Академический Документы

Профессиональный Документы

Культура Документы

The Effects of Alloying Elements On Steels

Загружено:

Rahul PandeyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

The Effects of Alloying Elements On Steels

Загружено:

Rahul PandeyАвторское право:

Доступные форматы

Technische Universitt Graz

Institut fr Werkstoffkunde, Schweitechnik und Spanlose Formgebungsverfahren

Christian Doppler Laboratory for Early Stages of Precipitation

The Effects of Alloying Elements on Steels (I)

Mehran Maalekian

October 2007

M.Maalekian

CDL/ESOP

Contents

1 2 3 4 5 6 7 8 9 10 10.1 10.2 11 12 Classification of Iron Alloy Phase Diagrams ........................................... 3 Effect on the Eutectoid Point .................................................................. 6 Distribution of Alloying Elements ............................................................ 8 Alloy Carbides ...................................................................................... 10 Effects on Transformation Diagrams .................................................... 13 Effect on Ferrite Hardness .................................................................... 14 Effect on Martensite Transformation Temperature ............................... 15 Nitride-forming Elements ...................................................................... 16 Effect on Hardenability.......................................................................... 17 Effect on Tempering .......................................................................... 21 Effect on the formation of iron carbides ......................................... 22 The Formation of Alloy Carbides (Secondary Hardening) ............. 24 Effect on Grain Growth...................................................................... 29 Bibliography ...................................................................................... 36

M.Maalekian

CDL/ESOP

1 Classification of Iron Alloy Phase Diagrams

It is a log-standing tradition to discuss the various alloying elements in terms of the properties they confer on steel. However, it would be impossible to include a detailed survey of the effects of alloying elements on the iron-carbon equilibrium diagram in this short literature review. In the simplest form this would need analysis of a large number of ternary alloy diagrams over a wide temperature range. However, the characteristics of the transformation in the various iron binary equilibrium systems permit a classification as in Fig. 1 as: open and closed -field systems, and expanded and contracted -field systems [1]. This approach indicates that alloying elements can influence the equilibrium diagram in two ways:

(i)

By expanding the -field, and encouraging the formation of austenite over wider compositional limits. These elements are called -stabilizer.

(ii)

By contracting the -field, and encouraging the formation of ferrite over wider compositional limits. These elements are called -stabilizers.

The form of the diagram depends to some degree on the electronic structure of the alloying elements which is reflected in their relative positions in the periodic classification. Type 1: Open -field. The important steel alloying elements Ni and Mn as well as Co and the inert metals such as Pt belong to this group. These alloying elements widens the temperature range for stable austenite by depressing the transformation and raising the - transformation. Both Ni and Mn, if added in sufficiently high concentration, completely eliminate the bcc -iron phase and replace it, down to room temperature, with the phase. So Ni and Mn lower both Ae1 and Ae3 (Fig. 1 a). It is also easier to obtain metastable austenite by

M.Maalekian

CDL/ESOP

quenching from the austenite region to room temperature, consequently Ni and Mn are useful elements in the austenitic steels. Type 2: Expanded -field. C and N are the most important elements in this group. The phase field is expanded, but its range of existence is cut short by compound formation (Fig. 1 b). Cu, Zn and Au have similar influence. The expansion of the phase by carbon, and nitrogen, underlies the whole of the heat treatment of steels, by allowing formation of a homogenous solid solution (austenite) comprising up to 2.0 wt% of carbon or 2.8 wt% of nitrogen. Type 3: Closed -field. Many elements restrict the formation of -iron, causing the -area of the diagram to contract to a small area referred to as gamma loop (Fig. 1 c). This means that the relevant elements are encouraging the formation of bcc iron (ferrite), and one result is that the and phase

fields become continuous. These alloys are, therefore, not amenable to the normal heat treatments involving cooling through the / phase transformation. Si, Al, Be, and P fall into this category, together with the strong carbide-forming elements, Ti, V, Mo and Cr. Type 4: Contracted -field. The -loop is strongly contracted, but is

accompanied by compound formation (Fig. 1 d). Boron is the most important element of this group, together with the carbide-forming elements Ta (tantalum), Zr and Nb. Fig. 2 shows the influence of different alloying elements on the -loop of various binary systems of iron.

M.Maalekian

CDL/ESOP

Fig. 1 Classification of iron alloy phase diagrams: (a) open field; (b) expanded field; (c) closed field; (d) contracted field [1].

Fig. 2 -loops formed in various binary systems of iron.

M.Maalekian

CDL/ESOP

Thus it appears from these phase diagrams that the crystal structure of solid solutions of iron at room temperature is the important basis for classifying steels. If austenite is predominant at room temperature because of the addition of sufficiently large amounts of Ni or Mn, it is called austenitic steel. Examples are: Hadfield steel containing 13% Mn, 1.2% Cr, and 1% C; and 18% Cr and 8% Ni austenitic stainless steel (all in wt%). On the other hand, if the room-temperature structure consists mostly of

iron solid solution that is made possible by the ferrite-forming elements (e.g., Cr, Si, Mo, W and Al), it is called ferritic steel. Examples are Fe-Cr alloys containing more than 13% Cr, and low-carbon transformer steel containing about 3% Si.

2 Effect on the Eutectoid Point

Austenite and ferrite stabilizers widen the respective phase fields. The effect of alloying elements on the Fe-Fe3C phase diagram is strongly reflected in the eutectoid temperature, which is raised or lowered by the alloying addition. The austenite stabilizers lower the eutectoid temperature, thereby widening the temperature range over which austenite is stable. Similarly, the ferrite formers raise the eutectoid temperature, thereby restricting the phase field. Fig. 3 shows the influence of alloying addition on eutectoid temperature and eutectoid carbon content.

M.Maalekian

CDL/ESOP

Fig. 3 Influence of alloying element additions on the eutectoid temperature and the eutectoid carbon content [4].

One convenient way of illustrating quantitatively the effect of an alloying element on the -phase field of the Fe-C system is to project on to the Fe-C plane of the ternary system the -phase field boundaries for increasing concentration of a particular alloying element. This is illustrated in Fig. 4 for Ti, Cr, Mo and Mn, from which, for example, it is evident that just over 1 wt% Ti will eliminate the -loop, whereas 20 wt% Cr is required to reach this point. Associated changes in eutectoid temperature and composition are also illustrated.

M.Maalekian

CDL/ESOP

(a)

(b)

(c)

(d)

Fig. 4 Effect of alloying additions on the -phase field: (a) Mn; (b) Mo; (c) Cr; (d) Ti [1].

3 Distribution of Alloying Elements

In commercial alloy steels, which are multicomponent systems, alloying elements can be found (i) in the free state; (ii) as intermetallic compound with iron or with each other; (iii) as oxides, sulfides, and other nonmetal inclusions; (iv) in the form of carbides; or (v) as a solution in iron [5]. As to the character of their distribution in steel, alloying elements may be divided into two groups:

1) Elements that do not form carbides in steel (e.g. Ni, Si, Co, Al, Cu and N) 2) Elements that form stable carbides in steel (e.g. Cr, Mn, Mo, W, V, Ti, Zr, and Nb).

