Академический Документы

Профессиональный Документы

Культура Документы

MEC207

Загружено:

Senthil Muthu Kumar TАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MEC207

Загружено:

Senthil Muthu Kumar TАвторское право:

Доступные форматы

MEC207

MANUFACTURING TECHNOLOGY

L 3

T 1

P 0

C 4

Course plan for the academic year 2009-2010 (Even Semester) Name of the staff : Mr.S.Rajesh and Subject Dr. M.Uthayakumar, Mr.K.Balamurugan ,

Mr.T.Senthil Muthukumar : Manufacturing Technology (MEC207)

Semester and branch: IV semester B.Tech., Mechanical Engineering 1. Pre-requisite : Basic knowledge in Mechanical Engineering. 2. Objectives : To learn about the different techniques of manufacturing and fabrication process. In addition to this the topics like sheet metal forming and processing of plastics also be dealt. 3. Learning outcome: Student can gain thorough knowledge on manufacturing, with pros and cons of each process. They can also get exposure in the area of metal joining and fabrication of plastics. 4. Text books: 1. Jain, R.K., Production Technology, Khanna Publishers, 2002. 5. Reference books: 1. Hajra Choudhry, Elements of Workshop Technology-Vol I, Dhanpat Rai and Sons, 2. HMT Production Technology, Tata Mc Graw-Hills Publishing Co. Ltd, 1994. 3. Chapman, W.A.J., Workshop Technology-Vol - II, Oxford and IBH Publishing. 5. Web resources: http://nptel.iitm.ac.in/ http://me.emu.edu.tr/me364/lecnotes.html www.ebooknetworking.net/ebooks/sheet-metal-lecture.html www.azom.com/details.asp www.wikipedia.org

www.polymerplace.com/tips/tips_process_methods.htm www.advanceweldinginstitute.com me.emu.edu.tr/me364/lecnotes.html 6. Lesson plan:

Topi c No. 1. Topic Name Reference Books UNIT- I No. of Period s Cumulati ve Hours

2. 3. 4. 5. 6. 7. 8. 9. 10. 11.

Introduction to Manufacturing Moulding sands-types and properties Patterns-types selection of pattern-allowance Casting types and moulding methods Special casting techniques Fettling and finishing of casting Defects in castings Tutorial Unit I

R1,T1 R1,T1 R1,T1 R1,T1 R1,T1 R1,T1 R1,T1 R1,T1

1 2 2 2 2 1 1 1 1 2

1 3 5 7 9 10 11 12 13 15

12. 13. 14. 15. 16. 17.

UNIT- II Introduction to fabrication R1,T1 process Classification of welding process- principle of gas R1,T1 welding Principle of arc weldingresistance welding-solid state welding Thermo R1,T1 chemical welding-radiant energy welding Brazing and soldering R1,T1 Thermal cutting of metals R1 and alloys Tutorial Unit II R1,T1 UNIT- III Introduction on bulk R1,T1 deformation process Forging-classification, R1,T1 defects and inspection Rolling-classification, rolling R1,T1

4 1 2 2 1 2 3

19 20 22 24 25 27 30

mill, rolling of bars and shapes 18. Extrusion-classifications and equipments 19. Tutorial Unit III 20. 21. 22.

R1,T1

3 2 2 3

33 35 37 40

23. 24. 25. 26.

R1,T1 UNIT- IV Introduction of sheet metal R1,T1 forming process High velocity forming, explosive forming, electro R1,T1 hydraulic forming Magnetic pulse forming, pneumatic forming, R1,T1 Mechanical high velocity forming Tutorial- Unit IV R1,T1 UNIT- V Introduction of plastics, R1,T1 Forming of plastics Plastics-types, moulding R1,T1 process, defects Tutorial Unit V R1,T1

4 2 2 2 1

44 46 48 50 51

7) Test Portions: Test Sessional - 1 Sessional - 2 End semester 8. Seminar topics UNIT-I Unit-II Unit-III Unit- IV Unit- V Pattern making/ Casting defects Extrusion / Rolling Bulk manufacturing process High velocity forming, explosive forming Defects in plastics. Topics 1 to 10 11 to 22 1 to 26

9. Additional topics (beyond syllabus) Case study on comparison of different manufacturing methods for a typical product. Powder metallurgy. Rapid prototyping. Group Technology Automated Guided Vehicles

