Академический Документы

Профессиональный Документы

Культура Документы

Mortar Testing Tools and Machines

Загружено:

Kelvin LoriaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mortar Testing Tools and Machines

Загружено:

Kelvin LoriaАвторское право:

Доступные форматы

KELVIN AUSTIN A.

LORIA

TEST FOR MORTAR

CE 413c

Mortar Testing

What is a MORTAR (MASONRY)?

Mortar is a workable paste used to bind construction blocks together and fill the gaps between them. The blocks may be stone, brick, cinder blocks, etc. Mortar becomes hard when it sets, resulting in a rigid aggregate structure. Modern mortars are typically made from a mixture of sand, a binder such as cement or lime, and water. Mortar can also be used to fix, or point, masonry when the original mortar has washed away.

The following tests are conducted on the prepared mortars to ensure their quality: 1. Crushing Test 2. Tensile Strength Test 3. Adhesive Test 4. Setting Test 1. CRUSHING TEST: Brick masonry or stone masonry lay in mortar to be tested in crushed in compression testing machine. The masonry crushes gives the crushing strength to which suitable factor of safety may be applied to get the safe strength. Approximate safe strength of mason with few types of mortars are given below Burnt brick masonry in cement mortar 1:3 Burnt brick masonry in cement mortar 1:6 Burnt brick masonry in cement mortar (1 lime:3 sand) Burnt brick masonry in cement mortar (1:1:6 or 1:2:9) 2. TENSILE STRENGTH TEST: The mortar prepared is placed in a mould of bricket which has central cross-sectional area as 38 mm 38 mm. After curing the briquette [Fig. 2.3] is pulled under the grips of tensile testing machine. The ultimate load noted. Then the tensile strength of mortar is load divided by the central cross-sectional area. 750 KN/ sq. m 450 KN/ sq. m 450 KN/ sq. m 500 KN/ sq. m

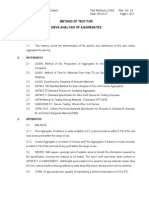

TEST OF MORTARS

KELVIN AUSTIN A. LORIA 3. ADHESIVE TEST:

TEST FOR MORTAR

CE 413c

Two bricks are joined together with mortar to be tested as shown in Fig. 2.4. The upper brick is suspended from an overhead support. A board is hung from the lower brick. Then weights are added to the board till the bricks separate. The adhesive strength is the load divided by area of contact.

4. TESTING FOR SETTING: Mortar is tested in VICAT APPARATUS for the setting time. The test may conducted after one day, 3 days or 1 week depending on the type of lime mortar. For cement mortar, this test is conducted within 3 to 5 minutes of adding water.

TOOLS AND MACHINES FOR TESTING This section introduces products used to evaluate compression, tensile strength, soundness, expansion, and setting time of cement mortar.

Cube Mold Set The cube mold set is used to prepare 2 in. (51 mm) cube specimens of high strength materials for compression testing, such as lime, Portland cement, mortars, capping compound and gypsum. The three gang, in line mold is made from machined brass and employs polyethylene liners to contain the samples and eliminate mold clean-up. Supplied as a kit. Order C-23707 for replacement plastic liners. Applicable Standards: ASTM C 87, C 109, C 141, C 257, C 267, C 306, C 472, C 379, C 396 AASHTO T-106. Durham Geo also carries bronze and plastic cube molds, cube test sand, and tensile sand. Mortar Mixer The mortar mixer is used for mixing cement and mortar pastes. The heavy duty mixer has 3 operating speeds, lever to adjust the height of the 5 qt (4.73 L) bowl and a planetary mixing action to ensure thorough and complete mixing. Supplied complete with a stainless steel bowl, flat beater and a wire whip. Applicable Standards: ASTM C 305 AASHTO T-162

