Академический Документы

Профессиональный Документы

Культура Документы

General Configuration For Liquid Flow Calculation

Загружено:

said_rahmansyah4750Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

General Configuration For Liquid Flow Calculation

Загружено:

said_rahmansyah4750Авторское право:

Доступные форматы

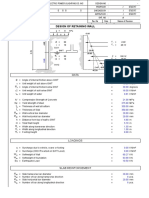

Calculations Liquid Flow (Table #51)

General Configuration for Liquid Flow Calculation

Configure the liquid flow calculation and enable it from the General page. Calculation: Enable/disable the liquid flow calculation here. Descriptor: Enter a text string that identifies the calculation. Meter ID: Enter a text string that identifies or names the device associated with the calculation. Flow Type: Select whether a turbine or orifice meter is used. API Table Used: Select the API table to be used for this calculation. Options are listed below.

Table 23/24 A Table 23/24 B Table 24 C Old Table 23/24 Table 23/24 E Table 53/54 A Table 53/54 B Table 54 C Old Table 53/54 Propylene (CH 11.3.3) Ethylene (API 2565) Ethylene (NBS 1045)

Turbine Pickup: If you selected turbine as the flow type, select a single or dual turbine meter pickup pulse.

Thermo Fisher Scientific

Calculations Liquid Flow (Table #51)

SG Override: To use a live API/SG/density input, enter '0' in this field. Otherwise, enter the API/SG/density override value. Atmospheric Pressure: Enter the current atmospheric pressure in psi measured at the installation site. K-Factor: Enter the meter's K-Factor. Include HYC Fact: If you selected an API A/B table, enter the glass hydrometer correction factor. Refer to API Chapter 9 or other appropriate density/hydrometer standards for further explanation. Contract Hour: Enter the time of day that the flow computer stores an archive in the daily historical log and starts a new set of averages and accumulations for a new day. ASTM 1250 Selection: Select the ASTM standard being used (ASTM1250-1980 or ASTM 1250-2004). Meter Pulse Hz: This is a read-only field that displays the current meter pulse. Meter Accumulator Pulse: Connect this field to a live value (typically a #20-Physical Accumulator entry). Current Product Index: This field displays the index of the product that is currently running. Reference Temperature: Enter the correction temperature used to calculate SG at 60F or density at 15F. The default is to 60. BS&W % (Water Cut): Enter the volume percentage of BS&W (basic sediments and water). Meter Active Threshold Hz: This entry determines when a batch starts. If flowmeter input (Hz) is greater than this value, a batch will start. Pulse Deviation Threshold: This field is available if you selected a dual turbine meter pickup pulse. If pulse frequency exceeds this value, the system will begin comparing and totalizing error counts. Density Type: If measuring density, select the type. Options are listed below.

None 420 mA: If you select 420 mA as the density type, choose the input type (SG, API, Density) in the Density Input Select field. Density Calc #1#6: Select one of these options if you are using a densitometer and have configured a density calculation.

Density Input Select: Select the density input type. Options are: SG, API, density. Static Pressure: Enter the current line pressure measured on the pipe, or connect this field to a live value (typically a #16-Physical Analog Input entry). Temperature: Enter the temperature of the fluid, or connect this field to a live value (typically a #16-Physical Analog Input entry). Reference Density: If you selected ethylene or propylene as the API table being used, enter density value used to calculate net flow rate. Alpha T (E-6): If you selected a table C as the API table being used, enter the thermal expansion coefficient. Error Pulse Hz: If you selected a dual turbine meter pickup pulse, this field displays the current error pulse. Error Accumulator Pulse: If you selected a dual turbine meter pickup pulse, connect this field to a live value (typically a #20-Physical Accumulator entry).

Thermo Fisher Scientific

Calculations Liquid Flow (Table #51)

Density Temperature Selection: Select whether the meter temperature or density temperature is being used. Density Pressure Selection: Select whether the meter pressure or density pressure is being used. Density Temperature: Enter the density temperature. Density Pressure: Enter the density pressure. Month Start Day: Enter the day of the month which starts a new contract month. Error Count Limit: If any unbalance exists in the two pulse trains and the error counts exceed this threshold, the AutoEXEC will issue an alarm. The error counts will be cleared at the end of a batch.