10. Related books and magazines/journals

International Journal of Advance Manufacturing Technology. Journal of material processing technology. Manufacturing technology today from CMTI. International Journal of Metal casting International journal of metal forming Magazine of plastic news

Staff signature

Course coordinator/ HOD / Mech

Вам также может понравиться

- Engines Teaching ManualДокумент151 страницаEngines Teaching ManualSenthil Muthu Kumar TОценок пока нет

- Sample BOQ Central HVACДокумент7 страницSample BOQ Central HVACbookjaman92% (12)

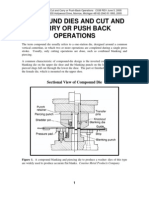

- Compound Die DesignДокумент6 страницCompound Die Designfzulkarnaen_1Оценок пока нет

- Desilting and Dewatering in 39 TH DivДокумент12 страницDesilting and Dewatering in 39 TH Divsasidharkatari91572100% (1)

- General Question Paper 1Документ5 страницGeneral Question Paper 1indusampathОценок пока нет

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationОт EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationОценок пока нет

- Automotive Safety HandbookДокумент2 страницыAutomotive Safety HandbookSenthil Muthu Kumar T0% (1)

- Manufacturing Engineering Guide BookДокумент2 страницыManufacturing Engineering Guide BookGiridharan SharmaОценок пока нет

- Iti-Fitter-Multiple-Choice-Questions-Heat-Treatment-Chapter-For-Iti-Job, - Iti-Fitter-Job, - Iti-Fitter-Govt-Job PDFДокумент7 страницIti-Fitter-Multiple-Choice-Questions-Heat-Treatment-Chapter-For-Iti-Job, - Iti-Fitter-Job, - Iti-Fitter-Govt-Job PDFJerome100% (1)

- Table UHA-23 High Alloy Steel: SA-1a2 520910 FXM LLДокумент4 страницыTable UHA-23 High Alloy Steel: SA-1a2 520910 FXM LLAAISAT100% (1)

- PDFДокумент4 страницыPDFGeorge CamachoОценок пока нет

- ME2201 Manufacturing Technology-IДокумент9 страницME2201 Manufacturing Technology-IHiru Purushothaman HirudayanathanОценок пока нет

- RTM Nagpur University Syllabus (Theory)Документ5 страницRTM Nagpur University Syllabus (Theory)Milind KshirsagarОценок пока нет

- 5 MPДокумент3 страницы5 MPASIST MechОценок пока нет

- Outcomes:: Pec / Dome / Ii Year-Mechanical Engineering / Iii Sem / Me 6302: Manufacturing Technology - IДокумент68 страницOutcomes:: Pec / Dome / Ii Year-Mechanical Engineering / Iii Sem / Me 6302: Manufacturing Technology - IDineshОценок пока нет

- FINAL MCW-17ME35A - Notes PDFДокумент108 страницFINAL MCW-17ME35A - Notes PDFAMOGHОценок пока нет

- Manufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Документ2 страницыManufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Madduri HemantОценок пока нет

- Credits Total Marks: Sathyabama Institute of Science and TechnologyДокумент1 страницаCredits Total Marks: Sathyabama Institute of Science and TechnologyGiridharan RuОценок пока нет

- Emg 4102 CN 1Документ3 страницыEmg 4102 CN 1MaxwellОценок пока нет

- Manufacturing Tech SyllДокумент4 страницыManufacturing Tech SyllJagjit SinghОценок пока нет

- ME311 Manufacturing Processes 3-0-0-3 2016 Prerequisite: NilДокумент2 страницыME311 Manufacturing Processes 3-0-0-3 2016 Prerequisite: NilaslamОценок пока нет

- Production Technology Course OutДокумент5 страницProduction Technology Course Outmurjass85Оценок пока нет

- B.SC. Mechanical Engineering Course Skeleton Manufacturing Processes Muhammad Amjad 2010 3 Sept. 2011-Jan. 2012 3 1 Books and ReferencesДокумент1 страницаB.SC. Mechanical Engineering Course Skeleton Manufacturing Processes Muhammad Amjad 2010 3 Sept. 2011-Jan. 2012 3 1 Books and ReferencesAmin FarukiОценок пока нет

- Course OverviewДокумент14 страницCourse OverviewVinayaka G PОценок пока нет

- Part 0 Introduction To CourseДокумент15 страницPart 0 Introduction To Coursefake12062017 fakeОценок пока нет