KELVIN AUSTIN A. LORIA

TEST FOR MORTAR

CE 413c

Length Comparator The Length Comparator allows measurement of the changes in length of cement/mortar and concrete test bar specimens. The instrument is provided with substantial rigidity through the use of a solid frame and cast steel base. The lower fixed anvil and the upper movable anvil are designed to accept the cast-in points of the specimen bars. The comparator includes a precision dial indicator and an Invar steel reference bar. Applicable Standards: ASTM C 151, C227, C 490, C 531, C 359 AASHTO T-107, T-160 Specimen Contact Points The precision machined, stainless steel Specimen Contact Points, 0.25 in. diameter and 0.75 in. long, are cast into the specimen cement bars. They are used as reference points when placed in the Length Comparator. Applicable Standards: ASTM C 151, C 151, C 227, C 490 AASHTO T-107, T-160

Cement/Mortar Autoclave The Cement/Mortar Autoclave is used to conduct accelerated soundness test or autoclave expansion test on cement mixtures. Designed to provide a constant steam pressure, adjustable between 60 to 350 psi (414 to 2413 kN/m2), at a constant temperature.

Test Specimen Holder The test specimen holder is used to hold bar specimens in an upright position when placed in the cement/mortar autoclave. It ensures that each of up to eight specimens are exposed to the pressurized steam in the same way. The holder is made from corrosion resistant materials. Applicable Standards: ASTM C 141, C 151 AASHTO T107

Bar Molds Bar molds produce standard sized specimens for accelerated soundness testing using the autoclave. Available in three types for 10 in. (25.4 cm) long bar specimens. Applicable Standards: ASTM C 141, C 151 AASHTO T-107 < Flow Table The flow table provides an efficient means of determining the flow of cement pastes and hydraulic cement mortars. A specific volume of material is molded on the table using the included flow mold. The mold is then removed and the table subjected to a specific number of 1/2 in. (12.7 mm) drops using the crank handle. The increase in average diameter of the sample indicates the flow. An electric model is also available.

KELVIN AUSTIN A. LORIA

TEST FOR MORTAR

CE 413c

Mortar Penetrometer The mortar penetrometer is used to determine the rate of hardening of the mortar component of fresh concrete. The mortar is extracted by sieving. Measurement is made by first attaching one of the six penetration needles to the calibrated spring dynamometer. The Penetrometer is then pushed into the sample and the sliding will indicate the maximum test reading on the handle stem. Blaine Air Permeability Apparatus The Blaine Apparatus is used to determine the fineness of Portland cement. The fineness is measured in terms of the specific area of cement expressed as total surface area in square centimeters per gram of cement. The apparatus consists of a stainless steel test cell incorporating a perforated disc and plunger with a ground joint for the test cell to attach to a calibrated U-tube manometer. A stopcock and rubber bulb are attached to the manometer to provide a means to draw a definite air volume through the test cell. It is supplied with an 8 oz (240 ml) bottle of red manometer fluid, filter paper, a wood block to hold the test cell during filling and a funnel. It is mounted on a finished wood panel. Applicable Standards: ASTM C 204 AASHTO T-153 Gilmore Apparatus The Gilmore Apparatus determines the time of set for cement. It comprises a rigid aluminum and steel frame with two precisely machined stainless steel points and associated weights. Applicable Standards: ASTM C 91, C 141, C266, C 266 AASHTO T-154

Portable Mixers Portable Mixers are used in the laboratory to prepare concrete or cement/mortar batch mixes. They have a dry batch capacity of 3 cubic feet (85 L). Optional wheel kit available to move mixer about laboratory. Inquire as to other models available as special orders from 1-1/2 to 9 cubic ft. and powered by either electric motor or gasoline engines.

Masonry Saw The C-825, Electric Masonry Saw, accepts a 14-in diameter blade with a 1-in diamater arbor. The saw can be used for wet or dry cutting of concrete, cores, blocks, rock and masonry. A 5 hp gasoline engine version is also available.

