Академический Документы

Профессиональный Документы

Культура Документы

Boil Out SOP - 060508

Загружено:

wisokresnoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Boil Out SOP - 060508

Загружено:

wisokresnoАвторское право:

Доступные форматы

DOCUMENT TITLE

CHEMICAL CLEANING PROCEDURE FOR BOIL OUT BOILER HRSG 25 TON/HOUR REVISION No : MHN-00

UNIT ISSUING R&D DEPT. APPROVED BY : CHEM. DIV. MGR DATE : 08 10 - 2007 PAGE : 1 OF 4

I. OUT LINE 1. GENERAL The internal surfaces of the economizer and steam generating sections (hereafter referred to as the boiler) should be cleaned to remove dirt, oil, grease and protective coatings. The company does not require acid cleaning of the unit as an initial clean out of the unit. This initial clean out of the unit is to be accomplished by means of a degreasing flush. Since commercial degreasing formulations and concentrations. At ambient temperature, approximately 25C (77F), the suggested degreasing concentration in the flush water is 0.6% by volume (6 liters of liquid degreasing per 1000 liters of flushing solution). For cleaning solutions heated to above 65C (150F), the suggested degreasing concentration in the flush water is 0.5% by volume. Higher (or lower) concentrations may be used, depending on the type of degreasing considered, plant-specific design conditions and vendor recommendations.

2. SCOPE OF SUPPLY No. 1. Description Chemical Magna 106 (Emulsion Degreaser) & Magna - 700 (Passivating Agent) Circulation Pump Chemical Circulation Drum High Pressure Cleaner Pump Tool Kits Personal Safety Equipment Scaffolding Ladder PT. AWMC X X X X X X X X If needed PT. . Remarks

2. 3. 4. 6. 7. 8. 9.

Page 1 of 4

11. 12. 13. 14. 15. 16. 17. 18.

Electric Power Supply Soft Water Supply Steam (Hot Water) Lighting Temporary Piping/Horse and Valve Disposal Area (Waste Handling) Chemical Engineer Site Office Temporary

X X X X X X X X

Scope of Works No. 1. 2. 3. 4. 5. Description Cleaning & Flushing Pipe Line with oil system Chemical Transfer to Pipe System Equipment Cleaning Preparation Temporary Pipe/Horse connection to Pipe System Preparation of Pipe System before Circulation. (Isolation of Valves, Level Gauge, Instrumentation Line, Level Control Open / Close the Pipe Line System) Mechanical & Electrical Works (Flank, Packing, Electric power on site and or Welding for Circulation Process) Project Engineer Waste Water Treatment (Disposal Area & Demob Waste to Disposal Area) PT. AWMC X X X X X X X X PT. . Remarks

6.

7. 8.

X X

II. SOP 1. DEGREASING/FLUSHING PROCESS a. Preparation work. b. Install all the hoses and circulating pump needed to water supply valve, boiler, and chemical tank. c. Open the boiler manhole on the top of the boiler.

Page 2 of 4

d. Fill the boiler with demineralized water until boiler operating water level. e. Heat the water in the boiler up to 60 70C (Steam/hot water by Nestle). f. Circulating the water for 45 minutes and maintain the water temperature at 60 70C during the circulating period. g. Shut off boiler and drain the water from the boiler system. h. Refill the boiler with demineralized water until boiler operating water level. i. Heat the water in the boiler up to 60 70C. j. Inject 10-20% Magna 106 (Emulsion Degreaser) needed gradually into the boilers manhole, and maintain the water temperature at 60 70C. k. Check the boiler: the water pH, TDS/Conductivity, Calcium (Total Hardness), Silica, Iron, Grease Content and water clearness by visual inspection. l. For every next 30 minutes check the water pH, TDS/Conductivity, Calcium (Total Hardness), Silica, Iron, Grease Content and water clearness by visual inspection. m. Boiler retubing degreasing process usually will last at 6 8 hours. It would depend on the oil film in the tubing. n. When the degreasing process ended, drain all the water from boiler. o. Flush the boiler with demineralized water, until the drained water from blowdown lineclean. p. Check the pH of the water taken from the demineralized water supply valve and the pH of the water taken from blowdown line. It should be same. q. Until this step the degreasing process could be ended. Note : Degreasing/Flushing Process just remove grease/oil content, dirt and light corrosion from carbon/stainless steel pipe system. Its not remove Hard Scale (Carbonate/Silica Scale & Hard Corrosion from Carbon Steel pipe. So, Visual inspection from Degreasing Process is not change surface metal and its not make Carbon Steel clean (Natural carbon steel color before scale & corrosion). For make Carbon Steel clean (Natural carbon steel color before scale & corrosion) we need one process again after Degreasing/Flushing. That process is Acid Cleaning or Pickling Process.