M.Maalekian

CDL/ESOP

The first group elements do not form chemical compounds with iron and carbon, and consequently the only possible form in which they can be present in steel is in solid solutions with iron. The only exceptions are Cu and N. Copper dissolves in -iron at normal temperatures in amounts of up to 1.0%. If the Cu

content exceeds 7%, iron will contain copper in the free state as metal inclusions. Nitrogen also has a limited solubility in ferrite. When the N content is higher than 0.015%, nitrogen is found in steel in the form of chemical compounds with iron or some alloying elements (V, Al, Ti, and Cr). These chemical compounds are called nitrides. Alloying elements whose affinity for oxygen is greater than that of iron are capable of forming oxides and other nonmetal compounds. When added at the very end of the steel melting process, such elements (e.g., Al, Si, V, Ti) deoxidize steel by taking oxygen from iron. The deoxidizing reaction yields Al 2O3, TiO2, V2O5 and other oxides. Owing to the fact that deoxidizers are introduced at the final stages of the steel melting process, the majority of oxides have no time to coagulate or to pass to slag, and as a result they are retained in the solid steel as fine nonmetal inclusions. In addition to a great affinity for oxygen, some alloying elements have a greater affinity for sulfur than iron does, and upon being introduced into steel, they form sulfides. Alloying elements that form stable carbides in steel can be found in the form of chemical compounds with carbon and iron or be present in the solid solution. The distribution of theses elements depends on the carbon contents of steel and the concurrent presence of other carbide-forming elements. If a steel contains a relatively small amount of carbon and a great quantity of an alloying element, then, carbon will be bound to carbides before the carbide-forming elements are completely used. For this reason excess carbide-forming elements will be found in the solid solution. If a steel has a large amount of carbon and little of the alloying elements, the latter will be present in the steel mainly as carbides. Most alloying elements, except C, N, O, B and metalloids standing far from iron in the periodic table, dissolve in great amount in iron. The elements standing to the right of iron (Co, Ni, Cu, etc.) form solutions in iron only and do not enter

M.Maalekian

CDL/ESOP

10

into carbides. Thus one can state that alloying elements dissolve predominantly into basic phases (ferrite, austenite, cementite) of iron-carbon alloys or form special carbides [5].

4 Alloy Carbides

The addition to iron-carbon alloys of elements such as Ni, Si, Mn, which do not form carbides in competition with cementite, does not basically alter the microstructures formed after transformation. However, in the case of strong carbide-forming elements such as Mo, Cr and W, cementite will be replaced by the appropriate alloy carbides, often at relatively low alloying element concentrations. Still stronger carbide- forming elements such as Nb, Ti and V are capable of forming alloy carbides preferentially at alloying concentrations less than 0.1wt%. It would, therefore, be expected that the microstructures of steels containing these elements would be radically altered. Carbides are formed in steels only by iron and metals that stand to the left of iron in the periodic table. The strong carbide-forming elements are shown in Fig. 5.

Fig. 5 The periodic table showing the positions of strong carbide-forming elements [6].

M.Maalekian

CDL/ESOP

11

In steel six kinds of carbides can be formed as shown in Table 1, where M denotes a sum of carbide-forming (metal) elements. The carbides placed in group I posses a complicated crystal structure; an examples is cementite (Fe3C), or Cr23C6. A specific structural feature of the carbides of group II as interstitial phases is a simple crystal lattice (e.g., TiC, WC, NbC and Mo2C).

Table 1 Possible variants of carbide formation in steels.

Carbides of group I Carbides of group II M3C M23C6 M7C3 M6C MC M2C

The stability of the alloy carbides and nitrides in steels relative to that of cementite is shown in Fig. 6, where the enthalpies of formation ( Hf) are plotted (cementite is the reference, i.e. Hf-cementite=0). It should be noted that the

effectiveness of the carbides as strengtheners depends on the fineness of the dispersion and the volume fraction precipitated. The fineness of the dispersion depends on the activation energy barrier ( G*) for nucleation which in turn is influenced by the free energy of formation of the carbide, the interfacial energy and the misfit. Fig. 6 can be used as a guide in this regard. The finest precipitate dispersions are generally obtained from VC, NbC, TiC, TaC and HfC. Theseare all close-packed intermetallic compounds. On the other hand the carbides with complex crystal structures and low heats of formation, e.g. M7C3, M6C and M23C6, generally form relatively coarse dispersions [7].

M.Maalekian

CDL/ESOP

12

Fig. 6 Enthalpies of formation of carbides, nitrides and borides [7].

The volume fraction of carbide precipitated depends on the solubility of the alloy carbide in the austenite prior to quenching, relative to the solubility in ferrite. Fig shows the solubility products of various carbides and nitrides in austenite as a function of temperature. The solubilities of these compounds in ferrite are very much lower and to a first approximation can be considered to be approximately equal. It is clear therefore that chromium, molybdenum and vanadium with highest solubilities in austenite, should precipitate in the highest volume fractions in the ferrite.

M.Maalekian

CDL/ESOP

13

Fig. 7 Solubility product of carbides and nitrides in austenite as a function of temperature [7].

5 Effects on Transformation Diagrams

Alloying elements have considerable influence on the kinetics and mechanism of all three types of transformation of austenite to pearlite, bainite and martensite. Alloying elements that dissolve only in ferrite and cementite without the formation of special carbides exert just a quantitative effect on the transformation processes (Fig. 8). Cobalt speeds up a transformation but the majority of elements, including NI, Si, Cu, Al, etc., slow it down.

M.Maalekian

CDL/ESOP

14

Carbide- forming elements produce both quantitative and qualitative changes in the kinetics of isothermal transformations (Fig. 8). They (e.g., Cr, Mo, W, V, etc.) influence the austenite decomposition differently at different temperatures:

i. ii. iii.

At 700-500 C (pearlite formation), they slow the transformation At 500-400 C, they dramatically slow the transformation At 400-300 C (bainite formation), they speed up the transformation

Therefore, steels alloyed with carbide-forming elements have two maxima of the austenite isothermal decomposition rate separated by a region of relative stability undercooled austenite (Fig. 8).

Fig. 8 Diagrams of isothermal transformation. (a) Carbon steel and steel alloyed with non-carbide-forming elements; (b) carbon steel and steel alloyed with carbideforming elements [5].

6 Effect on Ferrite Hardness

All alloying elements that form solid solutions in ferrite affect its hardness. The hardness increase caused by substitutional solution is shown in Fig. 9. Si and Mn, the most frequently occurring alloying elements, have a relatively potent effect on the hardness of ferrite, while Cr gives the smallest hardness increase.

M.Maalekian

CDL/ESOP

15

For this reason Cr is a most convenient alloying element in steel that is to be processed by cold working in which good hardenability is required.

Fig. 9 Effect of substitutional alloying element additions on ferrite hardness [8].

7 Effect on Martensite Transformation Temperature

Most alloying elements which enter into solid solution in austenite lower the martensite start temperature (Ms), with the exception of Co and Al (Fig. 10). However, the interstitial solutes carbon and nitrogen have a much larger effect than the metallic solutes. From Fig. 10 it can be seen that 1wt% of carbon lowers the Mf (martensite finish temperature) by over 300 C. Note that above 0.7wt% C the Mf temperature is below room temperature and consequently higher carbon steels quenched into water will normally contain substantial amounts of retained austenite.

M.Maalekian

CDL/ESOP

16

Fig. 10 Effect of (a) carbon content and (b) alloying elements at 1% C on the martensite transformation [5].

