Академический Документы

Профессиональный Документы

Культура Документы

Flow Phenomenon in Steam Turbine Disk

Загружено:

rashm006ranjanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Flow Phenomenon in Steam Turbine Disk

Загружено:

rashm006ranjanАвторское право:

Доступные форматы

FLOW PHENOMENON IN STEAM TURBINE DISK-STATOR CAVITIES CHANNELED BY BALANCE HOLES

ABSTRACT Computational fluid dynamic (CFD) analysis of the region the secondary flow path of high pressure steam turbine was conducted. Region included two adjacent to disc cavities and section of main flow path. The cavities were channeled by balance holes located in the disk. Two geometrical models were considered: single disk cavity and both cavities with balance holes. 2D axisymmetric and 3D analyses were conducted for the first model, however only 3D study was performed for the second one. Analysis of the single disk cavity has revealed appearance of vortexes in circumferential direction even in case when all boundary conditions and geometry features were close to the axi-symmetric case. The trend of the average pressure distributions along radius was found for 2D and 3D models. The transient analysis of the two cavity model revealed vortexes movement in circumferential direction with higher than disk rotation velocity. It induces periodic conditions at the inlet and outlet of balance hole and periodic steam mass flow rate through the holes. The flow pattern in the two cavities with balance holes is so complicated that common 1D net flow representation should be considered as significant simplification. INTRODUCTION Steam/gas mass flow distributions in the secondary turbine flow path is usually treated with method replacing real hydraulic system with equivalent graph. Branches of such graph are 1D models of flow in elements like tubes, annulus, valves and so on. Existing 1D models are essentially correlation dependencies of hydraulic resistance upon various parameters.

Mass flow rate and pressure distributions in the whole hydraulic system of the secondary flow path are calculated using mass conservation law at each graph node and pressure drops on each branch. The most of the correlations in simple cases are reliable for the wide range of operation and geometry parameters. The complicated flow such as flow in the disk-stator axial seals couldnt be treated with the same accuracy as simple ones, and unfortunately its influence on the whole secondary flow path is significant. In reality flow in the axial seal is substantially 3D, especially when adjacent to seal cavities are channeled with balance holes. In spite of that, often such flows are treated with simple methods when whole turbine secondary path is analyzed for the lack of more accurate methods. Turbine design requires development of reliable and rapid methods of secondary flow path prediction. Such methods must be based on deep understanding of processes in axial disk-stator seals and should extract accurate 1D models applicable for turbine designer needs. An alternative way is axi-symmetric CFD modeling of the turbine secondary flow path with several additional assumptions related to labyrinth seals, balance holes and others elements that induce 3D effect [1]. This approach promises more accurate results but several assumptions used in reduction of the problem from 3D to 2D axisymmetric formulation need to be validated. Flow in cavities between rotating disk and fixed stator is a subject of many investigations [2, 3, 4, 6, 7, 8] and remains a point of considerable interest due to a variety of disk cavity and rim seal geometries that are explored in current

gas and steam turbines. Influence of geometrical details on the flow inside cavity is very strong and therefore slight variations in seal geometries lead to dramatic differences in flow patterns. That is why researchers often conduct specific design studies using general understanding of flow phenomenon. The latest studies [2, 3, 4] include numerical/experimental analyses and only a few old papers [5, 9] were devoted to developing simple methods that could be used for the conceptual design of steam/gas turbine secondary flow path. One of the challenging problems of the secondary flow path modeling is predicting of pump effect caused by rotating disk. Known methods for calculating pump effect rely on the solution of momentum equations in 1D formulation evolved for fluid volume enclosed in between flat rotating and fixed disks [5, 9]. It is assumed that fluid in the boundary layer on the disk moves centrifugally, meanwhile it moves centripetally on the stator. Besides, disk and stator surfaces are supposed to be smooth that provides continuous flow. In practice, in order to meet the design and technology requirements, the disk/stator must have more complex surfaces (in gas turbines, especially); therefore, the flow will be substantially different from idealized one. Moreover, above mentioned approach doesnt include neither the seal at the disks band, nor its shape, although it's known that these factors influence the flow dramatically. Steam migration through balance holes adds even more complexity to the situation. This paper doesnt claim to provide a general solution. It describes flow modeling in near disk adjacent cavities of a steam turbine high pressure cylinder in 2D and 3D formulations, complemented with analysis of the differences and comparison with reduced-order modeling results. The analysis has shown a very intricate flow pattern in considered system. Flow through the balance holes exhibit significant swirling and heterogeneity. Two kinds of stream were observed in the system: the first strong stream is directed from the cavity with higher pressure to the cavity with lower pressure. The second weaker stream runs in opposite direction, i.e. in the direction of adverse pressure gradient. It was revealed that balance holes generate near regular vortex structures that move in the cavities mainly circumferentially. The flow appeares transient and can be characterized as practically periodic one. Due to this reason, mass exchange between cavities and main flow path was also periodic, i.e. in the same band seal, main steam flow ingress was alternated in time with secondary steam flow injection into the turbine main flow path. Changes in other characteristics were also periodic in time. For instance, static pressure

at inlet/outlet of balance hole changed periodically, so that pressure drop was either positive or negative. It is obvious that the periodic flow pattern dramatically differs from existing models. At the same time, 2D CFD analysis didnt demonstrate any instability that could be identified as periodicity which leads to noticeable difference from results of 3D CFD analysis. The paper shows that an averaged in time flow pattern in the disc-rotor cavities couldnt be correctly determined by means of existing relevant equations used in a framework of net model. NOMENCLATURE A G K Re d p r s u x v z Area or coefficient in Equation (5) Mass flow rate Rotation factor Reynolds number Balance hole diameter Pressure Radius of the disk Width of the cavity Axial velocity Reduced radius, x = r / r1 Tangent velocity Number of balance hole