Thermo Fisher Scientific

Вам также может понравиться

- CV of Res EngДокумент5 страницCV of Res Engyasir_irfan01Оценок пока нет

- Material Balance Vs Reservoir SimulationДокумент7 страницMaterial Balance Vs Reservoir Simulationpampizzle100% (1)

- PVTSim Method Documentation by CALSEPДокумент179 страницPVTSim Method Documentation by CALSEPAnonymous Vbv8SHv0bОценок пока нет

- Nigeria Factories Act, 1987Документ56 страницNigeria Factories Act, 1987Ethelbert AkwuruahaОценок пока нет

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsОт EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsОценок пока нет

- Ayc Ic & Itp SealerДокумент6 страницAyc Ic & Itp Sealermoytabura96Оценок пока нет

- Spe 99446Документ8 страницSpe 99446Nana Silvana AgustiniОценок пока нет

- 5.2. Clean Up A Well's DiscussionДокумент16 страниц5.2. Clean Up A Well's DiscussionHermilih SiregarОценок пока нет

- CO2 Storage Projects in Europe Map 120919Документ10 страницCO2 Storage Projects in Europe Map 120919av1986362Оценок пока нет

- Petroleum Production Optimization: TechnologyДокумент18 страницPetroleum Production Optimization: TechnologybehnamjpОценок пока нет

- Hamdon Echometer Model E Well Analyzer BrochureДокумент4 страницыHamdon Echometer Model E Well Analyzer BrochurearispriyatmonoОценок пока нет

- 06 - Well Test - Type CurvesДокумент20 страниц06 - Well Test - Type CurvesNanthini PalanisamyОценок пока нет

- Project Economics Decision Analysis V1 Deterministic Models TOC SampleДокумент15 страницProject Economics Decision Analysis V1 Deterministic Models TOC SampleRalmeОценок пока нет

- INSTALLATION Multiphase FlowmeterДокумент3 страницыINSTALLATION Multiphase FlowmeterHafizszul Feyzul100% (3)

- Bourdet vs. Additional Derivatives: In/heshammokhtaraliДокумент11 страницBourdet vs. Additional Derivatives: In/heshammokhtaralimanish.7417Оценок пока нет

- Cathodic Protection SystemДокумент11 страницCathodic Protection SystemphuongОценок пока нет

- OLGA 7-NotesДокумент10 страницOLGA 7-NotesraminabkОценок пока нет

- Jason PowerLogFrac BrochureДокумент4 страницыJason PowerLogFrac BrochureAlvaro Quinteros CabreraОценок пока нет

- MER - Maximum Efficient RateДокумент13 страницMER - Maximum Efficient Ratealizareiforoush100% (1)

- Effect of Gas Lock in Transient Flow in HDPEДокумент1 страницаEffect of Gas Lock in Transient Flow in HDPEBhupendra PalОценок пока нет

- L.A.C.T. Unit DesignДокумент3 страницыL.A.C.T. Unit DesignBill Gu100% (2)

- Pvtsim Technical Overview 2016 Download v3Документ16 страницPvtsim Technical Overview 2016 Download v3Jorge Vásquez CarreñoОценок пока нет

- MEERA Reservoir Simulation Software IntroductionДокумент19 страницMEERA Reservoir Simulation Software IntroductionShahrukh SadiqОценок пока нет

- Pressure Transient PDFДокумент11 страницPressure Transient PDFenriqueg_53Оценок пока нет

- Spe 162985 MSДокумент11 страницSpe 162985 MScalos cariОценок пока нет

- KAPPA Workstation Installation v5.30.03Документ6 страницKAPPA Workstation Installation v5.30.03GhulamОценок пока нет

- Shell Tank Overfill Model Bow TieДокумент17 страницShell Tank Overfill Model Bow Tiehvananth100% (1)

- Sulphur Recovery UnitДокумент39 страницSulphur Recovery UnitChetal Bhole100% (1)

- Fundamentals of Flow MeterДокумент12 страницFundamentals of Flow Meteralan_yaobin8409Оценок пока нет

- Volumetric Reserves EstimatesДокумент34 страницыVolumetric Reserves EstimatesmhmdsaalemОценок пока нет

