Академический Документы

Профессиональный Документы

Культура Документы

Guide To Manual Processing of NDT Films: Technical Data / Non-Destructive Testing

Загружено:

carlosИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Guide To Manual Processing of NDT Films: Technical Data / Non-Destructive Testing

Загружено:

carlosАвторское право:

Доступные форматы

TECHNICAL DATA / NON-DESTRUCTIVE TESTING

February 2008 TI-2643

Guide to Manual Processing of NDT Films

To reach the desired density on a radiograph, many people use set exposure factors and then adjust development time or "sight develop"to compensate for under- or overexposed images. Today, you can eliminate that guesswork and get more consistent results by using KODAK INDUSTREX Films with our exclusive T-GRAIN Emulsion technology. The key is to use the correct exposure factors when you shoot the images. We provide handy KODAK NDT Exposure Calculators to help you determine the right factors for each situation. By removing the processing variable, you will get better consistency and higher productivity in the darkroom. Our films provide stable contrast and a relatively stable speed over a wider range of developer temperaturesunlike older film technologies that have highly variable speed, relative to developer temperature and immersion time. When using an Ir-192 source, you can use the KODAK NDT Exposure Calculator to determine correct exposure (based upon density desired). Then follow these simple processing recommendations.

RECOMMENDED CHEMICALS

Developer Use KODAK INDUSTREX Single-Part Developer and Replenisher. Stop Bath Use KODAK Indicator Stop Bath or any acetic acid stop bath mixed at a 3% solution (mix KODAK 28% Acetic Acid at 110 mL/L). Use a stop bath for 30 seconds. Using a stop bath checks developmentrapidly preventing most spotting or streakingand prolongs the life of the fixing bath. A running water rinse for one minute may be substituted for a stop bath. However, it may not provide results equivalent to an acetic acid stop bath solution. Fixer Use KODAK INDUSTREX LO Fixer and Replenisher or KODAK Rapid Fixer.

Replenishment Rates

Maintain the chemical activity and solution level in the tank by adding replenisher according to instructions below:

Solution Replenishment Volume per 35 x 43 cm (14 x 17 inch) sheet Developer Fixer*

*

Timer and Thermometer

The Time and Thermometer are essential. They must be accurate and in good condition.

per m2 665 mL 1200 mL

Safelight

Use a KODAK LED Safelight (660nm red) or a red safelight filter (i.e. KODAK 1, 1A, or 2 Safelight Filter) in a suitable safelight lamp equipped with a 15-watt bulb. Keep the film at least 4 feet (1.2 metres) from the safelight. Note: Other safelight filters (i.e. KODAK 8 and GBX-2 Safelight Filter) which block radiation at 550nm and shorter wavelengths are also suitable for use.

100 mL 180 mL

For optimum archivability, a 10% increase in fixer replenishment rate may be desirable.

Stir solutions vigorously after each addition. Follow the manufacturers instructions for the specific developer replenisher and fixer replenisher you are using. Additionally: When removing films from developer tank, DO NOT ALLOW EXCESS SOLUTION TO DRAIN BACK INTO TANK. Normally this will carry out the proper amount of solution to permit correct replenishment. Use floating covers on developer tanks to reduce oxidation and evaporation; store developer replenisher in a closed container. Fill the developer and fixer tank to its original level each morning with developer or fixer replenisher solution (topping off). Discard solution after adding two tank volumes of replenisher to tank, or at least once a month, and refill with fresh solution.

Film Handling

Do not bend the film. Handle the film only by the edges to avoid finger marks and abrasions when loading on hangers. Separate the hangers in solutions so that films will not touch each other or the tank wall.

Carestream Health, Inc. 2008

ENSURING PROCESS QUALITY

Residual Thiosulfate Test To ensure good keeping characteristics for radiographs, use a test kit such as the KODAK Hypo Test Kit (CAT 196 5847). This test determines whether film has been adequately washed and provides an estimate of the archival life you can expect. The kit comes complete with testing solution and a visual estimator. Residual Silver Test Solution An overworked fixing bath contains complex silver thiosulfate compounds that cannot be removed completely by washing. KODAK Residual Silver Test Solution ST-1 provides a quick and accurate method for determining when a fixing bath should be discarded.

Water Sodium Sulfide (Anhydrous) 100 mL 2 grams

Fixer Test Solution KODAK Fixer Test Solution, FT-1, checks the silver content of the fixer bath.

