Академический Документы

Профессиональный Документы

Культура Документы

Power Cycle Piping Scope

Загружено:

JackSparrow86Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Power Cycle Piping Scope

Загружено:

JackSparrow86Авторское право:

Доступные форматы

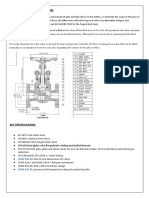

CLAUSE NO.

Scope of Supply & Services

Sub Section III Power cycle Piping

1.00.00

1.01.00

GENERAL

Scope of supply and works for Power Cycle piping system shall include the piping systems as listed below. (a.) Complete main steam, hot reheat & cold reheat piping between boiler and turbine nozzles, HP bypass and LP bypass piping. (b.) Complete auxiliary PRDS & Auxiliary Steam piping system upto TP. (c.) (d.) Complete Feed water piping including booster pumps suction, discharge, boiler feed discharge piping, re-circulation, BFP warm up (if applicable), leak off. BFP turbine exhaust to condenser.

(e.) All extraction steam piping (f.) Spray piping system for the following. (1.) Reheater attemperation, (2.) Superheater attemperation (3.) Auxiliary PRDS system (4.) HP/ LP Bypass system (g.) Condensate piping and makeup system. (h.) Heater drains and vents piping system. (i.) (j.) (k.) (l.) Steam drains from piping /equipment(s) in the scope of bidder. Valve gland sealing piping system. Miscellaneous line drains and vents. Complete safety valve exhaust piping for SVs on Heaters, Deaerator and Auxiliary PRDS and piping in Bidders scpoe.

(m.) Complete steam blowing piping system (Temporary). (j) Complete chemical cleaning piping system (Temporary).

(k) Flash tanks including drain and vent piping. (l) HP Bypass & LP bypass warm-up line.

(m) Any other piping system required to make the power cycle piping, in the bidders scope, complete.

KODERMA TPS ( 2 X 500 MW) POWER PLANT TURNKEY PACKAGE

Bid Doc. No.: CS9451-108-2

TECHNICAL SPECIFICATIONS SECTION VI, A

Sub section III-A-03 Power Cycle Piping

Page 1 of 7

CLAUSE NO.

Scope of Supply & Services Design, manufacture, supply, erection, testing and commissioning of complete piping /fittings/ accessories, valves and specialties, strainers, expansion joints, snubbers, restraints, hangers/ supports with all components, thermal insulation and auxiliary structures including structure in C-D Bay, , etc., for the above piping systems. For the above piping system scope shall include complete design and engineering including but not limited to pipe sizing, flexibility and dynamic analysis, hanger / snubber support engineering, engineering of thermal insulation etc. and shall be to Employer's review and approval. Steam blowing of piping systems, as specified elsewhere in the specification, after complete erection is to be carried out, which includes supply, erection and dismantling of temporary piping, valves and fittings etc. Chemical cleaning of piping systems, as specified elsewhere in the technical specification, after complete erection is to be carried out, which also includes complete supply, erection and dismantling of temporary piping, valves and fittings etc.

1.02.00

1.03.00

1.04.00

1.05.00

Providing other necessary services for making the piping systems in bidders scope complete. All paints and primers as required and suitable for environment / conditions prevailing at site. All supplies, works, services shall comply with the detailed scope given in the subsequent clauses of this Sub-section. LP dosing system complete with dosing pumps, tanks, associated piping, fittings, valves, instrumentation & control etc. shall be provided as specified elsewhere.

1.06.00

1.07.00

1.08.00

2.00.00

2.01.00

SCOPE OF SUPPLY.

Pipes and fittings (a.) Piping, fittings, plugs, flanges, caps, steam traps, break-down orifice, drip pan and other accessories for the piping systems identified above and as per approved schemes. (b.) The contractor shall supply all standard and non-standard matching pieces as may be needed for connection of piping systems with equipment terminals. (c.) Pipe stubs for mounting thermowells and other instrumentation, including for the instruments supplied by others, along with necessary root valves, reducers / matching pieces and instrument tubing

(d.) Thermal insulation and cladding along with all necessary accessories for all piping systems, equipment and tanks etc. in bidders scope.