8 Nitride-forming Elements

All carbide formers are also nitride former. Nitrogen may be introduced into the surface of the steel by nitriding. By measuring the hardness of various alloy steels do treated it is possible to investigate the tendency of the different alloying elements to form hard nitrides or to increase the hardness of the steel by a mechanism known as precipitation hardening. The results obtained by such investigations are shown in Fig. 11, from which it can be seen that very high hardnesses result from alloying a steel with Al or Ti in amounts of about 1.5%. On nitriding the base material in Fig. 11 a hardness of about 400 HV is obtained and according to the diagram the hardness is unchanged if the steel is alloyed with Ni since this element is not a nitride former and hence does not contribute to any hardness increase.

M.Maalekian

CDL/ESOP

17

Fig. 11 Effect of alloying element additions on hardness after nitriding. Base composition is 0.25% C, 0.30% Si, 0.70% Mn [8].

9 Effect on Hardenability

The ability of a steel to form martensite on quenching is referred to as the hardenability. This can be simply expressed for steel rods of standard size, as the distance below the surface at which there is 50% transformation to martensite after standard quenching treatment, and this is thus a measure of the depth of hardening. Alloying elements which slow down the ferrite and pearlite reactions increase hardenability. The austenite grain size and carbon content also affect the hardneability of steels. The severity of quench, H, was employed by Grossmann and co-workers in developing the concepts of critical diameter (D0)1 and ideal diameter (Di)2 which

The diameter of a steel bar that would just transform to 50% martensite at the center when

quenched into a bath having a known H value.

2

D0 increases as H increases, until the ideal diameter is reached when H becomes infinite.

M.Maalekian

CDL/ESOP

18

are the bases for most producers for estimating hardenability of steels from chemical composition. The diagram correlating D0 and Di is shown in Fig. 12. The value of Di obtained is hence a measure of the hardenability of the steel is independent of the cooling medium. In practice the Di -values are used to determine the values of D0 for bars quenched in various media, using the diagram in Fig. 12.

Fig. 12 Chart for determining ideal diameter (Di) from the critical diameter (D0) and the severity of quench (H) for carbon and medium alloy steels[8].

In order to assess the effect of alloying elements quantitatively, first step is to determine the effect of grain size and carbon content. Data are available, in so far as Di has been determined for steels with carbon in the range 0.2-1 wt%, and for a range of grain sizes (ASTM 4-8), as shown in Fig. 13. Use of this diagram for any steel provides a base hardenability figure, DiC, which must be modified by taking into account the effect of additional alloying elements. This is done by use of multiplying factors which have been experimentally determined for the familiar alloying elements (Fig. 14). empirical relationship: The ideal diameter Di is then found from the

Di=Dic 2.21(%Mn) 1.40(%Si) 2.13(%Cr) 3.275(%Mo) 1.47(%Ni) (wt%)

M.Maalekian

CDL/ESOP

19

Further corrections have to be made for different austenitizing temperatures when dealing with high carbon steels, but, on the whole the relationship is quite effective in predicting actual hardening behavior [6].

Fig. 13 Effect of carbon content and grain size on base hardenability [8].

Fig. 14 Hardenability multiplying factors for common alloying elements[8].

The Boron Effect Boron is added to steel for only one reason-to increase hardenability. Borontreated steels have certain peculiar characteristics [9] :

M.Maalekian

CDL/ESOP

20

1.

Boron increases hardenability in hypoeutectoid steel, has no effect on eutectoid steel, and decreases hardenability in hypereutectoid stee.

2.

As the austenite grain site becomes finer, the hardenability effect of B increases.

3. 4.

Austenitizing at high temperature reduces the hardneability effect of B. For the maximum B effect, the concentration should be in the range 0.0005 to 0.003 wt%.

5.

Increasing hardenability by adding B does not decrease the M s temperature.

These arise because of the manner in which B produces its effect and the interactions of B with other elements in steel. To be effective, B must be in solid solution in austenite. The solubility of B in austenite is very low, for example, the solubility at 912C is about 0.001 wt% , increasing with temperature to a maximum value of about 0.005 wt% at the eutectic. In -iron, the solubility is

essentially zero, but is influenced by the impurities present. Because of its low solubility in austenite, B can be highly concentrated in grain boundaries. When a boron steel is cooled from the hardening temperature the solubility of boron is reduced, which results in a still greater concentration of B at the grain boundaries. Minute grains of boron carbide Fe23(BC)6 are formed there and to some extent they assume an orientation coherent with one of the two austenite grains between them which separate out. Atomic contact is thereby established between Fe23(BC)6 and austenite, resulting in a reduction in the surface tension and grain-boundary energy. The presence of boron in solid solution and coherent boron carbide in the grain boundaries delays the formation of ferrite and pearlite and also to some extent, bainite; hence increasing the hardenability of the steel [8]. The effect of B may be expressed quantitatively as the boron factor, which is the ratio of the ideal diameters, Di, (according to Grossmann) for the steel with and without boron, viz.

BF Di with B Di without B

M.Maalekian

CDL/ESOP

21

Di (with boron) is derived from the Jominy end-quench hardenability curve; Di (without boron) is calculated from the chemical composition of the steel. The optimum B content, near 0.002 wt%, for increasing hardenability in 0.2% C, 0.65% Mn, 0.55% Mo (wt%) steel is shown in Fig. 15. Boron contents above about 0.003 wt% lead to a loss in hardenability, and B in excess of about 0.004 wt% causes a loss in toughness through precipitation of Fe 2B in austenite grain boundaries.

Fig. 15 Boron hardenability factor as a function of boron content in a 0.20% C, 0.55% Mo, 0.65% Mn steel [9].

10 Effect on Tempering

Martensite in steels can be a very strong and in its virgin condition rather brittle. It is then necessary to modify its mechanical properties by heat treatment in the range 150-700 C. This process is called tempering, in which the microstrucrure activation[6],[3]. approaches equilibrium under the influence of thermal

M.Maalekian

CDL/ESOP

22

The general trend during the tempering of martensite begins with the rejection of excess carbon to precipitate carbides but the substitutional solutes do not diffuse during this process. The end result of tempering is a dispersion of coarse carbides in a ferritic matrix which bears little resemblance to the original martensite. The addition of alloying elements to a steel has a substantial effect on the kinetics of the transformation, and also of the pearlite reaction. As pointed out previously, most common alloying elements move the time-temperaturetransformation (TTT) curves to longer times, with the result that it is much easier to miss the nose of the curve during quenching. This essentially gives higher hardenability, since martensite structures can be achieved at slower cooling rates and, in practical terms, thicker specimens can be made fully martensitic. The alloying elements also retard the rate of softening during tempering by stabilizing both the transition carbides (e.g. -iron carbide) and the

supersaturated martensitic structure to higher tempering temperature and by delaying considerably the precipitation and growth of cementite.