Page 3 of 4

2. PASSIVATING PROCESS a. Inject 2-5% of Magna 700 (Passivating Agent) as passivating agent needed into boiler via manhole. b. Check the pH, TDS and Nitrite concentration in the boiler water. c. Heat the water up to 60 70C, and maintain the temperature during the circulation period. d. Monitor the pH, TDS and Nitrite concentration in the boiler water on a 30 minutes basis. e. After 1 hour, inject the remaining passivating (Magna 700) into the boiler via manhole. f. Check the pH, TDS and Nitrite concentration in the boiler water. g. Monitor the pH, TDS and Nitrite concentration in the boiler water on a 30 minutes basis. h. Circulate continously for about 2 hours. i. Once the duration of circulation indicates the completion of the passivating process, drain the boiler water, and flushed the boiler with demineralized water. j. Fill the boiler with demineralized water up to boiler water operating level. k. Inject the water treatment chemicals needed to prevent the future scalling and corrosion. Note : Passivating Process is needed for carbon steel after cleaning to protective carbon steel for corrosion process later. Oxygen and water content in piping are main substance caused corrosion. Passivating Agent can give protection by forming light filming on carbon steel metal and inhibit oxygen and water contact with metal.

Page 4 of 4

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Jadwal Kursus 2012Документ1 страницаJadwal Kursus 2012Fareza Tri RizkyОценок пока нет

- 2000 09 KMДокумент8 страниц2000 09 KMwisokresnoОценок пока нет

- Government Relations Sen..., PT - Jobsdb IndonesiaДокумент2 страницыGovernment Relations Sen..., PT - Jobsdb IndonesiawisokresnoОценок пока нет

- GAMELAN: A Knowledge Management Approach For Digital Audio Production WorkflowsДокумент6 страницGAMELAN: A Knowledge Management Approach For Digital Audio Production WorkflowswisokresnoОценок пока нет

- Diploma 2013 256217 AbstractДокумент1 страницаDiploma 2013 256217 AbstractwisokresnoОценок пока нет

- SE2221 Sumarsam Intro GamelanДокумент28 страницSE2221 Sumarsam Intro GamelanDaphneGohОценок пока нет

- Filling Technology EДокумент16 страницFilling Technology Earachman297988100% (1)

- Business Intelligence and Decision Support SystemДокумент26 страницBusiness Intelligence and Decision Support SystemSanjay MishraОценок пока нет

- Serac's aseptic filling control and monitoring probe technologyДокумент6 страницSerac's aseptic filling control and monitoring probe technologywisokresnoОценок пока нет

- Introduction To Capacity Building - Jul09Документ6 страницIntroduction To Capacity Building - Jul09Charles DonkorОценок пока нет

- Pengaruh Faktor Harga, Produk, Kebersihan dan Layanan terhadap Kepuasan Pelanggan Restoran MamamiaДокумент35 страницPengaruh Faktor Harga, Produk, Kebersihan dan Layanan terhadap Kepuasan Pelanggan Restoran MamamiawisokresnoОценок пока нет

- How To Become A Better Politician (English)Документ75 страницHow To Become A Better Politician (English)wisokresnoОценок пока нет

- APSN Language Resources KAMUS LSMДокумент74 страницыAPSN Language Resources KAMUS LSMwisokresnoОценок пока нет

