Академический Документы

Профессиональный Документы

Культура Документы

ITCC in Riyadh Residential Complex J10-13300 08120-1 Aluminum Doors and Frames

Загружено:

uddinnadeemИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ITCC in Riyadh Residential Complex J10-13300 08120-1 Aluminum Doors and Frames

Загружено:

uddinnadeemАвторское право:

Доступные форматы

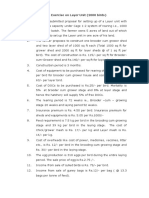

SECTION 08120 ALUMINUM DOORS AND FRAMES 00000000PART 1 - GENERAL 1.1 SECTION INCLUDES A. 1.

2 Aluminum doors and frames as shown on Drawings and as specified herein.

REFERENCES A. SASO Saudi Arabian Standards Organization SASO 79 SASO 80 Aluminum and aluminum alloys for building purposes - part 1: Rods/Bars, tubes and profiles Testing methods for aluminum and aluminum alloys products for building purposes part 1; Sheets, strips, bars and structural Methods of test for aluminum windows and doors Aluminum windows Aluminum doors

SASO 1032 SASO 1033 SASO 1034 B.

AAMA - American Architectural Manufacturer Association AAMA 101 AAMA 603.8 AAMA 605.2 AAMA 606.1 AAMA 607.1 AAMA 701.2 Aluminum Prime windows and Sliding Glass Doors Pigmented Organic Coating on Extruded Aluminum. High Performance Organic Coatings on Architectural Extrusions and Panels Color Anodic Finishes for Architectural Aluminum Clear Anodic Finishes for Architectural Aluminum Voluntary Specification for Pile Weather Stripping

C.

AA - Aluminum Association Aluminum Association Designation System for Aluminum Finishes

D.

ANSI - American National Standards Institute A134.1 Specification for Aluminum Prime windows

E.

ASTM - American Society of Testing and Materials

ITCC in Riyadh Residential Complex J10-13300

08120-1

Aluminum Doors And Frames

ASTM B 136 ASTM B 137 ASTM B 209 ASTM B 211 ASTM B 221 ASTM B 244 ASTM D 2287 ASTM D 3656 ASTM E 283 ASTM E 330 ASTM E 331 ASTM E 547 ASTM F 468 F.

Stain Resistance of Anodic Coatings on Aluminum Weight of Coatings on Anodically Coated Aluminum Aluminum and Aluminum-Alloy Sheet and Plate Aluminum and Aluminum-Alloy Bars, Rods and Wire Aluminum-Alloy Extruded Bars, Rods, Wire, Shapes and Tubes Thickness of Anodic Coatings on Aluminum with EddyCurrent Instrument Non-Rigid Vinyl Chloride Polymer and Copolymer Molding and Extrusion Compounds Insect Screening and Louver Cloth Woven From VinylCoated Glass fiber Yarn Rate of Air Leakage Through Exterior Windows, Curtain Walls and Doors Structural Performance of Exterior Windows, Curtain Walls and Doors under the Influence of Wind Loads Water Penetration of Exterior Windows, Curtain Walls and Doors by Uniform Static Pressure Difference Loads Water Penetration of Exterior Windows, Curtain Walls and Doors by Cyclic Static Air Pressure Difference Loads Nonferrous Bolts, Hex Cap Screws, and Studs for General Use

DIN - Deutsches Institut fuer Normung DIN 4108 DIN 18055 Heat Insulation in Buildings. Windows; Air Permeability of Joints, Water Tightness and Mechanical Strain.

G.

AWS - American Welding Society: D1.1 D1.2 Structural Welding Code, Steel. Structural Welding Code, Aluminum.

1.3

SUBMITTALS A. Product Data: Submit Manufacturer's specifications, standard details, and installation recommendations for components of aluminum doors and framing required for project, including data that products have been tested and comply with performance requirements.

ITCC in Riyadh Residential Complex J10-13300

08120-2

Aluminum Doors And Frames

B.

Shop Drawings: Submit shop drawings for fabrication and installation of aluminum doors and framing, including elevations, detail sections of typical composite members, anchorages, reinforcement, expansion provisions, and glazing Certification: Submit statement certified by registered structural engineer that systems including glass will withstand specified wind-loads. Samples: Submit samples of each type and color of aluminum finish, on 300 mm long sections of extrusions or formed shapes and on 150 mm square sheets.