KODERMA TPS ( 2 X 500 MW) POWER PLANT TURNKEY PACKAGE

Bid Doc. No.: CS9451-108-2

TECHNICAL SPECIFICATIONS SECTION VI, PART-A

SubSection-III-A-03 Power Cycle piping

Page 2 of 7

CLAUSE NO.

Scope of Supply & Services (e.) The contractor shall also design and provide for additional guides/ stops/restraints/ snubbers/ dampers, etc. along with auxiliary steel for control of pipe line vibration within allowable/ acceptable limits (f.) Supply and installation of creep measuring instrument on the piping operating in creep region viz. Main steam and Hot Reheat

2.02.00

Valves and Specialties Valves, safety valves, safety relief valves, valve actuators and specialties including orifice plate assemblies, steam traps, strainers, instrument root valves, etc. for the systems specified The Contractor shall also supply special accessories like floor stands, chain operator, extended spindle etc. as required. Valve, especially for which approach from existing floors are not possible for O&M, bidder shall provide appropriate platforms with the access ladders for the same.

2.03.00

Hangers and Supports All pipe supporting elements such as constant load spring hangers, variable spring hangers, supports, guides, restraints, stops, etc. and all associated auxiliary steel and hardware such as beams, channels, insert plates section attachments to pipe supports, pipe and beam clamps, straps, slings, stools, shoes, saddles, devices, rods, turn buckles, graphite/steel plate / Teflon sheet etc. for all the systems specified.

2.04.00

Snubbers Snubbers or shock absorbers as required on the main steam, hot reheat, cold reheat, HP/LP bypass piping etc. to take up forces due to impact and surge forces arising from sudden closure of turbine stop valves and blowing of safety valves. The requirement of snubbers will be decided by the Contractor while undertaking dynamic analysis of the piping systems. The snubbers shall be hydraulic type. It will be responsibility of the contractor to do the static/ dynamic analysis for complete piping systems as required. Also it will be the responsibility of the contractor to engineer and supply snubbers required for the above piping systems

2.05.00

Miscellaneous Erection and cleaning Materials (a.) All erection material such as bolts, nuts, washers, gaskets, electrodes, filler materials, welding gas, consumable inserts and backing rings, accessories and miscellaneous specialties required for the proper installation of piping systems. (b.) All temporary piping, supports, valves, blanking plates, plugs, target plates, spool pieces for valves, flow nozzles & specialties and other accessories required to complete the steam blowing operation and Hydro testing of piping systems as specified.

3.00.00

SCOPE OF OTHER SERVICES

KODERMA TPS ( 2 X 500 MW) POWER PLANT TURNKEY PACKAGE

Bid Doc. No.: CS9451-108-2

TECHNICAL SPECIFICATIONS SECTION VI, A

Sub section III-A-03 Power Cycle Piping

Page 3 of 7

CLAUSE NO.

Scope of Supply & Services Complete design, engineering, etc. for the power cycle piping systems and other piping systems included in this specification shall be the responsibility of the Contractor. Employer's responsibility/ function in this connection shall be limited to review and approval of Bidder's design/ calculation, engineering, drawings, documents. Bidder's scope of services for complete engineering of the power cycle piping systems shall include but not be limited to the following : (a.) Preparation of engineering piping diagram indicating flow schematic, flow parameter, pipe sizes, line designations and tag nos. of various components etc. and submission of same to Employer for review. (b.) Design parameter selection, pipe sizing calculation, pipe schedule, valve schedule, insulation schedule, specialties schedule and hanger schedule for the systems included in the Bidder's scope. (c.) Preparation of preliminary as well as final composite piping layout drawings and isometric drawing of pipe size 65mm NB & above and submission of same to Employer for review and approval.

