Академический Документы

Профессиональный Документы

Культура Документы

Turning N Milling Formula

Загружено:

Haris Setiawan0 оценок0% нашли этот документ полезным (0 голосов)

124 просмотров2 страницыThe document provides terminology and formulas related to turning and milling technical data. Key terms defined include cutting speed, spindle speed, feed rate, chip thickness, material removal rate, and cutting power. Formulas are given for calculating cutting speed, spindle speed, material removal rate, cutting power requirements, and machining time for turning and milling operations based on machine parameters such as workpiece diameter, depth of cut, and feed rate. Period of engagement and spiral cutting length formulas are also included for turning operations.

Исходное описание:

Оригинальное название

Turning n Milling Formula

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe document provides terminology and formulas related to turning and milling technical data. Key terms defined include cutting speed, spindle speed, feed rate, chip thickness, material removal rate, and cutting power. Formulas are given for calculating cutting speed, spindle speed, material removal rate, cutting power requirements, and machining time for turning and milling operations based on machine parameters such as workpiece diameter, depth of cut, and feed rate. Period of engagement and spiral cutting length formulas are also included for turning operations.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

124 просмотров2 страницыTurning N Milling Formula

Загружено:

Haris SetiawanThe document provides terminology and formulas related to turning and milling technical data. Key terms defined include cutting speed, spindle speed, feed rate, chip thickness, material removal rate, and cutting power. Formulas are given for calculating cutting speed, spindle speed, material removal rate, cutting power requirements, and machining time for turning and milling operations based on machine parameters such as workpiece diameter, depth of cut, and feed rate. Period of engagement and spiral cutting length formulas are also included for turning operations.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

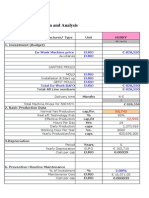

Technical data Turning

Terminology and units

Dm = Machined diameter vc n Tc Q lm Pc = Cutting speed = Spindle speed = Period of engagement = Metal removal rate = Machined length = Cutting power net mm m/min r/min min cm3/min mm kW N/mm2 fn r r ap = Feed per revolution = Entering angle = Insert nose radius = Cutting depth mm/r degree m mm mm mm m

Rmax = Profile depth

hex = Max chip thickness SCL = spiral cutting length

k c 0,4 = Specific cutting force for chip thickness 0,4 mm

Formulas

Cutting speed (m/min)

vc = D m n 10 3

3 n = vc 10 Dm

Spindle speed (r/min) Metal removal rate (cm 3/min)

Q = vc ap fn vc ap f n k c 0,4 60 103

Power requirement (kW)

Pc

0,29 0,4 f n sin r

Facing and taper cuts at constant vc

Period of engagement (min)

Constant n

Tc =

lm fn n = f n 2 125 r

Tc =

lm

fn n

Profile depth (m)

max

Max chip thickness

Insert shapes: C, D, S, T, V, W

Round inserts

hex = f n sin r

hex = f n

4ap

iC

( 2a )

p iC

SCL (Spiral Cutting Length) input info in mm result in m

External or internal turning Facing Taper cutting

SCL = Dm1 x x 1000

lm fn

SCL = Dm1+Dm2 x x lm1 2 1000 fn

SCL = Dm1+Dm2 x x lm2 2 1000 fn

Period of engagement (min)

SCL Tc = vc

How to calculate: lm2

lm2 = (lm1)2 +

Dm1 - Dm2 2 2

124

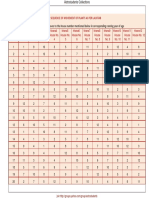

Technical data Milling

Terminology and units

Dc = lm = Dap = ap = ae vc Q Tc zn fz fn vf hex hm zc = = = = = = = = = = Cutting diameter Machined length Max cutting diameter at a specific depth Cutting depth Working engagement Cutting speed Metal removal rate Period of engagement Total number of edges in the tool Feed per tooth Feed per revolution Table feed (feed speed) Max chip thickness Average chip thickness mm mm mm mm mm m/min cm3/min min piece mm mm mm/min mm mm piece kc1 = Specific cutting force (for hex =1 mm) n = Spindle speed Pc = Cutting power net mt = Efficiency N/mm2 rev/min kW degrees

r = Major cutting edge angle

vc0 = Constant for cutting speed cvc = Correction factor for cutting speed mc = Rise in specific cutting force (kc) as a function of chip thickness iC = inscribed circle