Water at 27 C (80 F) Potassium Iodide Water to make 750 mL 190 grams 1 litre

To 5 drops of KODAK Fixer Test Solution, FT-1, add 5 drops of the fixing bath and 5 drops of water. Discard the fixer if a yellow-white precipitate forms instantly. (Any slight milkiness can be disregarded.) You can also use Silver Estimating Test Papers to measure the silver content in your fixer. One supplier is USI International, Inc. (www.silverprofit.com). KODAK NDT Exposure Calculator The KODAK NDT Exposure Calculator eliminates guesswork in determining the proper exposure and processing when using an Ir-192 source. It provides the proper exposure for a given material thickness, distance, source strength, and development*. Today, many shots are lost due to sight adjustment of density during the development cycle, so we removed the development variable to make your results more consistent. But again, getting the proper exposure is criticalso use the calculator for the correct factor for your situation.

Metric Imperial CAT 841 9335 CAT 176 9967

To Use: Store stock solution in a small stoppered bottle not more than 3 months. Dilute 1 part stock solution with 9 parts water. (Replace working solution weekly.) Place a drop of ST-1 Solution on the margin of processed film. Remove solution after 2 to 3 minutes. Any yellowing of test area indicates the presence of silver. Refix film in fresh fixer and rewash. The yellow stain is permanent.

* The KODAK NDT Exposure Calculator was standardized with a development time of 4 minutes at 72 F (22 C).

Guide to Manual Processing of NDT Films TI-2643

Your Step-by-Step Guide to Processing KODAK INDUSTREX Films

1) Stir Solutions 3) Load Film on Hanger

Stir developer and fixer to equalize their temperatures. Use separate paddles for each to avoid contamination.

2) Check Temperature

Attach film carefully to proper-sized hanger. Attach lower corners first. Avoid finger marks, scratches or bending.

4) Set Timer for Developing

Check temperature of solutions with an accurate thermometer, rinsing it off after checking each one. Adjust temperature as needed.

Set timer. 5 minutes at 68 F (20 C) is recommended. (4 minutes at 72 F [22 C] if using the KODAK NDT Exposure Calculator).

Guide to Manual Processing of NDT Films TI-2643

5) Immerse Film in Developer

7) Drain (Outside Developer)

Completely immerse film. Do it smoothly, and without pausing to avoid streaking. Start timer.

6) Agitate Film

When the timer goes off, quickly lift the hanger out of the developer. Then drain film for a moment into the space between the tanks. For faster drainage, tilt the hanger.

8) Immerse in Stop Bath

Tap hanger to dislodge air bubbles immediately after immersion in the developer. Agitate for 5 seconds every 30 seconds.

Place film in stop bath for 30 seconds. Then agitate moderately, lift from stop bath, and drain well.

Guide to Manual Processing of NDT Films TI-2643

9) Fix Adequately

11) Final Rinse

Immerse film in fixer for 3 to 6 minutes, agitating for 5 seconds very 30 seconds. Film should remain in fixer for twice the time it takes to "clear" it (when the milky look disappears). Never fix film for less than 3 minutes.

10) Wash Completely

If facilities permit, use a final rinse of KODAK PHOTO-FLO Solution to speed drying aand prevent water marks. Immerse film for about 30 seconds, and then drain for several seconds.

12) Place in Dryer

Place film hangers in tank of running water for 10 to 30 minutes. Keep ample space between hangers (water must flow over the tops).

Dry film at room temperature in a dust-free area or suitable drying cabinet. Temperature must not exceed 120 F (49 C). When dry remove from hangers and insert in envelopes.

Guide to Manual Processing of NDT Films TI-2643

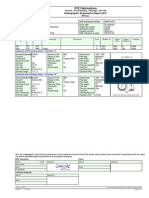

Guide to Manual Processing of NDT Films

Developer Times and Temperatures

Developer Temperature 68 F (20 C) 72 F (22 C) 75 F (24 C) 79 F (26 C)

*

Development Time (Minutes)* 5 4 3 2

Acetic Acid Stop Bath

Fixer

Wash 10 to 30 minutes in running water (8 volume changes per hour)

3 to 6 minutes or twice the time to 30 to 60 seconds clear film (Vigorous agitation (Continuous for 15 seconds then moderate agitation) 5 seconds every 30 seconds)

If it is necessary to process film at temperatures around 75 F (23.9 C) the fixer solution should be renewed frequently. The film should be fixed to provide maximum hardening and the washing time should be limited to 15 minutes. KODAK Hypo Clearing Agent can be used following the fixer to reduce wash times and conserve water. First rinse films in running water for 30 seconds, then use Hypo Clearing Agent for 1 to 2 minutes, followed by a final running water wash for 5 minutes. KODAK Photo-Flo Solution may be used after washing to reduce water spots and drying marks.