3.01.00

(d.) Preparation of fabrication and erection isometric (with material take off) drawings for shop fabricated piping which are of size 65 mm NB and above and submission of the same to the Employer for review and approval . (e.) Preparation of layout drawings for site routed piping and submission of the same to the Employer for records. (f.) AS BUILT" drawing of the piping layout shall also be prepared by the Contractor based on any layout modifications made at site and submitted to Employer for records.

(g.) Approval from Statutory Authorities (1.) It is the sole responsibility of the contractor to identify and obtain all necessary approvals from various Government agencies/board/statutory authorities/IBR etc., as applicable for the design, manufacture and testing of pipes, valves, fittings, specialties etc. (2.) The contractor shall also identify and obtain all necessary approvals from the IBR authority in the state where the plant is being installed, for the erection/testing/commissioning and any other requirement as required by IBR. (3.) In order to obtain the above approvals, all necessary documentation etc. required shall be arranged and furnished by the Contractor to the statutory authorities. 3.02.00 The Contractor shall design in detail all piping supports including restraints, guides, stops, snubbers etc., after deciding the final location of hangers and supports and based on final stress analysis/ dynamic analysis and hanger/ support load data originated by him. Bidder shall submit to Employer for review his hanger design document in the form of hanger GA drawings and hanger schedule.

KODERMA TPS ( 2 X 500 MW) POWER PLANT TURNKEY PACKAGE

Bid Doc. No.: CS9451-108-2

TECHNICAL SPECIFICATIONS SECTION VI, PART-A

SubSection-III-A-03 Power Cycle piping

Page 4 of 7

CLAUSE NO.

Scope of Supply & Services The Contractor shall furnish separate sketches for each hanger/ support, restraint, anchor, etc. These sketches shall include the location with reference to column coordinates, identification number, bills of material, design loads, operating load, spring stiffness, amount of spring pre-compression etc., the method of attachment to the pipe and steel structure. Additionally the sketches shall show a key plan referenced to plant north and centre line elevation of the pipe at the point of attachment for cold and hot conditions. In order to ensure that all supporting elements, anchor and restraints have been installed and adjusted in accordance with design documentation, the Contractor shall inspect and log the hanger readings for the hangers associated with the power cycle piping system as follows: (a.) After hydrostatic test with the piping in the cold position, with all travel stops removed, with the pipe completely insulated and in all respect ready for startup. (b.) Piping in hot position, with the unit operating at rated parameters (c.) Piping in hot position (rated parameter condition) after six (6) months of operation

3.03.00

3.04.00

(d.) Piping in cold position during the first complete shutdown after at least six (6) months of operation. (e.) After steam blowing, in case steam blowing is applicable for the line 3.05.00 At the time of each inspection, the Contractor will determine the necessity for revision, adjustment or replacement of pipe supporting elements, restraints and anchors. Any changes proposed shall be subject to the concurrence of the Employer. The changes shall be incorporated by the Bidder after Employer's concurrence. A written record shall be furnished to the Employer. Design and engineering of all temporary piping that are required for the commissioning activities of power cycle piping system shall be as specified herein. All shop tests as required by the applicable codes, ANSI Standards, IBR and other standards enumerated or specified. (a.) Obtaining approval from Chief Inspector of Boiler as per Indian Boiler Regulations (IBR - 1950). This shall include furnishing all necessary certificates for design, manufacture and testing for pipe, valves, fittings, specialties, certificate of manufacture and test for each erected piping in the relevant formats to the Chief Inspector of Boilers, obtaining his approval and furnishing the same to the Employer. (b.) The Contractor shall also identify and satisfy all other statutory code requirements as may be required for the piping systems covered in this specification. 3.08.00 Certified copies of test reports for all tests and examinations specified in the specification and for the mandatory test and analysis required by ASME/ ASTM

3.06.00

3.07.00

KODERMA TPS ( 2 X 500 MW) POWER PLANT TURNKEY PACKAGE

Bid Doc. No.: CS9451-108-2

TECHNICAL SPECIFICATIONS SECTION VI, A

Sub section III-A-03 Power Cycle Piping

Page 5 of 7

CLAUSE NO.