= Effective nubmer of teeth

Formulas

Cutting speed (m/min) Spindle speed (rev/min) Table feed (feed speed) (mm/min) Feed per tooth (mm) Feed per revolution (mm/rev) Removal rate (cm 3 ) Specific cutting force (N/mm 2) Average chip thickness (mm) (Side and facemilling) when ae/Dc 0,1 vc = Dc n 1000 n = vc 1000 Dc vf = fz n zn fz = vf n zn

fn = vf n ap ae vf 1000 kc = kc1 hm-mc a D

Q=

hm fz

e c

Average chip thickness (mm) when ae/Dc 0,1

hm =

sin r 180 ae f z Dc arcsin ae Dc lm vf

( )

Machining time (min) Net power (kW)

Tc =

Pc = ap ae vf kc 60 106

125

Вам также может понравиться

- Example For Milling CalculationДокумент3 страницыExample For Milling CalculationAbd Muhaimin AmmsОценок пока нет

- Calculation Manufacturing ProcessДокумент18 страницCalculation Manufacturing ProcessEncik MaaОценок пока нет

- Chanfer ToolsДокумент4 страницыChanfer ToolscljserviceОценок пока нет

- Process of Press Tool Design and Its Manufacturing For Blanking OperationДокумент8 страницProcess of Press Tool Design and Its Manufacturing For Blanking OperationamdevaОценок пока нет

- Digital Die Design SystemДокумент17 страницDigital Die Design Systemjagas123455123Оценок пока нет

- KORLOY Product Catalog - English: Aerospace Industry Automotive Industry Railway Industry Medical IndustryДокумент1 333 страницыKORLOY Product Catalog - English: Aerospace Industry Automotive Industry Railway Industry Medical IndustryD3nnSGTAVОценок пока нет

- 5 TurningДокумент26 страниц5 Turningprakashp111100% (1)

- Cutting Force of End Cutting Tool Milling MachiningДокумент24 страницыCutting Force of End Cutting Tool Milling MachiningGabryel BogdanОценок пока нет

- End Mill Training Website PDFДокумент64 страницыEnd Mill Training Website PDFDejan Jovanovic100% (1)

- A Method For Predicting Chatter Stability For Systems SchmitzДокумент8 страницA Method For Predicting Chatter Stability For Systems SchmitzOvidiu RusuОценок пока нет

- Speed and Feed For Lathe MachiningДокумент6 страницSpeed and Feed For Lathe MachiningThinesh ChanderОценок пока нет

- Compression Molding Machine PriceДокумент13 страницCompression Molding Machine PriceSalma FarooqОценок пока нет

- Metal Cutting TrainingДокумент13 страницMetal Cutting Trainingநளின் கான்Оценок пока нет

- Carbide GradesДокумент51 страницаCarbide GradesRicardo BravoОценок пока нет

- Tooln Die Design Part OneДокумент14 страницTooln Die Design Part Oneazizmaarof100% (2)

- Lathe and VMC Cycle Time CalculatorДокумент5 страницLathe and VMC Cycle Time CalculatorDhanus KodiОценок пока нет

- Bending and DrawingДокумент14 страницBending and DrawingStelwin FernandezОценок пока нет

- Sintered Metal BushДокумент5 страницSintered Metal Bush124swadeshiОценок пока нет

- End MillsДокумент140 страницEnd MillsGuru PrasadОценок пока нет

- How To Compute Tonnage RequirementsДокумент5 страницHow To Compute Tonnage RequirementsPrabhat SharmaОценок пока нет

