Академический Документы

Профессиональный Документы

Культура Документы

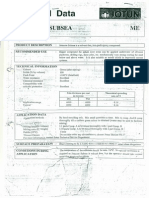

Australianan and International Standards - Coating Sysytems PDF

Загружено:

hemnОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Australianan and International Standards - Coating Sysytems PDF

Загружено:

hemnАвторское право:

Доступные форматы

30.

AUSTRALIAN AND INTERNA TIONAL COA TING ST ANDARDS

INTRODUCTION With the globalisation of commerce and industry, there is an imperative to ensure that performance benchmarks are set in all jurisdictions. International standards are increasingly called up in specications, and Standards Australia has adopted a policy of aligning all Australian standards with International Standards Organisation (ISO) standards as they are published or revised. The importance of consistent standards in an international trading environment is essential to ensure that suppliers are competing on an equal footing in terms of product specications and quality. While the world is rapidly moving towards uniform standards, there are still many regional, national and internal standards that are called up in specications. These may include standards from: United Kingdom International United States Germany New Zealand Japan Canada - BSI - ISO, EC, ETSI - ANSI, ASTM, ASME - DIN - SANZ - JIS - CSA

There are now many Australian/New Zealand standards that have been released in recent times, related to coatings on steel in particular. Those related to zinc-based (galvanized) coatings on steel products are of particular interest, as most address identication issues that are important to speciers. Many zinc-based coatings look similar, but can vary signicantly in durability performance as a result of the technology used in their application. This chapter is aimed at listing the more important of these new standards, and highlighting the performance related issues addressed therein. In addition, we have included a complete listing of current Australian standards associated with coatings for reference. CATEGORIES OF COATING STANDARDS There are six categories into which the current coating standards fall. These are: 1. Process applied coatings 2. Manually applied coatings 3. Product related standards that dene coating performance requirements 4. Environmental classication standards 5. Methods of measurement standards. 6. Generic materials standards (e.g. zinc metal, organic and inorganic coatings etc.) While most of these standards are designed as stand-alone documents, most reference related standards and hence form a matrix of information sources that can be quite complex.

1. Process applied coatings. These include galvanized coatings of all types, powder coatings, electroplated coatings and any other coating that is applied to an item in a purpose designed facility. The coatings characteristics are determined by the process and are usually maintained to tight specications in a controlled environment. 129

30. AUSTRALIAN AND INTERNATIONAL COATING STANDARDS

2.Manually applied coatings. These include most types of commercial and industrial paint coatings, where the surface preparation is at the discretion of the operator, as is the application of the coating. These coatings are heavily dependent on the skill of the applicator and the ability to deal with the variables of the environmental conditions prevailing at the time of application. 3. Product related standards that dene coating performance requirements. These types of standards reect the shift to performance-based standards rather than prescriptive standards. The recently published AS/NZS 2699.3:2003 Built-in components for masonry construction Lintels and shelf angles (durability requirements) is a good example of this new generation of standards. A minimum performance life (50 years) is nominated, and complying coatings are listed in the standard for a range of exposure classications. In 2008, Standards Australia released a new standards: AS 2309 Durability of galvanized and electrogalvanized zinc coatings for the protection of steel in structural applications that denes the performance of the various types of zinc-based coatings for steel with respect to their thickness in atmospheric exposures in Australia. 4. Environmental classication standards. These standards are intended to provide environmental classications based on a range of corrosivity factors, which can then be overlaid on coating standards to determine system performance. AS/NZS 2312:2002 Guide to the protection of structural steel against atmospheric corrosion by the use of protective coatings, along with ISO standards ISO 9223, 9224, 9225, and 9226 cover the classication of environments. A new standard (AS 4312 Corrosivity zones in Australia, has been developed by Standards Australia, that will be a single-source document for this application. 5. Methods of measurement standards. There is a large number of very specic standards related to the measurements and test procedures associated with the application and performance of applied coatings of all types. These standards range from methods of measurement of coating thickness to the determination of surface cleanliness. 6. Generic materials standards. These standards related to the quality requirements for the basic materials used in the protective coating process. Some are incorporated into the coatings standards. Examples include a standard for testing the metallic zinc content of zinc-rich paint coatings and the component requirements for twopack epoxy paint designed for industrial applications. The aim of all standards is to clearly dene the requirements of the product or process for the purposes of specication and the assurance of the quality of the nished product. Most standards are quite product-specic, and rarely give rise to confusion in the specication process. One exception is zinc (galvanized and electroplated) coatings, which until recently, have not been separated sufciently the facilitate clear specication based on required performance. For that reason, these standards will be dealt with in more detail in this summary. THE ZINC-COATED (GALVANIZED) STEEL STANDARDS. AS/NZS 4680:2006 Hot dip galvanized (zinc) coatings on fabricated ferrous articles AS/NZS 4680 Is specic to after-fabrication galvanizing and species the heaviest galvanized coatings. In most cases, the hot dip coating will always exceed the specied minimum thickness 130