- Manufacturing ProcessesДокумент136 страницManufacturing ProcessesArijit GhoshОценок пока нет

- R PT Instruction PlanДокумент6 страницR PT Instruction PlanVipin KumarОценок пока нет

- Manufacturing TechnologyДокумент34 страницыManufacturing TechnologyGeorge OliverОценок пока нет

- Me 8392 - Manufacturing Technology: 14. Course OutcomesДокумент6 страницMe 8392 - Manufacturing Technology: 14. Course OutcomesERKATHIRОценок пока нет

- Manufaturing ProcessДокумент2 страницыManufaturing ProcessSakshi VermaОценок пока нет

- Production TechnologyДокумент5 страницProduction TechnologyAparnaa MoorthyОценок пока нет

- M T 1Документ2 страницыM T 1sumikannuОценок пока нет

- Gujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyДокумент3 страницыGujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyPratik VishwakarmaОценок пока нет

- Gujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyДокумент3 страницыGujarat Technological University: Semester - V Subject Name: Manufacturing TechnologystarboyОценок пока нет

- ME F219 - Course Handout - 2022-23Документ3 страницыME F219 - Course Handout - 2022-23YERRAMILLI SRIVATSAVОценок пока нет

- Bmp-Course Plan and Evaluation PlanДокумент4 страницыBmp-Course Plan and Evaluation PlanVikas KamathОценок пока нет

- ME104 Manufacturing Process: Suggested ReadingsДокумент1 страницаME104 Manufacturing Process: Suggested ReadingsAditya KumarОценок пока нет

- Me8351 Manufacturing Technology-I SyllabusДокумент1 страницаMe8351 Manufacturing Technology-I SyllabusAnonymous ZB6qyhD6Оценок пока нет

- Computer Integrated Manufacturing 05 63xxДокумент97 страницComputer Integrated Manufacturing 05 63xxAnonymous mcFvPwzXОценок пока нет

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringДокумент49 страницRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringAbhi SharmaОценок пока нет

- IM112Manufacturing Technology PDFДокумент2 страницыIM112Manufacturing Technology PDFEmurhohwo JeremiahОценок пока нет

- Manufacturing Processes IIДокумент2 страницыManufacturing Processes IIAmrat PatelОценок пока нет

- ME 503-N Manufacturing TechnologyДокумент4 страницыME 503-N Manufacturing Technologyhrana287Оценок пока нет

- PP-I Syllabus (SH2019)Документ2 страницыPP-I Syllabus (SH2019)Vishwa RohindОценок пока нет

- Semester Within The Dates Specified by GTUДокумент6 страницSemester Within The Dates Specified by GTUvishallchhayaОценок пока нет

- Diploma Work Shop TechnologyДокумент10 страницDiploma Work Shop TechnologyadarshОценок пока нет

- Manufacturing and Materials SyllabusДокумент3 страницыManufacturing and Materials SyllabusAstroNirav SavaliyaОценок пока нет

- FP Syllabus R20Документ2 страницыFP Syllabus R20rajyal343Оценок пока нет

- PP Syllabus (R2019)Документ3 страницыPP Syllabus (R2019)shaikh javedОценок пока нет

- Manufacturing Processes SyllabusДокумент14 страницManufacturing Processes SyllabusdeekamittalОценок пока нет

- MT-1 (English) - N SchemeДокумент288 страницMT-1 (English) - N SchemeKumar Subramanian100% (1)

- Manufacturing TechДокумент6 страницManufacturing TechSachi MensiОценок пока нет

- ME3162 Module OutlineДокумент4 страницыME3162 Module OutlinedabudhabicozОценок пока нет

- Electrical Drives and ControlsДокумент26 страницElectrical Drives and ControlsAsha VermaОценок пока нет

- Me8392 Manufacturing Technology L T P CДокумент1 страницаMe8392 Manufacturing Technology L T P CERKATHIRОценок пока нет

- MP ppt1Документ224 страницыMP ppt1गिरीधर सदानंद चव्हाण100% (1)

- Amp New SyllabusДокумент3 страницыAmp New Syllabussimon rosarioОценок пока нет

- Gujarat Technological University: Semester - V Subject Name: Manufacturing Technology-IIДокумент3 страницыGujarat Technological University: Semester - V Subject Name: Manufacturing Technology-IITemp WorkОценок пока нет

- Manfacturing TechnologyДокумент2 страницыManfacturing TechnologyRamu AmaraОценок пока нет