- Robert Cialdini - The Power of Persuasion An Executive Briefing Robert Cialdini - NegotiationДокумент4 страницыRobert Cialdini - The Power of Persuasion An Executive Briefing Robert Cialdini - Negotiationapi-3804479100% (5)

- H-3 Power Point (Air Heater)Документ63 страницыH-3 Power Point (Air Heater)wisokresno100% (1)

- CB - Building - Capacity in Non Profit OrganizationДокумент102 страницыCB - Building - Capacity in Non Profit OrganizationTantri Yanuar Rahmat Syah100% (1)

- Makala HДокумент8 страницMakala HwisokresnoОценок пока нет

- Report GCGДокумент7 страницReport GCGwisokresnoОценок пока нет

- Going For A New JobДокумент11 страницGoing For A New Jobsweetlittlegirl_92Оценок пока нет

- Cuu Long Delta Rice Research Institute (CLRRI) Can Tho University (CTU)Документ7 страницCuu Long Delta Rice Research Institute (CLRRI) Can Tho University (CTU)wisokresnoОценок пока нет

- Catalogue of Cleaning & Maintenance ChemicalsДокумент24 страницыCatalogue of Cleaning & Maintenance ChemicalswisokresnoОценок пока нет

- BetonДокумент19 страницBetonwisokresnoОценок пока нет

- Bank TanahДокумент1 страницаBank TanahwisokresnoОценок пока нет

- Penawaran Mesin Utk ZeoliteДокумент3 страницыPenawaran Mesin Utk ZeolitewisokresnoОценок пока нет

- Corium 4060Документ2 страницыCorium 4060wisokresnoОценок пока нет

- Adsorption Properties of Modified Zeolite For Ammonia RemovalДокумент4 страницыAdsorption Properties of Modified Zeolite For Ammonia RemovalwisokresnoОценок пока нет

- Adsorption Properties of Modified Zeolite For Ammonia RemovalДокумент4 страницыAdsorption Properties of Modified Zeolite For Ammonia RemovalwisokresnoОценок пока нет

- Brinedril VisДокумент1 страницаBrinedril ViswisokresnoОценок пока нет

- Adobe Zeolite Sucofindo SpecДокумент1 страницаAdobe Zeolite Sucofindo SpecwisokresnoОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Form 1 Science - Unit 3.3: The Concept of DensityДокумент1 страницаForm 1 Science - Unit 3.3: The Concept of DensitySuhaila SaniОценок пока нет

- Chemistry of Carbon CompoundsДокумент12 страницChemistry of Carbon CompoundsSubhadip HaldarОценок пока нет

- B. Pharm. First Year Subjects and Marks BreakupДокумент133 страницыB. Pharm. First Year Subjects and Marks BreakupAshutosh GuptaОценок пока нет

- Recipes For MilletsДокумент20 страницRecipes For MilletsRavi TejaОценок пока нет

- Structures and Properties of CeramicsДокумент38 страницStructures and Properties of CeramicsArjayОценок пока нет

- Chemistry Investigatory Project Efforts By: Yash Raj Singh Xii-DДокумент15 страницChemistry Investigatory Project Efforts By: Yash Raj Singh Xii-DSatyam NegiОценок пока нет

- Mastication Is Process During Which The Elastic Rubber Achieves Plastic PropertiesДокумент1 страницаMastication Is Process During Which The Elastic Rubber Achieves Plastic PropertiesBhubanDip BisWasОценок пока нет

- Murex Tig Poster 2008 PDFДокумент1 страницаMurex Tig Poster 2008 PDFPCОценок пока нет

- Anderol General BrochureДокумент12 страницAnderol General BrochureepesanoОценок пока нет

- Stability of Food Emulsions (2) : David Julian McclementsДокумент37 страницStability of Food Emulsions (2) : David Julian McclementsscribdGMMEGAОценок пока нет

- ASTM D6224 Eksploataciono Praćenje UljaДокумент14 страницASTM D6224 Eksploataciono Praćenje UljaDejan DejanovicОценок пока нет