Greek Rotation factor, ratio of average tangent velocity of fluid to disk velocity at the current radius Resistance factor Flow factor Kinematic viscosity

Subscripts 1 2 op rotation stationary Hub of the disk Rim of the disk Operational pressure Rotation case Stationary case

Boundary conditions

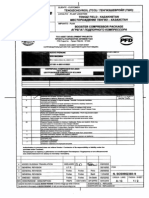

3D MODEL Model An object of the study was steam flow in two adjacent near disk cavities of the first stage of a large steam turbine high pressure cylinder. All disks of the rotor have 7 balance holes of 45mm in diameter. It was possible to model only 1/7 of the cavity volume (Fig.1). Disk thickness was 50 mm. Average (reference) value of steam pressure was 16.3 MPa. Steam temperature was 750K and density 47-50 kg/m3. Boundaries conditions were determined from existing results of modeling of steam turbine main and secondary flow path that were carried out with traditional engineering methods. Thus the pressure and velocities upstream and downstream blade's root zone were extracted from flow path prediction, Fig.1. We had to tolerate some inaccuracies in assigning boundary conditions. For example, it is obviously that stationary nozzles and rotating blades intensify interaction between the main and the secondary steam flows. However, we had to omit these details in order to be able to run the problem on commercially available PC. Therefore, the flow path zone was simplified in the model and represented by hollow cylinders above the hub and the diaphragm, Fig. 1. Boundary conditions before/after labyrinth seals Surface A, Fig. 2, located upstream can be used for specification of inflow parameters and surface F, located downstream can be used for specification of outflow parameters. Boundary conditions on these surfaces shell be discussed in details. It seems that pressure (total/static) is the most appropriate kind of BC to assign, because pressure is known on each node of hydraulic net system of secondary flow path. However,, by doing so the pump (centrifugal) effect will be predetermined. In reality we dont know how to estimate correctly the pump effect and study of which is one of the goals of this work. Therefore, the mass flow rate was assigned to both surfaces. This allowed studying pressure development under centrifugal forces. Values of inflow and outflow were about the same and equal to 2/7 kg/s, etc. ~1% of the main steam flow. (Full mass flow rate was 2 kg/s, only one sector, i.e. 1/7 of the flow path was modeled, thus 2/7 kg/s). This value was determined by the previous net calculation of secondary path. Besides mass flow rate at the surface A, a tangential velocity was assigned on that surface that was about 0.3-0.4 of rotor rotational speed. Figure 1. Model of the disk cavities (green sectors) chanelled with balance holes (white sector) Analysis was performed by using FLUENT solver version 6.0. Grids were generated by Gambit. All models were meshed with boundary layer refinement near the walls. Grid study was conducted by varying the number of elements in 2D model by two times, and essentially it didnt change the results. Wall cell Y+ for 2D model was in range of 40-500. A full 3D model comprised of 224,230 hexahedral elements that included detailed meshing near wall regions (Fig. 2). The range of Y+ was about 40-1000. Standard wall functions were used for treatment near wall region. All computations were conducted according to the scheme of second-order approximation. The iterations were stopped when residuals of all quantities were approximately 10-5. Main steam flow boundary conditions To mimic interaction between flows inside disc cavities and steam main flow there were created two zones extending into turbine flow path. Zones were sized in such a way to avoid direct influence of the location of boundaries on mass exchange between main/secondary flows. Velocity components and steam temperature were assigned on B and D surfaces and static pressure was applied to C and E surfaces (Fig.1). Tangential component of velocity at the surface B was ~200 m/s and practically axial flow was specified at the surface D. Axial component was about 50 m/s through both surfaces while radial component was null. The relative

static pressure was set at the surfaces and pressure (taking into account radial effect.

Figure 2. CFD model of near disk cavities Boundary conditions at the walls "No slip" conditions were assigned at the all wall surfaces. The model rotated with angular velocity 314 rad/s; hence, rotor surfaces were stationary in relative motion, while stator surfaces were stationary in absolute motion. Periodicity Periodic boundary conditions were applied to surfaces of the segments cross-sections (Fig.2). Single disk cavity A single disk cavity without balance hole was taken as an object of investigation. The results of analysis allowed to draw some important conclusions with respect to further study of the full model. Flow nature in the disk-stator systems is extremely unstable, especially, in the case of steam forced injection into the gaps from labyrinth seal of upstream diaphragm. At this point, steam moves predominantly from axis of symmetry to the disk rim under adverse pressure gradient. Small obstacles or great value of pressure gradient can cause flow separation that has substantially 3D nature. In other words, under certain conditions, the problem can be adequately treated only as 3D one.