C. D. 1.4

TRANSPORTATION, HANDLING AND STORAGE A. Deliver aluminum entrance material to the site in packages or containers; labeled for identification with the Manufacturer's name, brand and contents. Store aluminum entrance material in weather tight and dry storage facility. Protect from damage from handling, weather and construction operations before, during and after installation.

1.5

WARRANTY A. Submit 2 copies of written guarantee signed by the Manufacturer, Installer and Contractor, agreeing to replace aluminum door units that fail in material or workmanship within 2 years of date of substantial handing over.

1.6

QUALITY ASSURANCE A. B. Standards: Comply with applicable provisions of Metal Curtain Wall, Window, Storefront and Entrance Guide Specifications Manual - AAMA. Performance and Testing: 1. Thermal Movement: Fabricate exterior components from Manufacturer's stock systems which have been designed to provide for expansion and contraction resulting from ambient temperature range of 48 oC. Wind Loading: Fabricate exterior components from Manufacturer's stock systems which have been tested in accordance with ASTM E 330 to withstand at least the following loadings: a. b. 3. Uniform Pressure: 97.6 kg/m inward; 97.6 kg/m outward. Maximum Deflection: 1/175 of clear span any framing member.

2.

Weather Resistance: Fabricate exterior components from Manufacturer's stock systems which have been tested to demonstrate permanent resistance to leakages as follows with test pressure differential of 10 percent of design loading (excluding operable door edges). a. b. Air Infiltration: Tested in accordance with ASTM E 283 and shall have a minimum of 0.6 m3/min/m of crack. Water penetration and leakage shall not be allowed when tested in accordance with ASTM E 331 at a water application rate 10 percent more than the design rate.

08120-3 Aluminum Doors And Frames

ITCC in Riyadh Residential Complex J10-13300

PART 2 - PRODUCTS 2.1 MATERIALS AND ACCESSORIES A. Aluminum Members: 1. 2. 3. B. Extrusions of Bars, Rods and Tubes: 6063-T6 Alloy conforming to ASTM B 221. Sheets and Plates: 5005-H14 alloy conforming to ASTM B 209. Doors and frames shall be manufacturer standard systems of extrusions not less than 2.2 mm thick suitable for double glazing.

Fasteners: Aluminum, or non-magnetic stainless steel, or other materials warranted by Manufacturer to be non-corrosive and compatible with aluminum components. 1. 2. Do not use exposed fasteners except where unavoidable for application of hardware. Match finish of adjoining metal. Provide Phillips flat-head machine screws for exposed fasteners.

C. D.

Glazing Gasket: Manufacturer's standard vinyl glazing gasket. Brackets and Reinforcements: Manufacturer's high- strength aluminum units where feasible; otherwise, non-magnetic stainless steel or hot-dip galvanized complying with ASTM A 386. Concrete/Masonry Inserts: Cast iron, malleable iron, or hot-dip galvanized steel complying with ASTM A 386. Bituminous Coatings: Cold-applied asphalt mastic complying with SSPC - Paint 12, compounded for 20 mil thickness per coat. Glass: Provide 24 mm double tempered glass. Glass and glazing materials shall be as specified in Section 08800 - GLAZING and as indicated on Drawings with all doors factory glazed. Hardware: Provide aluminum doors with Manufacturer's standard, factory-installed hardware conforming to the requirements of Section 08710 - DOOR HARDWARE.

E. F. G.

H. 2.2 FINISH A.

Exposed aluminum surfaces shall have the manufacturer's standard finish, unless otherwise indicated on Drawings and in accordance with the following: 1. Anodized Finish: Conform to AA C22A42; 22 micron thick; with shop-applied protective coating of clear acrylic lacquer or any coating in accordance with AAMA 602.2, 0.5 mil dry film thickness, over anodized finish. Color shall be as approved by the Engineer.

2.3

FABRICATION

ITCC in Riyadh Residential Complex J10-13300

08120-4

Aluminum Doors And Frames

A.