- Polyester Fiber Production Flow ChartДокумент2 страницыPolyester Fiber Production Flow ChartMuhammad Jafor IqbalОценок пока нет

- Choose the Right Lubricant for Your Komatsu Forest MachineДокумент4 страницыChoose the Right Lubricant for Your Komatsu Forest MachineyovannyОценок пока нет

- Lower and Higher Heating Values of Gas Liquid and Solid FuelsДокумент2 страницыLower and Higher Heating Values of Gas Liquid and Solid FuelsElwathig BakhietОценок пока нет

- Gardner 1980Документ10 страницGardner 1980thomas cookОценок пока нет

- Properties of Carbon Monoxide, Silicon Dioxide and CarbondioxideДокумент1 страницаProperties of Carbon Monoxide, Silicon Dioxide and CarbondioxidePuppika DogОценок пока нет

- Thermodynamics and Kinetic Stability of Coordination ComplexesДокумент27 страницThermodynamics and Kinetic Stability of Coordination ComplexesMONIRUZZAMAN MONIR100% (1)

- Corrosione - Abstract From SchneiderДокумент5 страницCorrosione - Abstract From SchneiderMaxОценок пока нет

- Organic Chemistry Some Basic Principles and Techniques - WatermarkДокумент29 страницOrganic Chemistry Some Basic Principles and Techniques - WatermarkPrathviraj SinghОценок пока нет

- A Study On Spinel Formation PDFДокумент5 страницA Study On Spinel Formation PDFBagas Prasetyawan Adi NugrohoОценок пока нет

- Jiacheng Yang, Tianbo Tang, Yu Jiang, Georgios Karavalakis, Thomas D. Durbin, J. Wayne Miller, David R. Cocker III, Kent C. JohnsonДокумент9 страницJiacheng Yang, Tianbo Tang, Yu Jiang, Georgios Karavalakis, Thomas D. Durbin, J. Wayne Miller, David R. Cocker III, Kent C. JohnsonMohamed TaalbiОценок пока нет

- Lithium Metaborate: Libo Formula WT 49.75 CAS No. 13453-69-5Документ4 страницыLithium Metaborate: Libo Formula WT 49.75 CAS No. 13453-69-5jycortesОценок пока нет

- Pko Cno PDFДокумент26 страницPko Cno PDFmindcrОценок пока нет

- Wolaita Sodo University: General Chemistry (Chem.1012) Chapter FourДокумент56 страницWolaita Sodo University: General Chemistry (Chem.1012) Chapter FourAbdulmajid AbdellaОценок пока нет

- Pricing Information of Vet Products..HarisДокумент17 страницPricing Information of Vet Products..HarisMirza Hassan75% (4)

- Lesson Plan in Science 10 Chemistry: John Glenn E. Labrador Bsed - IvДокумент20 страницLesson Plan in Science 10 Chemistry: John Glenn E. Labrador Bsed - IvJohn Glenn E. L.Оценок пока нет

- European Patent Application C07F 7/08: Method For Preparation of Organohydrogen PolysiloxanesДокумент5 страницEuropean Patent Application C07F 7/08: Method For Preparation of Organohydrogen Polysiloxanesswaroop_exlncОценок пока нет

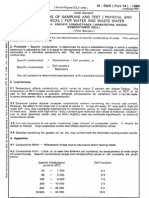

- UDC IS: 3025 (Part 14) - 1984,: Reprint JULY 1998) (IДокумент4 страницыUDC IS: 3025 (Part 14) - 1984,: Reprint JULY 1998) (IrambinodОценок пока нет

- Trabelsi 2019Документ10 страницTrabelsi 2019Հեղինե ՂազոյանОценок пока нет

- Lesson Plan in Grade 9 - Science: Grade Level: Grade - 9 Time Allotment: 60 MinutesДокумент2 страницыLesson Plan in Grade 9 - Science: Grade Level: Grade - 9 Time Allotment: 60 MinutesMike Serdica79% (14)