- Turning Formulas Milling Formulas: Feed Rate: Feed RateДокумент1 страницаTurning Formulas Milling Formulas: Feed Rate: Feed RateStaew PrecisionОценок пока нет

- Cutter GuideДокумент1 страницаCutter GuideCarlos RamirezОценок пока нет

- IV ReportДокумент22 страницыIV ReportMuhammad Zulhilmi0% (1)

- Price Breakup Format - ForgingДокумент13 страницPrice Breakup Format - ForgingHarshanand KalgeОценок пока нет

- 1 ShearingДокумент29 страниц1 ShearingSriram MuruganОценок пока нет

- Reaction Injection MoldingДокумент8 страницReaction Injection MoldingAmeer_Takashim_9385Оценок пока нет

- Press Tool Components Die MakingДокумент29 страницPress Tool Components Die Makingmayank123100% (1)

- Prediction of Chatter Vibration in Vertical Milling Center Using FRFДокумент6 страницPrediction of Chatter Vibration in Vertical Milling Center Using FRFInternational Journal of Innovative Science and Research Technology0% (1)

- 2 Tool Wear & Tool Life 2Документ40 страниц2 Tool Wear & Tool Life 2haile mehariОценок пока нет

- Gaging InspectionДокумент22 страницыGaging Inspectiongeav25653855Оценок пока нет

- Calculation of Hourly Rate For Laser Cutting Machine - 500W Input of Data Calculations. Yearly Work Capacity 4800Документ2 страницыCalculation of Hourly Rate For Laser Cutting Machine - 500W Input of Data Calculations. Yearly Work Capacity 4800Susheel ShuklaОценок пока нет

- Machine Tool Vibration and DampersДокумент42 страницыMachine Tool Vibration and DampersLuis NunesОценок пока нет

- Economics of Metal Cutting OperationsДокумент64 страницыEconomics of Metal Cutting OperationsrohanОценок пока нет

- Gears Cutting and GrindingДокумент8 страницGears Cutting and GrindingАлександар ВујаковићОценок пока нет

- Tool Design Calculation: Cutting ForceДокумент4 страницыTool Design Calculation: Cutting ForceRaja SathishОценок пока нет

- Catalogo Holders TungaloyДокумент156 страницCatalogo Holders Tungaloyabsalon_jarvОценок пока нет

- Design and Analysis of Progressive Tool For An Automobile ComponentДокумент9 страницDesign and Analysis of Progressive Tool For An Automobile ComponentAnna100% (1)

- Turning and Lathe - Guia de Estudo - 2016Документ10 страницTurning and Lathe - Guia de Estudo - 2016Anderson R. RojasОценок пока нет

- Blanking Process Cost CalculationДокумент3 страницыBlanking Process Cost CalculationVenkateswaran venkateswaran100% (1)

- NC CNC Machine ToolДокумент50 страницNC CNC Machine ToolShoaib MultaniОценок пока нет

- Final ReportДокумент25 страницFinal ReportAdil SaleemОценок пока нет

- Cutting SpeedДокумент5 страницCutting SpeedsandigricОценок пока нет

- ByStar Fiber Datasheet Eng Original 14278Документ2 страницыByStar Fiber Datasheet Eng Original 14278Trần Ngọc ThànhОценок пока нет

- CH 5 DrillingДокумент39 страницCH 5 DrillingMANJEET KUMARОценок пока нет

- Theory of Metal Cutting, Metal FormingДокумент181 страницаTheory of Metal Cutting, Metal Formingprabhjotbhangal100% (1)

- GPI - Cost Sheet For Cap Prodcution-2Документ54 страницыGPI - Cost Sheet For Cap Prodcution-2Narayana MugalurОценок пока нет

- Tonnage CalculationДокумент3 страницыTonnage CalculationEmba MadrasОценок пока нет

- Tailor Welded BlanksДокумент52 страницыTailor Welded BlanksYuvaraj YuvarajОценок пока нет