Figure 3. Pressure distribution with 3D (left) and 2D (right) models of the fore near-disk cavity. Above - Pop=1MPa, below Pop=16.3 MPa It was a matter of interest to compare two kinds of models. With this goal, axi-symmetric 2D model and 3D model were developed for the single disk seal (only fore cavity of whole model shown on Fig.1). Boundary conditions were the same as in the whole model, however fluid was ideal gas (air). It allowed analysis for different values of operation pressure (air density). We studied flow with forced injection of air from the labyrinth seal and without it. The computations showed unexpected results. At relatively small value of operation pressure (1 to 3 MPa), axisymmetric computations completely coincided with 3D analysis results (Fig.3, above). Air moved circumferentially and its streamlines remained undistorted. At pressure above 3 MPa, the powerful vortex structures were generated. The process lost its stationery nature due to transition of those structures in tangential direction. At the same time, pressure distribution averaged in time along radius in 3D computations was almost similar to results of stationery 2D analysis. To avoid mistakes, these results were validated by numerous computations. The following reasoning can serve as the foundation for understanding this phenomenon. Pressure growth leads to density increase; correspondingly, pump effect is intensified together with increasing of adverse pressure gradient. It promotes fluid separation around the rim and distortion of axis-symmetric character of the flow. As the result powerful vortexes appear and move along circumference of the seal.

Full model Complete analysis of the flow in two near disk cavities channeled by balance hole was performed under reference pressure of 16.3 MPa only, i.e. for real conditions of steam turbine HPC. Computations were carried out for non-stationery formulation. Transient analysis is very computationally expensive, nevertheless, corresponding computations have been conducted to cover the period of attainment of the solutions periodicity. Figure 5. Static pressure difference in fore and rear cavities along surface of annulus enveloping balance holes. G - Steam flow rate through balance holes. Character of the flow through balance hole is very different from that can be obtained with 1D model. Flow in the balance hole often runs against pressure gradient, i.e. there are two flows running simultaneously -- following gradient and against it, Fig. 5. At the point of minimum pressure drop averaged along annulus surface, zone of pressure maximum is placed right over the hole and steam is directed to the hole (Fig.6). In the case of maximal pressure difference (Fig.7), a vortex zone of reduced pressure is located over the hole that causes even inverse rear-to-fore cavity steam movement.

Fig. 4 Disk surface of averaging (hatched area) Transient behavior of circumference vortex structure was revealed in the fore cavity that caused significant irregularity of static pressure. For instance, static pressure fluctuation of 0.25MPa was observed at balance holes radius, meanwhile the difference of static pressure values averaged within the annulus that envelopes the balance holes (Fig.4) on both sides of the disk fluctuated approximately within the same range of values (Fig.5). Fluctuation in pressure inside the cavities leads to periodic variation of steam flow rate through the balance holes (Fig.5). Flow rate fluctuation frequency is close to frequency of rotor (and disk) rotation and is in the range 55 - 80Hz. As to rear cavity, a pressure distribution pattern there appeared not as explicit as it was in the fore cavity and vortex structures are less pronounced. If in the rear cavity steam is pumped in from main flow path, then an inverse process is performed in the fore cavity, i.e. very often periodic blow-out to main flow path has been occurred. In that case, flow in the fore cavity had hubtotip direction and inverse motion was in the rear cavity where steam suction from turbine flow path was observed.

Figure 6. Flow near fore surface of the disk at maximal pressure drop and respective minimum of through holes flow rate. Reported analysis is valid for selected operation points. Computations carried out under other operational conditions showed that transient nature of that phenomenon becomes apparent in different ways. For example, as the overall pressure decreases (that, in fact, means reduced steam density) the fluctuation amplitude also decreases.

Figure 7. Flow near fore surface of disk at minimal pressure drop and respective maximum of through holes flow rate Flow in the balance hole can be characterized as extremely random (Fig.8). Steam moves to the hole (Fig.8, flow 1) and gets twisted under impact of centrifugal forces. As result, a powerful vortex structure is generated inside the hole that overlaps most of effective cross-section. It prevents steam proceeding from one cavity to another. Then, steam flows out to the rear cavity in the direction opposite to disk rotation (flow 3). A reverse steam flow from rear to fore cavity also exists. Thus, two opposite flows run in opposite directions through the balance hole at the same time. 2D MODEL 3D simulation demonstrated quite complex periodic flow nature in two adjacent near disk cavities channeled with balance holes. Meanwhile, existing methods for flow rate prediction rely on some integral flow characteristics that in fact are quite sensitive to the method of averaging. Pressure in the disk cavity can vary even at the same radius around the seal circumference, as well as with distance along width of a seal between disk and diaphragm. Especially, it refers to the fore cavity that features transient periodic flow nature. In spite of substantially 3D character of flow there is a desire to treat it as 2D axis-symmetric one, in order to evaluate possibilities of more simple and rapid solutions. For this purpose each cavity was studied separately (Fig.1, green zone) and mass exchange through balance holes from fore cavity to rear one was modeled by a steam flow through equivalent virtual annular channel. In fact, case when the steam that leaves the fore cavity through the annulus boundary comes to rear cavity through similar boundary (Fig.4) was considered. The size of boundary varied to obtain more accurate coincidence with 3D computations.