- Enrtl-Rk Rate Based PZ ModelДокумент24 страницыEnrtl-Rk Rate Based PZ ModelsamandondonОценок пока нет

- Advanced Techniques For Acoustic Liquid Level DeterminationДокумент14 страницAdvanced Techniques For Acoustic Liquid Level Determinationmáté_galambosiОценок пока нет

- KAPPA Rubis TutorialДокумент22 страницыKAPPA Rubis TutorialSARTHAK BAPAT100% (1)

- Basic Cash Formulas Manual April 2009 - 2.8Документ123 страницыBasic Cash Formulas Manual April 2009 - 2.8horns2034Оценок пока нет

- PIPESIM Pipeline and Facilities Modeling: Identify and Engineer The Best Pipelines and Facilities DesignДокумент2 страницыPIPESIM Pipeline and Facilities Modeling: Identify and Engineer The Best Pipelines and Facilities DesignpertmasterОценок пока нет

- Ukti Guide To Doing Business in The Nigerian o & G Sector - Current 05Документ135 страницUkti Guide To Doing Business in The Nigerian o & G Sector - Current 05rnoordin100% (1)

- Ogp Risk Assessment Data DirectoryДокумент26 страницOgp Risk Assessment Data Directoryandrew_chen5758Оценок пока нет

- New Method To Estimate Surface-Separator Optimum Operating PressuresДокумент12 страницNew Method To Estimate Surface-Separator Optimum Operating PressuresIkramullohОценок пока нет

- Pig OlgaДокумент24 страницыPig OlgaCitlalli QuetzalcoatlОценок пока нет

- Lectures On Well Testing 1AДокумент37 страницLectures On Well Testing 1APatrick KariukiОценок пока нет

- Merak Peep Workflow Excel Import: Schlumberger Information SolutionsДокумент20 страницMerak Peep Workflow Excel Import: Schlumberger Information SolutionsTripoli ManoОценок пока нет

- Setting Up A Reservoir Simulation ModelДокумент30 страницSetting Up A Reservoir Simulation ModelMariam Tatty LeonОценок пока нет

- The Main Installations: 1. Degassing StationsДокумент4 страницыThe Main Installations: 1. Degassing Stationsعمار ياسرОценок пока нет

- 2016اسس هندسة النفط2Документ31 страница2016اسس هندسة النفط2mustafa jassimОценок пока нет

- Production Decline AnalysisДокумент10 страницProduction Decline AnalysisDing J. LimОценок пока нет

- Echometer Well AnalysisДокумент1 страницаEchometer Well AnalysisefrasozaОценок пока нет

- Meter Linearity Turbine Meter PerspectiveДокумент3 страницыMeter Linearity Turbine Meter PerspectiveraminОценок пока нет

- Schedule 03Документ70 страницSchedule 03Tarek HassanОценок пока нет

- Sandoa Acoustic TelemetryДокумент90 страницSandoa Acoustic Telemetrygsmsby100% (1)

- PRE - RE1 2017 Chapter 7-2Документ17 страницPRE - RE1 2017 Chapter 7-2Hari TharanОценок пока нет

- Eclipse Tutorial4Документ11 страницEclipse Tutorial4Cara BakerОценок пока нет

- PDFДокумент8 страницPDFmsmsoft90Оценок пока нет

- Paper 39 Lawrence (Flow Measurement)Документ15 страницPaper 39 Lawrence (Flow Measurement)Philip A Lawrence C.Eng. F. Inst M.C.Оценок пока нет

- Reservoir ManagementДокумент67 страницReservoir ManagementSajad FalahОценок пока нет

- List of Abbreviations in Oil and Gas Exploration and ProductionДокумент46 страницList of Abbreviations in Oil and Gas Exploration and ProductionDhanushОценок пока нет

- ID-017 Instrument Communications PDFДокумент70 страницID-017 Instrument Communications PDFФизули АбиловОценок пока нет

- A Method To Estimate The Drainage Area of A Horizontal WellДокумент8 страницA Method To Estimate The Drainage Area of A Horizontal Wellabnou_223943920Оценок пока нет

- OFM Installation GuideДокумент26 страницOFM Installation GuideHomero Castilla100% (1)