10.1 Effect on the Formation of Iron Carbides

The structural changes during the early stage of tempering are difficult to follow. However, it is clear that certain elements, notably silicon, can stabilize the -iron carbide to such an extent that it is still present in the microstructure after tempering at 400C in steels with 1-2 wt% Si, and even higher temperatures if the silicon is further increased. The evidence suggests that both the nucleation and growth of the carbide is slowed down and that the silicon enters into the carbide structure. It is also clear that the transformation of -iron carbide to

cementite is delayed considerably. While the tetragonality of martensite disappears by 300C in plain carbon steels, in steels containing some alloying elements, e.g. Cr, Mo, W, V, Ti, Si, the tetragonal lattice is still observed after tempering at 450C and even as high as 500C. It is clear that these alloying

M.Maalekian

CDL/ESOP

23

elements increase the stability of the supersaturated iron carbide solid solution. In contrast Mn and Ni decrease the stability (Fig. 16).

Fig. 16 Effect of Ti and Mn on the tetragonality of martensite during tempering [3].

Alloying elements also greatly influence the proportion of austenite retained on quenching. Typically, a steel with 4% Mo, 0.2% C, in the martensitic state contains less than 2% austenite, and about 5% is detected in a stel with 1% V and 0.2% C. On tempering each of the above steels at 300C, the austenite decomposes to give thin grain boundary films of cementite which, in the case of the higher concentrations of retained austenite, can be fairly continuous along the lath boundaries. It is likely that this interlath cementite is responsible for tempered martensite embrittlement, frequently encountered as a toughness minimum in the range 300-350C, by leading to easy nucleation of cracks, which then propagate across the tempered martensite laths.

M.Maalekian

CDL/ESOP

24

Coarsening of cementite in the tempering temperature range 400-700C, representing the forth stage of tempering, can be hindered effectively when alloying elements such as Si, Cr, Mo and W are present in steels. These alloying elements retain the fine Widmansttten precipitation of cementite up to higher temperatures either by segregation at the carbide/ferrite interface or by entering into the cementite structure [2].

10.2 The Formation of Alloy Carbides (Secondary Hardening)

A number of the familiar alloying elements in steels form carbides which are thermodynamically more stable than cementite. It is interesting to note that this is also true of a number of nitrides and borides. Nitrogen and boron are increasingly used in steels in small but significant concentrations. The alloying elements Cr, Mo, V, W and Ti all form carbides with substantially higher enthalpies compared to the iron carbide, while the elements Ni, Co and Cu do not form carbide phases. Manganese is a weak carbide former, found in solid solution in cementite and not in a separate carbide phase [3]. It would therefore, be expected that when strong carbide-forming elements are present in a steel in sufficient concentration, their carbides would be formed in preference to cementite. Nevertheless, during the tempering of all alloy steels, alloy carbides do not form until the temperature range 500-600C, because below this the metallic alloying elements cannot diffuse sufficiently rapidly to allow alloy carbides to nucleate. The metallic elements diffuse substitutionally with low diffusivities, therefore, high temperatures are needed for the necessary diffusion of the alloying elements prior to the nucleation and growth of the alloy carbides and, in practice, for most of the carbide-forming elements this is in the range 500-600C. It is the ability of certain alloying elements to form fine alloy carbide dispersions in the range 500-600C, which remain very fine even after prolonged tempering. Indeed, the formation of alloy carbides between 500C and 600C is accompanied by a marked increase in strength, often in excess of that of the asquenched martensite (Fig. 17). This phenomenon, which is referred to as

M.Maalekian

CDL/ESOP

25

secondary hardening, is best shown in steels containing Mo, V, W, Ti and also in chromium steels at higher alloy concentrations. This secondary hardening process is a type of age hardening reaction, in which a relatively coarse cementite dispersion is replaced by a new and much finer alloy carbide dispersion. In Fig. 17 the effect of increasing Mo content is demonstrated in a series of steels containing 0.1 wt% carbon.

Fig. 17 The effect of molybdenum on the tempering of quenched 0.1 wt% C steels [7].

The effects of C and some alloying elements on the tempering of a 10%Ni steel are illustrated in Fig. 18. Beginning with an alloy of Fe-10%Ni, successive additions of C, Co, Cr, and Mo were made. Co, although it does not enter the

M.Maalekian

CDL/ESOP

26

carbide, delays tempering. The addition of Cr provides an increase in strength during tempering, and Mo gives a sharp secondary hardening peak.[9]

Fig. 18 Effect of carbon, cobalt, chromium, and molybdenum on tempering of 10%Ni steels [8].

Tempering of Steels Containing Vanadium Vanadium is a strong carbide former and, in steel with as little as 0.1 wt% V, the FCC vanadium carbide (VC) is formed. It is often not of stoichiometric composition, being frequently nearer V4C3, but with other elements in solid solution within the carbide. Many steels containing vanadium will exhibit extensive vanadium carbide precipitation on tempering, because of the stability of this carbide (VC or V4C3), not only with respect to cementite but also the several chromium carbides and molybdenum carbide. The large effect of V is presumably due to the formation of VC or V4C3 carbides which replace cementite-type carbides at high tempering temperature and persist as fine

M.Maalekian

CDL/ESOP

27

dispersion up to A1 temperature. V is an important constituent of steels for elevated temperature service [2],[3],[9].

Tempering of Steels Containing Chromium In chromium steels, two chromium carbides are very often encountered: Cr7C6 (trigonal) and Cr23C6 (complex cubic). The normal carbide sequence during tempering is: Matrix (FeCr)3C Cr7C3 Cr23C6. While this sequence occurs in higher-chromium steels, below about 7wt% Cr, Cr23C6 is absent unless other metals such as molybdenum are present. Cr is a weaker carbide former than V, which is illustrated by the fact that Cr7C3 does not normally occur until the chromium content of the steel exceeds 1 wt% at a carbon level of about 0.2 wt%. In steels up to 4 wt% Cr, the transformation from Fe 3C to Cr7C3 occurs mainly by nucleation at the Fe3C/ferrite interfaces. Steels up to 9 wt% Cr do not show secondary hardening peaks in tempering curves (Fig. 19). however, theses curves do exhibit plateaus at higher Cr content, which are associated with the precipitation of Cr7C3. Chromium diffuses more rapidly in ferrite than most metallic alloying elements, with the result that Cr7C3 is detected during tempering at temperatures as low as 500C, and in comparison with vanadium carbide, chromium carbide coarsens rapidly. Thus, in a 2 wt% Cr-0.2 wt% C steel, continuous softening will normally occur on tempering between 500C and

700C, although addition of other alloying elements, e.g. Mo, can reduce the rated of coarsening of Cr7C3. In contrast, a 12 wt% Cr steel will exhibit secondary hardening in the same temperature range (Fig. 19) due to precipitation of Cr7C3. additionally, Cr23C6 nucleate at about the same time but at different sites, particularly formes austenite grain boundaries and at ferrite lath boundaries. This precipitate grows at the expense of the Cr7C3 which eventually disappears from the microstructure,

M.Maalekian

CDL/ESOP

28

at which stage the steel has completely over-aged. This transition from Cr7C3 to Cr23C6 in high-chromium steels is by separate nucleation and growth. Further alloying additions can promote one or other of these carbide reactions, e.g. addition of W encourages formation of Cr23C6 by allowing it to nucleate faster, while V tends to stabilize Cr7C3. in doing so, it decreases the rate of release into solution of Cr and C needed for the growth of Cr23C6. Clearly, V would be a preferred addition to W, if fine stable Cr-carbide dispersion is needed in the temperature range 550-650C. [3]

Fig. 19 The effect of Cr on the tempering of a 0.35 wt% C steel [3].