Scope of Supply & Services material specification, for the materials used for piping, shall be furnished to Employer.

3.09.00

Drawings, data and design calculations as specified in this Sub-section and elsewhere in the specification shall be furnished by the Contractor to the Employer for review. Cleaning including steam blowing & chemical cleaning of all applicable systems (as specified herein) and installation of temporary pipe work for the same. Making temporary closures on piping system as required for hydrostatic testing and performing hydrostatic test on all piping Making interface piping connections (for the piping in contractors scope) at TP with equipment / piping etc. as applicable. Installation/mounting of pipe mounted items, supplied by employer/others, on the piping system. Providing complete interface engineering with the suppliers of other equipment and piping with which the piping systems in the contractors scope is to be connected or have interface in any other way. Performing all tests and implementing all quality control procedures as specified herein including provision of testing equipment, stress relieving equipment, radiography equipment and any other equipment necessary to meet the requirements of the specification. Apart from carrying out steam blowing & chemical cleaning, the work shall include disposal of water, clean up, reinstatement of the cleaned piping system, dismantling and removal all temporary piping, equipment and materials from site. Final painting of piping system in accordance with the stipulations laid down elsewhere in this specification. Weather hood for pipes crossing ceilings and walls. Stress / Dynamic Analysis The Contractor shall carryout stress analysis of piping system and submits for Employers approval. Contractor shall also carryout the dynamic analysis of piping systems as required and submitted for employer's approval. (a.) A write up on the stress analysis /dynamic analysis design conditions considered. including codes used and

3.10.00

3.11.00

3.12.00

3.13.00

3.14.00

3.15.00

3.16.00

3.17.00

3.18.00 3.19.00

(b.) A copy of the computer print out for input data for the various design conditions considered for stress analysis along with the stress diagram ( piping isometric marked with node points marked.)

KODERMA TPS ( 2 X 500 MW) POWER PLANT TURNKEY PACKAGE TECHNICAL SPECIFICATIONS SECTION VI, PART-A SubSection-III-A-03 Power Cycle piping

Bid Doc. No.: CS9451-108-2

Page 6 of 7

CLAUSE NO.

Scope of Supply & Services (c.) Analysis results in tabular form giving calculated and allowable reactions/forces/moments on equipment nozzles / terminals for the various design conditions considered for analysis.

(d.) Allowable and calculated code stresses at various node points in the piping for the design conditions considered based on code requirements for analysis. (e.) Analysis results giving calculated forces and moments and movements at various hanger/support/restraint/anchor points from dynamic analysis as well as from the static analysis corresponding to various thermal /operating conditions, sustained load case, hydro load case (other than water lines) and occasional loads ,as applicable, for each piping system analysed .

KODERMA TPS ( 2 X 500 MW) POWER PLANT TURNKEY PACKAGE

Bid Doc. No.: CS9451-108-2

TECHNICAL SPECIFICATIONS SECTION VI, A

Sub section III-A-03 Power Cycle Piping

Page 7 of 7

Вам также может понравиться

- AnswersДокумент3 страницыAnswersrajuraikar100% (1)

- HRSG Equipment DimensionsДокумент15 страницHRSG Equipment Dimensionsshaikhsajid242100% (1)

- Boiler Documentation OverviewДокумент90 страницBoiler Documentation Overviewmaneesh_0375% (4)

- Duyen Hai 3 Thermal Power Project Commissioning ProcedureДокумент24 страницыDuyen Hai 3 Thermal Power Project Commissioning ProcedureLan Rung100% (1)

- Boiler Erection 1Документ30 страницBoiler Erection 1Sam100% (1)

- BFP BHEL Manual For 500MWДокумент675 страницBFP BHEL Manual For 500MWtanumay.gemini83% (12)

- TDBFP ManulДокумент266 страницTDBFP ManulJackSparrow8678% (9)

- BFP BHEL Manual For 500MWДокумент675 страницBFP BHEL Manual For 500MWtanumay.gemini83% (12)

