Академический Документы

Профессиональный Документы

Культура Документы

Insulation Knowledge

Загружено:

abhisurajИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Insulation Knowledge

Загружено:

abhisurajАвторское право:

Доступные форматы

K-FLEX produces flexible insulating tubing and sheeting made of black synthetic, vulcanized foam.

Selfdhesive versions are also available. A variety of product types, from tubing to flat sheeting, is available with specific technical characteristics for individual applications. Where the tubing has to be cut for applications purposes, its thermal insulating characteristics are maintained using K-FLEX K 420 glue. With large diameter pipes or conduits, lagging is carried out using elastomeric sheeting which can be cut to size. LISOLANTE K-FLEX recommends that fitting has to be carried out to the highest possible standards to optimise the insulation effectiveness.

K-FLEX ACCESSORIES

CURVES K90/T A useful accessories pre-cut in the thickness and diameter required. K-FLEX K 420 GLUE K-FLEX K 420 glue is specifically designed for use with K-FLEX products and provides secure bonding. The glue hardens on drying and is thus resistant to ageing and is weatherproof.

K-FLEX CUTTER

It features a special, anatomic grip, and makes accurate longitudinal cuts easy in K-FLEX insulation tubing so that they can be installed on fitted pipes. K-FLEX THINNER It is recommended that surfaces to be lagged should first be cleaned with K-FLEX thinner, which is suitable for use with K-FLEX K 420 glue. The glue will adhere perfectly to surfaces cleaned with the proprietory thinner. K-FLEX thinner can also be used to clean tools (brush, spatula, etc.). Shelf life: unlimited while sealed. K-FLEX INSULATED PIPE SUPPORTS Specifically designed to ensure that thickness of the insulating material is absolutely correct, especially in the fixing points. K-FLEX FINISH K-FLEX finish is an acrylic paint that can be diluted in water to protect insulation both indoors and outdoors. The paint is environmentally safe and odorless, making it particularly suitable for use in confined spaces. It gives a professional, durable finish. It dries rapidly, and provides excellent coverage. When used as a primer, subsequent layers of white paint retain their color even in dark surroundings. Colors are fade resistant. ADHESIVE PVC TAPE A special PVC, self-adhesive insulating tape for covering gaps or finishing off insulated

sections. K-FLEX ADHESIVE INSULATING TAPE Special, 3mm-thick, selfadhesive, 5-cm wide insulating tape for covering gaps or sealing insulated sections.

K-FLEX GLUE DISPENSER It facilitates the gluing of the surface avoiding the continuous dipping of the brush in the can. The controlled flow of the adhesive allows proper and regular quantity on the surface to glue.

USING PRODUCTS AND ACCESSORIES

CLEANING SURFACES The surfaces to be glued must be perfectly clean and free of grease (use K-FLEX thinner). Ensure that the surface of the K-FLEX insulating material is also clean, otherwise it will not stick properly. COATED SURFACES Where surfaces have previously been painted, ensure that the glue is compatible and will adhere to the paint. Do not use the glue on surfaces that have been treated with products containing asphalt, bitumen or linseed oil. Use only chrome-zinc rust inhibitors and removers. USING THE GLUE Preparation and storage. Before use, stir the K-FLEX K 420 glue thoroughly. To store the glue, close the lid tightly to prevent the solvents evaporating. If the glue should become too hard (eg. when stored in contact with the air or in extreme temperatures), dilute with K-FLEX thinner. Method of application. When using a large quantity (eg. a tin of 2.6 litres), pour a small amount out into a separate container and top off when necessary. When applying K-FLEX insulation to metallic or other surfaces, the K 420 glue must first be applied to the insulating material, then to the corresponding surface.

Conditions for use. Do not apply to systems that are in use. Do not use in sunlight. The insulation should be left to dry for 36 hours before turning the system back on. The ideal working temperature of the glue is +20 C. Do not use the glue at temperatures below +5 C as drying times are excessive. At temperatures above +30 C, the glue dries very rapidly. HARDENING TIME : STORAGE : SHELF LIFE : QUANTITIES USED : 36 hours in cool conditions, away from cold and heat one year with insulation sheets, from 0.2 to 0.3 litres per mtr

CHOOSING K-FLEX INSULATING MATERIALS Before starting, choose the right type of K-FLEX insulation for the parts to be lagged. Use the thicknesses and sizes which are most suitable for the individual parts of the installation. Dont forget - your K-FLEX dealer can give expert advice. USING K-FLEX INSULATING MATERIALS Insulating tubing that is oval or flattened (eg. the larger cross-sections) should be cut along the flattened surface. USING K-FLEX-FINISH PAINT The paint can be applied as soon as the K-FLEX K 420 glue has dried. Paint within two weeks of fitting.