Tempering of Steels Containing Molybdenum and Tungsten When Mo or W is predominant alloying element in a steel, a number of different carbide phases are possible, but for composition between 4 and 6wt% of the element the carbide sequence is likely to be:

M.Maalekian

CDL/ESOP

29

Fe3C M2C M6C. The carbides responsible for the secondary hardening in both case of W and Mo are the isomorphous hexagonal carbides Mo2C and W 2C, both of which in contrast to vanadium carbide, have a well-defined rodlet morphology. M2C also nucleates at former austenite and ferrite lath boundaries. As in the case of vanadium steels, M2C precipitate nucleates both on dislocations in the ferrite, and at the Fe3C/ferrite interfaces, but the secondary hardening arises primarily from the dislocation-nucleated dispersion of M2C. On prolonged tempering at 700c, the complex cubic M6C forms predominantly at grain boundaries as massive particles which grow quickly, while the M2C phase goes back into solution. For similar atomic concentrations, the secondary hardening response in the case of tungsten steels is less than that of molybdenum steels. The M 2C dispersion in the former case is coarser, probably because the slower diffusivity of tungsten allows a coarsening of the dislocation network prior to being pinned by the nucleation of particles.

11 Effect on Grain Growth

The elements Al, Nb, Ti and V in small amounts from 0.03 wt% to 0.10 wt% are important factors in inhibiting grain growth at the austenitizing temperature. This is because these elements are present as highly dispersed carbides, nitrides or carbo-nitrides (Al only as nitride) and that a high temperature is required to make them go into solution. Fig. 20 shows that in a steel containing about 0.05 wt% Nb or Ti and 0.20 wt% C the niobium and titanium carbides are not dissolved until the temperature exceeds 1200C.[8] For V and N contents of 0.1 wt% and 0.010 wt% respectively the vanadium nitrides remain undissolved at temperatures up to and somewhat above 1000C. Should the temperature rise so high that the phasesinhibiting grain growth pass into solution there will be a

M.Maalekian

CDL/ESOP

30

pronounced increase in grain size. The above-mentioned elements have found great use as microconstituents in the high strength low ally steels (HSLA).

Fig. 20 Solubility isotherms of niobium carbide, titanium carbide and vanadium nitride in steel at different temperatures [8].

Ferrite grain refinement in ferrite-pearlite steels is accomplished through restricting the growth of austenite grains during hot rolling and/or by inhibiting the recrystalization of austenite during hot rolling so that the transformation

occurs in unrecrastalized austenite. For example, in the hot rolling of semikilled carbon steels, recrystalization of austenite occurs at temperature down to about 760C. A 30% reduction at 815C is sufficient for about 10% recrystalization. In a similar steel containing 0.03 wt% Nb, 10% recrystalization occurred after the steel was reduced 50% at 925C. This explains why it is so difficult to refine grains in carbon steels until the rolling temperature drops below 815C. It is usually less expensive to normalize a carbon steel than to obtain grain refinement by controlled rolling. In contrast, grain refinement in niobium steels can be obtained at finishing temperatures as high as 925C. In most instances, all Nb, C and N are in solution at the start of the hot rolling of austenite, but precipitation occurs during the rolling as the temperature of the steel drops. The precipitate particles hinder growth of austenite grains, and at still lowertemperatures the particles (or precipitation clusters) inhibit recrystalization of the deformed austenite grains. As indicated in Fig. 21, the effectiveness of

M.Maalekian

CDL/ESOP

31

microalloying elements in refining ferrite grains is in the same order as the solubility of their carbides in austenite (see Fig. 20).

Fig. 21 Effect of microalloy content (Nb, Ti and V) on the ferrite grain size of as-hotrolled low-carbon steel strip [9].

Grain coarsening in microalloyed and Al-killed steels in the temperature range of 900-1300C is, however, characterized by continuous growth at low and high temperatures; between these temperature regions is a narrow temperature range where abnormal grain growth occurs. The influence of Nb on austenite grain growth characteristics in various concentrations is illustrated in Fig. 22. Increasing Nb content causes an increase in the abnormal or discontinuous grain growth temperature. A general overview of the effects of microalloying additions on the grain coarsening of austenite is shown in Fig. 23. In Al, V, and Ti steels, these are largely controlled by the microalloying level and the nitrogen content, due to the pronounced stability of the nitrides compared with their respective carbides. The differential between the solubilities of the carbide and nitride is somewhat reduced in the case of Nb (see Fig. 7) and, NbC can be stable at quite high temperatures (1200C) with modest Nb additions to high carbon steels. However,

M.Maalekian

CDL/ESOP

32

the extremely low solubility of TiN in austenite (Fig. 7) has resulted in the development and extensive application of TiN technology. Fig. 23 illustrates that the grain coarsening during reheating in C-Mn steels with microalloyed additions that form with a volume fraction of ~0.0005 of alloy carbides and/or nitrides. It also illustrates that -grains grow very little with

increasing temperature during continuous grain growth, while grain growth becomes very rapid during abnormal or discontinuous grain growth. It is thus apparent that steels containing microalloyed second phases are susceptible to grain coarsening in particular temperature range. Increased amounts of V above 0.14 wt% refine the -grain size at

temperatures up to ~1000C and do not contribute any marked effect above 1100C due to appreciable solubility of VCN in austenite [2]. The grain coarsening temperature in Al-killed steel is above 1050C. Nb-bearing steels have sufficiently higher grain coarsening temperature than the V-bearing steels and Al-killed steels. The grain refinement of austenite by Nb addition is more effectively accomplished (relative to Ti, V, and Zr addition) on both the reheated grain size and recrystalized grain size when Nb content is up to 0.1 wt% and the temperature is up to 1200C. Ti addition up to 0.040 wt% causes the formation of stable nitride, which raises the grain coarsening temperature to about 1300C during both isothermal soaking and hot deformation. It should be noted that the solubility of carbide particles in the austenite increases in the order NbC, TiC, VC, while the nitrides with normally lower solubility increase in solubility in the order TiN, NbN, AlN, VN (see Fig. 7). It is thus apparent that NbC and TiN are the most stable particles and the most effective grain size refiners. However, Al, V, and Ti are more effective in highnitrogen steels, by forming comparatively stable AlN, V(CN), and Ti(CN) in austenite, which may be potent in preventing grain coarsening on reheating but not effective in preventing recrystalization [2]. Fig. 24 also illustrates the difference in coarsening rates between vanadium nitride and titanium nitride at 1100C. As expected, VN shows a much more rapid rate of coarsening than is shown by TiN.

M.Maalekian

CDL/ESOP

33

Fig. 22 Austenite grain growth characteristics in various Nb steel. Hatched bars represent the range of duplex grains produced at the coarsening temperatures [2].

Fig. 23 The general effect of microalloy additions on the grain coarsening temperature of austenite in C-Mn steels contating a volume fraction of 0.0005 of alloy carbide or nitride. Specific grain coarsening temperatures are dependent upon microalloy content, nitrogen content, and the effects of prior thermal or thermomechanical cycles on the precipitated particle size [2],[10].

M.Maalekian

CDL/ESOP

34

Fig. 24 Comparison of the calculated particle coarsening rates of vanadium and titanium nitrides at 1100C [10].

