Академический Документы

Профессиональный Документы

Культура Документы

Emm Model April13

Загружено:

Karthik SubramaniАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

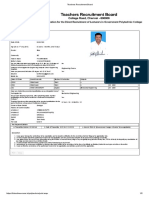

Emm Model April13

Загружено:

Karthik SubramaniАвторское право:

Доступные форматы

1.

What are the effects of crystal structure and atomic radii on formation of solid solution between two metallic elements? 2. Define peritectoid reaction. 3. What is the need for providing a tempering treatment after quench hardening of steels? 4. Define the terms ferrite and austenite in iron-carbon alloy system. 5. What properties are determined from tension test of metallic products? 6. Draw the sketch of a standard specimen used for charpy V-notch impact testing. 7. What is the purpose of magnesium treatment in producing S.G iron? 8. What is the main strengthening mechanism in high strength aluminium alloys? 9. What are the important uses of alumina and silicon nitride? 10. Draw the molecular structure of polyethylene and polypropylene. 11. (i)Draw the iron-carbon equilibrium diagram. (10) (ii)Discuss the similarities and differences between substitutional and interstitial solid solutions. (6) (OR) 12. Metal A has melting point of 1000C.Metal B has melting point of 500C.Draw one phase diagram(between the elements A and B) for each of the following conditions. (i)The two elements exhibit unlimited solid solubility. (4) (ii) The alloy system shows formation of two terminal solid solutions and a eutectic point, at 50%A and at 700C. (4) (iii)The alloy system shows formation of an intermetallic phase with the chemical formula A2B. (8) 13. (i)Explain the Jominy end quench test used for determining the hardenability of steels.(10) (ii)What are austempering and martempering treatments? What are their purposes?(6) (OR) 14. (i)Draw the schematic isothermal transformation diagram corresponding to 0.8% carbon steel(8) (ii)Explain the hardening and tempering process with respect to heat treatment procedure, microstructure and mechanical properties(8) 15. What are slip and twinning? What are their characteristics?(8)Discuss the characteristics of ductile fracture and brittle fracture(8) (OR) 16. Explain the testing procedure of Vickers hardness testing.(8)Explain the testing procedure of Izod impact testing(8) 17. How will you classify brasses based on the composition of zinc? Explain the properties and applications of the main types of brasses.(8)Explain the steps involved in precipitation hardening treatment.(8) (OR) 18. Discuss the austenitic stainless steels and Martensitic stainless steel with respect to composition, properties and applications.(8)Discuss the strengthening mechanism, composition and properties of any one type of maraging steels.(8) 19. Explain the following polymers with respect to their molecular structures, properties and applications.(i) Polypropylene (ii)Poly vinyl chloride (iii)Poly tetra fluoro ethylene (iv)Poly ethylene perethalate(4x4)

(OR) 20. Write a short note about the different types of matrix materials and reinforcement materials used to make polymer matrix composites.(10)Discuss the properties and applications of Al2O3 and SiC ceramics.(6)

PSNA COLLEGE OF ENGINEERING & TECHNOLOGY, DINDIGUL-624 622. DEPARTMENT OF MECHANICAL ENGINEERING. MODEL EXAM- APRIL-2013 ENGINEERING MATERIALS AND METALLURGY Subject Code: ME2253 Year: II Year Date: 29.04.13 Max. Marks: 100 Duration: 3hours. Section: A Answer all questions PART-A (10x2=20marks) 1. What are the effects of crystal structure and atomic radii on formation of solid solution between two metallic elements? 2. Define peritectoid reaction. 3. What is the need for providing a tempering treatment after quench hardening of steels? 4. Define the terms ferrite and austenite in iron-carbon alloy system. 5. What properties are determined from tension test of metallic products? 6. Draw the sketch of a standard specimen used for charpy V-notch impact testing. 7. What is the purpose of magnesium treatment in producing S.G iron? 8. What is the main strengthening mechanism in high strength aluminium alloys? 9. What are the important uses of alumina and silicon nitride? 10. Draw the molecular structure of polyethylene and polypropylene. PART-B (5x16=80marks) 11.(i)Draw the iron-carbon equilibrium diagram. (ii)Discuss the similarities and differences between substitutional and interstitial solid solutions. (OR) (10) (6)

Semester: IV Faculty In-charge: M.PalPandi

12.Metal A has melting point of 1000C.Metal B has melting point of 500C.Draw one phase diagram(between the elements A and B) for each of the following conditions. (i)The two elements exhibit unlimited solid solubility. (4) (ii) The alloy system shows formation of two terminal solid solutions and a eutectic point, at 50%A and at 700C. (4) (iii)The alloy system shows formation of an intermetallic phase with the chemical formula A2B. (8)

13.(i)Explain the Jominy end quench test used for determining the hardenability of steels. (ii)What are austempering and martempering treatments? What are their purposes? (OR)

(10) (6)