REFRIGERATION PLANTS AND AIR-CONDITIONING SYSTEMS - Treat steel surfaces with rust inhibitor prior to applying insulation. The paint should be left for a minimum of 24 hours to dry. - Take special care over glueing critical areas such as curved sections, flanging and support brackets. Ensure that the ends of the insulating material are always firmly attached to the piping. - Do not apply insulation where parts are too close together, as this will result in the insulation becoming squashed and losing some of its properties. When carrying out particularly complicated installations on nickel steel, refer to our Technical Office. (Refer K-FLEX folder for installation information)

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- V47 Components From Crank To Link Head (Conical) : Crank and Crank PlateДокумент4 страницыV47 Components From Crank To Link Head (Conical) : Crank and Crank PlatebalaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- G M CryocoolerДокумент22 страницыG M CryocoolerJaydeep PonkiyaОценок пока нет

- Structural Investigation of Historic Buildings - David C FischettiДокумент10 страницStructural Investigation of Historic Buildings - David C FischettiMohammad Javad AarabiОценок пока нет

- 2x2 Box CulvertДокумент5 страниц2x2 Box CulvertRE Solar AdaniОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Portfolio 2.4 DuctingДокумент69 страницPortfolio 2.4 Ductingjitendrashukla10836Оценок пока нет

- Toilet Cleaning ChecklistДокумент1 страницаToilet Cleaning ChecklistDipesh100% (4)

- Types of Joints in Concrete ConstructionsДокумент7 страницTypes of Joints in Concrete ConstructionsbotchОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Herion ValvesДокумент19 страницHerion ValvesTahir FadhilОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- SOP ExcavationДокумент5 страницSOP ExcavationCharantej TejaОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Constructability Concepts Significance and ImplemeДокумент11 страницConstructability Concepts Significance and ImplemeHari Dwi KisbiyantoroОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Polyclad 777 PL PDSДокумент4 страницыPolyclad 777 PL PDShakkianilОценок пока нет

- External Fire Fighting WorksДокумент28 страницExternal Fire Fighting WorksSaurabh Kumar Sharma100% (1)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsДокумент1 страница4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksОценок пока нет

- Contract Implementation Part 3: Contract ManagementДокумент64 страницыContract Implementation Part 3: Contract ManagementKryle Dayle VillanuevaОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Workover Program KE23B2Документ14 страницWorkover Program KE23B2Malau Arief100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Installation User Instruction (KMC Corporation)Документ33 страницыInstallation User Instruction (KMC Corporation)Dan StroescuОценок пока нет

- Production of Precast ConcreteДокумент7 страницProduction of Precast ConcreteDragosPatrascuОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Hollow SectionsДокумент199 страницHollow SectionsmandregomesОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Huamei Spec Sheets - 2018Документ1 страницаHuamei Spec Sheets - 2018Phan LongОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- TROX Chilled Beam Design GuideДокумент60 страницTROX Chilled Beam Design GuideBRYMOENОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Supa Doors Spec OverviewДокумент1 страницаSupa Doors Spec OverviewChelsiemea VargasОценок пока нет

- DODGE Torquearm PDFДокумент186 страницDODGE Torquearm PDFCesar Dominguez ParedesОценок пока нет

- Main Villa GF Arc Window Schedule 02Документ1 страницаMain Villa GF Arc Window Schedule 02MiteshSuneriyaОценок пока нет

- LAteral BucklingДокумент12 страницLAteral Bucklingabhi1648665Оценок пока нет

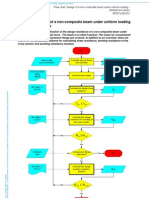

- EC3 Flow Chart Design of A Non-Composite Beam Under Uniform Loading - Detailed ProcedureДокумент5 страницEC3 Flow Chart Design of A Non-Composite Beam Under Uniform Loading - Detailed Procedurejskolmen100% (1)

- Excavator Cat 322c Diagram HydДокумент2 страницыExcavator Cat 322c Diagram Hydmekanicobucaro100% (5)

- Manual For Safety / Technical Audit of Power Distribution SystemДокумент44 страницыManual For Safety / Technical Audit of Power Distribution SystemAnand ShekharОценок пока нет

- Ajiya 2018 CATALOGUE-B2 Rev10-1Документ4 страницыAjiya 2018 CATALOGUE-B2 Rev10-1manova enterpriseОценок пока нет

- MK4 Posttensioning SpecificationsДокумент28 страницMK4 Posttensioning SpecificationsshashireshОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- TT - Revit Structure - Working With Foundation PDFДокумент13 страницTT - Revit Structure - Working With Foundation PDFAshutosh AnandОценок пока нет