The effects of various microalloy additions and concentrations on the recrystalization temperature are shown in Fig. 25. Niobium additions cause a more marked increase in the recrystalizytion temperature than are observed with other microalloys. To some extent, niobium is an ideal microalloying element to consider for the hot rolling and controlled rolling processes in that it can exhibit most of the effects that microalloying elements may have [10]. In particular

(i)

The niobium carbo-nitride can be substantially dissolved at commonly used soaking temperatures prior to hot rolling.

(ii)

Of the microalloying elements dissolved, niobium has by far the largest effect in retarding recrystalization.

(iii)

Strain inducement of niobium carbo-nitride occurs at temperatures between about 1000C and 800C which represent a commonly used temperature range for the completion of the hot rolling process.

M.Maalekian

CDL/ESOP

35

Fig. 25 The effects of microalloying addtitions on the recrystalizytion temperature of austenite in a low carbon 1.4wt% Mn steel [10].

M.Maalekian

CDL/ESOP

36

12 Bibliography

[1] Bain, E.C., Alloying Elements in Steels, ASM, Cleveland, Ohio, USA (1939). [2] Sinha, A.K., Ferrous Physical Metallurgy, Butterworth Publishers, USA (1989). [3] Bhadeshia, H.K.D.H, Honeycombe, R.W.K, Steels: Microstructure and Properties, Elsevier Ltd., UK (2006). [4] ASM Handbook, Vol. 4, Heat Treating, ASM International (1991). [5] Totten, G.E., Howes, M.A.H, Steel Heat Treatment Handbook, Marcel Dekker, Inc., USA (1997). [6] Bhadeshia, H.K.D.H, Design of Ferritic Creep-resistant Steel, ISIJ International, Vol. 41 (2001), No. 6, 626-640. [7] Porter, D.A., Easterling, K.E., Phase Transformations in Metals and Alloys, CRC Press, Taylor & Francis Group, Finland (2004). [8] Thelning, K.E., Steels and its Heat Treatment, Butterworth & Co. and K-E Thelning, UK (1984). [9] Leslie, W.C., The physical Metallurgy of Steels, McGraw-Hill, Tokyo, Japan, (1981). [10] Gladman, T., The Physical Metallurgy of Microalloyed Steels, The Institute of Materials, UK (1997).

Вам также может понравиться

- Fracture and Fracture Toughness of Cast Irons: W. L. Bradley and M. N. SrinivasanДокумент33 страницыFracture and Fracture Toughness of Cast Irons: W. L. Bradley and M. N. SrinivasanNarasimha Murthy InampudiОценок пока нет

- Din 1.4003Документ2 страницыDin 1.4003Dhaniel100% (1)

- Advanced Metal Cutting Technology (MAT-514 A) Patr 1Документ25 страницAdvanced Metal Cutting Technology (MAT-514 A) Patr 1Bizuayehu Tadesse100% (1)

- Data Sheet Width Flange BeamДокумент32 страницыData Sheet Width Flange BeamIrvan IskandarОценок пока нет

- Weldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructuresДокумент8 страницWeldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructurestheijesОценок пока нет

- Aluminum Alloy TubeДокумент7 страницAluminum Alloy TubeParamasivam VeerappanОценок пока нет

- 2.b Poster - Ferrous Material and AlloyДокумент1 страница2.b Poster - Ferrous Material and AlloyChristian Dave RoneОценок пока нет

- Welding Term PaperДокумент26 страницWelding Term PaperBiswajit SenОценок пока нет

- 277 - Galvanised Steel SheetsДокумент10 страниц277 - Galvanised Steel SheetsKaushik SenguptaОценок пока нет

- Advance StructuresДокумент6 страницAdvance StructuresManju NishaОценок пока нет

- Stainless Steel - Grade 321 (UNS S32100)Документ4 страницыStainless Steel - Grade 321 (UNS S32100)mp87_ingОценок пока нет

- Metal and Metal Alloys NotesДокумент18 страницMetal and Metal Alloys NotesKshitij SaojiОценок пока нет

- Stainless Steel Bars and Shapes: Standard Specification ForДокумент8 страницStainless Steel Bars and Shapes: Standard Specification ForkrkmurthyОценок пока нет

- Is Phosphorus Bad For SteelДокумент19 страницIs Phosphorus Bad For SteelKarun Dev100% (1)

- Handbook: Ferrous Materials &metallurgy IIДокумент5 страницHandbook: Ferrous Materials &metallurgy IITuanbk Nguyen100% (1)

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFДокумент16 страницA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrОценок пока нет

- 2062Документ17 страниц2062hswed91100% (1)

- Acom 3 2015Документ13 страницAcom 3 2015Joshua WalkerОценок пока нет

- Chapter-3 General Information of WeldingДокумент5 страницChapter-3 General Information of WeldingKumar DneshОценок пока нет

- Charles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelДокумент66 страницCharles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelAlarmakОценок пока нет

- Baosteel CRGO StandardДокумент12 страницBaosteel CRGO Standarddarkonikolic78Оценок пока нет

- SIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Документ5 страницSIS-S 501 50 AG Hot Rolled Steel Rounds (Up To Dia 180mm)Rajoo PrajapatiОценок пока нет

- Electrode Converted Into TextДокумент14 страницElectrode Converted Into TextNeha NimbarkОценок пока нет

- Am 363 PDFДокумент4 страницыAm 363 PDFsunsirОценок пока нет

- Welding of 5083 Aluminum AlloyДокумент6 страницWelding of 5083 Aluminum AlloyMario MirićОценок пока нет

- Bronze and Its Melting Process - 1Документ3 страницыBronze and Its Melting Process - 1dom250% (2)

- Riview On Cold Drawing Process PDFДокумент7 страницRiview On Cold Drawing Process PDFAmandeep Singh GujralОценок пока нет

- LM6 Alloy DetailДокумент4 страницыLM6 Alloy DetaildsoОценок пока нет

- Iron-Nickel-Cobalt Sealing Alloy: Standard Specification ForДокумент7 страницIron-Nickel-Cobalt Sealing Alloy: Standard Specification ForJurun_BidanshiОценок пока нет

- Amp16304p036 PDFДокумент3 страницыAmp16304p036 PDFMarius Alin LupașcuОценок пока нет

- High-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickДокумент2 страницыHigh-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickSadashiva sahooОценок пока нет

- Dezincinc of Galvanized Steel PDFДокумент278 страницDezincinc of Galvanized Steel PDFNicat MammadovОценок пока нет

- Is 1730Документ11 страницIs 1730maheshkbandari0% (1)

- The Precipitation Hardening SSsДокумент3 страницыThe Precipitation Hardening SSsClaudia MmsОценок пока нет

- Rr411802 Steel MakingДокумент4 страницыRr411802 Steel MakingSrinivasa Rao GОценок пока нет

- TitaniumДокумент18 страницTitaniumAbhishek PatilОценок пока нет

- Alloys: I) IntroductionДокумент12 страницAlloys: I) IntroductionNikhil ShelarОценок пока нет

- Outokumpu Supra Range DatasheetДокумент12 страницOutokumpu Supra Range DatasheetMichelОценок пока нет

- Case Studies of Steel Structure Failures PDFДокумент6 страницCase Studies of Steel Structure Failures PDFAvim Wira RagendaОценок пока нет