30. AUSTRALIAN AND INTERNATIONAL COATING STANDARDS

because of the nature of the application process. Minimum coating thickness is specied on the basis of steel thickness. The coating is specied in grams/m2 which is usually converted to average coating thickness in microns so non-destructive measurement of the coating can be done. AS/NZS 4534:2006 Zinc and zinc/aluminium coatings on steel wire AS/NZS 4534 Is specic to continuously galvanized wire. The coating is applied in a continuous process. A number of coating classes are available that vary with wire diameter. A WXX identication system is used, with W10 being the standard class against which the other classes are rated. e.g. W20 is double the coating mass of W10 and W05 is half the coating mass of W10 for the same wire diameter

AS/NZS 4791:2006 Hot dip galvanized (zinc) coatings on ferrous open sections applied by a continuous or specialised process. AS/NZS 4792:12006 Hot dip galvanized (zinc) coatings on ferrous hollow sections applied by a continuous or specialised process. AS/NZS 4791 Open sections AS/NZS 4792 Hollow sections These two standards were developed specically for OneSteels Duragal continuously galvanized hollow and open sections and Palmer Tubes and Orrcons hollow sections manufactured from continuously galvanized (CG) strip. Some sections may be hot dip galvanized using a semi-continuous galvanizing process. Where the hot dip galvanized coating is used, the coating class is designated by the classication HDGXXX, where the XXX numerals are the coating mass per square metre on each surface. e.g. HDG200 is 200 g/m2 average. Where CG strip is used, the coating class is designated by the classication ZBXXX/XXX. The ZB indicates `zinc both sides and the XXX is the coating mass per side in g/m2. e.g. ZB100/100 represents 100 g/m2 coating mass average on both sides. Where the coating is applied by an in-line process (Duragal ), the coating class is designated by the classication ILGXXX, where ILG indicates in-line galvanized and the XXX is the single-side coating mass in g/m2. e.g. ILG100 represents 100 g/m2 on the outside of hollow sections and all surfaces of open sections. AS 1397:2001 Steel sheet and strip Hot dipped zinc coated and aluminium/zinc coated coated This standard has been virtually unchanged from previous editions and covers both galvanized (zinc), zinc/iron alloy and Zincalume coated steel sheet and strip. The Zincalume coating contains approximately 60% aluminium and 40% zinc. The steel strength grade is designated by a GXXX classication, where the XXX represents the steels yield strength in megapascals (MPa). e.g. G350 indicates a 350 MPa minimum yield strength. The coating type is designated by ZXXX for galvanized (zinc) coatings, ZFXXX for zinc/iron alloy coatings and AZXXX for Zincalume coatings, where the XXX represents the total average coating mass on BOTH sides of the sheet. e.g. Z350 indicates a galvanized coating with a total coating mass on BOTH sides of the sheet of 350 g/m2 or 175 g/m2 on each side of the sheet. 131