- Startup and Shutdown ProcedureДокумент16 страницStartup and Shutdown Procedurevardan_vardan100% (3)

- Bypass ControllerДокумент4 страницыBypass Controllernjc6151Оценок пока нет

- Formal 17 12 04 PDFДокумент184 страницыFormal 17 12 04 PDFJose LaraОценок пока нет

- FZ16 9B 1KD2 (Patada) PDFДокумент62 страницыFZ16 9B 1KD2 (Patada) PDFPanthukalathil Ram100% (1)

- INSPECTION AND TEST PLAN FOR AIR PREHEATERДокумент27 страницINSPECTION AND TEST PLAN FOR AIR PREHEATERBui van DiepОценок пока нет

- 3.2 Big Block Assembly 3.2.1 Work Shop Assembly Pre-RequisitionsДокумент14 страниц3.2 Big Block Assembly 3.2.1 Work Shop Assembly Pre-RequisitionsEur-Ing Nicola GalluzziОценок пока нет

- Super Heater Trouble Shooting Report at A Hi Plant by KKPДокумент68 страницSuper Heater Trouble Shooting Report at A Hi Plant by KKPparthi20065768100% (2)

- Presentation BoilerДокумент24 страницыPresentation BoilerRanjanaWaje100% (1)

- Unit Operating ProcedureДокумент60 страницUnit Operating ProcedurepurvgargОценок пока нет

- 660MW Air Cooled CondenserДокумент26 страниц660MW Air Cooled CondenserRaj_Jai030% (1)

- Erection Procedure Rev 0Документ5 страницErection Procedure Rev 0Arturo Suarez VillaoОценок пока нет

- Super-Critical BoilerДокумент32 страницыSuper-Critical BoilerSURENDRA KUMARОценок пока нет

- AFBC BoilerДокумент12 страницAFBC BoilerNaman Sharma0% (1)

- Vol-Ii B936Документ113 страницVol-Ii B936Anonymous uXdS9Y7Оценок пока нет

- Maintenance BFPДокумент28 страницMaintenance BFPYulianto Kartono100% (1)

- Cold Start Up Check ListДокумент6 страницCold Start Up Check ListSreekanthMylavarapuОценок пока нет

- First Fill Bed Material Calculation For Bed Plate W DДокумент3 страницыFirst Fill Bed Material Calculation For Bed Plate W DRAJKUMARОценок пока нет

- BFP TDДокумент22 страницыBFP TDArvind ShuklaОценок пока нет

- Heat Recovery Steam GeneratorДокумент69 страницHeat Recovery Steam GeneratorAayushi Agarwal100% (5)

- Bhatia Gummidipoondi WHRSG O&m Manual FinalДокумент224 страницыBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadОценок пока нет

- PE3.3.9 Boiler OperationДокумент15 страницPE3.3.9 Boiler Operationdennishay100% (5)

- Procedure For Commissioning of Auxiliary Prds SystemДокумент14 страницProcedure For Commissioning of Auxiliary Prds SystemJackSparrow86100% (1)

- Condenser Flood Test 8 of 11Документ14 страницCondenser Flood Test 8 of 11Sara LopezОценок пока нет

- List of CHP EquipmentsДокумент7 страницList of CHP EquipmentsbrockОценок пока нет

- Write Up On Aux PrdsДокумент6 страницWrite Up On Aux PrdsYousuf AliОценок пока нет

- Terminal Points for Main Plant EquipmentДокумент6 страницTerminal Points for Main Plant Equipmentpunitg_2Оценок пока нет

- My Latest CV - EngineerДокумент3 страницыMy Latest CV - EngineersasibhushanОценок пока нет

- Boiler: Sabari Girish N Sr. Engineer (O)Документ37 страницBoiler: Sabari Girish N Sr. Engineer (O)Deepak SinghОценок пока нет

- 20TPH Dump Condenser Datasheet 12-1-2022Документ4 страницы20TPH Dump Condenser Datasheet 12-1-2022Manoj BОценок пока нет