Sizes and Profiles: Required sizes for door and frame units including profile requirements, shall be as shown on Drawings. Variable dimensions shall be indicated, together with maximum and minimum dimensions required to achieve design requirements and coordination with other work. Prefabrication: Complete fabrication, assembly, finishing, hardware application, and other work before shipment to project site. Disassemble components only as necessary for shipment and installation. Sequence: Complete cutting, fitting, forming, drilling, and grinding of metal work prior to cleaning, finishing, surface treatment, and application of finishes. Remove arises from cut edges and ease edges and corners. Welding: Comply with AWS recommendations to avoid discoloration; grind exposed welds smooth and restore mechanical finish. Reinforcing: Install reinforcing as necessary for performance requirements; separate dissimilar metals with bituminous paint or other separator which will prevent corrosion. 1. Provide continuous steel reinforcing stiffening members within jambs and heads of all doorframes, except omit at jambs that are secured to adjacent fixed walls. Cut vertical reinforcing 50 mm less than mullion height and cut horizontal reinforcing 75 mm less than door head framing member. Securely fasten in a manner so that fasteners will not be visible in finished work. Fasten aluminum sections to steel reinforcing 150 mm from each end and intermediately at a maximum spacing of 600 mm on centers. Doorframes shall be free of vibration and distortion when doors are used.

B.

C.

D. E.

2. 3.

4. F. G. H.

Maintain accurate relation of planes and angles, with hairline fit of contacting members. Fasteners: Conceal fasteners wherever possible. Weatherstripping: For exterior doors, provide compression weatherstripping against fixed strip; at other edges, provide sliding weatherstripping retained in adjustable strips mortised in other edge.

PART 3 - EXECUTION 3.1 INSTALLATION A. B. Comply with Manufacturer's instructions and recommendations for installation of aluminum doors and frames. Set units plumb, level, and true to line, without warp or rack of framing members, doors, or panels. Anchor securely in place, separating aluminum and other corrodible metal surfaces from sources of corrosion or electrolytic action at points of

08120-5 Aluminum Doors And Frames

ITCC in Riyadh Residential Complex J10-13300

contact with other materials with bituminous coating. C. D. Set sill members and other members in bed of compound as shown, or with joint fillers or gaskets as shown to provided weathertight construction. Expansion and Contraction: Allow for expansion and contraction due to temperature and building movement, and for practical building tolerances in connections to basic structure and in connections to work by others. At no place should window wall grid or framing impart any expansion or contraction forces on panels or glass. Hardware Preparation and Installation: Cut, reinforce, drill and tap aluminum work for application of finish hardware. Provide cover boxes in frames back of cutouts for hardware also install finish hardware in accordance with hardware Manufacturer's instructions and template requirements also use concealed fasteners wherever possible. Caulking: Seal joints between metal members and between metal and adjacent surfaces in accordance with the requirements of Section 07900 - SEALANTS. Refer to Section 08800 - GLAZING for installation of glass and glazing requirements.

E.

F. G. 3.2

ADJUST AND CLEAN A. B. Adjust operating hardware to function properly, without binding, and to provide tight fit at contact points and weatherstripping. Clean completed systems, inside and out, promptly after erection and installation of glass and sealants. Remove excess glazing and sealant compounds, dirt, and other substances from aluminum surfaces. Remove protective coating when completion of adjoining works and construction activities no longer requires its retention. Institute protective measures and other precautions required to assure that aluminum doors and frames will be without damage or deterioration, other than normal weathering, at time of acceptance. END OF SECTION

C. D.

ITCC in Riyadh Residential Complex J10-13300

08120-6

Aluminum Doors And Frames

Вам также может понравиться

- ITCC in Riyadh Residential Complex J10-13300: 08520-1 Aluminum WindowsДокумент7 страницITCC in Riyadh Residential Complex J10-13300: 08520-1 Aluminum WindowsuddinnadeemОценок пока нет

- Aluminum FramesДокумент5 страницAluminum Frameseromax1Оценок пока нет

- BSD Aluminum Doors and FramesДокумент4 страницыBSD Aluminum Doors and FramesBinh Hung OngОценок пока нет