Вам также может понравиться

- CementДокумент28 страницCementhboespn100% (1)

- 3 Ways To Measure Mortar Consistency - tcm68-1375847 PDFДокумент3 страницы3 Ways To Measure Mortar Consistency - tcm68-1375847 PDFJay PatelОценок пока нет

- Bond and Compressive Strength of Masonry For Locally Available BricksДокумент8 страницBond and Compressive Strength of Masonry For Locally Available BricksKamran JavedОценок пока нет

- Fineness Test On CementДокумент13 страницFineness Test On CementTvsp Sekhar50% (2)

- Hardened ConcreteДокумент50 страницHardened ConcreteMayank KapriОценок пока нет

- Compaction Factor Test&Slump Test ReportДокумент1 страницаCompaction Factor Test&Slump Test ReportMUN SIM SOHОценок пока нет

- Conrete Mix Design & Making and Curing of Test SpecimenДокумент15 страницConrete Mix Design & Making and Curing of Test SpecimenBlesОценок пока нет

- Testing of Cement: Free Powerpoint Templates Free Powerpoint TemplatesДокумент23 страницыTesting of Cement: Free Powerpoint Templates Free Powerpoint TemplatesVivekChaudharyОценок пока нет

- Concret CementДокумент29 страницConcret CementKamal Hameed Al-taiy100% (1)

- Chapter 6 MORTAR (Compatibility Mode) PDFДокумент14 страницChapter 6 MORTAR (Compatibility Mode) PDFBerhanu Mengstu AlemayohОценок пока нет

- Hyper CreteДокумент2 страницыHyper CretedjgiumixОценок пока нет

- Experiment 2Документ5 страницExperiment 2jp gutierrezОценок пока нет

- AGGREGATE ABRASION TEST VALUESДокумент6 страницAGGREGATE ABRASION TEST VALUESAbdur RazzakОценок пока нет

- Specific Gravity of Cement TestДокумент9 страницSpecific Gravity of Cement TestSyed Mohd MehdiОценок пока нет

- The Effect of Excess Water in ConcreteДокумент2 страницыThe Effect of Excess Water in ConcreteKevin NacalabanОценок пока нет

- 3.3 Road Note No. 4-1Документ40 страниц3.3 Road Note No. 4-1Asad Choudhary100% (1)

- Proportioning Concrete Mixtures With Graded AggregatesДокумент86 страницProportioning Concrete Mixtures With Graded AggregatesM HAFEEZ RAJA100% (1)

- Experimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Документ6 страницExperimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Siddhesh Kamat Mhamai100% (2)

- Concrete Mixed Design MethodДокумент11 страницConcrete Mixed Design Methodabdicasis rashidОценок пока нет

- Determining Soundness and Impact Value of Concrete MaterialsДокумент61 страницаDetermining Soundness and Impact Value of Concrete MaterialsUbaid RajputОценок пока нет

- Viscosity Penetration Test ReportДокумент7 страницViscosity Penetration Test ReportMoganraj100% (3)

- Shrinkage TestДокумент12 страницShrinkage TestAlsonChinОценок пока нет

- C917 PDFДокумент9 страницC917 PDFDIAZCORDOBAОценок пока нет

- Shrinkage of ConcreteДокумент3 страницыShrinkage of Concretegmgoutam550Оценок пока нет

- List of Standards Edit 2Документ5 страницList of Standards Edit 2volminkОценок пока нет

- Setting Time of ConcreteДокумент2 страницыSetting Time of ConcretevempadareddyОценок пока нет

- Sand Cement Brick Containing Recycled PDFДокумент7 страницSand Cement Brick Containing Recycled PDFsyakirohОценок пока нет

- Is Concrete Mix DesignДокумент21 страницаIs Concrete Mix DesignahmedanyОценок пока нет

- Sieve Analysis ProcedureДокумент0 страницSieve Analysis ProcedureAbdul Raheem U LОценок пока нет

- Test On Cement PDFДокумент6 страницTest On Cement PDFIrfan NazirОценок пока нет

- Standard Consistency and Setting TimeДокумент3 страницыStandard Consistency and Setting TimeFirdaus RoslimОценок пока нет

- Ree Buddha College of Engineering, Pattoor: ConcreteДокумент9 страницRee Buddha College of Engineering, Pattoor: ConcreteBala GopalОценок пока нет

- Aggregate Impact ValueДокумент5 страницAggregate Impact Valueonline researchОценок пока нет

- AggregateДокумент65 страницAggregateShawonОценок пока нет

- Determining properties of AAC blocksДокумент7 страницDetermining properties of AAC blocksindrajit sodhaОценок пока нет