14(i) Draw the schematic isothermal transformation diagram corresponding to 0.8% carbon steel . (8) (ii)Explain the hardening and tempering process with respect to heat treatment procedure, microstructure and mechanical properties 15(i) What are slip and twinning? What are their characteristics? (ii)Discuss the characteristics of ductile fracture and brittle fracture (OR) 16. (i) Explain the testing procedure of Vickers hardness testing. (ii)Explain the testing procedure of Izod impact testing (8) (8)

(8) (8) (8)

17. (i)How will you classify brasses based on the composition of zinc? Explain the properties and applications of the main types of brasses. (8) (ii)Explain the steps involved in precipitation hardening treatment. (OR) 18. (i)Discuss the austenitic stainless steels and Martensitic stainless steel with respect to composition, properties and applications. (8) (8)

(ii)Discuss the strengthening mechanism, composition and properties of any one type of maraging steels. 19. Explain the following polymers with respect to their molecular structures, properties and applications. (i) Polypropylene (ii)Poly vinyl chloride (iii)Poly tetra fluoro ethylene (iv)Poly ethylene perethalate (OR) 20.(i)Write a short note about the different types of matrix materials and reinforcement materials used to make polymer matrix composites. (10) (ii)Discuss the properties and applications of Al2O3 and SiC ceramics. (6) (4x4)

STAFF I/C

HOD/MECH.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Fracture Mechanics - 2nd Ed - Solution ManualДокумент120 страницFracture Mechanics - 2nd Ed - Solution ManualMahesh Raja50% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Practice - Geometric ConstructionДокумент13 страницPractice - Geometric ConstructionKarthik SubramaniОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Design of Hydraulic and Pneumatic Systems - QPДокумент11 страницDesign of Hydraulic and Pneumatic Systems - QPKarthik SubramaniОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Hydraulics and Pneumatics: Varun Pratap SinghДокумент38 страницHydraulics and Pneumatics: Varun Pratap SinghKarthik SubramaniОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Me6012 Me Mech Viist Au Unit IVДокумент21 страницаMe6012 Me Mech Viist Au Unit IVKarthik SubramaniОценок пока нет

- Me6012 Me Mech Viist Au Unit III PDFДокумент20 страницMe6012 Me Mech Viist Au Unit III PDFKarthik SubramaniОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- PDFДокумент108 страницPDFKarthik SubramaniОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- 16 Hoisting and Conveying EquipmentДокумент71 страница16 Hoisting and Conveying EquipmentVenkata DineshОценок пока нет

- Maintenance Engineering - VijayaragavanДокумент6 страницMaintenance Engineering - VijayaragavanKarthik SubramaniОценок пока нет

- Journallist 1 PDFДокумент400 страницJournallist 1 PDFRajasekar PichaimuthuОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- 2013 RegulationДокумент2 страницы2013 RegulationKarthik SubramaniОценок пока нет

- CS8591 Computer Networks L T P C 3 0 0 3 ObjectivesДокумент5 страницCS8591 Computer Networks L T P C 3 0 0 3 Objectivesjayaprasanna1230% (1)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Me6012 Me Mech Viist Au Unit III PDFДокумент20 страницMe6012 Me Mech Viist Au Unit III PDFKarthik SubramaniОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- PD5091-Product Lifecycle ManagementДокумент8 страницPD5091-Product Lifecycle ManagementKarthik Subramani67% (3)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- SafteyДокумент5 страницSafteyKarthik SubramaniОценок пока нет

- Crane CompressedДокумент69 страницCrane CompressedJhonRider100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- DislocationMotion STR Recovery Ch7Документ40 страницDislocationMotion STR Recovery Ch7Karthik SubramaniОценок пока нет

- Experimental Investigation and Analysis A Mechanical Properties of Hybrid Polymer Composite PlatesДокумент8 страницExperimental Investigation and Analysis A Mechanical Properties of Hybrid Polymer Composite PlatesKarthik SubramaniОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Dislocation Stress Fields: Theory of DislocationsДокумент17 страницDislocation Stress Fields: Theory of DislocationsAbdulRehmanОценок пока нет

- HMT University Solved ProblemsДокумент69 страницHMT University Solved ProblemsKendra Kaiser60% (5)

- Me6012 Me Mech Viist Au Unit IVДокумент21 страницаMe6012 Me Mech Viist Au Unit IVKarthik SubramaniОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Jaw Aid 2013Документ6 страницJaw Aid 2013Karthik SubramaniОценок пока нет

- B.e.cseДокумент107 страницB.e.cseSangeetha ShankaranОценок пока нет

- Approx Method Draw Involute ToothДокумент10 страницApprox Method Draw Involute ToothAustin BruceОценок пока нет

- Ch3 AxisymmДокумент2 страницыCh3 AxisymmKarthik SubramaniОценок пока нет

- Maintenance Engineering - Vijayaragavan1Документ7 страницMaintenance Engineering - Vijayaragavan1Karthik SubramaniОценок пока нет

- Maintenance Engineering - Vijayaragavan1Документ6 страницMaintenance Engineering - Vijayaragavan1Karthik SubramaniОценок пока нет

- Maintenance Engineering - VijayaragavanДокумент6 страницMaintenance Engineering - VijayaragavanKarthik SubramaniОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Cs8383 Oops Lab ManualДокумент81 страницаCs8383 Oops Lab ManualKarthik Subramani83% (12)