- FL - Aluminum Doors and WindowsДокумент9 страницFL - Aluminum Doors and WindowsAmro Ahmad AliОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsДокумент6 страницITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsuddinnadeemОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 08920-1 Glazed Aluminum Curtain WallsДокумент9 страницITCC in Riyadh Residential Complex J10-13300 08920-1 Glazed Aluminum Curtain WallsuddinnadeemОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 08470-1 Revolving DoorsДокумент16 страницITCC in Riyadh Residential Complex J10-13300 08470-1 Revolving DoorsuddinnadeemОценок пока нет

- 08 11 16cliДокумент7 страниц08 11 16clibrian walter abarintosОценок пока нет

- Glazed Aluminum CWДокумент9 страницGlazed Aluminum CWhayat49000Оценок пока нет

- Section - 08 11 16 - Aluminum Doors and FramesДокумент2 страницыSection - 08 11 16 - Aluminum Doors and FramesEliseo LagmanОценок пока нет

- Metal Doors and Frames - MSTДокумент14 страницMetal Doors and Frames - MSTwafikmh4Оценок пока нет

- Division 8 - Doors and Windows Section 08111 - Steel Doors and Frames Part 1 - GeneralДокумент10 страницDivision 8 - Doors and Windows Section 08111 - Steel Doors and Frames Part 1 - GeneralOrin Orang InsyafОценок пока нет

- 4 Bar HingeДокумент9 страниц4 Bar HingelalalamxОценок пока нет

- 2808-084413 - Glazed Aluminum Curtain WallsДокумент52 страницы2808-084413 - Glazed Aluminum Curtain WallsAmro Ahmad AliОценок пока нет

- DOMINGO PUA 08125 - Interior Aluminum FramesДокумент9 страницDOMINGO PUA 08125 - Interior Aluminum Framesjuristdaneniel.domingoОценок пока нет

- SECTION 08520 Aluminum Windows Part 1 - General 1.1 General RequirementsДокумент6 страницSECTION 08520 Aluminum Windows Part 1 - General 1.1 General RequirementsIm ChinithОценок пока нет

- Section 077100 - Roof SpecialtiesДокумент6 страницSection 077100 - Roof SpecialtiesWENDING HUОценок пока нет

- SECTION 07 72 00 Roof AccessoriesДокумент8 страницSECTION 07 72 00 Roof AccessoriesJuanPaoloYbañezОценок пока нет

- W2700 Window Wall Specification FinalДокумент11 страницW2700 Window Wall Specification FinalSharlette SaulОценок пока нет

- 06 - Technical Specifications - Steel Doors and FramesДокумент6 страниц06 - Technical Specifications - Steel Doors and FramesMarcons Jon Maturan CasabaОценок пока нет

- 04 3023 01Документ5 страниц04 3023 01U MariappanОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 08100-1 Hollow Metal Doors and FramesДокумент9 страницITCC in Riyadh Residential Complex J10-13300 08100-1 Hollow Metal Doors and FramesuddinnadeemОценок пока нет

- DOMINGO PUA 08110-Steel Doors and FramesДокумент11 страницDOMINGO PUA 08110-Steel Doors and Framesjuristdaneniel.domingoОценок пока нет

- Kusen AluminiumДокумент11 страницKusen AluminiumNan BudiОценок пока нет

- Section 07820 Acrylic Walkway CoverДокумент3 страницыSection 07820 Acrylic Walkway CoverBergadamusОценок пока нет

- Louvers CSI SpecificationДокумент6 страницLouvers CSI SpecificationRowdyRaheelОценок пока нет

- 08 63 00 PDFДокумент11 страниц08 63 00 PDFAnonymous hk1fhAkwyОценок пока нет

- CSI SECTION: 08 41 13 Aluminum - Framed Entrances & Storefronts Product Series Ykk Ap Yes 45 Fs/Fi Series Part 1 General 1.01 SummaryДокумент5 страницCSI SECTION: 08 41 13 Aluminum - Framed Entrances & Storefronts Product Series Ykk Ap Yes 45 Fs/Fi Series Part 1 General 1.01 SummarySarah OnlineОценок пока нет

- Section 08113 Custom Steel Door FramesДокумент6 страницSection 08113 Custom Steel Door FramesMØhãmmed ØwięsОценок пока нет