- Elster Instromet Q.sonicДокумент2 страницыElster Instromet Q.sonicsaid_rahmansyah4750Оценок пока нет

- Eng Guide LiquidДокумент8 страницEng Guide Liquidsaid_rahmansyah4750Оценок пока нет

- Instrument OpticДокумент19 страницInstrument Opticsaid_rahmansyah4750Оценок пока нет

- BioEngineering - CompДокумент2 страницыBioEngineering - Compsaid_rahmansyah4750Оценок пока нет

- Engrguid GasДокумент2 страницыEngrguid Gassaid_rahmansyah4750Оценок пока нет

- LiquidДокумент2 страницыLiquidsaid_rahmansyah4750Оценок пока нет

- EngrguidДокумент20 страницEngrguidsaid_rahmansyah4750Оценок пока нет

- Isolating Driver: MTL4549/C/Y - MTL5549/YДокумент1 страницаIsolating Driver: MTL4549/C/Y - MTL5549/Ypradeepchennai10_959Оценок пока нет

- DS - EnCal - 3000 - EN - 2012.04.30Документ4 страницыDS - EnCal - 3000 - EN - 2012.04.30said_rahmansyah4750Оценок пока нет

- Elster-Instromet M2000 FCДокумент0 страницElster-Instromet M2000 FCsaid_rahmansyah4750Оценок пока нет

- Api PДокумент2 страницыApi Psaid_rahmansyah4750Оценок пока нет

- 901-100 TP48Документ4 страницы901-100 TP48said_rahmansyah4750Оценок пока нет

- FD960 Density MeterДокумент2 страницыFD960 Density Metersaid_rahmansyah4750Оценок пока нет

- Elster-Instromet Encal3000 GCДокумент0 страницElster-Instromet Encal3000 GCsaid_rahmansyah4750Оценок пока нет

- 570 Data SheetДокумент2 страницы570 Data Sheetsaid_rahmansyah4750Оценок пока нет

- Instromet Explore QsonicДокумент25 страницInstromet Explore Qsonicsaid_rahmansyah4750Оценок пока нет

- ID900 Density MeterДокумент2 страницыID900 Density Metersaid_rahmansyah4750Оценок пока нет

- SG900 Specific GravityДокумент2 страницыSG900 Specific Gravitysaid_rahmansyah4750Оценок пока нет

- FD910 Density MeterДокумент2 страницыFD910 Density Metersaid_rahmansyah4750Оценок пока нет

- ID900 Density MeterДокумент2 страницыID900 Density Metersaid_rahmansyah4750Оценок пока нет

- Sequence Control - LC64Документ34 страницыSequence Control - LC64said_rahmansyah4750Оценок пока нет

- 2205Документ5 страниц2205chacon123Оценок пока нет

- Ca'e 'Ate' L ! I I: Ilv I LL - UgeДокумент5 страницCa'e 'Ate' L ! I I: Ilv I LL - Ugesaid_rahmansyah4750Оценок пока нет

- Yokogawa FFДокумент41 страницаYokogawa FF1907nirmal100% (1)

- CH 11 OrganizationДокумент1 страницаCH 11 OrganizationSaid RahmansyahОценок пока нет

- Sequence Control - LC64Документ34 страницыSequence Control - LC64said_rahmansyah4750Оценок пока нет

- CH 11 OrganizationДокумент1 страницаCH 11 OrganizationSaid RahmansyahОценок пока нет

- CH 11 OrganizationДокумент1 страницаCH 11 OrganizationSaid RahmansyahОценок пока нет

- CPL and CTL CalculationДокумент9 страницCPL and CTL CalculationnoxleekОценок пока нет

- Chapter 2 Loads On StructuresДокумент21 страницаChapter 2 Loads On StructuresMarissa BrownОценок пока нет

- Experiment - 5 - Thermal Coefficient of The Bad Conductor - Lee and CharltonДокумент9 страницExperiment - 5 - Thermal Coefficient of The Bad Conductor - Lee and CharltonsurajОценок пока нет

- Weld Design-GrДокумент58 страницWeld Design-Grvenky100% (1)

- 5 Practice Questions - VentДокумент6 страниц5 Practice Questions - VentRehman MuzaffarОценок пока нет