Figure 8. Steam flow in fore cavity (above) and inside balance hole (below) Numerous axi-symmetric computations showed that flow obtained via 2D and 3D solutions are quite different at high pressures, i.e. when flow is substantially transient. Various boundary sizes were considered. For example, annulus channel width was assumed to be equal to the balance holes diameter. In another approach it was computed from assumption that total cross section of balance holes is equal to cross section of annulus channel. In all cases, in order to preserve the same through-holes flow rate that was computed in 3D formulation, a greater pressure drop was needed in 2D modeling. Thus, in 3D case there is better pressure equalization between two cavities than in 2D model at the account of steam migration through balance hole. Correlations of pressure variation in 2D formulation with 3D instantaneous pressure values along selected radii are shown in Fig. 9 and 10. As diagrams indicate, when pressure is low, both types of simulation provide with almost similar pressure values, excluding radii that cross the balance hole axis. In high pressure case, an essential difference of the curves is obvious and this is an evidence of inadequacy of 2D computations at these conditions.

Comparison of 2D and 3D simulations Type of simulation Relative pressure at balance hole entry (kPa) Relative pressure at balance hole exit (kPa)

3D pressure is averaged in time and along area of annulus that envelopes balance holes 2D width of annulus equals balance hole diameter 2D annulus area equals to total area of the balance holes 1D MODEL Flow through balance hole

109.2

103.2

192.9

139.7 Figure 9. Distribution of relative static pressure along radii crossing balance hole axis (hole), vortex center (min) and zone of maximal pressure (max) in 3D model and along radius in 2D model for fore and rear cavities at reference pressure 16.3 MPa Mass flow rate or resistance coefficient is determined usually by the experimental correlations that incorporate the following parameters: Disk/stator seal width; - Relative pitch of holes arrangement along disk; - Ratio of holes leading edge radius to its diameter; - Ratio of disk rotation velocity at radius of the holes location to velocity axial component in the hole. All following analysis has been carried out as comparison with 3D solution. Numerous axi-symmetric computations showed that flow obtained via 2D and 3D solutions are quite different at high pressures, i.e. when flow is substantially transient. Various boundary sizes were considered. For example, annulus channel width was assumed to be equal to the balance holes diameter. In another approach it was computed from assumption that total cross section of balance holes is equal to cross section of annulus channel. In all cases, in order to preserve the same through-holes flow rate that was computed in 3D formulation, a greater pressure drop was needed in 2D modeling. Thus, in 3D case there is better pressure equalization between two cavities than in 2D model at the account of steam migration through balance hole. Correlations of pressure variation in 2D formulation with 3D instantaneous pressure values along selected radii are shown in Fig. 9 and 10. As diagrams indicate, when pressure is low, both types of simulation provide with almost similar pressure values, excluding radii that cross the balance hole axis. In high pressure case, an essential difference of the curves is obvious and this is an evidence of inadequacy of 2D computations at these conditions.

248.5

117.9

Engineering approach to mass flow rate prediction through balance holes is based on equations (1) (2) <> where - mass flow rate coefficient, - balance hole area, d hole diameter, z holes number, - fluid density at hole inlet, p1, p2 pressure at the radius of holes arrangement in fore and rear cavities, - resistance coefficient related to flow rate coefficient as

<>

(3) In order to find solution of (1) and (2) one needs to know values of or , and either value of pressure drop at the balance holes radius, or mass flow rate.

inherent to operation of steam turbine high pressure cylinders. Pressure variation along radius in the cavities As a rule, 1D computations of disk-stator system assume usage of equations based on the law of angular momentum conservation. This approach was first offered in [9] and then developed in [5, 10] in a form shown below:

(5) <> Figure 10. Distribution of relative static pressure along radii crossing balance hole axis (hole), vortex center (min) in 3D model and along radius in 2D model for fore and rear cavities at reference pressure 1.0 MPa 3D analysis reported 1.74 kg/s mass flow rate through balance holes that took place under small pressure drop equal to 0.007MPa. Using (1), (2) we arrive on the following values for the coefficients: = 0.32, = 9.8. An attempt to estimate mass flow rate coefficient was undertaken using one of standard methods [8]. However, it precise value couldn't be found because a set of the complexes composed from above mentioned parameters dropped out of the confidence interval, although in the considered example near disk cavities geometrical characteristics and operational conditions were assigned with respect to real design of high pressure cylinder and parameters of operation. Nevertheless, obtained data for flow rate coefficient allows to estimate its value as less than 0.08, i.e. its computed value appeared 4 times smaller than actual one. Shvetz, and Duban [5] proposed to define for balance holes by taking into account rotation influence by the following equation (Eq. 4): rotation = stationary (1+0.6K+0.082K2-0.024K3) (4) <> (7) <> (8) <> Using Eq. (2 - 4) it has been found that rotation = 26 that exceeded the actual value by 2.6 times. Comparison of both methods showed their drawbacks for reliable computations of secondary flow path under high pressure conditions. However, these conditions are Here s disk-diaphragm gap; r1, r2 radiuses of diaphragm seal and axial seal at disk rim (peripheral radius); x=r/r1 dimensionless current radius. Fig.11 presents a comparison of Eq. (5 - 8) solution with pressure factor distribution in the fore cavity along selected radiuses for one of moments in 3D (transient solution) and 2D (steady state solution) formulations. The diagram shows 5. Shvetz, I.T., Dyban, E.P., 1974, Air cooling of gas turbine parts, Kiev, 488 p. (in Russian)

Figure 11. Pressure factor distribution in the fore cavity at reference pressure 16.3 MPa. 3D instantaneous values along radiuses crossing balance hole axis (hole), vortex center (min), and maximal pressure zone (max); 2D along radius; Eq.5 - 1D analysis based on equations (5-8).