- Fundamentals of CuttingДокумент56 страницFundamentals of CuttingTrevor WarnerОценок пока нет

- Metal Cutting Theory and MechanismДокумент75 страницMetal Cutting Theory and Mechanismnishantdubey1183Оценок пока нет

- ECN Balzers 20april10 AC Falen PresterenДокумент76 страницECN Balzers 20april10 AC Falen PresterenMiguelОценок пока нет

- Incremental Forming in Tailor Welded BlanksДокумент24 страницыIncremental Forming in Tailor Welded BlanksSitanshu S0% (1)

- CNC Machining Cycle Time CalculationДокумент4 страницыCNC Machining Cycle Time CalculationRathnakrajaОценок пока нет

- Sheet Metal Forming ProcessesДокумент38 страницSheet Metal Forming ProcessesRavichandran GОценок пока нет

- Milling Machine ToolДокумент42 страницыMilling Machine ToolSai SashankОценок пока нет

- 2013 Theory All Inc Casting PDFДокумент65 страниц2013 Theory All Inc Casting PDFaamir_00Оценок пока нет

- Production of Automotive Components: Jerome GДокумент24 страницыProduction of Automotive Components: Jerome GMr. Jerome Nithin Gladson100% (1)

- Century Star CNC System Programming Guide For Milling Machines PDFДокумент147 страницCentury Star CNC System Programming Guide For Milling Machines PDFDiego Steven Pulido AriasОценок пока нет

- Calculation: Specification of MotorДокумент7 страницCalculation: Specification of MotorMahar Tahir Sattar MtsОценок пока нет

- Orientasi SummeДокумент2 страницыOrientasi SummeHaris SetiawanОценок пока нет

- Overview Summer Program MeДокумент8 страницOverview Summer Program MeHaris SetiawanОценок пока нет

- Machine Setup SheetДокумент6 страницMachine Setup SheetHaris SetiawanОценок пока нет

- Cara Re Store PДокумент1 страницаCara Re Store PHaris SetiawanОценок пока нет

- Machine Setup SheetДокумент6 страницMachine Setup SheetHaris SetiawanОценок пока нет

- Overview Summer Program MeДокумент8 страницOverview Summer Program MeHaris SetiawanОценок пока нет

- Introduction of CNC TurningДокумент18 страницIntroduction of CNC TurningHaris SetiawanОценок пока нет

- Introduction of CNC TurningДокумент18 страницIntroduction of CNC TurningHaris SetiawanОценок пока нет

- 2plasma TA2018-FEA Studies Report 2018-09-18Документ21 страница2plasma TA2018-FEA Studies Report 2018-09-18Haris SetiawanОценок пока нет

- Introduction To Numerical ControlДокумент17 страницIntroduction To Numerical ControlHaris SetiawanОценок пока нет

- Okamoto Ogm IIIДокумент10 страницOkamoto Ogm IIIHaris SetiawanОценок пока нет

- CNC OPERATING SYSTEM v-1Документ23 страницыCNC OPERATING SYSTEM v-1Haris SetiawanОценок пока нет

- Complete 1988 Mazda 323 Workshop ManualДокумент1 129 страницComplete 1988 Mazda 323 Workshop ManualGergely Palcsó90% (21)

- Msga MSGBДокумент12 страницMsga MSGBHaris SetiawanОценок пока нет

- Islam GuideДокумент80 страницIslam Guideaaghamdi100% (17)

- AB-005-2020 Dated 10.09.2020 (SKF-Prestine)Документ3 страницыAB-005-2020 Dated 10.09.2020 (SKF-Prestine)AliasgarОценок пока нет

- ER288 090714 5082 CV OKP (089) Method Statement For Plate Baring TestДокумент3 страницыER288 090714 5082 CV OKP (089) Method Statement For Plate Baring TestWr ArОценок пока нет

- Static Power Conversion I: EEE-463 Lecture NotesДокумент48 страницStatic Power Conversion I: EEE-463 Lecture NotesErgin ÖzdikicioğluОценок пока нет