- Experiment 1-Vapour Pressure and Enthalpy of VaporisationДокумент5 страницExperiment 1-Vapour Pressure and Enthalpy of VaporisationStefani KavangoОценок пока нет

- 1.1 Review of Elementary Mechanics of Materials (Aka Strengths of Materials)Документ11 страниц1.1 Review of Elementary Mechanics of Materials (Aka Strengths of Materials)Boonme ChinnaboonОценок пока нет

- Lab Report Heat of ReactionДокумент8 страницLab Report Heat of ReactionLera May BenavidezОценок пока нет

- Fracture Toughness Properties of High-StrengthДокумент10 страницFracture Toughness Properties of High-StrengthEngels OchoaОценок пока нет

- Temperature Changes Using A Heat Transfer Bar: Time (Minutes)Документ3 страницыTemperature Changes Using A Heat Transfer Bar: Time (Minutes)Denny GrapesОценок пока нет

- Callister - Concept Check AnswersДокумент58 страницCallister - Concept Check AnswersGöksun Güven75% (4)

- OTC 23521 Foundation Modeling and Assessment in The New ISO Standard 19905-1Документ23 страницыOTC 23521 Foundation Modeling and Assessment in The New ISO Standard 19905-1Zine L DelОценок пока нет

- Tablon Retaining Wall Ht. - Clark - With WindДокумент27 страницTablon Retaining Wall Ht. - Clark - With WindclarkgaguiОценок пока нет

- MERMindexДокумент68 страницMERMindexgashaw251Оценок пока нет

- Belmokhtar Triaxial 2018 HALДокумент39 страницBelmokhtar Triaxial 2018 HALSaad JuventinoОценок пока нет

- Lab Guide - Francis TurbineДокумент14 страницLab Guide - Francis TurbineBonifacioОценок пока нет

- Water CoolerДокумент37 страницWater Coolerpramo_dassОценок пока нет

- Agricultural and Biological Engineering: Psychrometric Chart UseДокумент6 страницAgricultural and Biological Engineering: Psychrometric Chart Usenaevus91Оценок пока нет

- Numerical Modeling of Rock Slopes in Siwalik Hills Near Manali Region: A Case StudyДокумент21 страницаNumerical Modeling of Rock Slopes in Siwalik Hills Near Manali Region: A Case Studywidayat81Оценок пока нет

- Fluid Mechanics - Multiple Choice Questions and Answers (MCQ) - ScholarexpressДокумент4 страницыFluid Mechanics - Multiple Choice Questions and Answers (MCQ) - Scholarexpressnitesh_kumar079976Оценок пока нет

- Compressible Fluid Dynamics Thompson)Документ340 страницCompressible Fluid Dynamics Thompson)kiapoulo100% (1)

- Thermodynamics 2 E7Документ41 страницаThermodynamics 2 E7taya699Оценок пока нет

- National Standard Examination in Physics (NSEP) 2015 A Detailed Analysis by ResДокумент4 страницыNational Standard Examination in Physics (NSEP) 2015 A Detailed Analysis by ResAnurag PrasadОценок пока нет

- Sagar K R-ResumeДокумент6 страницSagar K R-ResumeAdithya HbОценок пока нет

- Brinkman EquationДокумент5 страницBrinkman EquationAdegbite Jamiu OyekanОценок пока нет

- Design Construction EjectorДокумент136 страницDesign Construction EjectorChirag SabalparaОценок пока нет

- Chem 1220 Assignment 1Документ2 страницыChem 1220 Assignment 1KathiОценок пока нет

- PH6151-Engineering Physics-I PDFДокумент133 страницыPH6151-Engineering Physics-I PDFRìzwàñ Checkzz II100% (1)

- Pressure Relief SystemsДокумент30 страницPressure Relief SystemsBibek MerОценок пока нет

- PTAP El Portico Proyecto III HVAC Load Analysis: Prepared byДокумент8 страницPTAP El Portico Proyecto III HVAC Load Analysis: Prepared bykatherine palominoОценок пока нет

- Stress Concentration at NotchesДокумент510 страницStress Concentration at NotchesRodrigo MarinОценок пока нет