(6)

where rotation, stationary - resistance coefficient of rotating and stationery disk; K = v / u - parameter of rotation, v tangential velocity of disk rotation at the holes axis radius; u fluid average velocity.

that 1D model is close enough to 2D case and dramatically

differs from instantaneous distributions in 3D model. The latter evidently demonstrates that 1D and 2D models can not describe correctly the intricate nature of periodic flow in the fore cavity. CONCLUSIONS - Flow pattern in disk-rotor cavities is highly depended upon operational pressure, and it becomes transient at typical for HPC pressures. - Amplitude of static pressure variation at the disk fore side at the radius defining balance hole location is commensurable with pressure drop in the balance holes. - Frequency of characteristic flow variation is close to disk rotation frequency. - Through-holes steam flow rate and pressure difference vary in time in a counter-phase manner. - Amplitude of fluctuations is decreased with steam pressure decreasing, i.e. with density reduction. - 2D axi-symmetric analysis doesnt allow flow modeling in near disk cavities with reasonable accuracy. - 1D methods of computations are not as correct as it is required for high pressure flow modeling and need further improvement. REFERENCES 1. Moroz, L, Tarasov, A, 2003, Coupled CFD and thermal steady state analysis of steam turbine secondary flow path, International Joint Power Generation Conference, June 16-19, 2003, Atlanta, Georgia, USA, IJPGC2003-40058 2. Wilson, M., Pilbrow, R., Owen, J.M., 1997, Flow and heat transfer in a preswirl rotor-stator system, ASME Journal of Turbomachinery, Vol. 119, pp.364-373 3. Cao, C, Chew, J.W., Millington, P.R., Hogg, S.I. Interaction of rim seal and annulus flows in an axial flow turbine, Proceedings of ASME Turbo Expo 2003, Power for Land, Sea, and Air, June 1619, 2003, Atlanta, Georgia, USA, GT2003-38368 4. Pilbrow, R., Karabay, H., Wilson, M., Owen, J.M., 1999, Heat transfer in a cover-plate preswirl rotatingdisk system, ASME Journal of Turbomachinery, Vol. 121, pp.249-256

6. Matveev, Yu. Ya., Pustovalov, V.N., 1982, Laminar viscous flow calculation between rotated disks, Fluid and Gas Mechanics, Proceeding of the Academic Science of USSR, 1, pp. 76-81 (in Russian) 7. Kapinos, V. M., 1966, Convective heat transfer of turbulent flow between rotated disks in closed cavity, Proceeding of Higher School Aviation technique, 1, pp. 132-129 (in Russian) 8. Kapinos, V. M., Matveev, Yu. Ya., Pustovalov, V.N., 1983, Natural convection of unventilated cavities of steam turbines rotors, Moscow, Heat-and-Power Engineering , 8, pp. 36-39 (in Russian) 9. Lomakin, A.A., Axial pressure in the centrifugal pumps with take into account a clearance, 1940, Moscow, Soviet boiler fabrication, 12, pp.431-437 (in Russian) 10. RTM 108.020.113-77 Fixed steam and gas turbines, 1979, Leningrad, CKTI, 103 p. (in Russian)

Вам также может понравиться

- Handbook5 PDFДокумент257 страницHandbook5 PDFZAKROUNОценок пока нет

- 03 - Confined Space EntryДокумент18 страниц03 - Confined Space Entryrashm006ranjanОценок пока нет

- Human at Mars PDFДокумент55 страницHuman at Mars PDFVuningoma BoscoОценок пока нет

- Mr. A. K. Sinha - Energy Efficiency Industrial Utilities - Boiler SystemsДокумент63 страницыMr. A. K. Sinha - Energy Efficiency Industrial Utilities - Boiler Systemsjanakiram2010Оценок пока нет

- Rotor Dynamics Lund Stability CriteriaДокумент6 страницRotor Dynamics Lund Stability CriteriathunderОценок пока нет

- Maximize Machine Reliability Through Precision Lubrication SkillsДокумент12 страницMaximize Machine Reliability Through Precision Lubrication Skillsrashm006ranjan50% (2)

- Rotor Dynamics of Aircraft Gas Turbine EnginesДокумент5 страницRotor Dynamics of Aircraft Gas Turbine EnginesfengrotorОценок пока нет

- Jet Bit Nozzle Size SelectionДокумент46 страницJet Bit Nozzle Size SelectionBharat BhattaraiОценок пока нет

- Oil Whirl in Floating Ring SealsДокумент11 страницOil Whirl in Floating Ring SealsMuhammad Irfan AnwarОценок пока нет

- Steam Ejector CalculationsДокумент11 страницSteam Ejector Calculationsrashm006ranjanОценок пока нет

- Steam Turbine Study Emg 32/25: Title: Document Code RevisionДокумент23 страницыSteam Turbine Study Emg 32/25: Title: Document Code RevisionUdhayakumar VenkataramanОценок пока нет

- BIRKOSIT - Sealing Compound Application ProcedureДокумент1 страницаBIRKOSIT - Sealing Compound Application ProcedureProject Sales CorpОценок пока нет