- Buyers GuideДокумент32 страницыBuyers GuideFord cellОценок пока нет

- Concrete Mix DesignДокумент20 страницConcrete Mix DesignRony BaloyiОценок пока нет

- Properties and Testing of Hardened ConcreteДокумент17 страницProperties and Testing of Hardened ConcreteKannan KandappanОценок пока нет

- MortarДокумент3 страницыMortarrghazzaoui1793Оценок пока нет

- Flexural TestДокумент13 страницFlexural TestAliaОценок пока нет

- Cement Hydration: Tricalcium Silicate (3cao - Sio C S)Документ3 страницыCement Hydration: Tricalcium Silicate (3cao - Sio C S)chandra shekharОценок пока нет

- Determination of Aggregate CrushingДокумент8 страницDetermination of Aggregate CrushingPoovan Rajaratnam100% (2)

- Sorptivity Test 01Документ5 страницSorptivity Test 01Shaheer Ahmed KhanОценок пока нет

- High Performance ConcreteДокумент27 страницHigh Performance ConcretePratik MandlikОценок пока нет

- Mass ConcreteДокумент22 страницыMass Concreteceice2013Оценок пока нет

- Concrete Mix Design GuideДокумент42 страницыConcrete Mix Design GuidesereneОценок пока нет

- Clay Products GuideДокумент4 страницыClay Products Guide11520035Оценок пока нет

- Optimal Mix Design For Pervious ConcreteДокумент9 страницOptimal Mix Design For Pervious ConcretejanakarajОценок пока нет

- C-35 Mix Design by Estimate of MassДокумент26 страницC-35 Mix Design by Estimate of MassTewodros TadesseОценок пока нет

- Compressive Strength of Mortar Cubes AssignmentДокумент11 страницCompressive Strength of Mortar Cubes AssignmentPablo Gomes80% (5)

- Compressive Strength of Concrete - Cube Test Procedure ResultsДокумент5 страницCompressive Strength of Concrete - Cube Test Procedure ResultsAriyan AriyanОценок пока нет

- Tests For Workability of ConcreteДокумент5 страницTests For Workability of ConcretelsatchithananthanОценок пока нет

- Concrete NewДокумент30 страницConcrete Newpankaj_paul6451Оценок пока нет

- Civil Engg Materials Lab ManualДокумент34 страницыCivil Engg Materials Lab ManualAli RazaОценок пока нет

- Astm C341Документ4 страницыAstm C341GUO LEIОценок пока нет

- Testing self compacting concrete flowability with Slump-flow, L-Box, and flow table testsДокумент9 страницTesting self compacting concrete flowability with Slump-flow, L-Box, and flow table testsSantosh ChowdaryОценок пока нет

- Soil Cone Penetrometer: Hot Air OvenДокумент3 страницыSoil Cone Penetrometer: Hot Air OvenSarah Mae GonzalesОценок пока нет

- Co 34Документ10 страницCo 34Baskar Srinivas SОценок пока нет

- AstmДокумент4 страницыAstmHilal kan uyarОценок пока нет

- EngineeringДокумент6 страницEngineeringKelvin LoriaОценок пока нет

- Architectural Specs. (Ormoc)Документ1 страницаArchitectural Specs. (Ormoc)Kelvin LoriaОценок пока нет

- First Step Asep Psep (Me0216 4a)Документ5 страницFirst Step Asep Psep (Me0216 4a)Kelvin LoriaОценок пока нет

- Construction Equipment Lab ReportДокумент3 страницыConstruction Equipment Lab ReportKelvin LoriaОценок пока нет

- 8a-Advanced Waste Water TreatmentДокумент43 страницы8a-Advanced Waste Water TreatmentSathish GlОценок пока нет

- Disinfect water with UV lightДокумент16 страницDisinfect water with UV lightsleonОценок пока нет

- The Ultimate GHS Hazard Classification Guide - ERA Software SolutionsДокумент32 страницыThe Ultimate GHS Hazard Classification Guide - ERA Software SolutionsDina AzizОценок пока нет

- Astm g32 10Документ19 страницAstm g32 10gidlavinayОценок пока нет

- Lect 1Документ14 страницLect 1nagaraj108100% (1)