- Introduction To SCRДокумент19 страницIntroduction To SCRAlbin RobinОценок пока нет

- Pedagogical Leadership. Baird - CoughlinДокумент5 страницPedagogical Leadership. Baird - CoughlinChyta AnindhytaОценок пока нет

- 09-11-2016 University Exam PaperДокумент34 страницы09-11-2016 University Exam PaperSirisha AsadiОценок пока нет

- Gastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterДокумент9 страницGastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterPier Pasquale TrausiОценок пока нет

- Time Table & Instruction For Candidate - Faculty of Sci & TechДокумент3 страницыTime Table & Instruction For Candidate - Faculty of Sci & TechDeepshikha Mehta joshiОценок пока нет

- 8 Lesson 13 Viking FranceДокумент2 страницы8 Lesson 13 Viking Franceapi-332379661Оценок пока нет

- Aerated Concrete Production Using Various Raw MaterialsДокумент5 страницAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- Harmony Guide DatabaseДокумент7 страницHarmony Guide DatabaseAya SakamotoОценок пока нет

- Validación Española ADHD-RSДокумент7 страницValidación Española ADHD-RSCristina Andreu NicuesaОценок пока нет

- INSTRUCTIONAL SUPERVISORY PLAN 1st Quarter of SY 2023 2024 Quezon ISДокумент7 страницINSTRUCTIONAL SUPERVISORY PLAN 1st Quarter of SY 2023 2024 Quezon ISayongaogracelyflorОценок пока нет

- DLL CW 7Документ2 страницыDLL CW 7Bea67% (3)

- BC 672772 RBRS Service TraningДокумент385 страницBC 672772 RBRS Service TraningTeknik Makina100% (2)

- Soil Liquefaction Analysis of Banasree Residential Area, Dhaka Using NovoliqДокумент7 страницSoil Liquefaction Analysis of Banasree Residential Area, Dhaka Using NovoliqPicasso DebnathОценок пока нет

- Activity 2Документ5 страницActivity 2DIOSAY, CHELZEYA A.Оценок пока нет

- Selecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationДокумент35 страницSelecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationJhenn Mhen Yhon100% (1)

- Each Life Raft Must Contain A Few ItemsДокумент2 страницыEach Life Raft Must Contain A Few ItemsMar SundayОценок пока нет

- Creative LibrarianДокумент13 страницCreative LibrarianulorОценок пока нет

- High Performance Vector Control SE2 Series InverterДокумент9 страницHigh Performance Vector Control SE2 Series InverterhanazahrОценок пока нет

- Methods of Estimation For Building WorksДокумент22 страницыMethods of Estimation For Building Worksvara prasadОценок пока нет

- 【SIEMENS】Cios Spin-FlyerДокумент8 страниц【SIEMENS】Cios Spin-FlyerAshleyОценок пока нет

- VPZ M BrochureДокумент2 страницыVPZ M BrochuresundyaОценок пока нет

- IVISOR Mentor IVISOR Mentor QVGAДокумент2 страницыIVISOR Mentor IVISOR Mentor QVGAwoulkanОценок пока нет

- Lecture 11 - Performance AppraisalsДокумент23 страницыLecture 11 - Performance AppraisalsCard CardОценок пока нет

- Company Profile PT. Geo Sriwijaya NusantaraДокумент10 страницCompany Profile PT. Geo Sriwijaya NusantaraHazred Umar FathanОценок пока нет

- Citroen CX Manual Series 2 PDFДокумент646 страницCitroen CX Manual Series 2 PDFFilipe Alberto Magalhaes0% (1)

- TOA Project Presentation (GROUP 5)Документ22 страницыTOA Project Presentation (GROUP 5)Khadija ShahidОценок пока нет

- Lalkitab Varshphal Chart PDFДокумент6 страницLalkitab Varshphal Chart PDFcalvinklein_22ukОценок пока нет