- Section 02820 Ornamental Metal Fences and GatesДокумент14 страницSection 02820 Ornamental Metal Fences and GatesMØhãmmed ØwięsОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 08620-2 Plastic Unit SkylightsДокумент4 страницыITCC in Riyadh Residential Complex J10-13300 08620-2 Plastic Unit SkylightsuddinnadeemОценок пока нет

- 3 Part Specification Thermally Improved Aluminum Doors: Specification Begins On The Following PageДокумент9 страниц3 Part Specification Thermally Improved Aluminum Doors: Specification Begins On The Following PageRОценок пока нет

- OpeningsДокумент159 страницOpeningssadoonОценок пока нет

- Spek AluminiumWindows PDFДокумент13 страницSpek AluminiumWindows PDFSantoso Simanjuntak100% (1)

- FlashingДокумент8 страницFlashingmasahinОценок пока нет

- Section 10200 Louvers and VentsДокумент3 страницыSection 10200 Louvers and VentsMØhãmmed ØwięsОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilingДокумент5 страницITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilinguddinnadeemОценок пока нет

- Guide Specification Aluminum Composite Wall PanelsДокумент9 страницGuide Specification Aluminum Composite Wall PanelsJosielyn100% (1)

- Section 08630 Metal-Framed SkylightДокумент4 страницыSection 08630 Metal-Framed SkylightMØhãmmed ØwięsОценок пока нет

- Aluminium FramesДокумент4 страницыAluminium FramessoorajОценок пока нет

- SECTION 08112 Steel Doors and FramesДокумент11 страницSECTION 08112 Steel Doors and FramesIm ChinithОценок пока нет

- 04 3020 00Документ4 страницы04 3020 00Phạm Khắc HảiОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 05810-1 Expansion Joint Cover AssembliesДокумент5 страницITCC in Riyadh Residential Complex J10-13300 05810-1 Expansion Joint Cover AssembliesuddinnadeemОценок пока нет

- V6JN5 3part CsiДокумент3 страницыV6JN5 3part CsiWahyu Candra WardanaОценок пока нет

- Aluminium Window SpecificationДокумент4 страницыAluminium Window SpecificationPraveenSharma100% (1)

- Guide Specification - SDP 200: GeneralДокумент10 страницGuide Specification - SDP 200: GeneralhbookОценок пока нет

- 08 33 23 Overhead Coiling DoorsДокумент14 страниц08 33 23 Overhead Coiling Doorsomar shadyОценок пока нет

- Section 07720 Roof AccessoriesДокумент5 страницSection 07720 Roof AccessoriesMØhãmmed ØwięsОценок пока нет

- GFRCДокумент11 страницGFRCMhmd AbdoОценок пока нет

- Aluminum WindowsДокумент14 страницAluminum Windowshayat49000Оценок пока нет

- SECTION 08 36 13 Sectional DoorsДокумент9 страницSECTION 08 36 13 Sectional DoorsJuanPaoloYbañezОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 09250-1 Gypsum BoardДокумент5 страницITCC in Riyadh Residential Complex J10-13300 09250-1 Gypsum BoarduddinnadeemОценок пока нет

- SP-008 Doors and WindowsДокумент100 страницSP-008 Doors and WindowsmcbluedОценок пока нет

- 17 Metal WorkДокумент10 страниц17 Metal WorkUlfathbary ABОценок пока нет

- P.O. Number: 7200018725Документ6 страницP.O. Number: 7200018725sethu1091Оценок пока нет

- HVAC Ducts and CasingsДокумент10 страницHVAC Ducts and CasingsmanikantanОценок пока нет

- Prescriptive SpecificationДокумент10 страницPrescriptive SpecificationDebbie Jhem DicamОценок пока нет

- 09 51 00 - Suspended Ceiling PDFДокумент6 страниц09 51 00 - Suspended Ceiling PDFmasoodaeОценок пока нет

- Spot Welding Interview Success: An Introduction to Spot WeldingОт EverandSpot Welding Interview Success: An Introduction to Spot WeldingОценок пока нет

- Electrical Engineer CV (M Bilal M)Документ4 страницыElectrical Engineer CV (M Bilal M)uddinnadeemОценок пока нет