- Iron Carbon Phase DiagramДокумент4 страницыIron Carbon Phase DiagramMizanur RahmanОценок пока нет

- Materials Science Lec 04 Phase & Iron-Carbon DiagramДокумент53 страницыMaterials Science Lec 04 Phase & Iron-Carbon DiagramKrishna SarkarОценок пока нет

- A723A723M-18a 1.05 PDFДокумент5 страницA723A723M-18a 1.05 PDFist93993Оценок пока нет

- Stainless Steel Applications in Electrical EngineeringДокумент9 страницStainless Steel Applications in Electrical EngineeringUmang SoniОценок пока нет

- MINEX Metallurgical CoДокумент41 страницаMINEX Metallurgical CoPriyank SamagraОценок пока нет

- Steels For Structural and General Engineering ApplicationsДокумент1 страницаSteels For Structural and General Engineering Applicationsasa_aha789Оценок пока нет

- Testing of WeldsДокумент44 страницыTesting of Weldspkn_pnt9950Оценок пока нет

- W6 Lecture 6.surface Hardening of Steel PDFДокумент28 страницW6 Lecture 6.surface Hardening of Steel PDFYota KimireОценок пока нет

- Astm A1008 CRC Crs PDFДокумент9 страницAstm A1008 CRC Crs PDFArul Edwin VijayОценок пока нет

- Aluminium Alloy Applications PDFДокумент3 страницыAluminium Alloy Applications PDFKhanHasibKaisarОценок пока нет

- Brass MachiningДокумент68 страницBrass MachiningVaibhav ShuklaОценок пока нет

- Astm A 143M-03Документ3 страницыAstm A 143M-03MritunjayОценок пока нет

- The Effects of Alloying Elements On Steels 1Документ36 страницThe Effects of Alloying Elements On Steels 1Common ManОценок пока нет

- 1.the Basics of Ferrous MetallurgyДокумент83 страницы1.the Basics of Ferrous MetallurgyfenasikerimОценок пока нет

- Tugas Individu 1 - Radifan Abrar Tahrizi - 1806187732Документ6 страницTugas Individu 1 - Radifan Abrar Tahrizi - 1806187732Radifan AbrarОценок пока нет

- Decomposition of Austenite in Austenitic Stainless SteelsДокумент13 страницDecomposition of Austenite in Austenitic Stainless SteelsTina GharaОценок пока нет

- Decomposition of Austenite in Austenitic Stainless SteelsДокумент13 страницDecomposition of Austenite in Austenitic Stainless SteelsregistrosegОценок пока нет

- Weldability of Metals - NPTELДокумент18 страницWeldability of Metals - NPTELKaushal Gandhi0% (1)

- Me17 6-9 PDFДокумент55 страницMe17 6-9 PDFMico CampoОценок пока нет

- Chap 07 PDFДокумент26 страницChap 07 PDFdada jamdarОценок пока нет

- Advanced Metaullrgy FinalweldingДокумент34 страницыAdvanced Metaullrgy FinalweldingAfam-Anadu UcheОценок пока нет

- PrintДокумент9 страницPrintRahul PandeyОценок пока нет

- Full Advt 09 - 2023Документ10 страницFull Advt 09 - 2023Muhammad Saquib AnjumОценок пока нет

- Presentation ON SMS: Prepared By:Shashank Poddar Metallurgy (5 Sem)Документ15 страницPresentation ON SMS: Prepared By:Shashank Poddar Metallurgy (5 Sem)Rahul PandeyОценок пока нет

- U - Chart Exercise: Step 1Документ2 страницыU - Chart Exercise: Step 1Rahul PandeyОценок пока нет

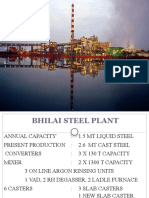

- Bhilai Steel PlantДокумент15 страницBhilai Steel PlantRahul PandeyОценок пока нет

- NP - Chart Exercise: Complete The Header Information and Step 2 Record The Data (Page 115)Документ2 страницыNP - Chart Exercise: Complete The Header Information and Step 2 Record The Data (Page 115)Rahul PandeyОценок пока нет

- Roll No 33Документ39 страницRoll No 33Rahul PandeyОценок пока нет

- A Report On Steel Melting ShopДокумент18 страницA Report On Steel Melting ShopRahul PandeyОценок пока нет

- Chhattisgarh Swami Vivekanand Technical University, Bhilai Scheme of Teaching & ExaminationДокумент15 страницChhattisgarh Swami Vivekanand Technical University, Bhilai Scheme of Teaching & ExaminationSiddharth VermaОценок пока нет

- By Chan, Sam and EllyДокумент10 страницBy Chan, Sam and EllyRahul PandeyОценок пока нет

- Aditya Pratap Singh: Prepared ByДокумент14 страницAditya Pratap Singh: Prepared ByRahul PandeyОценок пока нет

- (Steel Melting Shop) : Training Duration:-21 May-28JuneДокумент11 страниц(Steel Melting Shop) : Training Duration:-21 May-28JuneRahul PandeyОценок пока нет

- Introducation of Blast FurnaceДокумент13 страницIntroducation of Blast FurnaceRahul PandeyОценок пока нет

- Aditya Pratap Singh: Prepared ByДокумент14 страницAditya Pratap Singh: Prepared ByRahul PandeyОценок пока нет

- Summer Vocational Training Report: Bhilai Steel Plant, Sail ON "Mill Zone"Документ26 страницSummer Vocational Training Report: Bhilai Steel Plant, Sail ON "Mill Zone"Rahul PandeyОценок пока нет

- Presentation ON Steel Melting Shop: Rupendra Naik 3203810037Документ19 страницPresentation ON Steel Melting Shop: Rupendra Naik 3203810037Rahul PandeyОценок пока нет

- Presentation On SMS: BY:-Ram Prasad Choudhary 3203810034Документ19 страницPresentation On SMS: BY:-Ram Prasad Choudhary 3203810034Rahul PandeyОценок пока нет

- A Presentation On Dri-Ii in JSPL, Raigarh: By:-Harish Patel (Meta-5 Sem)Документ14 страницA Presentation On Dri-Ii in JSPL, Raigarh: By:-Harish Patel (Meta-5 Sem)Rahul PandeyОценок пока нет

- A Project Report On Summer Vocational Training in Bhilai Steel PlantДокумент24 страницыA Project Report On Summer Vocational Training in Bhilai Steel PlantRahul PandeyОценок пока нет

- A Presentation ON Vocational Training: Sandeep Pradhan 3203810039Документ22 страницыA Presentation ON Vocational Training: Sandeep Pradhan 3203810039Rahul PandeyОценок пока нет

- A Presentation On Dri-Ii: BY:-Vikash Ranjan Sharma Metallurgy - 5 SEM 3203810051Документ15 страницA Presentation On Dri-Ii: BY:-Vikash Ranjan Sharma Metallurgy - 5 SEM 3203810051Rahul PandeyОценок пока нет

- Presentation On Steel Melting Shop: BY: Dipti Dubey. Metallurgy 5 SEMДокумент18 страницPresentation On Steel Melting Shop: BY: Dipti Dubey. Metallurgy 5 SEMRahul PandeyОценок пока нет