- MP366 Modern Manufacturing ConceptsДокумент2 страницыMP366 Modern Manufacturing ConceptsDr. Mubarak AliОценок пока нет

- 3140204Документ3 страницы3140204vikas raiОценок пока нет

- Syllabus - BE Mech II Wef 2012-13 PDFДокумент28 страницSyllabus - BE Mech II Wef 2012-13 PDFPavan KishoreОценок пока нет

- Production Techniques - I: CO1. CO2Документ2 страницыProduction Techniques - I: CO1. CO2Manu RavuriОценок пока нет

- Academic Plan For Vth-Semester Mae (2011-12) : Subject: Microprocessor and Applications Subject Code: ETME-301Документ5 страницAcademic Plan For Vth-Semester Mae (2011-12) : Subject: Microprocessor and Applications Subject Code: ETME-301Jayesh KatariaОценок пока нет

- Production Syllabus 2017-18-1Документ71 страницаProduction Syllabus 2017-18-1Akankshya MishraОценок пока нет

- Manufacturing Technology 2Документ2 страницыManufacturing Technology 2Jeremaiah HaylingОценок пока нет

- MEC304 Production Process - I 4: Coursecommon To Mech/AutoДокумент1 страницаMEC304 Production Process - I 4: Coursecommon To Mech/AutoHoney SinghОценок пока нет

- Combustion TechnologyДокумент1 страницаCombustion TechnologySenthil Muthu Kumar TОценок пока нет

- Synthesis of Biopolymers Proteins, Polyesters, PolysaccharidesДокумент5 страницSynthesis of Biopolymers Proteins, Polyesters, PolysaccharidesSenthil Muthu Kumar TОценок пока нет

- Rapid PrototypingДокумент3 страницыRapid PrototypingSenthil Muthu Kumar TОценок пока нет

- The Fingerprint of BiopolymersДокумент3 страницыThe Fingerprint of BiopolymersSenthil Muthu Kumar TОценок пока нет

- Quick Review Ic EnginesДокумент87 страницQuick Review Ic EnginesVikram ManthriОценок пока нет

- Automotive Safety - AUT408: Understanding Traffic Signs and Signals - Unit 1Документ39 страницAutomotive Safety - AUT408: Understanding Traffic Signs and Signals - Unit 1Senthil Muthu Kumar TОценок пока нет

- Automotive Laboratory Manual: MAK 411E Experimental Methods in Mechanical EngineeringДокумент22 страницыAutomotive Laboratory Manual: MAK 411E Experimental Methods in Mechanical EngineeringSenthil Muthu Kumar TОценок пока нет

- School of Mechanical Sciences (SMS) : Kalasalingam UniversityДокумент5 страницSchool of Mechanical Sciences (SMS) : Kalasalingam UniversitySenthil Muthu Kumar TОценок пока нет

- Automotive Laboratory Manual: MAK 411E Experimental Methods in Mechanical EngineeringДокумент22 страницыAutomotive Laboratory Manual: MAK 411E Experimental Methods in Mechanical EngineeringSenthil Muthu Kumar TОценок пока нет

- AUT 281 Course PlanДокумент3 страницыAUT 281 Course PlanSenthil Muthu Kumar TОценок пока нет

- MBA IInd SEM POM Chapter 01 IntroДокумент43 страницыMBA IInd SEM POM Chapter 01 IntroPravie100% (1)

- Grease Testing HandoutДокумент27 страницGrease Testing HandoutSenthil Muthu Kumar TОценок пока нет

- A - Unsprung Mass Is Kept Minimum: - Is The Central Components of The Chain Converter Transmission.Документ6 страницA - Unsprung Mass Is Kept Minimum: - Is The Central Components of The Chain Converter Transmission.Senthil Muthu Kumar TОценок пока нет

- Engineering Management NotesДокумент188 страницEngineering Management NotesJoyce Ann CleofeОценок пока нет

- Hydrodynamic Drive Unit - 2Документ28 страницHydrodynamic Drive Unit - 2Senthil Muthu Kumar TОценок пока нет

- Auto - Power PlugДокумент1 страницаAuto - Power PlugSenthil Muthu Kumar TОценок пока нет

- ESEC Alumni SurveyДокумент2 страницыESEC Alumni SurveySenthil Muthu Kumar TОценок пока нет

- Ch11metalcastingprocДокумент74 страницыCh11metalcastingprocCharurat KongyangОценок пока нет