30. AUSTRALIAN AND INTERNATIONAL COATING STANDARDS

AS 4750:2003 Electro- galvanized (zinc) coatings on ferrous hollow sections. This standard was developed to complement the other in-line galvanizing standards, where the zinc coating is applied by a continuous electroplating process, rather than using a molten zinc bath. There are a number of hot-dip galvanizing standards related to structural fasteners. These standards are similar with respect to coating specications, but are differentiated by the types of fasteners. These standards include: AS 1214:1983 Hot-dip galvanized coatings on threaded fasteners (ISO Metric coarse thread series) AS/NZS 1559:1997 Hot-dip galvanized steel bolts with associated nuts and washers for tower construction. AS/NZS 1252:1996 High strength steel bolts with associated nuts and washers for structural engineering. AS/NZS 1390:1997 Cup head bolts with ISO metric coarse pitch threads. THE ENVIRONMENTAL CLASSIFICATION STANDARDS. The most signicant document in the Standards Australia library on the classication of environments for corrosivity is AS/NZS 2312:2002 Guide to the protection of structural steel against atmospheric corrosion by the use of protective coatings. The section in this standard covering classication of atmospheres is largely descriptive and makes no attempt to quantify corrosivity in given environments. AS/NZS 2312 references a suite of ISO standards that are intended to provide the platform for classication of corrosivity or atmospheres. These standards are: ISO 9223 - Corrosivity of atmospheres Classication ISO 9224 Corrosivity of atmospheres Guiding values for corrosivity categories ISO 9225 Corrosivity of atmospheres Measurement of pollution ISO 9226 Corrosivity of atmospheres Determination of corrosion rate for standard specimens for the evaluation of corrosion. While these standards provide the metrics to determine atmospheric corrosivity, they have been developed for Northern hemisphere conditions, and fall short in some areas that are appropriate for the Asia-Pacic region. These shortcomings have been recognized by Standards Australia and a local standard, AS 4312 Corrosivity zones in Australia (Draft) is under development in 2004 at Standards Committee level. Standards of this type will become increasingly important as the determination of durability of construction materials will lead to more performance based, rather than prescriptive, standards being published and also incorporated in to building codes and standard specications. FINDING THE STANDARD It is no longer necessary to reference a large printed catalogue of standards, or even purchase a printed standard from an authorized distributor. Standards Australia develops the standards and they are them sold through SAI Global which is a public company with exclusive distribution rights for Standards 132

30. AUSTRALIAN AND INTERNATIONAL COATING STANDARDS

Australia publications. Information about individual standards is available from the SAI Global web site, and any Australian or international standard can be purchased as a hard copy or as a downloadable .pdf le from the SAI Global site. Students can register with Standards Australia and this will allow access to any standard for downloading for reference. These les are time stamped and copyrighted and have very short use-by date after downloading, but provide students with standards access on a 24/7 basis. The Standards Australia web address is www.standards.com.au. The SAI Global web address is www. saiglobal.com. COATING STANDARDS SURVEY This listing contains most of the Australian Standards that cover industrial protective coatings. There are additional standards that deal with specialised coatings (gold plating, vitreous enamel, etc) that have been excluded for practical reasons from this listing.

Standard

AS 1231 2000 AS 4750 2003 AS 1192 -2004 AS 4397 - 1996 AS 1897 1976 AS 1798 2003 AS/NZS 2312 2002 AS 1214-1983 AS/NZS 4680 2006 AS/NZS 4791 -2006 AS/NZS 4792 -2006 AS 4750 - 2003 AS/NZS 1559 -1997 AS 2483 2003 AS 1247- 2004 AS 2331.3.11 2001 AS 2331.3.2 2001

Title

Aluminium and aluminium alloys Anodic oxidation coatings Electrogalvanized (zinc) coatings on ferrous hollow and open sections Electroplated coatings nickel and chromium Electroplated coatings of zinc on steel fasteners with imperial threads Electroplated coatings on threaded components (metric coarse series) Electroplated zinc (electro galvanized) coatings on ferrous articles (batch process) Guide to the protection of structural steel against atmospheric corrosion by the use of protective coatings. Hot-dip coatings on threaded fasteners (ISO metric coarse thread series) Hot-dip galvanized (zinc) coatings on fabricated ferrous articles Hot-dip galvanized (zinc) coatings on ferrous hollow sections, applied by a continuous or specialised process. Hot-dip galvanized (zinc) coatings on ferrous open sections, applied by a continuous or specialised process. Electrogalvanized (zinc) coatings on ferrous and open sections Hot-dip galvanized steel bolts with associated nuts and washers for tower construction Metal finishing Recommended sampling plans for the inspection and testing of coatings (ISO 4519:1980, Mod) Metallic coatings Rating of test specimens and manufactured articles subject to corrosion tests Methods of test for metallic and related coatings - Corrosion and related property tests Chemical residue tests Chemical residue tests Methods of test for metallic and related coatings - Corrosion and related property tests Chemical residue tests Acetic acid salt spray test (ASS test) Methods of test for metallic and related coatings - Corrosion and related property tests Chemical residue tests Copper accelerated acetic acid salt spray test (CASS test)