- 125 - Performance Guarantee - Maan - R4Документ4 страницы125 - Performance Guarantee - Maan - R4Ahmad ShekhОценок пока нет

- HRSG StartupДокумент20 страницHRSG Startupsujiv_sujiv1278100% (1)

- Flue Gas System Air Pre Heater: May 24, 2012 PMI Revision 00 1Документ56 страницFlue Gas System Air Pre Heater: May 24, 2012 PMI Revision 00 1ASHIL PRABHAKARОценок пока нет

- Energy Management System For Combined Cycle Power Plant TrainingДокумент4 страницыEnergy Management System For Combined Cycle Power Plant Trainingglenlcy100% (1)

- Bhel Pipe Color Code-Aa10630 1Документ7 страницBhel Pipe Color Code-Aa10630 1Vamsikrishna LakamsaniОценок пока нет

- Thermal Power Plant Color Code For Piping PDFДокумент11 страницThermal Power Plant Color Code For Piping PDFalwynnithinherbert50% (4)

- Commissioning Steps Power Plant Under 40Документ3 страницыCommissioning Steps Power Plant Under 40ssheart_mind100% (1)

- TurboДокумент8 страницTurboKorichiKarimОценок пока нет

- ABB+Marine WHRS+infographicДокумент1 страницаABB+Marine WHRS+infographicBenjamin StricklandОценок пока нет

- Thermal Power Plant BasicДокумент19 страницThermal Power Plant Basicravikant singhОценок пока нет

- Hrsgs Behind FR 9E GTS: (123.4 MW Iso)Документ20 страницHrsgs Behind FR 9E GTS: (123.4 MW Iso)api-19986783100% (1)

- Design and Analysis of Boiler Pressure Vessels Based On IBR CodesДокумент9 страницDesign and Analysis of Boiler Pressure Vessels Based On IBR Codesgermantoledo244596Оценок пока нет

- Commissioning Procedure of Boiler Ignition SystemДокумент7 страницCommissioning Procedure of Boiler Ignition SystemJ Bagien100% (1)

- TechnicalDiary500MW SGTPPДокумент254 страницыTechnicalDiary500MW SGTPPJoydev Ganguly100% (2)

- Steam Turbine SpecificationДокумент43 страницыSteam Turbine SpecificationPulkit Agarwal100% (2)

- Supercritical PMIДокумент76 страницSupercritical PMIVinod Mahajan100% (1)

- Globe Valve Bs 1873 and Api 602: ASME B16.10Документ7 страницGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILОценок пока нет

- Boiler Types and Classifications - WikiДокумент21 страницаBoiler Types and Classifications - WikiKarthik ChillaОценок пока нет

- Super Critical Boiler Cycle GuideДокумент32 страницыSuper Critical Boiler Cycle GuideJayaraman Kamaraj100% (1)

- Once Through: Steam GeneratorsДокумент21 страницаOnce Through: Steam GeneratorsrajrampallyОценок пока нет

- Installation of Auxiliary Steam Boiler PackageДокумент10 страницInstallation of Auxiliary Steam Boiler Packagesharif339Оценок пока нет

- Boiler Tube Repair PracticeДокумент1 страницаBoiler Tube Repair PracticejagyanduttaОценок пока нет

- Stack SpecДокумент10 страницStack SpecHoney TiwariОценок пока нет

- Chap 28 PDFДокумент30 страницChap 28 PDFnelson escuderoОценок пока нет

- Spiral Wall System PDFДокумент22 страницыSpiral Wall System PDFSomdeb Banerjee100% (1)

- CCW Pump First Trial Run Check ListДокумент8 страницCCW Pump First Trial Run Check ListA.PRABHAKARANОценок пока нет

- SUR - Erection BOQ - ST & Geno - Rev AДокумент5 страницSUR - Erection BOQ - ST & Geno - Rev Ashaikhsajid242Оценок пока нет

- Modern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantОт EverandModern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantA. SherryРейтинг: 4 из 5 звезд4/5 (5)