NOTICE: While the sensitometric data in this publication are typical of production coatings, they do not represent standards which must be met by Carestream Health, Inc. Varying storage, exposure, and processing conditions will affect results. The company reserves the right to change and improve product characteristics at any time.

Guide to Manual Processing of NDT Films Publication No. TI-2643 Carestream Health, Inc. 150 Verona Street Rochester, NY 14608

Revised 02-08 Printed in U.S.A. Industrex is a trademark of Carestream Health, Inc. T-Grain, Photo-Flo, the Kodak trademark and trade dress are used under license from Kodak

Вам также может понравиться

- Manual Processing (Radiography) PDFДокумент6 страницManual Processing (Radiography) PDFKeng LengОценок пока нет

- Guide To Manual Processing of NDT Films: Technical Data / Non-Destructive TestingДокумент6 страницGuide To Manual Processing of NDT Films: Technical Data / Non-Destructive Testingravi00098Оценок пока нет

- MSDS Pelicula AA 400 Film-DataДокумент4 страницыMSDS Pelicula AA 400 Film-DataPercy Junior Berrios Muñoz100% (1)

- Kodak Industrex Aa400 Film: Technical Data / Non-Destructive TestingДокумент4 страницыKodak Industrex Aa400 Film: Technical Data / Non-Destructive TestingmozymezoОценок пока нет

- KODAK INDUSTREX LO Fixer and Replenisher Processing Films - TechdataДокумент4 страницыKODAK INDUSTREX LO Fixer and Replenisher Processing Films - TechdatajotapinzonОценок пока нет

- Kodak Professional Plus-X 125 Film / 125PX: Technical Data / Black-And-White FilmДокумент10 страницKodak Professional Plus-X 125 Film / 125PX: Technical Data / Black-And-White FilmGreg MartОценок пока нет

- Kodak Tri-X Data SheetДокумент16 страницKodak Tri-X Data SheetNate CochraneОценок пока нет

- Kodak Verichrome PanДокумент4 страницыKodak Verichrome Panfoster747Оценок пока нет

- TMAX Positive Process J87Документ8 страницTMAX Positive Process J87iinuiitОценок пока нет

- TDS - CHSP 8971 - Manual Processing INDUSTREX FilmsДокумент7 страницTDS - CHSP 8971 - Manual Processing INDUSTREX FilmsJulian COULETОценок пока нет

- Relative Exposure Factor Ti2294 Kodak Industrex Aa400Документ4 страницыRelative Exposure Factor Ti2294 Kodak Industrex Aa400Charles OnyechereОценок пока нет

- Interbond 600 PDFДокумент4 страницыInterbond 600 PDFTrịnh Minh KhoaОценок пока нет

- Kodak Verichrome 125 Technical PDFДокумент4 страницыKodak Verichrome 125 Technical PDFcyberlimaОценок пока нет

- Interzinc 75V: Zinc-Rich EpoxyДокумент4 страницыInterzinc 75V: Zinc-Rich EpoxyTrịnh Minh KhoaОценок пока нет

- Kodak EktarДокумент6 страницKodak EktarArchie Buensuceso FrescoОценок пока нет

- Intergard 276: Epoxy Undercoat/ Tie-CoatДокумент4 страницыIntergard 276: Epoxy Undercoat/ Tie-CoatAhmed IbrahimОценок пока нет

- Kodak, Single-Use Chemistry Kit, ProcessДокумент8 страницKodak, Single-Use Chemistry Kit, ProcessErden Sizgek100% (2)

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - A4 - 20160729Документ4 страницыE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - A4 - 20160729Erwin MalmsteinОценок пока нет

- Producing A PCBДокумент6 страницProducing A PCBEduardo MoyaОценок пока нет

- KODAK TRI-X Reversal Film 7266Документ6 страницKODAK TRI-X Reversal Film 7266Alejandro FedezОценок пока нет