AS 2331.3.3 2001

133

30. AUSTRALIAN AND INTERNATIONAL COATING STANDARDS

AS 2331.3.4 2001 AS 2331.3.5 2001 AS 2331.3.6 2001 AS 2331.3.7 2001 AS 2331.3.8 2001 AS 2331.3.9 2001 AS 2331.3. 12001 AS 2331.0 2001 AS 2331.1.1 2001 AS 2331.1.2 2001 AS 2331.1.3 2001 AS 2331.1.4 2001 AS 2331.1.5 2001 AS 2331.4.2 1990 AS 2331.4.1 2001 AS 2331.4.4 2001 AS 2331.2.1 2001

Methods of test for metallic and related coatings - Corrosion and related property tests Thioacetamide anti-tarnish and porosity tests Methods of test for metallic and related coatings - Corrosion and related property tests Sulfur dioxide/hydrogen sulfide porosity tests Methods of test for metallic and related coatings - Corrosion and related property tests Electrographic porosity tests Methods of test for metallic and related coatings - Corrosion and related property tests Corrodkote (Corr) test (ISO 4541:1978.Mod) Methods of test for metallic and related coatings - Corrosion and related property tests- Humidity test 24 hour cycle Damp heat Methods of test for metallic and related coatings - Corrosion and related property tests Metallic coatings Porosity tests Ferroxyl test Methods of test for metallic and related coatings Corrosion and related property tests Neutral salt spay (NSS) tests Methods of test for metallic and related coatings Introduction and list of methods Methods of test for metallic and related coatings Local thickness tests Micrographic examination of cross section Methods of test for metallic and related coatings Local thickness tests Colourmetric method Methods of test for metallic and related coatings Local thickness tests Magnetic method Methods of test for metallic and related coatings Local thickness tests Magnetic induction and eddy current method Methods of test for metallic and related coatings Local thickness tests Beta backscatter method Methods of test for metallic and related coatings Physical tests Ductility test Methods of test for metallic and related coatings Physical tests Qualitative adhesion tests Methods of test for metallic and related coatings Physical tests Assessment of intensity of shot peening. Methods of test for metallic and related coatings Test for average coating mass per unit area or for thickness. Dissolution methods Strip and weight analytical Methods of test for metallic and related coatings Test for average coating mass per unit area or for thickness. Hydrogen evolution method for zinc coatings Paints and related materials Methods of test Application properties Roller coating Paints and related materials Methods of test Coatings Guide to assessing paint systems exposed to weathering conditions Paints and related materials Methods of test Durability and resistance to fouling Marine underwater paint systems Paints and related materials Methods of test Exposed to weathering Degree of flaking and peeling Paints and related materials Methods of test Exposed to weathering Degree of chalking Paints and related materials Methods of test Exposed to weathering Degree of colour change Paints and related materials Methods of test Exposed to weathering Degree of fungal and algal growth Paints and related materials Methods of test Exposed to weathering Discoloration (including bronzing)

AS 2331.2.3 2001

AS/NZS 1580.205.3 -1997 AS/NZS 1580.481.0 -2003 AS/NZS 1580.481.5 -1993 AS/NZS 1580.481.1.10 -1998 AS/NZS 1580.481.1.111998 AS/NZS 1580.481.1.12 -1998 AS/NZS 1580.481.1.13 -1998 AS/NZS 1580.481.1.2 -1998

