column LoadsДокумент2 страницыCheck Punching Of Raft Foundation For Column LoadsAhmedMahmoudОценок пока нет

- Raft & Footings Columns & Walls Neck: Footing F3Документ1 страницаRaft & Footings Columns & Walls Neck: Footing F3AhmedMahmoudОценок пока нет

- Interior Column According To Aci 318-02 (Nonprestressed Slabs) c81Документ2 страницыInterior Column According To Aci 318-02 (Nonprestressed Slabs) c81Love SemsemОценок пока нет

- Qa ConsultingjkljДокумент8 страницQa ConsultingjkljAhmedMahmoud100% (1)

- RCCen55 Axial Column ShorteningwwrДокумент78 страницRCCen55 Axial Column ShorteningwwrAhmedMahmoudОценок пока нет

- User GuidДокумент82 страницыUser GuidVirendra Kumar PareekОценок пока нет

- Printreg v1-1grДокумент1 страницаPrintreg v1-1grAhmedMahmoudОценок пока нет

- User Guid Supp LV 2 Very PreliminaryДокумент21 страницаUser Guid Supp LV 2 Very PreliminaryAhmedMahmoudОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Updated SP-511Документ7 страницUpdated SP-511Feroz GullОценок пока нет

- Sport Aviation Abr-1975Документ92 страницыSport Aviation Abr-1975laerciofilho100% (1)

- STEEL FRAMING SYSTEMSДокумент28 страницSTEEL FRAMING SYSTEMSSeason Ch'ngОценок пока нет

- Cold Rolling Mill For Aluminium Sheet: Dr. P. Mallesham, V.V. Ram BabuДокумент5 страницCold Rolling Mill For Aluminium Sheet: Dr. P. Mallesham, V.V. Ram BabuerpublicationОценок пока нет

- Recurrent Training & Checking CourseДокумент3 страницыRecurrent Training & Checking Coursepedati100% (1)

- 1.1 Pavement Applications - Highway Classification Systems (Philippines)Документ24 страницы1.1 Pavement Applications - Highway Classification Systems (Philippines)Jeffjr VallenteОценок пока нет

- Capacity Estimation Procedure For Two-Lane Roads Under Mixed Traffic ConditionsДокумент32 страницыCapacity Estimation Procedure For Two-Lane Roads Under Mixed Traffic ConditionsDinesh PoudelОценок пока нет

- FOB & CIF BasisДокумент4 страницыFOB & CIF BasisSrikrishna DharОценок пока нет

- BS2L99 Alloy DetailДокумент2 страницыBS2L99 Alloy Detailcharles_boyle_3Оценок пока нет

- Addendum-1 To DFPDS-2015 PDFДокумент29 страницAddendum-1 To DFPDS-2015 PDFPrakash RautОценок пока нет

- Replacement of Baay Bridge along Abra-Cervantes RoadДокумент10 страницReplacement of Baay Bridge along Abra-Cervantes RoadRobin DizonОценок пока нет

- Almaco's GM500A Press Release For Semi Submersible From QIdong, ChinaДокумент1 страницаAlmaco's GM500A Press Release For Semi Submersible From QIdong, ChinanskumarmОценок пока нет

- AI-Official Name, Headquarters & OwnersДокумент3 страницыAI-Official Name, Headquarters & OwnersZamora Enguerra EmmalyneОценок пока нет

- Indian Airline Industry AnalysisДокумент15 страницIndian Airline Industry Analysisekta_1011Оценок пока нет

- SCM ApoДокумент10 страницSCM ApopravanthbabuОценок пока нет

- OcalДокумент38 страницOcalSergio Daniel FernandezОценок пока нет

- 5083 Aluminum Plate SuppliersДокумент9 страниц5083 Aluminum Plate Supplierssanghvi overseas incОценок пока нет

- Railroad Drainage RehabДокумент23 страницыRailroad Drainage RehabUiОценок пока нет

- Logistics 2021 - BrochureДокумент2 страницыLogistics 2021 - BrochurekavenindiaОценок пока нет

- Managing Retailing, Wholesaling and LogisticsДокумент27 страницManaging Retailing, Wholesaling and LogisticsMary Rose Virtucio100% (1)

- Manufacturing Process of StaplerДокумент9 страницManufacturing Process of StaplerThoriq AliОценок пока нет

- Top 10 Logistics Companies in IndiaДокумент2 страницыTop 10 Logistics Companies in Indiaamit1002001Оценок пока нет

- Aircraft Structures Repair IДокумент17 страницAircraft Structures Repair IMohd Hanis100% (3)

- Vehicle Hoist Safe Work ProcedureДокумент2 страницыVehicle Hoist Safe Work ProcedureWiwinIndahSariEffendiОценок пока нет

- Final ZipcarДокумент12 страницFinal ZipcarOnkar SawantОценок пока нет

- Cold Chain Management in India: International PracticesДокумент30 страницCold Chain Management in India: International PracticesAkbar AliОценок пока нет

- GBT 1591-2008 - High Strength Low Alloy Structural SteelДокумент16 страницGBT 1591-2008 - High Strength Low Alloy Structural SteelDarren ThoonОценок пока нет

- Aci 117 R90Документ11 страницAci 117 R90Rafael Elgueta Aravena100% (1)

- TRU OrganicДокумент2 страницыTRU OrganicWarrenОценок пока нет

- Highways July 2015Документ60 страницHighways July 2015spc268Оценок пока нет