- Carboguard 885 PDSДокумент2 страницыCarboguard 885 PDSsyazwanjohnmazlanОценок пока нет

- Formula 152 Topcoat (MILDTL-24441)Документ4 страницыFormula 152 Topcoat (MILDTL-24441)Trịnh Minh KhoaОценок пока нет

- Interline MSDSДокумент4 страницыInterline MSDSUtomoОценок пока нет

- Interline 975: Solvent Free Epoxy Tank CoatingДокумент4 страницыInterline 975: Solvent Free Epoxy Tank Coatingnoto.sugiartoОценок пока нет

- TDS-JOTACOTE 5-EnglishДокумент4 страницыTDS-JOTACOTE 5-EnglishthirdОценок пока нет

- International Interswift 6800HS Antifouling Product Data SheetДокумент4 страницыInternational Interswift 6800HS Antifouling Product Data Sheetadul sungkatinОценок пока нет

- E Program Files An ConnectManager SSIS TDS PDF Interswift 6600 Eng A4 20170426Документ4 страницыE Program Files An ConnectManager SSIS TDS PDF Interswift 6600 Eng A4 20170426Erwin MalmsteinОценок пока нет

- Penguard Express ZPДокумент5 страницPenguard Express ZPMustafa Al-YasseriОценок пока нет

- Interzinc 22Документ4 страницыInterzinc 22dexterisОценок пока нет

- Rust O Cap: Surface Tolerant EpoxyДокумент3 страницыRust O Cap: Surface Tolerant EpoxySanthana SaravanaОценок пока нет

- Kodak 2254 - TI2651Документ6 страницKodak 2254 - TI2651程杰Оценок пока нет

- Hardtop CA Technical Data Sheet JotunДокумент5 страницHardtop CA Technical Data Sheet JotunSam JoseОценок пока нет

- E Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519Документ4 страницыE Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519ValentinОценок пока нет

- Interplate 317: Zinc Silicate Shop PrimerДокумент4 страницыInterplate 317: Zinc Silicate Shop PrimerMohamed NouzerОценок пока нет

- Jotacote 5Документ4 страницыJotacote 5Ridwan BaharumОценок пока нет

- Interzone 5140: Epoxy PrimerДокумент4 страницыInterzone 5140: Epoxy PrimerTrịnh Minh KhoaОценок пока нет

- Interlac 1 Gris MamaparoДокумент4 страницыInterlac 1 Gris Mamaparowilfran villegasОценок пока нет

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - Usa - A4 - 20210216Документ4 страницыE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - Usa - A4 - 20210216Zainal ArifinОценок пока нет

- AA400 SellsheetДокумент2 страницыAA400 SellsheetMido MahmoudОценок пока нет

- Interbond 808: Epoxy AnticorrosiveДокумент4 страницыInterbond 808: Epoxy AnticorrosivedcsamaraweeraОценок пока нет

- Interzone 101Документ0 страницInterzone 101hennawijayaОценок пока нет

- Primastic UniversalДокумент5 страницPrimastic UniversalaleventОценок пока нет

- E Program Files An ConnectManager SSIS TDS PDF Intergard 821 Eng A4 20151204Документ4 страницыE Program Files An ConnectManager SSIS TDS PDF Intergard 821 Eng A4 20151204Andrea Paola Chavez CentenoОценок пока нет

- E Program Files An ConnectManager SSIS TDS PDF Interswift 6800HS Eng A4 20160419Документ4 страницыE Program Files An ConnectManager SSIS TDS PDF Interswift 6800HS Eng A4 20160419shunanlatheefОценок пока нет

- (Painting) Jotamastic 87Документ5 страниц(Painting) Jotamastic 87Mohd FadliОценок пока нет

- 2-8 Kodak Digital Imaging PlatesДокумент6 страниц2-8 Kodak Digital Imaging PlatesJayeshОценок пока нет

- Kodak Flexicolor Small TankДокумент4 страницыKodak Flexicolor Small TankJohann Walter Carpio AcurioОценок пока нет

- Intershield 5150LWT: Light Weight Epoxy Non-Skid Deck CoatingДокумент4 страницыIntershield 5150LWT: Light Weight Epoxy Non-Skid Deck CoatingbandarbadhonОценок пока нет

- Berger: Product SpecificationsДокумент2 страницыBerger: Product SpecificationsAabhas UpadhyayaОценок пока нет