134

30. AUSTRALIAN AND INTERNATIONAL COATING STANDARDS

AS/NZS 1580.481.1.3 -1998 AS/NZS 1580.481.1.4 -1998 AS/NZS 1580.481.1.5 -1998 AS/NZS 1580.481.1.61998 AS/NZS 1580.481.1.7 -1998 AS/NZS 1580.481.1.8 -1998 AS/NZS 1580.481.1.9 -1998 AS 1580.481.5 - 2004 AS 3894.4 - 2002 AS 3894.1 - 2002 AS 3894.9 - 2002 AS 3894.3 - 2002 AS 3894.6 - 2002 AS 3894.5 - 2002 AS 3894.7 - 2002 AS 3894.11 - 2002 AS 3894.12 - 2002 AS 3894.13- 2002 AS 3894.14 - 2002 AS 3894.10 - 2002 AS 3894.0 - 2002 AS 3894.2 - 2002 AS 3894.8 - 2002 AS 1397 - 2001 AS/NZS 4506 2006 AS/NZS 4534 -2006 AS 4848.1 - 2006 AS 5056 - 2006

Paints and related materials Methods of test Exposed to weathering Degree of dirt collection Paints and related materials Methods of test Exposed to weathering Degree of dirt retention (after washing) Paints and related materials Methods of test Exposed to weathering Change in gloss Paints and related materials Methods of test Exposed to weathering Degree of erosion Paints and related materials Methods of test Exposed to weathering Degree of checking Paints and related materials Methods of test Exposed to weathering Degree of cracking Paints and related materials Methods of test Exposed to weathering Degree of blistering Paints and related materials Methods of test Coatings Durability and resistance to fouling Marine underwater paint systems Site testing of protective coatings Assessment of degree of cure Site testing of protective coatings Continuity testing High voltage (brush) method Site testing of protective coatings Determination of adhesion Site testing of protective coatings Determination of dry film thickness Site testing of protective coatings Determination of residual contaminants Site testing of protective coatings Determination of surface profile Site testing of protective coatings Determination of surface temperature Site testing of protective coatings Equipment report Site testing of protective coatings Inspection report - Coating Site testing of protective coatings Inspection report - Daily Site testing of protective coatings Inspection report Daily painting Site testing of protective coatings Inspection report Daily surface and ambient conditions Site testing of protective coatings Introduction and list of test methods Site testing of protective coatings non-conductive method Continuity testing Wet sponge method Site testing of protective coatings Visual determination of gloss Steel sheet and strip Hot-dip zinc coated or aluminium/zinc coated Thermoset powder coatings Zinc and zinc/aluminium alloy coatings on steel wire Application specifications for coating systems Single coat inorganic (zinc) silicate Solvent-bourne. Powder metal (and composites) applied by mechanical means at ambient temperature.