- Best Maintenance Repair PracticesДокумент4 страницыBest Maintenance Repair Practicessantosh_jslОценок пока нет

- Navneet QB - Science Grade 10Документ36 страницNavneet QB - Science Grade 10Himanshu NagareОценок пока нет

- Valence Shell Electron Pair Repulsion TheoryДокумент20 страницValence Shell Electron Pair Repulsion TheoryABDUL WAHABОценок пока нет

- SPE 89466 Measured Z-Factor of CO - Dry Gas/Wet Gas/Gas Condensates For CO Storage in Depleted Gas ReservoirsДокумент11 страницSPE 89466 Measured Z-Factor of CO - Dry Gas/Wet Gas/Gas Condensates For CO Storage in Depleted Gas ReservoirsmsmsoftОценок пока нет

- Ch1 MCQДокумент3 страницыCh1 MCQAnuj PalОценок пока нет

- Mechanical Properties: Chemical CompositionДокумент1 страницаMechanical Properties: Chemical CompositionHERSON FARID BUENO PIÑEROSОценок пока нет

- Apple Experiment: Come Down and Get An Apple and A Slice of Lemon. When You Get Back To Your SeatДокумент24 страницыApple Experiment: Come Down and Get An Apple and A Slice of Lemon. When You Get Back To Your SeatArun SharmaОценок пока нет

- Tensile Strength of FibersДокумент15 страницTensile Strength of FibersBharat PatelОценок пока нет

- Defend Gen Purpose Cleaner MSDS 1-1-2011Документ1 страницаDefend Gen Purpose Cleaner MSDS 1-1-2011M. White DentalОценок пока нет

- BNVD Eaufrance Metadonnees Vente 20230130Документ16 страницBNVD Eaufrance Metadonnees Vente 20230130moussaouiОценок пока нет

- Basic Drilling Fluid CourseДокумент63 страницыBasic Drilling Fluid CourseAhmed Salah KhalifaОценок пока нет

- 09 AbstractДокумент2 страницы09 AbstractlichenresearchОценок пока нет

- 0) Uv Weathering Test Method Cabot PDFДокумент12 страниц0) Uv Weathering Test Method Cabot PDFarthurОценок пока нет

- Glass To Metal JointsДокумент11 страницGlass To Metal JointsNeilОценок пока нет

- Rosuvastatin EP MonographДокумент7 страницRosuvastatin EP MonographJagdish Chander86% (7)

- Omeprazole Delayed-Release CapsulesДокумент3 страницыOmeprazole Delayed-Release CapsulesNaeem MalikОценок пока нет

- FACTORY PERFORMANCE (KPI) JULY 2021 TO MAY 2022 (Version 1) .XLSB Rev1 PDFДокумент2 страницыFACTORY PERFORMANCE (KPI) JULY 2021 TO MAY 2022 (Version 1) .XLSB Rev1 PDFGeorge oburaОценок пока нет

- Chemistry Olympiad Practice: Qualitative Analysis and Solid StateДокумент2 страницыChemistry Olympiad Practice: Qualitative Analysis and Solid StateEkasОценок пока нет

- Activity 08 LipidsДокумент36 страницActivity 08 LipidsMaria67% (3)

- Cement Kilns PDFДокумент321 страницаCement Kilns PDFVisnu Sankar100% (1)

- Co2 MoldingДокумент9 страницCo2 MoldingRahul Kumar SinhaОценок пока нет

- Motor Bensin InternasionalДокумент19 страницMotor Bensin InternasionalDwiky Adhi PrasetyoОценок пока нет

- Versene Dow Chelating AgentsДокумент2 страницыVersene Dow Chelating AgentsRahman AbdulahОценок пока нет

- Methods of Sterilization and DisinfectionДокумент45 страницMethods of Sterilization and DisinfectionThahseen TwzОценок пока нет

- Investigating Froth Stability A Comparative Study of Ionic Strengh and Frother DosageДокумент5 страницInvestigating Froth Stability A Comparative Study of Ionic Strengh and Frother DosageJaime Omar Godinez RevelesОценок пока нет

- Piping PresentationДокумент15 страницPiping PresentationVinod Varadan SОценок пока нет

- Jurnal Ochy FixДокумент13 страницJurnal Ochy FixTianSonОценок пока нет

- 17-7 Material PDFДокумент5 страниц17-7 Material PDFJothi ManiОценок пока нет

- C-Oncrete Admixtures - Specification (First Revision) : Indian StandardДокумент19 страницC-Oncrete Admixtures - Specification (First Revision) : Indian StandardSri Anup Kr. SenОценок пока нет

- 2D Nanomaterials As LubricantДокумент14 страниц2D Nanomaterials As LubricantwhutecompressorОценок пока нет

- 09 Chapter2 PDFДокумент31 страница09 Chapter2 PDFRamОценок пока нет

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesОт EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Shorting the Grid: The Hidden Fragility of Our Electric GridОт EverandShorting the Grid: The Hidden Fragility of Our Electric GridРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsОт EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AОт EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AОценок пока нет