- Interfine 691: Isocyanate-Free FinishДокумент4 страницыInterfine 691: Isocyanate-Free FinishTrịnh Minh KhoaОценок пока нет

- Carboguard 635 Thinned 50% - Sealer PDSДокумент5 страницCarboguard 635 Thinned 50% - Sealer PDSjakeОценок пока нет

- 5222 SSДокумент2 страницы5222 SSWilliamCondeОценок пока нет

- Intersleek 425: Elastomeric Foul Release CoatingДокумент4 страницыIntersleek 425: Elastomeric Foul Release CoatingTrịnh Minh KhoaОценок пока нет

- MVE Operating Instruction Manual For Liquid Nitrogen DewarsДокумент49 страницMVE Operating Instruction Manual For Liquid Nitrogen DewarsatmokarpoОценок пока нет

- Darkroom Dexter R. Rodelas, RRT, MaedДокумент45 страницDarkroom Dexter R. Rodelas, RRT, MaedRHONE100% (1)

- International Intertuf 262Документ4 страницыInternational Intertuf 262shunanlatheefОценок пока нет

- Sonocrete - Gel PatchДокумент4 страницыSonocrete - Gel PatchOgbedande Awo OrunmilaОценок пока нет

- Sigmafast 278Документ6 страницSigmafast 278stolemkd3Оценок пока нет

- RotoUTscan v8Документ2 страницыRotoUTscan v8carlosОценок пока нет

- Zetec Ultravision EC DatasheetДокумент2 страницыZetec Ultravision EC Datasheetcarlos0% (1)

- Winter 2018 Registration FormДокумент1 страницаWinter 2018 Registration FormcarlosОценок пока нет

- Setup Guide No 4 Weld Inspection WeldcheckДокумент7 страницSetup Guide No 4 Weld Inspection WeldcheckcarlosОценок пока нет

- Safety Data Sheet: SIR Chem® Dry Powder 63 RedДокумент6 страницSafety Data Sheet: SIR Chem® Dry Powder 63 RedcarlosОценок пока нет

- Aero Fab Catalog 2014Документ23 страницыAero Fab Catalog 2014carlosОценок пока нет

- Ndtspec Radiographic Nde ReportДокумент1 страницаNdtspec Radiographic Nde ReportcarlosОценок пока нет

- HDV Accessories: Videoscope Camera Probes & AccessoriesДокумент1 страницаHDV Accessories: Videoscope Camera Probes & AccessoriescarlosОценок пока нет

- Eddyliner PX User ManualДокумент146 страницEddyliner PX User ManualcarlosОценок пока нет

- AAR Manual of StandardsДокумент40 страницAAR Manual of StandardsKristian Marchena100% (3)

- 2.a.omniscan Setup - Calibration For Sectorial ScanДокумент34 страницы2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- VM Products Gain Test Box2Документ16 страницVM Products Gain Test Box2carlos100% (1)

- NDT MarketplaceДокумент1 страницаNDT MarketplacecarlosОценок пока нет

- Omniscan Setup - Basic SetupДокумент29 страницOmniscan Setup - Basic SetupcarlosОценок пока нет

- 2.a.omniscan Setup - Calibration For Sectorial ScanДокумент34 страницы2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- OmniSX MX2 Training 4A PA Calculator OverviewДокумент10 страницOmniSX MX2 Training 4A PA Calculator OverviewcarlosОценок пока нет

- 4.omniscan Setup - Min-Wheel Encoder SetupДокумент13 страниц4.omniscan Setup - Min-Wheel Encoder SetupcarlosОценок пока нет

- OmniSX MX2 Training 4C Phased Array WedgesДокумент37 страницOmniSX MX2 Training 4C Phased Array WedgescarlosОценок пока нет

- 55 Demag PipeДокумент2 страницы55 Demag PipecarlosОценок пока нет

- OmniSX MX2 Training 4B Phased Array ProbesДокумент49 страницOmniSX MX2 Training 4B Phased Array Probescarlos100% (2)

- Model BLR-1™ Blue Light RadiometerДокумент1 страницаModel BLR-1™ Blue Light RadiometercarlosОценок пока нет

- OmniSX MX2 Training 7 UT ConfigurationДокумент29 страницOmniSX MX2 Training 7 UT Configurationcarlos100% (2)

- ISONIC UtPod Operating Manual Revision 1 - 12Документ72 страницыISONIC UtPod Operating Manual Revision 1 - 12carlosОценок пока нет