- Specification Plumbing SystemДокумент16 страницSpecification Plumbing SystemGhiovani DayananОценок пока нет

- Sub-Section - A-9: Power Cycle PipingДокумент324 страницыSub-Section - A-9: Power Cycle PipingSugadev SinghОценок пока нет

- Technical Specifications - PlumbingДокумент19 страницTechnical Specifications - PlumbingVicVicОценок пока нет

- Operation Procedures For MDBFPДокумент7 страницOperation Procedures For MDBFPJackSparrow86100% (1)

- Difficulties FacedДокумент6 страницDifficulties FacedJackSparrow86Оценок пока нет

- Air Pre HeatingДокумент85 страницAir Pre Heatingmn_sundaraamОценок пока нет

- BFP TDДокумент22 страницыBFP TDJackSparrow8650% (2)

- Difficulties FacedДокумент6 страницDifficulties FacedJackSparrow86Оценок пока нет

- Air Preheater RetrofitДокумент16 страницAir Preheater RetrofitMallinatha PN100% (1)

- 1 212 AirPreheater Ljungstrom-DetailsДокумент14 страниц1 212 AirPreheater Ljungstrom-DetailsAmit Prajapati100% (2)

- BFP TDДокумент22 страницыBFP TDJackSparrow8650% (2)

- Operation Procedures For MDBFPДокумент7 страницOperation Procedures For MDBFPJackSparrow86100% (1)

- Interlocks & Protections-NTPCДокумент87 страницInterlocks & Protections-NTPCJackSparrow86100% (2)

- Crane HoistДокумент6 страницCrane HoistJackSparrow86Оценок пока нет

- Procedure For Bearing and Jack Oil Intial CirculationДокумент11 страницProcedure For Bearing and Jack Oil Intial CirculationLakshmi NarayanОценок пока нет

- Procedure For Governing Oil SystemДокумент29 страницProcedure For Governing Oil SystemLakshmi NarayanОценок пока нет

- TDBFP Main Control Valve SettingДокумент1 страницаTDBFP Main Control Valve SettingJackSparrow86Оценок пока нет

- KAHALGAON PROTECTIONSДокумент89 страницKAHALGAON PROTECTIONSJackSparrow8657% (7)

- TDBFP Auxiliary Control Valve SettingДокумент1 страницаTDBFP Auxiliary Control Valve SettingJackSparrow86Оценок пока нет

- Procedure For Condenser Flood Test and Vacuum Tightness TestДокумент13 страницProcedure For Condenser Flood Test and Vacuum Tightness TestJackSparrow86Оценок пока нет

- Alstom's Flexible Supercritical PowerДокумент34 страницыAlstom's Flexible Supercritical PowerelrajilОценок пока нет

- Procedure For Commissioning of Central Lube Oil Storage & Purification SystemДокумент12 страницProcedure For Commissioning of Central Lube Oil Storage & Purification SystemLakshmi NarayanОценок пока нет

- Low pressure bypass system controlДокумент7 страницLow pressure bypass system controlJackSparrow86Оценок пока нет

- TDBFP Main Control Valve SettingДокумент1 страницаTDBFP Main Control Valve SettingJackSparrow86Оценок пока нет

- HP LP Bypass System (Turbine)Документ9 страницHP LP Bypass System (Turbine)Debasish Dewan67% (3)

- BFP TDДокумент22 страницыBFP TDJackSparrow8650% (2)

- Testing Schedule For Turbine On Barring GearДокумент14 страницTesting Schedule For Turbine On Barring GearJackSparrow86Оценок пока нет

- Easyjet Group6Документ11 страницEasyjet Group6Rishabh RakhechaОценок пока нет

- Synopsis: A Study On Customer Satisfaction AT Nerolac Paints LTD., KadapaДокумент5 страницSynopsis: A Study On Customer Satisfaction AT Nerolac Paints LTD., KadapaAnu GraphicsОценок пока нет