- Paper Rotor DynamicsДокумент12 страницPaper Rotor DynamicsTony HeОценок пока нет

- Case Study Tuning Out Difficult Torsional Vibration ProblemДокумент15 страницCase Study Tuning Out Difficult Torsional Vibration Problempathakshashank100% (1)

- Syn Gas Compressor Oil Tank ExplosionДокумент6 страницSyn Gas Compressor Oil Tank Explosionarunanshu palОценок пока нет

- GE Steam Turbine Extraction Check Valves DesignДокумент8 страницGE Steam Turbine Extraction Check Valves DesignGaneshmohite123Оценок пока нет

- 01 220043enc Routine Turbine MaintenanceДокумент8 страниц01 220043enc Routine Turbine Maintenanceajipramudio100% (1)

- 0901d1968065f1f4 Bearing Preload - TCM - 12 299896Документ7 страниц0901d1968065f1f4 Bearing Preload - TCM - 12 299896anush_swaminathanОценок пока нет

- Turbine Overspeed Systems and Required Response TimesДокумент12 страницTurbine Overspeed Systems and Required Response Timesramnadh803181Оценок пока нет

- Two Dimensional Design of Axial CompressorДокумент160 страницTwo Dimensional Design of Axial CompressorMarcusHuynh88Оценок пока нет

- Rotor Dynamic Modelling As A Powerfull Tool For Vibrartion Analysis of Large TurbomachineryIFTOMM 2010Документ7 страницRotor Dynamic Modelling As A Powerfull Tool For Vibrartion Analysis of Large TurbomachineryIFTOMM 2010sainath_84Оценок пока нет

- Geared Up For SuccessДокумент32 страницыGeared Up For Successrashm006ranjanОценок пока нет

- Blade-St: The Complete Steam Turbine Blade Analysis ToolДокумент8 страницBlade-St: The Complete Steam Turbine Blade Analysis Toolramnadh803181Оценок пока нет

- API 617 stability analysis of centrifugal compressorsДокумент10 страницAPI 617 stability analysis of centrifugal compressorsthlim19078656Оценок пока нет

- 1982 - Korner - Design Features of Steam PDFДокумент6 страниц1982 - Korner - Design Features of Steam PDFramakantinamdarОценок пока нет

- Earned Value Management (EVM)Документ8 страницEarned Value Management (EVM)rashm006ranjanОценок пока нет

- Earned Value Management (EVM)Документ8 страницEarned Value Management (EVM)rashm006ranjanОценок пока нет

- VariStroke-I (VS-I) 26727 - GДокумент135 страницVariStroke-I (VS-I) 26727 - GOmar AnguloОценок пока нет

- Turbine Maintenance Book PDFДокумент223 страницыTurbine Maintenance Book PDFAnonymous mNQq7oj100% (1)

- 1st Place Undergraduate Team-The University of KansasДокумент98 страниц1st Place Undergraduate Team-The University of KansasKimberlly Costa Carvalho100% (2)

- Electrical Testing Procedures for Armatures and StatorsДокумент7 страницElectrical Testing Procedures for Armatures and StatorsCarlosОценок пока нет

- Grundfos Axial Flow Pumps BrochureДокумент7 страницGrundfos Axial Flow Pumps Brochurefg_111307359Оценок пока нет

- 660 MW Skoda TurbineДокумент52 страницы660 MW Skoda TurbineHucha Reddy100% (1)

- How To Design R.C. Flat Slabs Using Finite Element AnalysisДокумент16 страницHow To Design R.C. Flat Slabs Using Finite Element Analysisocenkt100% (10)

- APH Efficiency 1Документ12 страницAPH Efficiency 1Debabrata TantubaiОценок пока нет

- Comparison Between Single&multi Shaft Turbine PDFДокумент12 страницComparison Between Single&multi Shaft Turbine PDFcobrasrkОценок пока нет

- Vortex Transport and Blade Interactions in High Pressure TurbinesДокумент11 страницVortex Transport and Blade Interactions in High Pressure Turbinesapi-19772009100% (1)

- Polder Pumps ManualДокумент7 страницPolder Pumps ManualHiren PatelОценок пока нет

- STR 3 2010 18 20 Romero en Low PDFДокумент3 страницыSTR 3 2010 18 20 Romero en Low PDFBradley Nelson100% (2)

- Steam Turbine Components Welding PDFДокумент228 страницSteam Turbine Components Welding PDFShoaib AhmedОценок пока нет

- Heavy Manufacturing of Power PlantsДокумент18 страницHeavy Manufacturing of Power PlantsGurnam SinghОценок пока нет

- BHEL's Introduction and ProductsДокумент29 страницBHEL's Introduction and ProductsAkshayОценок пока нет

- TurbomachinesДокумент2 страницыTurbomachinesThesinghОценок пока нет

- Ebara Submersible Pump PDFДокумент28 страницEbara Submersible Pump PDFThinagaran N ManiamОценок пока нет

- BCL506 Centifigugal Compressor SpecificationДокумент13 страницBCL506 Centifigugal Compressor SpecificationhakimsalimiОценок пока нет

- G6600Документ13 страницG6600fazzlie100% (1)

- Doosan Skoda Product BrochureДокумент16 страницDoosan Skoda Product BrochureSai Shankar Lakshminarayanan100% (1)