- Ch05 Control ChartsДокумент29 страницCh05 Control Charts87bbОценок пока нет

- Cma Ejercicios PDFДокумент21 страницаCma Ejercicios PDFElisa VargasОценок пока нет

- Design and Analysis of Riser For Sand CastingДокумент16 страницDesign and Analysis of Riser For Sand Castingrpadhra8803Оценок пока нет

- VictaulicДокумент6 страницVictaulicAndreyОценок пока нет

- Sequential Leaching For The Production of Alumina From A Nigerian ClayДокумент7 страницSequential Leaching For The Production of Alumina From A Nigerian ClayPuturrú De Fuá100% (1)

- NPQS C3-20 ReinforcementДокумент0 страницNPQS C3-20 ReinforcementCasimir Ghee Heng LimОценок пока нет

- ASTM A 802 Standard Practice For Steel Castings, Iron Castings, Surface Acceptance, Visual ExaminationДокумент10 страницASTM A 802 Standard Practice For Steel Castings, Iron Castings, Surface Acceptance, Visual Examinationpsanches25100% (1)

- Galvanic Corrosion White PaperДокумент7 страницGalvanic Corrosion White Paperleo_hindartoОценок пока нет

- Steelworks Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler MetalsДокумент2 страницыSteelworks Industry: To Increase Your Productivity, Optimize Maintenance and Repair With Long-Life Filler Metalskamals55Оценок пока нет

- USEPA Procedure 3005aДокумент5 страницUSEPA Procedure 3005aronna_hОценок пока нет

- Surface Hardening enДокумент20 страницSurface Hardening enanhntran4850Оценок пока нет

- Practical 5Документ8 страницPractical 5Farid FazamyОценок пока нет

- - กลศาสตร์ของวัสดุนาโน Mechanics of Nanomaterials อาจารย์ประจ าวิชา:ผศ.ดร.วรรณวิลัย วิทยากร:อ.ดร.อภิลักษณ์ เอียดเอื้อДокумент60 страниц- กลศาสตร์ของวัสดุนาโน Mechanics of Nanomaterials อาจารย์ประจ าวิชา:ผศ.ดร.วรรณวิลัย วิทยากร:อ.ดร.อภิลักษณ์ เอียดเอื้อTan NakaphanОценок пока нет

- PRIR11 - Engineering Practice Lab Manual: Tiruchirappalli-620015Документ21 страницаPRIR11 - Engineering Practice Lab Manual: Tiruchirappalli-620015pranav kumarОценок пока нет

- S21. Restricted Limits On Elements S26. Low-Sulfur Steels: Table 3 Table 4Документ1 страницаS21. Restricted Limits On Elements S26. Low-Sulfur Steels: Table 3 Table 4Dipesh PatelОценок пока нет

- Phosphor Bronze To Bs 1400: Pb1Документ1 страницаPhosphor Bronze To Bs 1400: Pb1Rohan ShiyaniОценок пока нет

- Abstract of ASTM F568M 1996Документ12 страницAbstract of ASTM F568M 1996Jesse ChenОценок пока нет

- Different Parts of A HammerДокумент13 страницDifferent Parts of A HammerMark IsidroОценок пока нет

- Galvanising of Hot Rolled Strip91 - 1Документ8 страницGalvanising of Hot Rolled Strip91 - 1Suvro ChakrabortyОценок пока нет

- Mechanical One Line NotesДокумент35 страницMechanical One Line NotesVikky DhapodkarОценок пока нет

- SF 0010 0 Metco 320NS PDFДокумент8 страницSF 0010 0 Metco 320NS PDFMehdi KoneshlouОценок пока нет

- WJ 1995 05 s153 PDFДокумент7 страницWJ 1995 05 s153 PDFVijayakumar SamyОценок пока нет

- New 9.2 9.3 9.5 9.6 Extraction of MetalsДокумент10 страницNew 9.2 9.3 9.5 9.6 Extraction of MetalskolaОценок пока нет

- TruBolt™ Xtrem™ Tech Data SheetДокумент2 страницыTruBolt™ Xtrem™ Tech Data SheetWhite_rabbit2885764Оценок пока нет

- Butterfly Norris Series 285Документ12 страницButterfly Norris Series 285metasoniko2014Оценок пока нет

- Asme Section II A Sa-370Документ4 страницыAsme Section II A Sa-370Anonymous GhPzn1xОценок пока нет