- XXXXXX: Voltage Drop& Cable Sizing CalculationsДокумент5 страницXXXXXX: Voltage Drop& Cable Sizing CalculationsPradeesh Vijayan (v.prathi)Оценок пока нет

- Green Grounding ManualДокумент23 страницыGreen Grounding Manualuddinnadeem100% (1)

- Generator MaintenanceДокумент24 страницыGenerator MaintenancePablo Gaspar D'Agostini Amengual100% (9)

- Panel Board ShortCircuit RatingsДокумент2 страницыPanel Board ShortCircuit RatingsuddinnadeemОценок пока нет

- Panel Board ShortCircuit RatingsДокумент2 страницыPanel Board ShortCircuit RatingsuddinnadeemОценок пока нет

- SECTION 01300 Submittals 1.01 General: Vocational Training CenterДокумент11 страницSECTION 01300 Submittals 1.01 General: Vocational Training CenterulyjohnignacioОценок пока нет

- 16721-Fa SystemДокумент17 страниц16721-Fa SystemuddinnadeemОценок пока нет

- Nicet AlarmsДокумент23 страницыNicet AlarmsWERMERMОценок пока нет

- Where Indicated Supply and Apply On Concrete Screed A Multi Component Hard Wearing, Smooth, Matt or Satin Finish Polyurethane Based Flooring System at A Thickness of 2.5 MM UtilisingДокумент1 страницаWhere Indicated Supply and Apply On Concrete Screed A Multi Component Hard Wearing, Smooth, Matt or Satin Finish Polyurethane Based Flooring System at A Thickness of 2.5 MM UtilisinguddinnadeemОценок пока нет

- Panel BoardДокумент7 страницPanel BoarduddinnadeemОценок пока нет

- Submittal ReviewДокумент22 страницыSubmittal ReviewuddinnadeemОценок пока нет

- 15400Документ27 страниц15400uddinnadeemОценок пока нет

- Lightning ProtectionДокумент3 страницыLightning ProtectionuddinnadeemОценок пока нет

- 16716-Voice & Data SystemДокумент13 страниц16716-Voice & Data SystemuddinnadeemОценок пока нет

- 16461-Dry Type TransformerДокумент8 страниц16461-Dry Type TransformeruddinnadeemОценок пока нет

- 16504-Home Automation SystemДокумент23 страницы16504-Home Automation SystemuddinnadeemОценок пока нет

- 16715-Voice & Data CablingДокумент16 страниц16715-Voice & Data Cablinguddinnadeem100% (1)

- ITCC in Riyadh Residential Complex J10-13300 16610-1 UPSДокумент6 страницITCC in Riyadh Residential Complex J10-13300 16610-1 UPSuddinnadeemОценок пока нет

- GroundingДокумент6 страницGroundinguddinnadeemОценок пока нет

- 16453-Grounding & Bonding Telecommunication SystemДокумент6 страниц16453-Grounding & Bonding Telecommunication SystemuddinnadeemОценок пока нет

- LightingДокумент13 страницLightinguddinnadeemОценок пока нет

- BuswayДокумент5 страницBuswayuddinnadeemОценок пока нет

- 16342-Metal Clad MV SWGRДокумент14 страниц16342-Metal Clad MV SWGRuddinnadeemОценок пока нет

- 16410-Swiches & CBДокумент15 страниц16410-Swiches & CBuddinnadeemОценок пока нет

- Package SubstationДокумент9 страницPackage SubstationuddinnadeemОценок пока нет

- GeneratorДокумент19 страницGeneratoruddinnadeemОценок пока нет

- Phoenix Contact DATA SHEETДокумент16 страницPhoenix Contact DATA SHEETShivaniОценок пока нет

- Why Men Want Sex and Women Need Love by Barbara and Allen Pease - ExcerptДокумент27 страницWhy Men Want Sex and Women Need Love by Barbara and Allen Pease - ExcerptCrown Publishing Group62% (34)

- Nursing Management of Anti Fungal DrugsДокумент25 страницNursing Management of Anti Fungal DrugsJennyDaniel100% (1)