- LP Pressure TestingДокумент34 страницыLP Pressure TestinglisaОценок пока нет

- ARLA Rotor Dynamics Seminar 1Документ3 страницыARLA Rotor Dynamics Seminar 1cwfh779Оценок пока нет

- Impeller Repair Techniques For Centrifugal Compressors PDFДокумент8 страницImpeller Repair Techniques For Centrifugal Compressors PDFFonCKm09Оценок пока нет

- A Review of Tilting Pad Bearing TheoryДокумент31 страницаA Review of Tilting Pad Bearing TheoryJose Luis RattiaОценок пока нет

- Flow CalculationsДокумент22 страницыFlow CalculationsJay VoraОценок пока нет

- Rbalance Rotor Balancing ProcedureДокумент2 страницыRbalance Rotor Balancing ProcedureBradley NelsonОценок пока нет

- Appendix 6a - Technical Specifiction Spare Rotor Repair T10 and T20Документ17 страницAppendix 6a - Technical Specifiction Spare Rotor Repair T10 and T20Dino AndrianОценок пока нет

- Development of Gas Turbine Performance Models Using A Generic SimuДокумент10 страницDevelopment of Gas Turbine Performance Models Using A Generic SimuMahmood ElnagarОценок пока нет

- Oil Whirl Whip PDFДокумент9 страницOil Whirl Whip PDFbwelz100% (2)

- TPP Equipment and ServicesДокумент24 страницыTPP Equipment and ServicesmanojkumarОценок пока нет

- Manual B4601Документ159 страницManual B4601FER-ARTОценок пока нет

- Ebara Horizontal Multistage PumpДокумент27 страницEbara Horizontal Multistage PumpYohanes KrisОценок пока нет

- ANSYS Turbomachinery CFD System - 14.5 UpdateДокумент39 страницANSYS Turbomachinery CFD System - 14.5 UpdatePrabhuMurugesanОценок пока нет

- Alignment procedure formulaДокумент4 страницыAlignment procedure formulaWidhyatmika RestuОценок пока нет

- ROTALIGN-Ultra Shaft-Alignment ALI9-846 02-05 1.20 G PDFДокумент88 страницROTALIGN-Ultra Shaft-Alignment ALI9-846 02-05 1.20 G PDFDon FreemanОценок пока нет

- Turbogenerator Vibration Analysis and Maintenance ReportДокумент16 страницTurbogenerator Vibration Analysis and Maintenance ReportNestor Lopez100% (1)

- HRSG Steam Blow (Load 20 MW) PDFДокумент2 страницыHRSG Steam Blow (Load 20 MW) PDFKanzanah PettaraniОценок пока нет

- BORSIG Valve PresentationДокумент18 страницBORSIG Valve PresentationMachineryengОценок пока нет

- Scope of Work FR 9Документ3 страницыScope of Work FR 9Dharmesh Kumar KewatОценок пока нет

- List of GHS Hazard Statement & PictogramsДокумент33 страницыList of GHS Hazard Statement & PictogramsKhairul BarsriОценок пока нет

- CenssorsДокумент106 страницCenssorsChandraSekaranBmОценок пока нет

- PumpsДокумент45 страницPumpsMehmood Ul Hassan100% (1)

- 03 Iso 10816 NewДокумент3 страницы03 Iso 10816 NewFadooollОценок пока нет

- Rim Seal Ingestion in A Turbine Stage From 360-Degree Time-Dependent Numerical SimulationsДокумент12 страницRim Seal Ingestion in A Turbine Stage From 360-Degree Time-Dependent Numerical SimulationsShezan KanjiyaniОценок пока нет

- Numerical Simulation of Turbulent Flow Through A Francis Turbine RunnerДокумент6 страницNumerical Simulation of Turbulent Flow Through A Francis Turbine RunnerAngel CerriteñoОценок пока нет

- IADC/SPE-178881-MS Swab and Surge Pressures With Reservoir Fluid Influx Condition During MPDДокумент13 страницIADC/SPE-178881-MS Swab and Surge Pressures With Reservoir Fluid Influx Condition During MPDqjbsexОценок пока нет

- 9Документ8 страниц9armin heidariОценок пока нет

- NCQC 2016 RaipurДокумент8 страницNCQC 2016 Raipurrashm006ranjanОценок пока нет

- Irjet V3i11206Документ8 страницIrjet V3i11206rashm006ranjanОценок пока нет

- 3rd Floor Service Bldg. Intercom List 2nd Floor Service Bldg. Intercom ListДокумент2 страницы3rd Floor Service Bldg. Intercom List 2nd Floor Service Bldg. Intercom Listrashm006ranjanОценок пока нет

- ExamineeGuide May 2019Документ36 страницExamineeGuide May 2019Hemanth UsОценок пока нет

- Quality ControlДокумент32 страницыQuality ControlvignanarajОценок пока нет

- MCДокумент4 страницыMCViral PatelОценок пока нет

- Correlation Example 1 Output PDFДокумент1 страницаCorrelation Example 1 Output PDFrashm006ranjanОценок пока нет

- Ansys - Simply Supported BeamДокумент12 страницAnsys - Simply Supported Beamrashm006ranjanОценок пока нет

