Академический Документы

Профессиональный Документы

Культура Документы

Total Productive Maintenance Ex

Загружено:

Rifat HossainАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Total Productive Maintenance Ex

Загружено:

Rifat HossainАвторское право:

Доступные форматы

Productivity is beyond a Mathematical Formula

What is TPM* ? TPM is Total Productive Maintenance. Total Perfect Manufacturing, Total People Management, Total Profit Management and Total Productive Management are other acronyms for TPM . TPM is a stepwise process to Achieve and Maintain the highest level of Productivity in a manufacturing scenario. Developments are underway for applying TPM to service industry even. TPM is extremely useful in converting a traditional boss-subordinate, master-servant, I say you do, you tell I do styles of management into a participative management style. TPM synonymous with cultural change in the organization. Productivity is defined, mathematically, as the ratio of output to input in a production environment. Though many measurement yardsticks exist in many companies such as out put per machine, output per day, output per person etc, it is very essential to understand output as a combination of factors like Production output/unit time, Quality of the output (zero defects) Cost of production / unit output, On Time Deliveries to Customers, Safety and health at workplace, Zero effect on Environment and Morale of the people working for the company. This is something beyond a simple mathematical formula. As for the inputs, they are the usual ones viz., capital money, equipment, people, materials etc.,TPM is beyond a mathematical formula. Maximizing Productivity means to maximize each of above parameters viz., P,Q,C,D,S and M. The TPM way of increasing productivity is to not only to maximize the outputs but also simultaneously reduce inputs. While to achieve high Productivity is a task that must be undertaken, it is equally vital that these achievements are Maintained for all time to come.Obviously, this is possible only when all out participation of each person, connected to the company activities, exists. This is the meaning of Total. Hence the name, Total Productive Maintenance. Why TPM ? Any business looks at maximizing profits. Any activity which does not look at making profits as target is not a business activity as the case with many non-profit seeking organizations. Businesses have competition. It is in business, one has to be better than the competitors. Businesses which have no competition, like monopoly businesses,also need to maximize their profits. In any case, profits to be made with high level of social responsibility. TPM is a tool to achieve such objectives effectively.

Document Copyright TPM Association.com

It is highly essential to constantly work for Customer Satisfaction. Culture of a business organization is also revealed in Employee Satisfaction, Social Satisfaction and Global Satisfaction. In todays parlance of high-tech products and high competition, one must be highly reliable, flexible and price competitive for keeping customers happy on one side coupled with cost competitiveness (cost is what a company incurs to make a product) and employee satisfaction at home. Due to high growth of service industry, manufacturing industry is not able to attract skilled and talented people to work for. Manufacturing industry has a bad reputation of dirty, difficult and dangerous workplaces ! Also the Employee satisfaction is seldom low. Business strategy and operational excellence go together and one cannot survive without the other. In the realm of multi-product manufacturing, customer needs are very diversified. Companies must respond with high level of flexibility in operations with quick change-overs in tune with customer requirements in terms of variety of configuration of parts / products together with short batch sizes demanded by customers. High reliability in quality (one shot good product) consistency and On-Time-Deliveries is the order of the day. Ever rising labour and material costs cannot permit rework, scrap and low yield of materials in manufacturing processes. Equipment costs and their obsolesce demands that the machines be used to their peak capacities with Lowest Life-Cycle-Costs. Typically, TPM companies achieve such contrasting targets easily. Some of Benefits of TPM Production outputs to 1.5 to 2.0 times, Zero Manufacturing Defects, Cost reduction in manufacturing ranging from 15 to 30 % 100% on time deliveries of existing products to customers and quick New Product Development, Zero workplace Accidents, Zero Health Hazards and Zero Environmental effects and High employee morale which manifests in cheerful and confident attitudes, are the basic deliverables associated with JIPM-TPM process. This achievement is made possible only by an excellent all people participation in the process. TPM is a well designed and comprehensive way out to achieve all those tangible and intangible benefits. TPM way of working provides for meeting each of the requirements stated above in a very thorough and structured way thanks to JIPM which has been constantly on the job for past 5 decades and over. This is our experience.

* TPM is a property of Japan Institute of Plant Maintenance (JIPM), Tokyo, Japan. JIPM has originated, developed and promoting TPM worldwide since late 1960s.