- Stainless Steel Cable Tie GuideДокумент8 страницStainless Steel Cable Tie GuideSathorn TumОценок пока нет

- Advantages and Disadvantages of Using Absorption Chillers ToДокумент4 страницыAdvantages and Disadvantages of Using Absorption Chillers Toأحمد صلاحОценок пока нет

- NON-DESTRUCTIVE TESTING: OVERVIEW OF LIQUID PENETRANT AND MAGNETIC PARTICLE INSPECTIONДокумент30 страницNON-DESTRUCTIVE TESTING: OVERVIEW OF LIQUID PENETRANT AND MAGNETIC PARTICLE INSPECTIONshuklahouseОценок пока нет

- Samanea Saman 8Документ7 страницSamanea Saman 8Jesus Llorente mendozaОценок пока нет

- Ketoprofen Suppository Dosage Forms: in Vitro Release and in Vivo Absorption Studies in RabbitsДокумент6 страницKetoprofen Suppository Dosage Forms: in Vitro Release and in Vivo Absorption Studies in RabbitsTommyОценок пока нет

- Guidance For Robustness/Ruggedness Tests in Method ValidationДокумент48 страницGuidance For Robustness/Ruggedness Tests in Method ValidationonastasaОценок пока нет

- Urestone Binder 10-05-11Документ17 страницUrestone Binder 10-05-11Serkan EkingenОценок пока нет

- Water BottlesДокумент7 страницWater BottlesReanne MaskartОценок пока нет

- Id35 Honda GX630 GX660 GX690Документ20 страницId35 Honda GX630 GX660 GX690RodrigoChaves0% (1)

- SAFREP Reporting LineДокумент8 страницSAFREP Reporting LineMariaUngureanuОценок пока нет

- Tough, UN Rated 55-Gallon Steel Drums Are Made For Hazardous Waste, So You Can Rely On Them To Deliver Safety and ComplianceДокумент2 страницыTough, UN Rated 55-Gallon Steel Drums Are Made For Hazardous Waste, So You Can Rely On Them To Deliver Safety and ComplianceBrijeshОценок пока нет

- Dental Unit CS 300B Chair MountedДокумент3 страницыDental Unit CS 300B Chair MountedCatrin AfriliaОценок пока нет

- Method Statement: LokfixДокумент3 страницыMethod Statement: Lokfixkamalxd100% (1)

- Boiler OEE Calculation Ver1.00Документ29 страницBoiler OEE Calculation Ver1.00kumarjay36471530100% (1)

- Routes of Drug Delivery To The LungsДокумент4 страницыRoutes of Drug Delivery To The LungsAquiles VaestoОценок пока нет

- Piht0f402 Icmts Icad600tsДокумент2 страницыPiht0f402 Icmts Icad600tsamruta21Оценок пока нет

- Vision IAS Prelims 2020 Test 18 SДокумент34 страницыVision IAS Prelims 2020 Test 18 StriloksinghmeenaОценок пока нет

- Analysis of Amino Acids in Spinach and AppleДокумент1 страницаAnalysis of Amino Acids in Spinach and AppleSilwanus ManaoОценок пока нет

- KeratitisДокумент70 страницKeratitisHoopmen Silaen100% (1)

- BLENDEX 587msdsДокумент6 страницBLENDEX 587msdsAnonymous eq5zSUОценок пока нет

- Kami Export - Physical and Chemical Changes WorksheetДокумент2 страницыKami Export - Physical and Chemical Changes WorksheetTheo MillsОценок пока нет

- How To SterilizeДокумент27 страницHow To SterilizeTanzeil_Rehman_4731Оценок пока нет

- Abrasion & Impact TestДокумент10 страницAbrasion & Impact TestMuhammad Hafizuddin100% (1)

- Spartan 14 ManualДокумент570 страницSpartan 14 ManualDavor ŠestanОценок пока нет

- KENDRIYA VIDYALAYA SANGATHAN SAMPLE PAPER FOR PERIODIC TEST II EXAMДокумент4 страницыKENDRIYA VIDYALAYA SANGATHAN SAMPLE PAPER FOR PERIODIC TEST II EXAMhweta173Оценок пока нет