135

01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46

SPECIFIERS MANUAL INDUSTRIAL GALVANIZERS COMPANY PROFILE ADHESION OF PROTECTIVE COATINGS BOLTING GALVANIZED STEEL BURIED GALVANIZED STEEL CONCRETE DURABILITY & GALVANIZED REBAR CORROSION MAPPING COST FACTORS FOR HOT DIP GALVANIZED COATINGS CUSTOM COATING PACKAGES CUT EDGE PROTECTION DESIGNING FOR GALVANIZING ILLUSTRATED GUIDE TO DESIGN FOR GALVANIZING DEW POINT TABLES DIFFICULT STEELS FOR GALVANIZING DOCUMENTATION - CORRECT PAPERWORK ENSUES EFFICIENT PROCESSING ENVIRONMENTAL ISSUES FOR INDUSTRIAL COATINGS ZINC, HUMAN HEALTH AND THE ENVIRONMENT DEFECTS IN GALVANIZED COATINGS GALVANIC SERIES GLOSSARY OF GALVANIZING TERMS GUARANTEES FOR HOT DIP GALVANIZED COATINGS LIFE CYCLE COSTS OF INDUSTRIAL PROTECTIVE COATING SYSTEMS PAINTING OVER GALVANIZED COATINGS POWDER COATING OVER GALVANIZED COATINGS QUALITY AND SERVICE FACTORS AFFECTING GALVANIZED COATINGS RESTORATION OF PREVIOUSLY GALVANIZED ITEMS REPAIR OF GALVANIZED COATINGS STEEL STRENGTH AND HOT DIP GALVANIZING STANDARDS - AS/NZS 4680:2006 STANDARDS - AUSTRALIAN AND INTERNATIONAL STANDARDS STEEL SURFACE PREPERATION SURFACE PREPERATION FOR PAINTING HOT DIP GALVANIZED COATINGS THICKNESS MEASUREMENT OF PROTECTIVE COATINGS WELDING GALVANIZED STEEL AN INTRODUCTION TO THE HOT DIP GALVANIZING PROCESS ZINC COATING PROCESSES - OTHER METHODS GALVANIZED COATINGS AND BUSHFIRE LIQUID METAL ASSISTED CRACKING OF GALVANIZED STRUCTURAL STEEL SECTIONS GALVANIZING 500N GRADE REINFORCING BAR PREDICTING THE LIFE OF GALVANIZED COATINGS CHEMICALS IN CONTACT WITH GALVANIZED COATINGS. ATMOSPHERIC CORROSIVITY ASSESSMENT GLOBAL WARMING - CLIMATE CHANGE AND GALVANIZING STEEL - ITS CORROSION CHARACTERISTICS GALVANIZED STEEL AND TIMBER WHITE RUST PREVENTION AND TREATMENT

01 - SPECIFIERS MANUAL THIRD EDITION

Industrial Galvanizers Australian Galvanizing Division (IGAG) operates nine galvanizing plants around Australia, ranging in size from large structural galvanizing facilities to specialised small plants designed to process small parts. The Australian Galvanizing Division has galvanized in excess of 2 million tonnes of steel products in Australia since its rst plant was commissioned in 1965 and is recognized for its ability to handle complex and difcult projects, as well as routine contracts. This experience has been collated in the Speciers Design Manual, to assist those involved in the design of steel products and projects to better understanding the galvanizing process and allow the most durable and cost-effective solutions to be delivered to these products and projects. All sections of this Third Edition have been completely updated and additional sections have been included to provide additional technical information related to the use of hot dip galvanized steel. In addition to its Australian Galvanizing operations, Industrial Galvanizers Corporation has a network of manufacturing operations in Australia, as well as galvanizing and manufacturing businesses throughout Asia and in the USA. The companys staff in all these locations will be pleased to assist with advice on design and performance of hot dip galvanized coatings and products. Contact details for each of these locations are located elsewhere in this manual. This edition of the Industrial Galvanizers Speciers Manual has been produced in both html and .pdf formats for ease of access and distribution and all documents in the Manual are in .pdf format and can be printed if paper documents are required. The Speciers Manual is also accessible in its entirety on the companys web site at www.ingal.com.au. Additional copies of the Speciers Manual are available on CD on request. PUBLISHER: Industrial Galvanizers Australian Galvanizing Division, PO Box 503, MOOROOKA QLD 4105 Ph: 07 38597418 EDITOR: John Robinson, Mount Townsend Solutions Pty Ltd PO Box 355, JESMOND NSW 2299 Ph: 0411 886 884 Email: mt.solutions@optusnet.com.au LAYOUT AND DESIGN: Adrian Edmunds, Nodding Dog Design Ph: 0402 260 734 Email: adrian@noddingdogdesign.com Web: www.noddingdogdesign.com

Вам также может понравиться

- 101 Metal Repair Paste PS PDFДокумент2 страницы101 Metal Repair Paste PS PDFhemnОценок пока нет

- Oil Oisd STD 188Документ39 страницOil Oisd STD 188sekharsappa2100% (1)

- SAEJ987 V 001Документ22 страницыSAEJ987 V 001hemnОценок пока нет

- Statistical Methods in Data MiningДокумент20 страницStatistical Methods in Data MininghemnОценок пока нет

- Improving The Efficiency of HVACДокумент20 страницImproving The Efficiency of HVAChemnОценок пока нет

- Failure Assessment and Safe Life Prediction of Corroded Oil and Gas PipelinesДокумент20 страницFailure Assessment and Safe Life Prediction of Corroded Oil and Gas PipelineshemnОценок пока нет