- Omniscan Setup - Basic SetupДокумент29 страницOmniscan Setup - Basic SetupcarlosОценок пока нет

- PA Probes Specs Zion NDTДокумент1 страницаPA Probes Specs Zion NDTcarlosОценок пока нет

- Iso 10211 Heat2 Heat3Документ16 страницIso 10211 Heat2 Heat3nsk377416100% (1)

- View/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordДокумент2 страницыView/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordlakshmilavanyaОценок пока нет

- Report On Siddartha Bank LimitedДокумент24 страницыReport On Siddartha Bank LimitedSanim AmatyaОценок пока нет

- E85005-0126 - FireShield Plus Conventional Fire Alarm Systems PDFДокумент8 страницE85005-0126 - FireShield Plus Conventional Fire Alarm Systems PDFLuis TovarОценок пока нет

- Engg Prospect1usДокумент20 страницEngg Prospect1usArun KumarОценок пока нет

- New Microsoft Office Power Point PresentationДокумент21 страницаNew Microsoft Office Power Point PresentationSai DhanushОценок пока нет

- The Role of Social Media and Its Implication On Economic Growth On Society in IndiaДокумент3 страницыThe Role of Social Media and Its Implication On Economic Growth On Society in IndiaSara EmamiОценок пока нет

- Sandisk X400 SSD (Solid State Drive) : The World'S First 1Tb, Single-Sided SSDДокумент2 страницыSandisk X400 SSD (Solid State Drive) : The World'S First 1Tb, Single-Sided SSDlechurzОценок пока нет

- Attempt 1 OrgДокумент19 страницAttempt 1 OrgMohammed Irfan SheriffОценок пока нет

- OpenFoam of AppsДокумент20 страницOpenFoam of AppsM AliОценок пока нет

- Phase ShifterДокумент7 страницPhase ShifterNumanAbdullahОценок пока нет

- Why Rife Was Right and Hoyland Was Wrong and What To Do About ItДокумент4 страницыWhy Rife Was Right and Hoyland Was Wrong and What To Do About ItHayley As Allegedly-Called Yendell100% (1)

- Bombillas LedДокумент1 страницаBombillas LedElviore PeruОценок пока нет

- Building 101 - 25 Tips For A Tropical HomeДокумент11 страницBuilding 101 - 25 Tips For A Tropical HomeMelanie CabforoОценок пока нет

- IEC 60364-1 Electrical Installations in Buildings PDFДокумент80 страницIEC 60364-1 Electrical Installations in Buildings PDFMarin PopescuОценок пока нет

- Yaskawa TM.J7.01Документ96 страницYaskawa TM.J7.01Salvador CrisantosОценок пока нет

- H S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolДокумент58 страницH S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolCRISTIANОценок пока нет

- Cidtt The GuideДокумент268 страницCidtt The GuideAbdul Shameem100% (1)

- DataДокумент4 страницыDataQuế SươngОценок пока нет

- RAC D Expansion DevicesДокумент21 страницаRAC D Expansion DevicesSohaib IrfanОценок пока нет

- ERP and SCM Systems Integration: The Case of A Valve Manufacturer in ChinaДокумент9 страницERP and SCM Systems Integration: The Case of A Valve Manufacturer in ChinaiacikgozОценок пока нет

- AIX PowerHA (HACMP) CommandsДокумент3 страницыAIX PowerHA (HACMP) CommandsdanilaixОценок пока нет

- CMD LinecommandsДокумент14 страницCMD LinecommandsdesideriuОценок пока нет

- Residential Solar System Proposal ExampleДокумент13 страницResidential Solar System Proposal ExamplehernelandОценок пока нет

- Server Side - Java - Using Rmi With Apache JservДокумент16 страницServer Side - Java - Using Rmi With Apache JservTotoAlipioОценок пока нет

- AAE 11.3.1 User Guide ClientДокумент475 страницAAE 11.3.1 User Guide Clientme4ias100% (2)

- David Beard Composer CV ShortДокумент2 страницыDavid Beard Composer CV ShortEhsan KarimyОценок пока нет

- Gudenaaparken (Randers) - All You Need To Know BEFORE You GoДокумент8 страницGudenaaparken (Randers) - All You Need To Know BEFORE You GoElaine Zarb GiorgioОценок пока нет

- JeeleДокумент9 страницJeeleAnonymous SZDGk7SvGОценок пока нет