Document Copyright TPM Association.com

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Impact of Financial Innovations in Financial Performance of Banks in NigeriaДокумент95 страницThe Impact of Financial Innovations in Financial Performance of Banks in NigeriaObinna Steve Nwafor100% (1)

- E-Commerce Solutions in Business OrganizationДокумент50 страницE-Commerce Solutions in Business OrganizationTejasvee Tandon Jaipuria JaipurОценок пока нет

- Private sector role economic development PhilippinesДокумент14 страницPrivate sector role economic development PhilippinesJen DeeОценок пока нет

- The Question of International Trade ProtectionismДокумент10 страницThe Question of International Trade ProtectionismMinh Trang NguyễnОценок пока нет

- Kleaving Auto Cleaning and Detailing: Business PlanДокумент34 страницыKleaving Auto Cleaning and Detailing: Business PlanMuhammad Abu-BakarОценок пока нет

- Analysis of Sugar Industry Competitiveness in PakiДокумент16 страницAnalysis of Sugar Industry Competitiveness in PakiMalikXufyanОценок пока нет

- AP Industrial Policy Promotes Infrastructure and Investment IncentivesДокумент31 страницаAP Industrial Policy Promotes Infrastructure and Investment IncentivesVenkatesh KarnatiОценок пока нет

- EMI ProjectДокумент27 страницEMI Projectasta1234100% (7)

- Effects of Inventory Management On The Supply Chain of DellДокумент75 страницEffects of Inventory Management On The Supply Chain of DellArjun Thekadavan100% (9)

- Researching The Ventures - Feasibility Learning ObjectivesДокумент22 страницыResearching The Ventures - Feasibility Learning Objectivesمحمد عمران راناОценок пока нет

- Cardamom in NepalДокумент10 страницCardamom in NepalRewanta LuitelОценок пока нет

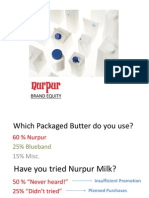

- Nurpur Brand EquityДокумент19 страницNurpur Brand EquityBilal100% (2)

- Case Study TataДокумент7 страницCase Study TataSamОценок пока нет

- Competition Law Project (G)Документ10 страницCompetition Law Project (G)yogeshОценок пока нет

- Dry Ports Public Private PartnershipДокумент16 страницDry Ports Public Private PartnershipgirishgujarОценок пока нет

- PDFДокумент12 страницPDFrubel-buОценок пока нет

- Bakery Business PlanДокумент13 страницBakery Business PlanAbhishek RohilОценок пока нет

- Annex 3 - Uber's Competitive Advantage Vis-à-Vis Porter's Generic StrategiesДокумент17 страницAnnex 3 - Uber's Competitive Advantage Vis-à-Vis Porter's Generic Strategiesalexander100% (1)

- ValuationsДокумент27 страницValuationsblabitan100% (1)

- International MarketingДокумент14 страницInternational MarketingShannon InmanОценок пока нет

- Does Bank Competition Promote Economic Growth? Empirical Evidence From Selected South Asian CountriesДокумент23 страницыDoes Bank Competition Promote Economic Growth? Empirical Evidence From Selected South Asian CountriesFajar SiddikОценок пока нет

- Reinventing Government with Strategic Leverage PointsДокумент21 страницаReinventing Government with Strategic Leverage PointsSjamsul BahrieОценок пока нет

- Part 3 Design Detail Marketing Strategy For Any Product Using Hypothetical Brand Name and Selecting Real Industry DataДокумент25 страницPart 3 Design Detail Marketing Strategy For Any Product Using Hypothetical Brand Name and Selecting Real Industry Dataystinu44Оценок пока нет

- Jeet KaushikДокумент91 страницаJeet Kaushikjitendra jaushik100% (1)

- Medical Transcription Business Marketing PlanДокумент19 страницMedical Transcription Business Marketing PlanPalo Alto Software100% (5)

- Hotel PerformanceДокумент33 страницыHotel PerformanceindahwatyОценок пока нет

- Môn thầy DavidДокумент30 страницMôn thầy DavidCao Minh Tuấn ĐạtОценок пока нет

- Components of Business EnvironmentДокумент5 страницComponents of Business EnvironmentYves GaelОценок пока нет

- New Definitions of Relevant Market and The Assault On Antitrust PitofskyДокумент61 страницаNew Definitions of Relevant Market and The Assault On Antitrust PitofskyMarcelo Mardones OsorioОценок пока нет

- STEP 8 - Quantitative Strategic Planning (QSPM) MatrixДокумент2 страницыSTEP 8 - Quantitative Strategic Planning (QSPM) Matrixdummy AccntОценок пока нет