- Failure Assessment and Safe Life Prediction of Corroded Oil and Gas PipelinesДокумент20 страницFailure Assessment and Safe Life Prediction of Corroded Oil and Gas PipelineshemnОценок пока нет

- Statistical Methods in Data MiningДокумент20 страницStatistical Methods in Data MininghemnОценок пока нет

- Failure Assessment and Safe Life Prediction of Corroded Oil and Gas PipelinesДокумент20 страницFailure Assessment and Safe Life Prediction of Corroded Oil and Gas PipelineshemnОценок пока нет

- Jozeveh Darsi Moghavemat 1Документ48 страницJozeveh Darsi Moghavemat 1cesc4clooneyОценок пока нет

- Matrix IntroductionДокумент3 страницыMatrix IntroductionhemnОценок пока нет

- Improving The Efficiency of HVACДокумент20 страницImproving The Efficiency of HVAChemnОценок пока нет

- ASTM Pipe Schedule DimensionsДокумент5 страницASTM Pipe Schedule DimensionshemnОценок пока нет

- Improving The Efficiency ofДокумент20 страницImproving The Efficiency ofhemnОценок пока нет

- Improving The Efficiency of HVACДокумент20 страницImproving The Efficiency of HVAChemnОценок пока нет

- Liftruck Manual PDFДокумент13 страницLiftruck Manual PDFhemnОценок пока нет

- Improving The Efficiency of HVACДокумент20 страницImproving The Efficiency of HVAChemnОценок пока нет

- Improving The Efficiency ofДокумент20 страницImproving The Efficiency ofhemnОценок пока нет

- Research World Landmarks To Create A Global Calendar: Microsoft in Education Lesson PlansДокумент4 страницыResearch World Landmarks To Create A Global Calendar: Microsoft in Education Lesson PlanshemnОценок пока нет

- Statistical Methods in Data MiningДокумент20 страницStatistical Methods in Data MininghemnОценок пока нет

- Is Your Bend Good Enough?: Eric LundinДокумент4 страницыIs Your Bend Good Enough?: Eric Lundinhemn0% (1)

- Improving The Efficiency ofДокумент20 страницImproving The Efficiency ofhemnОценок пока нет

- پوشش زیر دریاДокумент2 страницыپوشش زیر دریاhemnОценок пока нет

- God Related ExpressionsДокумент2 страницыGod Related ExpressionshemnОценок пока нет

- Pipeline Risk Management Basic ManualДокумент6 страницPipeline Risk Management Basic ManualhemnОценок пока нет

- Liftruck Manual PDFДокумент13 страницLiftruck Manual PDFhemnОценок пока нет

- ASTM Pipe Schedule DimensionsДокумент5 страницASTM Pipe Schedule DimensionshemnОценок пока нет

- Crane Manual PDFДокумент20 страницCrane Manual PDFhemnОценок пока нет

- Types of SoilДокумент35 страницTypes of SoilhemnОценок пока нет

- Pigging in Pipeline Pre-Commissioning PDFДокумент8 страницPigging in Pipeline Pre-Commissioning PDFhemn100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Full Catalogue 2008Документ58 страницFull Catalogue 2008Anonymous 1aHRPIIFfIОценок пока нет

- Summary of Bill A - Main Bill: 3107 Malta Tourism AuthorityДокумент21 страницаSummary of Bill A - Main Bill: 3107 Malta Tourism AuthoritySaurabh TiwariОценок пока нет

- Comprehensive Guidelines Inspection Repair of HDG Coatings PDFДокумент24 страницыComprehensive Guidelines Inspection Repair of HDG Coatings PDFHoangОценок пока нет

- Sec682 Reinforced Soil StructuresДокумент10 страницSec682 Reinforced Soil StructurespabulumzengОценок пока нет

- White Rust and Water Treatment: About Your Galvanized Cooling TowerДокумент1 страницаWhite Rust and Water Treatment: About Your Galvanized Cooling TowerAhmed TaherОценок пока нет