- AmountДокумент62 страницыAmountrashm006ranjanОценок пока нет

- Hourly temperature readings of TSE casing and HP shaftДокумент12 страницHourly temperature readings of TSE casing and HP shaftrashm006ranjan0% (1)

- Energy Audit For Electric MotorДокумент4 страницыEnergy Audit For Electric Motorrashm006ranjanОценок пока нет

- Hourly temperature readings of TSE casing and HP shaftДокумент12 страницHourly temperature readings of TSE casing and HP shaftrashm006ranjan0% (1)

- New Book Launch Schedule 36 Days: Planning Complete!Документ1 страницаNew Book Launch Schedule 36 Days: Planning Complete!rashm006ranjanОценок пока нет

- New Book Launch Schedule 36 Days: Planning Complete!Документ1 страницаNew Book Launch Schedule 36 Days: Planning Complete!rashm006ranjanОценок пока нет

- Project Launch OverviewДокумент1 страницаProject Launch Overviewrashm006ranjanОценок пока нет

- PR Approval Request for Digital Thermometer and AnemometerДокумент1 страницаPR Approval Request for Digital Thermometer and Anemometerrashm006ranjanОценок пока нет

- HyperGraph3D TutorialsДокумент41 страницаHyperGraph3D Tutorialsrashm006ranjanОценок пока нет

- 790Документ5 страниц790rashm006ranjanОценок пока нет

- Development Centre - Know It AllДокумент2 страницыDevelopment Centre - Know It Allrashm006ranjanОценок пока нет

- User ManualДокумент87 страницUser ManualebinjozerОценок пока нет

- Coal Mill Heat Balance SheetДокумент2 страницыCoal Mill Heat Balance Sheetrashm006ranjanОценок пока нет

- 2018 MunsellelectronicДокумент9 страниц2018 MunsellelectronicCristian Camilo Quitian MoralesОценок пока нет

- Egee 101 Reflective Essay 1Документ3 страницыEgee 101 Reflective Essay 1api-142590237Оценок пока нет

- Internal Resistance and Combinations of CellsДокумент10 страницInternal Resistance and Combinations of CellsSukoon Sarin67% (3)

- Journal of Power Sources: Pedro O. Lopez-Montesinos, Amit V. Desai, Paul J.A. KenisДокумент8 страницJournal of Power Sources: Pedro O. Lopez-Montesinos, Amit V. Desai, Paul J.A. KenisbernardОценок пока нет

- Static Mixers for Solid-Solid MixingДокумент8 страницStatic Mixers for Solid-Solid MixingSalsa_Picante_BabyОценок пока нет

- CGN 3421 - Numerical Methods Lecture 3Документ15 страницCGN 3421 - Numerical Methods Lecture 3sori1386Оценок пока нет

- Measuring Planck's Constant with LEDsДокумент7 страницMeasuring Planck's Constant with LEDsAngy100% (1)

- M04 TemperatureДокумент64 страницыM04 TemperatureLê Văn TrườngОценок пока нет

- ANSYS Model of A Cylindrical Fused Silica Fibre-01Документ15 страницANSYS Model of A Cylindrical Fused Silica Fibre-01lamia97Оценок пока нет

- Linear Stationary ModelsДокумент16 страницLinear Stationary ModelsKaled AbodeОценок пока нет

- Direct Determination of The Flow Curves of NoДокумент4 страницыDirect Determination of The Flow Curves of NoZaid HadiОценок пока нет

- Hiad 2Документ15 страницHiad 2Hrishikesh JoshiОценок пока нет

- 16.100 Take-Home Exam SolutionsДокумент3 страницы16.100 Take-Home Exam SolutionslarasmoyoОценок пока нет

- LS-DYNA-Intro 14.5 L01 Intro To Exp DynДокумент40 страницLS-DYNA-Intro 14.5 L01 Intro To Exp DynAnil KumarОценок пока нет

- Geogrids in Walls and SlopesДокумент6 страницGeogrids in Walls and SlopesYong Cheng Hung100% (1)

- Cluster Level Question Bank (Ahmedabad & Gandhinagar Cluster)Документ33 страницыCluster Level Question Bank (Ahmedabad & Gandhinagar Cluster)manpreetsingh3458417Оценок пока нет

- Mapua Institute of Technology: Field Work 1 Pacing On Level GroundДокумент7 страницMapua Institute of Technology: Field Work 1 Pacing On Level GroundIan Ag-aDoctorОценок пока нет

- Metodo Epa 18Документ40 страницMetodo Epa 18Luis TrejoОценок пока нет

- AAS 6300 Service ManualДокумент76 страницAAS 6300 Service Manualfuadye100% (1)

- Green Solvents PresДокумент74 страницыGreen Solvents PresTDSОценок пока нет

- 4th International Conference On Thermal Equipment, Renewable Energy and Rural Development PDFДокумент500 страниц4th International Conference On Thermal Equipment, Renewable Energy and Rural Development PDFMittapalli SaikiranОценок пока нет

- A2 Nuclear Models LiqDrop FermiGasДокумент19 страницA2 Nuclear Models LiqDrop FermiGasAbdul RehmanОценок пока нет

- 12 Class Physics 1-Chapter Sample Paper PDFДокумент9 страниц12 Class Physics 1-Chapter Sample Paper PDFharshОценок пока нет

- Chapter 4Документ36 страницChapter 4Sumedh KakdeОценок пока нет