- A Project Report On Summer Vocational Training in Bhilai Steel PlantДокумент24 страницыA Project Report On Summer Vocational Training in Bhilai Steel PlantRahul PandeyОценок пока нет

- Blast Furnac E: S.Megha Metallurgy SemesterДокумент18 страницBlast Furnac E: S.Megha Metallurgy SemesterRahul PandeyОценок пока нет

- Roll No 59Документ25 страницRoll No 59Rahul PandeyОценок пока нет

- Metallurgical Thermo Dynamics9 R H TupkaryДокумент208 страницMetallurgical Thermo Dynamics9 R H TupkaryRahul Pandey100% (7)

- Direct & Indirect Reduction IN Blast Furnace: NAME - Mahendra Kumar Patel. 3203810029 (5 Sem)Документ9 страницDirect & Indirect Reduction IN Blast Furnace: NAME - Mahendra Kumar Patel. 3203810029 (5 Sem)Rahul PandeyОценок пока нет

- SolutionsДокумент13 страницSolutionsRahul PandeyОценок пока нет

- Phase DiagramsДокумент72 страницыPhase DiagramsRahul PandeyОценок пока нет

- Regular SolutionsДокумент19 страницRegular SolutionsRahul PandeyОценок пока нет

- K 5 Premium Full Control Plus: Operating InstructionsДокумент84 страницыK 5 Premium Full Control Plus: Operating Instructionsronald DОценок пока нет

- Welded Wire Reinforcement Manual of Standard PracticeДокумент38 страницWelded Wire Reinforcement Manual of Standard PracticemarmusmanОценок пока нет

- Chapter 4 Forming and ShapingДокумент147 страницChapter 4 Forming and Shapingquan quanОценок пока нет

- 3 Types of Traffic Count: 3.1 Manual CountsДокумент3 страницы3 Types of Traffic Count: 3.1 Manual CountsRichard BryanОценок пока нет

- Pranav 1Документ14 страницPranav 1DesignОценок пока нет

- Virendra Oberoi-Automation in Ring Spinning MachinesДокумент28 страницVirendra Oberoi-Automation in Ring Spinning MachinesDurai RajОценок пока нет

- 548 HD End CutterДокумент36 страниц548 HD End CuttercyroniusОценок пока нет

- 01CB1S01Документ5 страниц01CB1S01raobabar21Оценок пока нет

- Strategic MGMT Ch-3Документ30 страницStrategic MGMT Ch-3Desu MekonnenОценок пока нет

- Newcon Suggested Specifications Rev 100715Документ1 страницаNewcon Suggested Specifications Rev 100715saroat moongwattanaОценок пока нет

- Gear Reference PDFДокумент15 страницGear Reference PDFXuan Phuong HuynhОценок пока нет

- Tugas PPM Deny Saputro Arifin 113170039Документ9 страницTugas PPM Deny Saputro Arifin 113170039Vira IrnandaОценок пока нет

- Knurling On CNC Lathes - 275: J3 SI S5Si 5Документ63 страницыKnurling On CNC Lathes - 275: J3 SI S5Si 5Cecep Devi NugrahaОценок пока нет

- Understanding Motor Controls 3rd Edition Herman Test BankДокумент4 страницыUnderstanding Motor Controls 3rd Edition Herman Test BankDebits100% (5)

- M 237Документ4 страницыM 237Katerin Hernandez0% (1)

- Corrosion Lecture ManchesterДокумент88 страницCorrosion Lecture ManchesterAli AbbasovОценок пока нет

- Smart Memory Alloys: Asim RahimatpureДокумент3 страницыSmart Memory Alloys: Asim RahimatpureKarneshwar SannamaniОценок пока нет

- IBR FormsДокумент204 страницыIBR FormsRajivharolikarОценок пока нет

- Draka 2Документ260 страницDraka 2Sakinah Cik KinoОценок пока нет

- Nanotech in ComputersДокумент7 страницNanotech in ComputersGopi SatyaОценок пока нет

- Astm A 563 14pdf PDFДокумент18 страницAstm A 563 14pdf PDFSathish KumarОценок пока нет

- DokwegII - Auxiliary - Maintenance Compressed Air SystemДокумент62 страницыDokwegII - Auxiliary - Maintenance Compressed Air SystemCarlin BabuchasОценок пока нет

- Pma2 6Документ9 страницPma2 6EllyYanaОценок пока нет

- Brochure D-R 290 enДокумент1 страницаBrochure D-R 290 enDandy Harris FirdiandaОценок пока нет

- Procedure For Flooring WorksДокумент4 страницыProcedure For Flooring WorksAkhilesh Kumar0% (1)

- Lathe Accessories: Work Holding Tool HoldingДокумент33 страницыLathe Accessories: Work Holding Tool HoldingSuhasОценок пока нет

- Manufacturing Companies in PuneДокумент3 страницыManufacturing Companies in Puneshyam ubaleОценок пока нет

- BS 00489-1999 PDFДокумент10 страницBS 00489-1999 PDFNayan jainОценок пока нет

- Concertina CoilДокумент4 страницыConcertina CoilvklsОценок пока нет

- GERALD POLLACK - The Fourth Phase of Water - Beyond Solid, Liquid, and Vapor PDFДокумент2 страницыGERALD POLLACK - The Fourth Phase of Water - Beyond Solid, Liquid, and Vapor PDFjulian_rosengren50% (6)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Process Plant Equipment: Operation, Control, and ReliabilityОт EverandProcess Plant Equipment: Operation, Control, and ReliabilityРейтинг: 5 из 5 звезд5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyОт EverandSodium Bicarbonate: Nature's Unique First Aid RemedyРейтинг: 5 из 5 звезд5/5 (21)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookОт EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookОценок пока нет

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookОт EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookОценок пока нет

- Guidelines for Chemical Process Quantitative Risk AnalysisОт EverandGuidelines for Chemical Process Quantitative Risk AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlОт EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlРейтинг: 4 из 5 звезд4/5 (4)

- Physical and Chemical Equilibrium for Chemical EngineersОт EverandPhysical and Chemical Equilibrium for Chemical EngineersРейтинг: 5 из 5 звезд5/5 (1)

- Operational Excellence: Journey to Creating Sustainable ValueОт EverandOperational Excellence: Journey to Creating Sustainable ValueОценок пока нет

- Pharmaceutical Blending and MixingОт EverandPharmaceutical Blending and MixingP. J. CullenРейтинг: 5 из 5 звезд5/5 (1)

- Guidelines for Engineering Design for Process SafetyОт EverandGuidelines for Engineering Design for Process SafetyОценок пока нет

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationОт EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationРейтинг: 4 из 5 звезд4/5 (18)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesОт EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesОценок пока нет

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksОт EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksРейтинг: 5 из 5 звезд5/5 (1)

- Guidelines for the Management of Change for Process SafetyОт EverandGuidelines for the Management of Change for Process SafetyОценок пока нет

- Recognizing Catastrophic Incident Warning Signs in the Process IndustriesОт EverandRecognizing Catastrophic Incident Warning Signs in the Process IndustriesОценок пока нет

- Chemical Process Safety: Learning from Case HistoriesОт EverandChemical Process Safety: Learning from Case HistoriesРейтинг: 4 из 5 звезд4/5 (14)

- Pharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryОт EverandPharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryOtilia M. Y. KooОценок пока нет