- Coupled Mode TheoryДокумент5 страницCoupled Mode TheoryRahul RoyОценок пока нет

- Letter of Recommendation For Nicolas Hallett From Big Ten Network's Casey Peterson.Документ1 страницаLetter of Recommendation For Nicolas Hallett From Big Ten Network's Casey Peterson.Nic HallettОценок пока нет

- Superior University: 5Mwp Solar Power Plant ProjectДокумент3 страницыSuperior University: 5Mwp Solar Power Plant ProjectdaniyalОценок пока нет

- Harry Styles: The Rise of a Pop StarДокумент9 страницHarry Styles: The Rise of a Pop StarBilqis LaudyaОценок пока нет

- Dubai Healthcare Providers DirectoryДокумент30 страницDubai Healthcare Providers DirectoryBrave Ali KhatriОценок пока нет

- Exp19 Excel Ch08 HOEAssessment Robert's Flooring InstructionsДокумент1 страницаExp19 Excel Ch08 HOEAssessment Robert's Flooring InstructionsMuhammad ArslanОценок пока нет

- Mint Delhi 13-12-2022Документ18 страницMint Delhi 13-12-2022Ayush sethОценок пока нет

- Macdonald v. National City Bank of New YorkДокумент6 страницMacdonald v. National City Bank of New YorkSecret SecretОценок пока нет

- Afar Partnerships Ms. Ellery D. de Leon: True or FalseДокумент6 страницAfar Partnerships Ms. Ellery D. de Leon: True or FalsePat DrezaОценок пока нет

- Maximizing Revenue of IT Project DevelopmentДокумент4 страницыMaximizing Revenue of IT Project DevelopmentJulius Mark CerrudoОценок пока нет

- How To: Create A Clickable Table of Contents (TOC)Документ10 страницHow To: Create A Clickable Table of Contents (TOC)Xuan Mai Nguyen ThiОценок пока нет

- Instruction/Special Maintenance Instruction (IN/SMI)Документ2 страницыInstruction/Special Maintenance Instruction (IN/SMI)ANURAJM44Оценок пока нет

- UPGRADEДокумент2 страницыUPGRADEVedansh OswalОценок пока нет

- High Uric CidДокумент3 страницыHigh Uric Cidsarup007Оценок пока нет

- Trustees Under IndenturesДокумент233 страницыTrustees Under IndenturesPaul9268100% (6)

- S0231689H02-B01-0001 Rev 02 Code 1 General Arrangement Drawing For 44 Kva Diesel Generator PDFДокумент6 страницS0231689H02-B01-0001 Rev 02 Code 1 General Arrangement Drawing For 44 Kva Diesel Generator PDFAnonymous AfjzJdnОценок пока нет

- Iqvia PDFДокумент1 страницаIqvia PDFSaksham DabasОценок пока нет

- Programming in Java Assignment 8: NPTEL Online Certification Courses Indian Institute of Technology KharagpurДокумент4 страницыProgramming in Java Assignment 8: NPTEL Online Certification Courses Indian Institute of Technology KharagpurPawan NaniОценок пока нет

- Axtraxng™: Networked Access Control Management Software V27.XДокумент2 страницыAxtraxng™: Networked Access Control Management Software V27.XChiluvuri VarmaОценок пока нет

- WSM 0000410 01Документ64 страницыWSM 0000410 01Viktor Sebastian Morales CabreraОценок пока нет

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDДокумент6 страницMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaОценок пока нет

- Building A Computer AssignmentДокумент3 страницыBuilding A Computer AssignmentRajaughn GunterОценок пока нет

- Coa - Ofx-8040a (H078K5G018)Документ2 страницыCoa - Ofx-8040a (H078K5G018)Jaleel AhmedОценок пока нет

- Illustrator CourseДокумент101 страницаIllustrator CourseGreivanОценок пока нет

- Current Affairs Q&A PDF June 9 2023 by Affairscloud 1Документ21 страницаCurrent Affairs Q&A PDF June 9 2023 by Affairscloud 1Yashika GuptaОценок пока нет