- Kavalani Hvac R Catalogue 2015Документ32 страницыKavalani Hvac R Catalogue 2015Anoop Jacob KunnappuzhaОценок пока нет

- Rusting and Corrosion: Conditions For Iron To RustДокумент3 страницыRusting and Corrosion: Conditions For Iron To Rusthussein hajiОценок пока нет

- Galvanising and Current TrendsДокумент32 страницыGalvanising and Current TrendsMritunjayОценок пока нет

- RM1 TEKSCREW & SKYLIGHT CANVASSДокумент7 страницRM1 TEKSCREW & SKYLIGHT CANVASSCapitol Steel ConstructionОценок пока нет

- Division 23 - Heating, Ventilating, and Air-Conditioning (Hvac) Section 230529 - Hangers and Supports For Hvac Piping and EquipmentДокумент14 страницDivision 23 - Heating, Ventilating, and Air-Conditioning (Hvac) Section 230529 - Hangers and Supports For Hvac Piping and EquipmentAhmed EbrahimОценок пока нет

- Thermal Spray Coating For Steel ProcessingДокумент5 страницThermal Spray Coating For Steel ProcessingRamkiyengarОценок пока нет

- 5PT10 / 5PT20: 1200 LB and 2000 LB Capacity Portable Davit CranesДокумент12 страниц5PT10 / 5PT20: 1200 LB and 2000 LB Capacity Portable Davit CranesDОценок пока нет

- M12 Bolt Bracing DetailsДокумент1 страницаM12 Bolt Bracing DetailsAmol GoleОценок пока нет

- KLH - Cornell-Cookson - Contra Fuego - ERD10 - ERD20Документ2 страницыKLH - Cornell-Cookson - Contra Fuego - ERD10 - ERD20NELSONОценок пока нет

- HAC Anchor Channels Inovation in V Form Brochure ASSET DOC LOC 3170761Документ2 страницыHAC Anchor Channels Inovation in V Form Brochure ASSET DOC LOC 3170761laeim017Оценок пока нет

- Small Cell Concealments Product Guide 2020 G09!00!123sm v5 2Документ56 страницSmall Cell Concealments Product Guide 2020 G09!00!123sm v5 2Fatih GençОценок пока нет

- TKDN Certificate ListДокумент6 страницTKDN Certificate ListwahyuОценок пока нет

- Cooling 2012 - RH - Ecat - 20120206Документ456 страницCooling 2012 - RH - Ecat - 20120206bryandown100% (1)

- Rolliflex Instrumentation Cables Presentation - PPSXДокумент15 страницRolliflex Instrumentation Cables Presentation - PPSXnikhilbhorОценок пока нет

- MetallurgyДокумент36 страницMetallurgyOneil Prettyboyswagg LeitchОценок пока нет

- 06-700-R1 Model CJB Cathode Junction BoxДокумент1 страница06-700-R1 Model CJB Cathode Junction Boxsoltani aliОценок пока нет

- Protective coating for hot-dip galvanised steelДокумент2 страницыProtective coating for hot-dip galvanised steelVincent BachellerieОценок пока нет

- Bollards PDFДокумент10 страницBollards PDFsiladharmaОценок пока нет

- Steel Framed Multi Storey Car Parks by CORUS - GKK 14may2012Документ36 страницSteel Framed Multi Storey Car Parks by CORUS - GKK 14may2012Kuvochi Karanja100% (2)

- Tube Clamps 2015Документ48 страницTube Clamps 2015Peter DavidsonОценок пока нет

- Fischer CatalogДокумент60 страницFischer CatalogAlex SihlanicОценок пока нет

- Is 5613 Part 3 Code of Practice For Design Installation Maintenance of Transmission Lines PDFДокумент27 страницIs 5613 Part 3 Code of Practice For Design Installation Maintenance of Transmission Lines PDFsavvymov50% (2)

- Pradhan Mantri Awas Yojana Housing For All (Urban) in AP StateДокумент120 страницPradhan Mantri Awas Yojana Housing For All (Urban) in AP StateKishore Nayak kОценок пока нет

- Model Estimate For CattleshedДокумент20 страницModel Estimate For CattleshedBANDA BANDA50% (2)