- Case Exercise On Layer Unit (2000 Birds)Документ2 страницыCase Exercise On Layer Unit (2000 Birds)Priya KalraОценок пока нет

- Pescatarian Mediterranean Diet Cookbook 2 - Adele TylerДокумент98 страницPescatarian Mediterranean Diet Cookbook 2 - Adele Tylerrabino_rojoОценок пока нет

- PL00002949Документ5 страницPL00002949Nino AlicОценок пока нет

- Evidence Based DesignДокумент4 страницыEvidence Based Designmartinadam82Оценок пока нет

- Plastic As Soil StabilizerДокумент28 страницPlastic As Soil StabilizerKhald Adel KhaldОценок пока нет

- 1.8 SAK Conservations of Biodiversity EX-SITU in SITUДокумент7 страниц1.8 SAK Conservations of Biodiversity EX-SITU in SITUSandipОценок пока нет

- Clinical Features, Evaluation, and Diagnosis of Sepsis in Term and Late Preterm Infants - UpToDateДокумент42 страницыClinical Features, Evaluation, and Diagnosis of Sepsis in Term and Late Preterm Infants - UpToDatedocjime9004Оценок пока нет

- Learning Guide No 5Документ19 страницLearning Guide No 5Menal JemalОценок пока нет

- Starbucks Reconciliation Template & Instructions v20231 - tcm137-84960Документ3 страницыStarbucks Reconciliation Template & Instructions v20231 - tcm137-84960spaljeni1411Оценок пока нет

- CLSI Laboratory Documents Development and Control Approved Guideline NAT L COMM CLINICAL LAB STANDARDS 2006 PDFДокумент100 страницCLSI Laboratory Documents Development and Control Approved Guideline NAT L COMM CLINICAL LAB STANDARDS 2006 PDFErvin RodriguezОценок пока нет

- HOPE 3-Module 8-Week 5-6Документ9 страницHOPE 3-Module 8-Week 5-6Freya SalorОценок пока нет

- ASK-M 72cells Monocrystalline Module: Key FeaturesДокумент2 страницыASK-M 72cells Monocrystalline Module: Key FeaturesNam Tran HoangОценок пока нет

- Thermit Welding (GB) LTD Process ManualsДокумент10 страницThermit Welding (GB) LTD Process ManualsAntónio AlmeidaОценок пока нет

- DTC P1602 Deterioration of Battery: DescriptionДокумент5 страницDTC P1602 Deterioration of Battery: DescriptionEdy SudarsonoОценок пока нет

- ReferensiДокумент4 страницыReferensiyusri polimengoОценок пока нет

- ZL Ap381Документ10 страницZL Ap381micyОценок пока нет

- Foundation Engineering. 02 Soil CompressibilityДокумент63 страницыFoundation Engineering. 02 Soil Compressibilitysammy lopezОценок пока нет

- Cataloge ICARДокумент66 страницCataloge ICARAgoess Oetomo100% (1)

- CASE 721F TIER 4 WHEEL LOADER Operator's Manual PDFДокумент17 страницCASE 721F TIER 4 WHEEL LOADER Operator's Manual PDFfjskedmmsme0% (4)

- Risk Appetite PresentationДокумент10 страницRisk Appetite PresentationAntonyОценок пока нет

- IS 4049-Part-IДокумент5 страницIS 4049-Part-ISrinivas KadivetiОценок пока нет

- NCP Ineffective Breathing ActualДокумент3 страницыNCP Ineffective Breathing ActualArian May Marcos100% (1)

- Celitron ISS 25L - Product Spec Sheet V 2.1 enДокумент9 страницCelitron ISS 25L - Product Spec Sheet V 2.1 enyogadwiprasetyo8_161Оценок пока нет

- Osh e MeerДокумент3 страницыOsh e MeerfatduckОценок пока нет

- Class 7 Work Book Answers Acid Bases and SaltsДокумент2 страницыClass 7 Work Book Answers Acid Bases and SaltsGaurav SethiОценок пока нет

- IWCF Comb. Supv Equip. 01Документ25 страницIWCF Comb. Supv Equip. 01andrzema100% (3)

- Do Statins Lower TestosteroneДокумент3 страницыDo Statins Lower TestosteroneNandia SeptiyoriniОценок пока нет